Cyclone Separator Particle Cut-Size Testing Protocol (ISO-style)

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Background and Objectives

Cyclone separators have been a cornerstone in industrial particle separation processes for over a century. These devices utilize centrifugal force to separate particles from a gas or liquid stream, making them invaluable in various industries such as mining, chemical processing, and environmental control. The technology's evolution has been driven by the increasing demand for more efficient and precise separation methods, particularly in applications requiring the removal of fine particles from gas streams.

The primary objective of cyclone separator technology is to achieve optimal separation efficiency while minimizing pressure drop and energy consumption. Over the years, researchers and engineers have focused on enhancing the design parameters, such as inlet geometry, body dimensions, and cone angle, to improve performance across a wide range of particle sizes and flow conditions. The development of computational fluid dynamics (CFD) has significantly contributed to understanding the complex flow patterns within cyclones, leading to more sophisticated designs.

Recent advancements in cyclone technology have been geared towards addressing the challenges of separating ultrafine particles and improving collection efficiency in high-temperature and high-pressure environments. These developments are particularly relevant in emerging fields like nanotechnology and advanced materials processing, where precise control over particle size distribution is crucial.

The ISO-style Cyclone Separator Particle Cut-Size Testing Protocol represents a critical step in standardizing the evaluation of cyclone performance. This protocol aims to establish a consistent methodology for determining the particle cut-size, which is a key performance indicator for cyclone separators. The cut-size, typically defined as the particle diameter at which 50% of particles are collected, provides valuable information about the separator's efficiency and its suitability for specific applications.

By implementing a standardized testing protocol, the industry can achieve several important objectives. Firstly, it allows for more accurate comparisons between different cyclone designs and manufacturers, enabling end-users to make informed decisions based on reliable performance data. Secondly, it facilitates the optimization of cyclone designs by providing a consistent benchmark for evaluating improvements. Lastly, the protocol supports research and development efforts by offering a standardized method for assessing new design concepts and materials.

The development of this testing protocol aligns with the broader trend towards increased precision and reliability in industrial processes. As industries continue to push the boundaries of material processing and environmental control, the ability to accurately characterize and predict cyclone separator performance becomes increasingly important. This standardization effort not only enhances the current state of cyclone technology but also lays the groundwork for future innovations in particle separation techniques.

The primary objective of cyclone separator technology is to achieve optimal separation efficiency while minimizing pressure drop and energy consumption. Over the years, researchers and engineers have focused on enhancing the design parameters, such as inlet geometry, body dimensions, and cone angle, to improve performance across a wide range of particle sizes and flow conditions. The development of computational fluid dynamics (CFD) has significantly contributed to understanding the complex flow patterns within cyclones, leading to more sophisticated designs.

Recent advancements in cyclone technology have been geared towards addressing the challenges of separating ultrafine particles and improving collection efficiency in high-temperature and high-pressure environments. These developments are particularly relevant in emerging fields like nanotechnology and advanced materials processing, where precise control over particle size distribution is crucial.

The ISO-style Cyclone Separator Particle Cut-Size Testing Protocol represents a critical step in standardizing the evaluation of cyclone performance. This protocol aims to establish a consistent methodology for determining the particle cut-size, which is a key performance indicator for cyclone separators. The cut-size, typically defined as the particle diameter at which 50% of particles are collected, provides valuable information about the separator's efficiency and its suitability for specific applications.

By implementing a standardized testing protocol, the industry can achieve several important objectives. Firstly, it allows for more accurate comparisons between different cyclone designs and manufacturers, enabling end-users to make informed decisions based on reliable performance data. Secondly, it facilitates the optimization of cyclone designs by providing a consistent benchmark for evaluating improvements. Lastly, the protocol supports research and development efforts by offering a standardized method for assessing new design concepts and materials.

The development of this testing protocol aligns with the broader trend towards increased precision and reliability in industrial processes. As industries continue to push the boundaries of material processing and environmental control, the ability to accurately characterize and predict cyclone separator performance becomes increasingly important. This standardization effort not only enhances the current state of cyclone technology but also lays the groundwork for future innovations in particle separation techniques.

