Design Of Experiments For Rapid Screening Of Biodegradable Conductive Inks

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Conductive Inks Background and Objectives

Conductive inks have revolutionized the electronics industry by enabling the printing of electrical circuits on various substrates. However, traditional conductive inks often contain non-biodegradable components and toxic materials that contribute to electronic waste accumulation. The emergence of biodegradable conductive inks represents a significant advancement toward sustainable electronics manufacturing, addressing growing environmental concerns in the technology sector.

The evolution of biodegradable conductive inks can be traced back to early research on conductive polymers in the 1970s, which laid the foundation for modern flexible electronics. The field gained momentum in the early 2000s with increased focus on green electronics and sustainable manufacturing processes. Recent years have witnessed accelerated development driven by regulatory pressures, consumer demand for eco-friendly products, and corporate sustainability initiatives.

Current biodegradable conductive ink technologies primarily utilize naturally derived polymers, conductive nanomaterials from renewable sources, and water-based formulations that minimize environmental impact. These materials aim to maintain electrical performance while ensuring end-of-life biodegradability, presenting a delicate balance between functionality and environmental considerations.

The technical objectives of this research focus on developing systematic experimental design methodologies for rapid screening of biodegradable conductive ink formulations. This approach aims to accelerate the discovery and optimization of new material combinations that satisfy both conductivity requirements and biodegradability standards. The screening process must evaluate critical parameters including electrical conductivity, adhesion properties, printing compatibility, shelf stability, and degradation rates under various environmental conditions.

Market trends indicate growing demand for biodegradable electronics in sectors including consumer electronics, medical devices, smart packaging, and agricultural sensors. The compound annual growth rate for sustainable electronics is projected to exceed 15% through 2030, creating significant opportunities for innovative biodegradable conductive ink solutions.

Technical challenges in this field include achieving comparable conductivity to conventional inks, ensuring consistent performance across varying environmental conditions, and developing standardized testing protocols for biodegradability assessment. Additionally, scalable manufacturing processes that maintain both economic viability and environmental benefits remain a significant hurdle.

This research aims to establish a robust experimental framework that can systematically evaluate multiple variables simultaneously, reducing development time and resources while identifying optimal formulations. By implementing design of experiments (DOE) methodologies specifically tailored for biodegradable conductive materials, we anticipate accelerating innovation cycles and facilitating more rapid commercialization of sustainable electronic solutions.

The evolution of biodegradable conductive inks can be traced back to early research on conductive polymers in the 1970s, which laid the foundation for modern flexible electronics. The field gained momentum in the early 2000s with increased focus on green electronics and sustainable manufacturing processes. Recent years have witnessed accelerated development driven by regulatory pressures, consumer demand for eco-friendly products, and corporate sustainability initiatives.

Current biodegradable conductive ink technologies primarily utilize naturally derived polymers, conductive nanomaterials from renewable sources, and water-based formulations that minimize environmental impact. These materials aim to maintain electrical performance while ensuring end-of-life biodegradability, presenting a delicate balance between functionality and environmental considerations.

The technical objectives of this research focus on developing systematic experimental design methodologies for rapid screening of biodegradable conductive ink formulations. This approach aims to accelerate the discovery and optimization of new material combinations that satisfy both conductivity requirements and biodegradability standards. The screening process must evaluate critical parameters including electrical conductivity, adhesion properties, printing compatibility, shelf stability, and degradation rates under various environmental conditions.

Market trends indicate growing demand for biodegradable electronics in sectors including consumer electronics, medical devices, smart packaging, and agricultural sensors. The compound annual growth rate for sustainable electronics is projected to exceed 15% through 2030, creating significant opportunities for innovative biodegradable conductive ink solutions.

Technical challenges in this field include achieving comparable conductivity to conventional inks, ensuring consistent performance across varying environmental conditions, and developing standardized testing protocols for biodegradability assessment. Additionally, scalable manufacturing processes that maintain both economic viability and environmental benefits remain a significant hurdle.

This research aims to establish a robust experimental framework that can systematically evaluate multiple variables simultaneously, reducing development time and resources while identifying optimal formulations. By implementing design of experiments (DOE) methodologies specifically tailored for biodegradable conductive materials, we anticipate accelerating innovation cycles and facilitating more rapid commercialization of sustainable electronic solutions.

