Cyclone Separator Performance Testing In Cement And Mining Plants

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Evolution and Objectives

Cyclone separators have been an integral part of cement and mining industries for decades, evolving significantly since their inception. Initially developed in the late 19th century, these devices have undergone numerous improvements to enhance their efficiency and applicability in various industrial processes.

The evolution of cyclone separators can be traced through several key stages. Early designs focused on basic separation principles, utilizing centrifugal force to separate particles from gas streams. As industrial demands grew, engineers refined these designs to handle higher throughputs and achieve better separation efficiencies. The introduction of computational fluid dynamics (CFD) in the late 20th century marked a significant milestone, allowing for more precise modeling and optimization of cyclone geometries.

In recent years, the focus has shifted towards developing cyclones capable of handling finer particles and operating under more extreme conditions. This has led to innovations in materials science, with the development of wear-resistant linings and advanced manufacturing techniques to produce more complex geometries. Additionally, the integration of smart sensors and real-time monitoring systems has enabled better control and optimization of cyclone performance in dynamic industrial environments.

The primary objectives of cyclone separator development in cement and mining plants have been multifaceted. Firstly, there is a continuous drive to improve separation efficiency, particularly for finer particles, which are often the most challenging to capture. This is crucial for meeting increasingly stringent environmental regulations and reducing product losses. Secondly, engineers strive to enhance the durability and reliability of cyclones, given the highly abrasive nature of cement and mining materials. This includes developing designs that minimize wear and extend operational lifetimes.

Another key objective has been to increase the flexibility of cyclone separators, allowing them to handle a wider range of particle sizes and densities. This is particularly important in mining operations, where ore compositions can vary significantly. Additionally, there has been a push to improve energy efficiency, as cyclones can be significant consumers of power in industrial processes. This has led to the development of low-pressure drop designs and more efficient fan systems.

Looking ahead, the evolution of cyclone separators is likely to continue along several trajectories. Advanced materials and manufacturing techniques, such as 3D printing, may enable the creation of more complex and efficient cyclone geometries. The integration of artificial intelligence and machine learning algorithms could lead to self-optimizing cyclones that adapt to changing process conditions in real-time. Furthermore, there is growing interest in hybrid systems that combine cyclone technology with other separation methods to achieve even higher levels of performance and versatility.

The evolution of cyclone separators can be traced through several key stages. Early designs focused on basic separation principles, utilizing centrifugal force to separate particles from gas streams. As industrial demands grew, engineers refined these designs to handle higher throughputs and achieve better separation efficiencies. The introduction of computational fluid dynamics (CFD) in the late 20th century marked a significant milestone, allowing for more precise modeling and optimization of cyclone geometries.

In recent years, the focus has shifted towards developing cyclones capable of handling finer particles and operating under more extreme conditions. This has led to innovations in materials science, with the development of wear-resistant linings and advanced manufacturing techniques to produce more complex geometries. Additionally, the integration of smart sensors and real-time monitoring systems has enabled better control and optimization of cyclone performance in dynamic industrial environments.

The primary objectives of cyclone separator development in cement and mining plants have been multifaceted. Firstly, there is a continuous drive to improve separation efficiency, particularly for finer particles, which are often the most challenging to capture. This is crucial for meeting increasingly stringent environmental regulations and reducing product losses. Secondly, engineers strive to enhance the durability and reliability of cyclones, given the highly abrasive nature of cement and mining materials. This includes developing designs that minimize wear and extend operational lifetimes.

Another key objective has been to increase the flexibility of cyclone separators, allowing them to handle a wider range of particle sizes and densities. This is particularly important in mining operations, where ore compositions can vary significantly. Additionally, there has been a push to improve energy efficiency, as cyclones can be significant consumers of power in industrial processes. This has led to the development of low-pressure drop designs and more efficient fan systems.