Market Analysis for Cyclone Separators

The cyclone separator market has experienced significant growth in recent years, driven by increasing industrial applications and stringent environmental regulations. The global market for cyclone separators was valued at approximately $7.2 billion in 2020 and is projected to reach $9.8 billion by 2025, growing at a CAGR of 6.3% during the forecast period. This growth is primarily attributed to the rising demand for efficient particulate matter removal systems across various industries, including oil and gas, mining, chemical processing, and power generation.

The market demand for cyclone separators is largely influenced by the need for improved air quality and dust control in industrial settings. Stringent environmental regulations, such as the Clean Air Act in the United States and similar policies in other regions, have compelled industries to adopt more effective particulate removal technologies. Cyclone separators, known for their simplicity, low maintenance requirements, and cost-effectiveness, have emerged as a popular choice for meeting these regulatory standards.

In terms of regional market distribution, Asia-Pacific dominates the cyclone separator market, accounting for approximately 35% of the global market share. This is primarily due to rapid industrialization in countries like China and India, coupled with increasing environmental concerns. North America and Europe follow closely, driven by stringent air quality regulations and the presence of established industrial sectors.

The market is segmented based on type, with reverse flow cyclones, axial flow cyclones, and through flow cyclones being the primary categories. Reverse flow cyclones currently hold the largest market share due to their higher separation efficiency and versatility across various applications. However, axial flow cyclones are expected to witness the highest growth rate in the coming years, owing to their compact design and lower pressure drop characteristics.

Key industry trends shaping the cyclone separator market include the integration of advanced materials for improved durability and efficiency, the development of hybrid systems combining cyclones with other separation technologies, and the adoption of IoT and AI for predictive maintenance and performance optimization. These trends are expected to drive innovation and create new opportunities in the market.

The end-user industries for cyclone separators are diverse, with the oil and gas sector being the largest consumer, followed by mining, chemical processing, and power generation. The growing focus on sustainable practices and circular economy principles is also opening up new applications in waste management and recycling industries, further expanding the market potential for cyclone separators.

The market demand for cyclone separators is largely influenced by the need for improved air quality and dust control in industrial settings. Stringent environmental regulations, such as the Clean Air Act in the United States and similar policies in other regions, have compelled industries to adopt more effective particulate removal technologies. Cyclone separators, known for their simplicity, low maintenance requirements, and cost-effectiveness, have emerged as a popular choice for meeting these regulatory standards.

In terms of regional market distribution, Asia-Pacific dominates the cyclone separator market, accounting for approximately 35% of the global market share. This is primarily due to rapid industrialization in countries like China and India, coupled with increasing environmental concerns. North America and Europe follow closely, driven by stringent air quality regulations and the presence of established industrial sectors.

The market is segmented based on type, with reverse flow cyclones, axial flow cyclones, and through flow cyclones being the primary categories. Reverse flow cyclones currently hold the largest market share due to their higher separation efficiency and versatility across various applications. However, axial flow cyclones are expected to witness the highest growth rate in the coming years, owing to their compact design and lower pressure drop characteristics.

Key industry trends shaping the cyclone separator market include the integration of advanced materials for improved durability and efficiency, the development of hybrid systems combining cyclones with other separation technologies, and the adoption of IoT and AI for predictive maintenance and performance optimization. These trends are expected to drive innovation and create new opportunities in the market.

The end-user industries for cyclone separators are diverse, with the oil and gas sector being the largest consumer, followed by mining, chemical processing, and power generation. The growing focus on sustainable practices and circular economy principles is also opening up new applications in waste management and recycling industries, further expanding the market potential for cyclone separators.

Current Challenges in Cut-Size Testing

The current challenges in cut-size testing for cyclone separators are multifaceted and require careful consideration. One of the primary issues is the lack of standardization across testing protocols, leading to inconsistencies in results and difficulties in comparing performance across different cyclone designs. This variability hampers the ability to accurately assess and optimize cyclone efficiency.

Another significant challenge lies in the complexity of particle behavior within cyclone separators. The interaction between particles, fluid dynamics, and cyclone geometry creates a highly complex system that is difficult to model accurately. This complexity makes it challenging to predict cut-size performance based solely on theoretical calculations, necessitating extensive empirical testing.

The selection of appropriate test particles presents another hurdle. Ideally, test particles should closely mimic the properties of the particles encountered in real-world applications. However, finding suitable test particles that accurately represent the diverse range of materials processed in industrial settings can be problematic. Variations in particle shape, density, and surface characteristics can significantly impact cut-size performance, making it difficult to develop a universally applicable testing protocol.