Looking ahead, the evolution of cyclone separators is likely to continue along several trajectories. Advanced materials and manufacturing techniques, such as 3D printing, may enable the creation of more complex and efficient cyclone geometries. The integration of artificial intelligence and machine learning algorithms could lead to self-optimizing cyclones that adapt to changing process conditions in real-time. Furthermore, there is growing interest in hybrid systems that combine cyclone technology with other separation methods to achieve even higher levels of performance and versatility.

Market Demand Analysis for Separation Technology

The global market for separation technology in cement and mining industries has been experiencing steady growth, driven by increasing demand for efficient and environmentally friendly processes. Cyclone separators, in particular, have gained significant traction due to their ability to effectively separate particles from gas streams, making them crucial in dust collection and material recovery applications.

In the cement industry, the demand for cyclone separators is primarily fueled by the need to comply with stringent environmental regulations and improve production efficiency. As cement production is a major contributor to industrial emissions, manufacturers are increasingly investing in advanced separation technologies to reduce their environmental footprint. The market for cyclone separators in cement plants is expected to grow as companies seek to optimize their production processes and meet sustainability goals.

The mining sector presents another substantial market for cyclone separators, with applications ranging from mineral processing to wastewater treatment. As mining operations strive to maximize resource recovery and minimize waste, the demand for efficient separation technologies continues to rise. Cyclone separators offer a cost-effective solution for removing particulates from various process streams, contributing to improved product quality and reduced environmental impact.

Performance testing of cyclone separators in cement and mining plants has become a critical aspect of technology adoption and optimization. Companies are increasingly focusing on conducting thorough evaluations to ensure that separation systems meet their specific operational requirements. This trend has led to a growing market for testing equipment and services, as well as increased collaboration between technology providers and end-users to develop customized solutions.

The market demand for cyclone separator performance testing is also driven by the need for continuous improvement in existing installations. As plants seek to enhance their operational efficiency and reduce maintenance costs, regular performance assessments have become essential. This has created opportunities for service providers offering specialized testing and optimization services for cyclone separators in cement and mining applications.

Geographically, emerging economies in Asia-Pacific and Latin America are expected to be key growth markets for cyclone separator technology and related testing services. Rapid industrialization and increasing environmental awareness in these regions are driving investments in advanced separation technologies across various industries, including cement and mining.

In the cement industry, the demand for cyclone separators is primarily fueled by the need to comply with stringent environmental regulations and improve production efficiency. As cement production is a major contributor to industrial emissions, manufacturers are increasingly investing in advanced separation technologies to reduce their environmental footprint. The market for cyclone separators in cement plants is expected to grow as companies seek to optimize their production processes and meet sustainability goals.

The mining sector presents another substantial market for cyclone separators, with applications ranging from mineral processing to wastewater treatment. As mining operations strive to maximize resource recovery and minimize waste, the demand for efficient separation technologies continues to rise. Cyclone separators offer a cost-effective solution for removing particulates from various process streams, contributing to improved product quality and reduced environmental impact.

Performance testing of cyclone separators in cement and mining plants has become a critical aspect of technology adoption and optimization. Companies are increasingly focusing on conducting thorough evaluations to ensure that separation systems meet their specific operational requirements. This trend has led to a growing market for testing equipment and services, as well as increased collaboration between technology providers and end-users to develop customized solutions.

The market demand for cyclone separator performance testing is also driven by the need for continuous improvement in existing installations. As plants seek to enhance their operational efficiency and reduce maintenance costs, regular performance assessments have become essential. This has created opportunities for service providers offering specialized testing and optimization services for cyclone separators in cement and mining applications.

Geographically, emerging economies in Asia-Pacific and Latin America are expected to be key growth markets for cyclone separator technology and related testing services. Rapid industrialization and increasing environmental awareness in these regions are driving investments in advanced separation technologies across various industries, including cement and mining.