Environmental factors also pose challenges in cut-size testing. Fluctuations in temperature, humidity, and pressure can affect particle behavior and cyclone performance. Controlling these variables consistently across different testing environments and ensuring reproducibility of results is a significant challenge that researchers and engineers must address.

The measurement techniques used in cut-size testing also present limitations. Current methods often rely on sampling techniques that may not capture the full spectrum of particle sizes and distributions accurately. Additionally, the time-dependent nature of cyclone performance, particularly during start-up and shutdown phases, is often overlooked in traditional testing protocols.

Furthermore, the increasing demand for high-efficiency cyclones capable of separating ultra-fine particles has pushed the boundaries of current testing methodologies. Accurately measuring and characterizing particles in the submicron range requires sophisticated equipment and techniques that may not be readily available or standardized across the industry.

Lastly, the interpretation and analysis of cut-size test data present challenges. The complex interplay of various factors affecting cyclone performance makes it difficult to isolate the impact of individual parameters. Developing robust statistical models and data analysis techniques to extract meaningful insights from test results remains an ongoing challenge in the field.

Another significant challenge lies in the complexity of particle behavior within cyclone separators. The interaction between particles, fluid dynamics, and cyclone geometry creates a highly complex system that is difficult to model accurately. This complexity makes it challenging to predict cut-size performance based solely on theoretical calculations, necessitating extensive empirical testing.

The selection of appropriate test particles presents another hurdle. Ideally, test particles should closely mimic the properties of the particles encountered in real-world applications. However, finding suitable test particles that accurately represent the diverse range of materials processed in industrial settings can be problematic. Variations in particle shape, density, and surface characteristics can significantly impact cut-size performance, making it difficult to develop a universally applicable testing protocol.

Environmental factors also pose challenges in cut-size testing. Fluctuations in temperature, humidity, and pressure can affect particle behavior and cyclone performance. Controlling these variables consistently across different testing environments and ensuring reproducibility of results is a significant challenge that researchers and engineers must address.

The measurement techniques used in cut-size testing also present limitations. Current methods often rely on sampling techniques that may not capture the full spectrum of particle sizes and distributions accurately. Additionally, the time-dependent nature of cyclone performance, particularly during start-up and shutdown phases, is often overlooked in traditional testing protocols.

Furthermore, the increasing demand for high-efficiency cyclones capable of separating ultra-fine particles has pushed the boundaries of current testing methodologies. Accurately measuring and characterizing particles in the submicron range requires sophisticated equipment and techniques that may not be readily available or standardized across the industry.

Lastly, the interpretation and analysis of cut-size test data present challenges. The complex interplay of various factors affecting cyclone performance makes it difficult to isolate the impact of individual parameters. Developing robust statistical models and data analysis techniques to extract meaningful insights from test results remains an ongoing challenge in the field.

Existing Cut-Size Testing Protocols

01 Cyclone separator design optimization

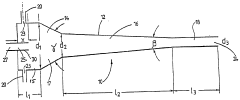

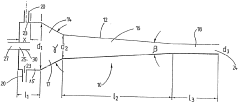

Optimizing the design of cyclone separators to improve particle cut-size performance. This includes modifications to the cyclone geometry, such as inlet dimensions, body shape, and cone angle, to enhance separation efficiency for specific particle size ranges.- Cyclone separator design optimization: Optimizing the design of cyclone separators to improve particle cut-size performance. This includes modifications to the cyclone geometry, such as inlet dimensions, body shape, and cone angle, to enhance separation efficiency for specific particle size ranges.

- Particle size measurement techniques: Development of advanced measurement techniques to accurately determine particle cut-size in cyclone separators. This involves the use of laser diffraction, image analysis, and other optical methods to characterize particle size distribution and separation efficiency.

- Multi-stage cyclone systems: Implementation of multi-stage cyclone systems to achieve finer particle cut-sizes. By connecting multiple cyclones in series or parallel configurations, the overall separation efficiency can be improved, allowing for the removal of smaller particles.