Current Challenges in Cyclone Separator Testing

Cyclone separators play a crucial role in cement and mining plants, yet their performance testing faces several significant challenges. One of the primary issues is the complex and dynamic nature of the multiphase flow within the separator. The interaction between solid particles, air, and sometimes liquid creates a highly turbulent environment that is difficult to model accurately. This complexity makes it challenging to predict and optimize separator performance under varying operational conditions.

Another major challenge is the lack of standardized testing procedures across the industry. Different plants and manufacturers often employ diverse methodologies for performance evaluation, making it difficult to compare results and establish benchmarks. This inconsistency hampers the development of universal performance metrics and hinders the ability to make informed decisions when selecting or optimizing cyclone separators for specific applications.

The harsh operating environment in cement and mining plants presents additional obstacles for accurate testing. High temperatures, abrasive materials, and corrosive substances can affect the performance of both the separator and the testing equipment. These conditions not only impact the reliability of test results but also necessitate frequent maintenance and calibration of measurement devices, adding to the complexity and cost of performance testing.

Furthermore, the variability in feed characteristics poses a significant challenge. The composition, particle size distribution, and moisture content of the material being processed can fluctuate considerably, even within the same plant. This variability makes it difficult to conduct consistent and repeatable tests, as slight changes in feed properties can significantly impact separator performance.

Scale-up issues also present a notable challenge in cyclone separator testing. Laboratory or pilot-scale tests may not accurately represent the behavior of full-scale industrial separators due to differences in flow patterns, particle interactions, and wall effects. This discrepancy often leads to unexpected performance variations when scaling up from test conditions to actual plant operations.

Lastly, the integration of advanced measurement techniques and data analysis methods remains a challenge. While technologies such as computational fluid dynamics (CFD) and particle image velocimetry (PIV) offer powerful tools for understanding separator behavior, their application in industrial settings is often limited by practical constraints and the need for specialized expertise. Bridging the gap between advanced analytical methods and practical, on-site testing continues to be a significant hurdle in improving cyclone separator performance evaluation in cement and mining plants.

Another major challenge is the lack of standardized testing procedures across the industry. Different plants and manufacturers often employ diverse methodologies for performance evaluation, making it difficult to compare results and establish benchmarks. This inconsistency hampers the development of universal performance metrics and hinders the ability to make informed decisions when selecting or optimizing cyclone separators for specific applications.

The harsh operating environment in cement and mining plants presents additional obstacles for accurate testing. High temperatures, abrasive materials, and corrosive substances can affect the performance of both the separator and the testing equipment. These conditions not only impact the reliability of test results but also necessitate frequent maintenance and calibration of measurement devices, adding to the complexity and cost of performance testing.

Furthermore, the variability in feed characteristics poses a significant challenge. The composition, particle size distribution, and moisture content of the material being processed can fluctuate considerably, even within the same plant. This variability makes it difficult to conduct consistent and repeatable tests, as slight changes in feed properties can significantly impact separator performance.

Scale-up issues also present a notable challenge in cyclone separator testing. Laboratory or pilot-scale tests may not accurately represent the behavior of full-scale industrial separators due to differences in flow patterns, particle interactions, and wall effects. This discrepancy often leads to unexpected performance variations when scaling up from test conditions to actual plant operations.

Lastly, the integration of advanced measurement techniques and data analysis methods remains a challenge. While technologies such as computational fluid dynamics (CFD) and particle image velocimetry (PIV) offer powerful tools for understanding separator behavior, their application in industrial settings is often limited by practical constraints and the need for specialized expertise. Bridging the gap between advanced analytical methods and practical, on-site testing continues to be a significant hurdle in improving cyclone separator performance evaluation in cement and mining plants.

Existing Performance Testing Methodologies

01 Design optimization for improved separation efficiency

Cyclone separator performance can be enhanced through design optimization. This includes modifications to the inlet geometry, vortex finder dimensions, and cone angle. These design improvements aim to increase the centrifugal force, reduce pressure drop, and minimize particle re-entrainment, resulting in better overall separation efficiency.- Design optimization for improved separation efficiency: Cyclone separator performance can be enhanced through design optimization. This includes modifications to the cyclone geometry, such as adjusting the inlet configuration, cone angle, and body dimensions. These design improvements aim to increase particle separation efficiency and reduce pressure drop across the separator.