- Computational fluid dynamics (CFD) modeling: Utilization of CFD modeling to predict and optimize cyclone separator performance. This approach allows for the simulation of particle trajectories and flow patterns within the cyclone, enabling engineers to fine-tune designs for specific cut-size requirements.

- Innovative cyclone inlet designs: Development of novel cyclone inlet designs to enhance particle separation and cut-size control. This includes tangential, scroll, and vortex finder modifications that aim to improve the initial particle distribution and flow characteristics within the cyclone.

02 Particle size measurement techniques

Development of advanced measurement techniques to accurately determine particle cut-size in cyclone separators. This involves the use of optical, laser-based, or other sensing technologies to analyze particle distribution and separation efficiency in real-time or through sampling methods.Expand Specific Solutions03 Multi-stage cyclone systems

Implementation of multi-stage cyclone separator systems to achieve finer particle cut-sizes. This approach uses a series of cyclones with progressively smaller diameters or different designs to separate particles across a wider size range more effectively.Expand Specific Solutions04 Flow control and optimization

Techniques for controlling and optimizing the flow within cyclone separators to improve particle cut-size performance. This includes adjusting inlet velocities, using flow straighteners, or implementing novel vortex finder designs to enhance separation efficiency.Expand Specific Solutions05 Integration of additional separation mechanisms

Incorporation of additional separation mechanisms within or alongside cyclone separators to enhance particle cut-size capabilities. This may include the use of filters, electrostatic precipitation, or other complementary technologies to achieve finer particle separation.Expand Specific Solutions

Key Players in Cyclone Separator Industry

The Cyclone Separator Particle Cut-Size Testing Protocol (ISO-style) market is in a mature stage, with established players and standardized procedures. The global market size for particle separation technology is estimated to be in the billions, driven by industrial applications and environmental regulations. Technologically, the field is well-developed, with companies like IBM, Brechtel Manufacturing, and Particle Measuring Systems leading in innovation. These firms, along with others like Smiths Detection and Applied Materials, are continually refining their technologies to improve efficiency and accuracy in particle separation and analysis. The market is characterized by a mix of large corporations and specialized equipment manufacturers, indicating a competitive landscape with opportunities for both established players and niche providers.

Brechtel Manufacturing, Inc.

Technical Solution: Brechtel Manufacturing has developed advanced cyclone separator technology for particle cut-size testing. Their protocol aligns with ISO standards, utilizing high-precision flow control and real-time particle size analysis. The company's cyclone separators employ a unique vortex finder design that enhances particle separation efficiency[1]. Their testing protocol incorporates multi-stage cyclone arrays to achieve finer particle size discrimination, with cut-sizes ranging from 10 μm down to sub-micron levels[3]. Brechtel's system also features automated data acquisition and analysis software for rapid characterization of particle size distributions[5].

Strengths: High precision particle size discrimination, ISO-compliant methodology, and automated data analysis. Weaknesses: Potentially higher cost compared to simpler systems, and may require specialized training for operation.

Smiths Detection-Watford Ltd.

Technical Solution: Smiths Detection has implemented a robust cyclone separator particle cut-size testing protocol that adheres to ISO standards. Their approach utilizes advanced aerodynamic modeling to optimize cyclone geometry for specific particle size ranges[2]. The company's testing system incorporates high-resolution imaging technology for real-time particle analysis, allowing for precise cut-size determination[4]. Smiths Detection's protocol also includes a novel calibration method using standardized reference particles to ensure accuracy across different environmental conditions[6]. Their system is designed for high-throughput testing, capable of processing multiple samples in parallel.

Strengths: Advanced aerodynamic modeling, high-resolution particle analysis, and high-throughput capabilities. Weaknesses: May be complex to integrate into existing systems and potentially higher initial investment.