- Integration of advanced monitoring and control systems: Incorporating advanced monitoring and control systems can significantly improve cyclone separator performance. These systems may include sensors for real-time monitoring of flow rates, pressure, and particle concentrations. Automated control mechanisms can adjust operational parameters based on the monitored data, optimizing separation efficiency and energy consumption.

- Multi-stage cyclone systems for enhanced performance: Multi-stage cyclone systems can be employed to achieve higher separation efficiencies. These systems typically consist of multiple cyclones arranged in series or parallel configurations. Each stage can be optimized for specific particle size ranges, allowing for improved overall separation performance across a wider range of particle sizes.

- Novel inlet designs for improved particle distribution: Innovative inlet designs can enhance cyclone separator performance by improving the initial distribution of particles within the cyclone. These designs may include spiral or tangential inlets, guide vanes, or specially shaped entry ports. Optimized inlet configurations can lead to better particle separation and reduced wear on cyclone components.

- Integration of auxiliary separation mechanisms: Cyclone separator performance can be enhanced by integrating auxiliary separation mechanisms. These may include electrostatic precipitation, acoustic agglomeration, or magnetic separation techniques. The combination of these methods with traditional cyclone separation can result in improved overall particle removal efficiency, especially for fine or hard-to-separate particles.

02 Integration of advanced monitoring and control systems

Incorporating advanced monitoring and control systems can significantly improve cyclone separator performance. These systems use sensors and data analysis to optimize operating parameters in real-time, adjusting factors such as inlet velocity and pressure drop. This approach allows for adaptive performance optimization across varying operating conditions.Expand Specific Solutions03 Multi-stage cyclone configurations

Multi-stage cyclone configurations can enhance overall separation performance. By arranging multiple cyclones in series or parallel, the system can achieve higher collection efficiencies for a wider range of particle sizes. This approach is particularly effective for applications requiring high-precision separation or dealing with complex particle distributions.Expand Specific Solutions04 Surface modifications for improved particle capture

Modifying the internal surfaces of cyclone separators can enhance particle capture and reduce wall losses. Techniques such as adding textured surfaces, applying special coatings, or incorporating electrostatic elements can improve the adhesion of particles to the walls and prevent re-entrainment, thereby increasing overall separation efficiency.Expand Specific Solutions05 Hybrid cyclone systems with additional separation mechanisms

Hybrid cyclone systems that combine cyclonic separation with other separation mechanisms can achieve superior performance. These systems may integrate features such as bag filters, electrostatic precipitators, or scrubbers to capture fine particles that might escape traditional cyclone separators. This approach results in higher overall collection efficiencies across a broader range of particle sizes.Expand Specific Solutions

Key Players in Cyclone Separator Industry

The cyclone separator performance testing market in cement and mining plants is in a mature stage, with established technologies and a stable competitive landscape. The global market size for this technology is estimated to be in the hundreds of millions of dollars annually, driven by the ongoing need for efficient particle separation in industrial processes. Key players like Polysius AG, thyssenkrupp Polysius GmbH, and SINOPEC Engineering (Group) Co., Ltd. have developed advanced testing methodologies and equipment. These companies, along with research institutions such as China University of Mining & Technology and Lanzhou University, continue to refine cyclone separator technologies, focusing on improving efficiency, reducing energy consumption, and enhancing overall performance in harsh industrial environments.

thyssenkrupp Polysius GmbH

Technical Solution: thyssenkrupp Polysius GmbH has developed advanced cyclone separator technology for cement and mining plants. Their POLCID™ system utilizes computational fluid dynamics (CFD) to optimize cyclone geometry and improve separation efficiency. The system incorporates sensors to monitor pressure drop, temperature, and particle concentration in real-time. This data is used to automatically adjust operating parameters such as gas flow rate and solids loading. Their cyclones achieve separation efficiencies up to 98% for particles down to 5 microns in size [1]. The company has also implemented machine learning algorithms to predict cyclone performance and maintenance needs based on historical operating data.

Strengths: High separation efficiency, real-time monitoring and adjustment, predictive maintenance. Weaknesses: High initial cost, complexity of implementation, requires specialized expertise to operate.

China University of Mining & Technology

Technical Solution: China University of Mining & Technology has conducted extensive research on cyclone separator performance in mining applications. Their approach focuses on experimental testing combined with numerical simulation. They have developed a novel multi-objective optimization method for cyclone design, considering factors such as pressure drop, cut size, and separation efficiency simultaneously [2]. Their research has led to the development of a hybrid cyclone-electrostatic separator that achieves higher efficiency for fine particle separation compared to conventional cyclones. The university has also pioneered the use of acoustic emission sensors to detect and characterize particle behavior inside cyclones during operation, providing valuable insights for performance optimization [3].

Strengths: Innovative hybrid designs, advanced optimization techniques, non-invasive monitoring methods. Weaknesses: Some technologies still at research stage, may require further development for industrial implementation.

Innovative Approaches in Separator Efficiency

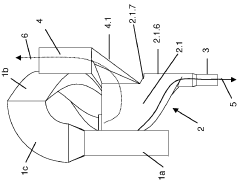

Cyclone separator

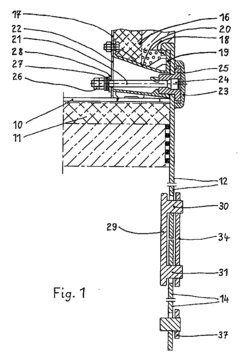

PatentInactiveEP0962255A3

Innovation

- The cyclone separator features radially arranged bolts with spacer bushes providing cooling through ambient air admission and forced ventilation, protected by covers, and a hook-shaped projection for secure fastening, ensuring stable attachment of detachable dip tube segments.

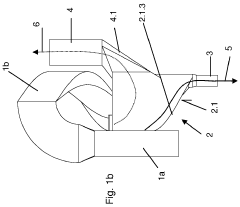

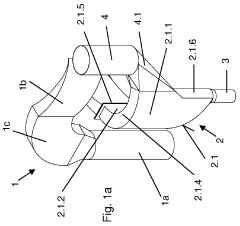

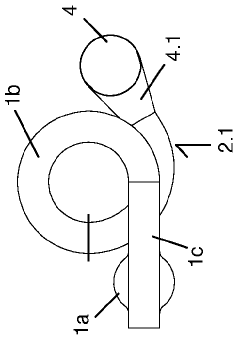

Device for separating a solid material and a gas and plant for producing cement

PatentWO2009155975A1

Innovation

- A device comprising a helical or spiral line with a connected separation chamber, featuring a curved section that widens in the direction of flow, allowing for improved separation by adjusting centrifugal forces and flow velocities, with separate lines for solid and gas discharge, enhancing the separation efficiency to 70-95%.

Environmental Impact Assessment

The environmental impact assessment of cyclone separator performance testing in cement and mining plants is a crucial aspect that requires thorough consideration. These industrial processes can have significant effects on the surrounding ecosystem and human health if not properly managed.

Air quality is a primary concern in cyclone separator testing. The release of particulate matter, including fine dust and potentially harmful substances, can contribute to air pollution. This may lead to respiratory issues for nearby communities and affect local flora and fauna. Proper filtration systems and emission controls are essential to mitigate these impacts.

Water resources can also be affected by cyclone separator testing. The process may require substantial water usage, potentially straining local water supplies. Additionally, there is a risk of contaminated wastewater discharge, which could harm aquatic ecosystems if not adequately treated. Implementing water recycling systems and effective wastewater treatment protocols is crucial to minimize these effects.