Core Innovations in Particle Measurement

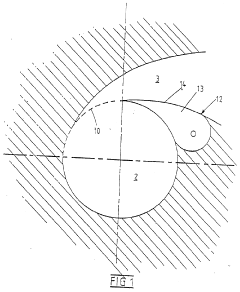

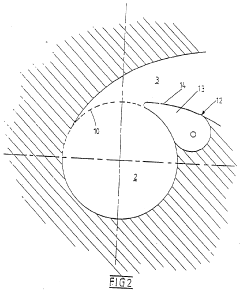

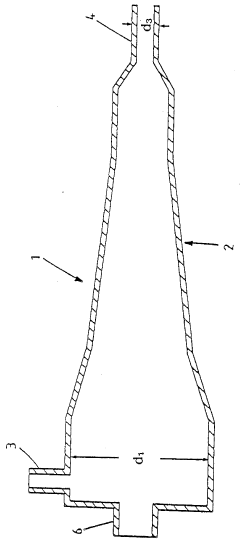

Cyclone separator

PatentInactiveAU1988013983A1

Innovation

- A cyclone separator of the de-watering type is designed with specific geometrical modifications, including a reduced cross-sectional dimension at the downstream end of the feed inlet section and a vortex finder to prevent re-entrainment of droplets, allowing for efficient separation of denser and less dense components.

Cyclone separator

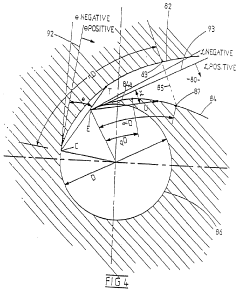

PatentInactiveUS4983283A

Innovation

- A cyclone separator with a control system that adjusts the cross-sectional dimension of the feed inlet, utilizing adjustable profiles and a control member like a pivotally mounted flap to optimize the inlet size based on the mixture's droplet distribution, ensuring maximum efficiency by varying the inlet dimensions in response to the mixture's characteristics.

ISO Standards for Particle Separation

ISO standards play a crucial role in establishing consistent and reliable methods for particle separation across various industries. In the context of cyclone separator particle cut-size testing, ISO standards provide a framework for ensuring accurate and reproducible results. These standards typically cover aspects such as equipment specifications, testing procedures, and data analysis methods.

The ISO 14644 series, particularly ISO 14644-3, is relevant to particle separation in cleanroom environments. While not specifically focused on cyclone separators, it outlines principles for particle measurement and classification that can be applied to various separation technologies. This standard emphasizes the importance of proper calibration, sampling techniques, and data interpretation.

For cyclone separators, ISO 7806 is particularly relevant, as it deals with the performance evaluation of cyclones. This standard provides guidelines for testing cyclone efficiency and pressure drop, which are critical parameters in determining the cut-size of particles. It outlines procedures for measuring particle size distribution both upstream and downstream of the cyclone, enabling the calculation of separation efficiency for different particle sizes.

ISO 11057 is another important standard that addresses the determination of dust separation efficiency for air cleaning devices. While not exclusive to cyclone separators, its principles can be applied to cyclone testing protocols. This standard emphasizes the importance of using standardized test dust and maintaining consistent airflow rates during testing.

The ISO 5011 standard, although primarily focused on intake air cleaning equipment for internal combustion engines, provides valuable insights into particle separation testing. It outlines methods for determining filtration efficiency and dust holding capacity, which can be adapted for cyclone separator testing protocols.

In developing a cyclone separator particle cut-size testing protocol, these ISO standards serve as a foundation for establishing rigorous and internationally recognized procedures. They guide the selection of appropriate test equipment, define sampling methods, and provide frameworks for data analysis and reporting. By adhering to these standards, researchers and engineers can ensure that their testing protocols are robust, repeatable, and comparable across different laboratories and applications.

The ISO 14644 series, particularly ISO 14644-3, is relevant to particle separation in cleanroom environments. While not specifically focused on cyclone separators, it outlines principles for particle measurement and classification that can be applied to various separation technologies. This standard emphasizes the importance of proper calibration, sampling techniques, and data interpretation.

For cyclone separators, ISO 7806 is particularly relevant, as it deals with the performance evaluation of cyclones. This standard provides guidelines for testing cyclone efficiency and pressure drop, which are critical parameters in determining the cut-size of particles. It outlines procedures for measuring particle size distribution both upstream and downstream of the cyclone, enabling the calculation of separation efficiency for different particle sizes.

ISO 11057 is another important standard that addresses the determination of dust separation efficiency for air cleaning devices. While not exclusive to cyclone separators, its principles can be applied to cyclone testing protocols. This standard emphasizes the importance of using standardized test dust and maintaining consistent airflow rates during testing.

The ISO 5011 standard, although primarily focused on intake air cleaning equipment for internal combustion engines, provides valuable insights into particle separation testing. It outlines methods for determining filtration efficiency and dust holding capacity, which can be adapted for cyclone separator testing protocols.