Noise pollution is another environmental factor to consider. The operation of cyclone separators and associated equipment can generate significant noise levels, potentially disturbing local wildlife and nearby residential areas. Implementing noise reduction measures, such as sound barriers or equipment modifications, can help address this issue.

Land use and habitat disruption are important considerations, especially in mining operations. The construction and operation of testing facilities may require land clearing, potentially impacting local ecosystems and biodiversity. Careful site selection and implementation of habitat restoration plans can help mitigate these effects.

Energy consumption is a significant factor in the environmental impact of cyclone separator testing. The process often requires substantial power, contributing to greenhouse gas emissions if non-renewable energy sources are used. Implementing energy-efficient technologies and exploring renewable energy options can help reduce the carbon footprint of these operations.

Waste management is another critical aspect of the environmental assessment. The testing process may generate various types of waste, including potentially hazardous materials. Proper disposal and recycling practices are essential to prevent soil and groundwater contamination.

Long-term ecological effects should also be considered in the assessment. Continuous testing operations may lead to cumulative impacts on local ecosystems, affecting soil quality, plant growth, and animal populations over time. Regular monitoring and adaptive management strategies are necessary to identify and address these long-term effects.

In conclusion, a comprehensive environmental impact assessment for cyclone separator performance testing in cement and mining plants must address air and water quality, noise pollution, land use, energy consumption, waste management, and long-term ecological effects. Implementing appropriate mitigation measures and adopting sustainable practices are essential to minimize the environmental footprint of these industrial processes.

Air quality is a primary concern in cyclone separator testing. The release of particulate matter, including fine dust and potentially harmful substances, can contribute to air pollution. This may lead to respiratory issues for nearby communities and affect local flora and fauna. Proper filtration systems and emission controls are essential to mitigate these impacts.

Water resources can also be affected by cyclone separator testing. The process may require substantial water usage, potentially straining local water supplies. Additionally, there is a risk of contaminated wastewater discharge, which could harm aquatic ecosystems if not adequately treated. Implementing water recycling systems and effective wastewater treatment protocols is crucial to minimize these effects.

Noise pollution is another environmental factor to consider. The operation of cyclone separators and associated equipment can generate significant noise levels, potentially disturbing local wildlife and nearby residential areas. Implementing noise reduction measures, such as sound barriers or equipment modifications, can help address this issue.

Land use and habitat disruption are important considerations, especially in mining operations. The construction and operation of testing facilities may require land clearing, potentially impacting local ecosystems and biodiversity. Careful site selection and implementation of habitat restoration plans can help mitigate these effects.

Energy consumption is a significant factor in the environmental impact of cyclone separator testing. The process often requires substantial power, contributing to greenhouse gas emissions if non-renewable energy sources are used. Implementing energy-efficient technologies and exploring renewable energy options can help reduce the carbon footprint of these operations.

Waste management is another critical aspect of the environmental assessment. The testing process may generate various types of waste, including potentially hazardous materials. Proper disposal and recycling practices are essential to prevent soil and groundwater contamination.

Long-term ecological effects should also be considered in the assessment. Continuous testing operations may lead to cumulative impacts on local ecosystems, affecting soil quality, plant growth, and animal populations over time. Regular monitoring and adaptive management strategies are necessary to identify and address these long-term effects.

In conclusion, a comprehensive environmental impact assessment for cyclone separator performance testing in cement and mining plants must address air and water quality, noise pollution, land use, energy consumption, waste management, and long-term ecological effects. Implementing appropriate mitigation measures and adopting sustainable practices are essential to minimize the environmental footprint of these industrial processes.

Safety Regulations in Cement and Mining

Safety regulations in cement and mining industries are crucial for protecting workers, the environment, and ensuring operational efficiency. These regulations are designed to address the unique hazards associated with cyclone separator performance testing in cement and mining plants. The Occupational Safety and Health Administration (OSHA) and the Mine Safety and Health Administration (MSHA) in the United States, along with similar regulatory bodies worldwide, have established comprehensive guidelines for these industries.

One of the primary safety concerns in cyclone separator testing is dust exposure. Cement and mining operations generate significant amounts of particulate matter, which can pose serious health risks to workers. Regulations mandate the use of personal protective equipment (PPE), including respirators, dust masks, and protective clothing. Additionally, proper ventilation systems must be in place to minimize dust concentration in the air.

Noise pollution is another critical safety issue addressed by regulations. Cyclone separators and associated equipment can produce high noise levels, potentially causing hearing damage. Safety standards require regular noise level monitoring and the implementation of noise reduction measures. Workers must be provided with appropriate hearing protection devices and undergo periodic audiometric testing.

Fall protection is a significant concern during cyclone separator testing, especially when accessing elevated areas for maintenance or inspection. Regulations stipulate the use of fall arrest systems, guardrails, and proper scaffolding. Regular inspection and maintenance of these safety systems are mandatory to ensure their effectiveness.

Chemical hazards are also addressed in safety regulations for cement and mining plants. Cyclone separators may handle materials containing hazardous substances. Proper storage, handling, and disposal procedures must be followed, and workers must be trained in hazardous material management. Material Safety Data Sheets (MSDS) must be readily available, and emergency response plans should be in place.

Mechanical safety is a critical aspect of cyclone separator operation. Regulations require proper guarding of moving parts, lockout/tagout procedures during maintenance, and regular equipment inspections. Emergency stop systems must be easily accessible and clearly marked.

Fire safety regulations are particularly important in these industries due to the presence of combustible materials and potential ignition sources. Fire suppression systems, emergency evacuation procedures, and regular fire drills are mandated. The storage and handling of flammable materials must adhere to strict guidelines.

Lastly, safety regulations emphasize the importance of comprehensive worker training and education. Employees must be trained on all relevant safety procedures, equipment operation, and emergency response protocols. Regular safety meetings and refresher courses are typically required to maintain a high level of safety awareness and compliance.

One of the primary safety concerns in cyclone separator testing is dust exposure. Cement and mining operations generate significant amounts of particulate matter, which can pose serious health risks to workers. Regulations mandate the use of personal protective equipment (PPE), including respirators, dust masks, and protective clothing. Additionally, proper ventilation systems must be in place to minimize dust concentration in the air.

Noise pollution is another critical safety issue addressed by regulations. Cyclone separators and associated equipment can produce high noise levels, potentially causing hearing damage. Safety standards require regular noise level monitoring and the implementation of noise reduction measures. Workers must be provided with appropriate hearing protection devices and undergo periodic audiometric testing.

Fall protection is a significant concern during cyclone separator testing, especially when accessing elevated areas for maintenance or inspection. Regulations stipulate the use of fall arrest systems, guardrails, and proper scaffolding. Regular inspection and maintenance of these safety systems are mandatory to ensure their effectiveness.

Chemical hazards are also addressed in safety regulations for cement and mining plants. Cyclone separators may handle materials containing hazardous substances. Proper storage, handling, and disposal procedures must be followed, and workers must be trained in hazardous material management. Material Safety Data Sheets (MSDS) must be readily available, and emergency response plans should be in place.

Mechanical safety is a critical aspect of cyclone separator operation. Regulations require proper guarding of moving parts, lockout/tagout procedures during maintenance, and regular equipment inspections. Emergency stop systems must be easily accessible and clearly marked.

Fire safety regulations are particularly important in these industries due to the presence of combustible materials and potential ignition sources. Fire suppression systems, emergency evacuation procedures, and regular fire drills are mandated. The storage and handling of flammable materials must adhere to strict guidelines.

Lastly, safety regulations emphasize the importance of comprehensive worker training and education. Employees must be trained on all relevant safety procedures, equipment operation, and emergency response protocols. Regular safety meetings and refresher courses are typically required to maintain a high level of safety awareness and compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!