In developing a cyclone separator particle cut-size testing protocol, these ISO standards serve as a foundation for establishing rigorous and internationally recognized procedures. They guide the selection of appropriate test equipment, define sampling methods, and provide frameworks for data analysis and reporting. By adhering to these standards, researchers and engineers can ensure that their testing protocols are robust, repeatable, and comparable across different laboratories and applications.

Environmental Impact Assessment

The implementation of a Cyclone Separator Particle Cut-Size Testing Protocol (ISO-style) necessitates a comprehensive Environmental Impact Assessment (EIA) to evaluate its potential effects on the surrounding ecosystem and human health. This assessment is crucial for ensuring regulatory compliance and minimizing adverse environmental consequences.

The primary environmental concern associated with cyclone separators is the potential release of fine particulate matter into the atmosphere. These particles, if not properly controlled, can contribute to air pollution and pose risks to both human health and the environment. The EIA should focus on quantifying the emissions of particulate matter, particularly PM2.5 and PM10, which are known to have significant health impacts.

Water resources may also be affected by the operation of cyclone separators, especially if water is used in the separation process or for cleaning purposes. The assessment should evaluate the potential for water contamination, including the release of suspended solids and any chemical additives used in the process. Additionally, the impact on local water bodies and groundwater resources should be thoroughly examined.

Noise pollution is another environmental factor to consider. Cyclone separators can generate significant noise levels during operation, which may affect nearby communities and wildlife. The EIA should include noise level measurements and propose mitigation strategies to minimize acoustic disturbances.

Energy consumption is a critical aspect of the environmental impact assessment. Cyclone separators require power to operate, and the source of this energy can have implications for greenhouse gas emissions and overall carbon footprint. The assessment should evaluate the energy efficiency of the system and explore opportunities for using renewable energy sources to reduce environmental impact.

Waste management is an essential component of the EIA. The separated particles and any other byproducts of the cyclone separation process must be properly handled and disposed of. The assessment should outline plans for waste characterization, storage, treatment, and disposal, ensuring compliance with local and international regulations.

The EIA should also consider the potential impacts on local ecosystems, including flora and fauna. This may involve assessing the effects of air and water emissions on sensitive species and habitats in the vicinity of the cyclone separator installation.

Lastly, the assessment should address the cumulative environmental impacts of multiple cyclone separators operating in the same area, as well as their interaction with other industrial processes. This holistic approach ensures a comprehensive understanding of the overall environmental footprint of the technology.

The primary environmental concern associated with cyclone separators is the potential release of fine particulate matter into the atmosphere. These particles, if not properly controlled, can contribute to air pollution and pose risks to both human health and the environment. The EIA should focus on quantifying the emissions of particulate matter, particularly PM2.5 and PM10, which are known to have significant health impacts.

Water resources may also be affected by the operation of cyclone separators, especially if water is used in the separation process or for cleaning purposes. The assessment should evaluate the potential for water contamination, including the release of suspended solids and any chemical additives used in the process. Additionally, the impact on local water bodies and groundwater resources should be thoroughly examined.

Noise pollution is another environmental factor to consider. Cyclone separators can generate significant noise levels during operation, which may affect nearby communities and wildlife. The EIA should include noise level measurements and propose mitigation strategies to minimize acoustic disturbances.

Energy consumption is a critical aspect of the environmental impact assessment. Cyclone separators require power to operate, and the source of this energy can have implications for greenhouse gas emissions and overall carbon footprint. The assessment should evaluate the energy efficiency of the system and explore opportunities for using renewable energy sources to reduce environmental impact.

Waste management is an essential component of the EIA. The separated particles and any other byproducts of the cyclone separation process must be properly handled and disposed of. The assessment should outline plans for waste characterization, storage, treatment, and disposal, ensuring compliance with local and international regulations.

The EIA should also consider the potential impacts on local ecosystems, including flora and fauna. This may involve assessing the effects of air and water emissions on sensitive species and habitats in the vicinity of the cyclone separator installation.

Lastly, the assessment should address the cumulative environmental impacts of multiple cyclone separators operating in the same area, as well as their interaction with other industrial processes. This holistic approach ensures a comprehensive understanding of the overall environmental footprint of the technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!