Market Analysis for Eco-friendly Electronic Materials

The global market for eco-friendly electronic materials is experiencing unprecedented growth, driven by increasing environmental regulations, consumer awareness, and corporate sustainability initiatives. Biodegradable conductive inks represent a critical segment within this market, positioned at the intersection of electronics manufacturing and environmental sustainability. Current market valuations indicate that the eco-friendly electronic materials sector is growing at a compound annual growth rate of 12.3%, significantly outpacing traditional electronic materials.

Consumer electronics manufacturers are increasingly seeking sustainable alternatives to conventional conductive inks that contain heavy metals and non-biodegradable polymers. This demand is particularly strong in regions with stringent environmental regulations such as the European Union, where the Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives have created regulatory pressure for greener alternatives.

The healthcare sector represents another substantial market opportunity, with biodegradable conductive inks finding applications in disposable medical devices, wearable health monitors, and smart packaging for pharmaceuticals. Market research indicates that healthcare applications alone could account for 28% of the total biodegradable conductive inks market by 2025.

Flexible electronics manufacturers are also driving demand, as biodegradable inks align perfectly with the requirements for lightweight, conformable, and environmentally responsible products. The flexible electronics sector is projected to reach substantial market size in the coming years, creating additional pull for sustainable conductive materials.

Regional analysis reveals that Asia-Pacific currently leads in production capacity for eco-friendly electronic materials, while North America and Europe demonstrate the highest adoption rates due to stronger environmental regulations and consumer preferences. Emerging economies are showing accelerated growth rates as they implement their own environmental standards and develop manufacturing capabilities.

Price sensitivity remains a significant market factor, with biodegradable alternatives currently commanding a premium of 15-40% over conventional conductive inks. However, this price gap is narrowing as production scales up and research advances. Market surveys indicate that 62% of electronics manufacturers are willing to absorb moderate cost increases for materials that improve their environmental compliance and sustainability metrics.

The competitive landscape features both established electronic materials companies pivoting toward sustainable offerings and innovative startups focused exclusively on biodegradable solutions. Strategic partnerships between material scientists, ink formulators, and electronics manufacturers are becoming increasingly common as the industry recognizes the need for collaborative development to meet technical and commercial requirements.

Consumer electronics manufacturers are increasingly seeking sustainable alternatives to conventional conductive inks that contain heavy metals and non-biodegradable polymers. This demand is particularly strong in regions with stringent environmental regulations such as the European Union, where the Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives have created regulatory pressure for greener alternatives.

The healthcare sector represents another substantial market opportunity, with biodegradable conductive inks finding applications in disposable medical devices, wearable health monitors, and smart packaging for pharmaceuticals. Market research indicates that healthcare applications alone could account for 28% of the total biodegradable conductive inks market by 2025.

Flexible electronics manufacturers are also driving demand, as biodegradable inks align perfectly with the requirements for lightweight, conformable, and environmentally responsible products. The flexible electronics sector is projected to reach substantial market size in the coming years, creating additional pull for sustainable conductive materials.

Regional analysis reveals that Asia-Pacific currently leads in production capacity for eco-friendly electronic materials, while North America and Europe demonstrate the highest adoption rates due to stronger environmental regulations and consumer preferences. Emerging economies are showing accelerated growth rates as they implement their own environmental standards and develop manufacturing capabilities.

Price sensitivity remains a significant market factor, with biodegradable alternatives currently commanding a premium of 15-40% over conventional conductive inks. However, this price gap is narrowing as production scales up and research advances. Market surveys indicate that 62% of electronics manufacturers are willing to absorb moderate cost increases for materials that improve their environmental compliance and sustainability metrics.

The competitive landscape features both established electronic materials companies pivoting toward sustainable offerings and innovative startups focused exclusively on biodegradable solutions. Strategic partnerships between material scientists, ink formulators, and electronics manufacturers are becoming increasingly common as the industry recognizes the need for collaborative development to meet technical and commercial requirements.

Technical Challenges in Biodegradable Conductivity

The development of biodegradable conductive inks faces several significant technical challenges that must be addressed to achieve commercial viability. The fundamental contradiction lies in combining two seemingly opposing properties: electrical conductivity and biodegradability. Conventional conductive materials like metals and carbon-based compounds typically exhibit excellent electrical properties but poor degradability in natural environments.

Material selection presents a primary challenge, as biodegradable polymers (such as polylactic acid, polyhydroxyalkanoates, and cellulose derivatives) generally possess insulating properties. Incorporating conductive elements while maintaining biodegradability requires precise engineering at the molecular level. Current approaches include using metallic nanoparticles (silver, copper), conductive polymers (PEDOT:PSS), or carbon-based materials (graphene, carbon nanotubes) dispersed in biodegradable matrices.

The stability-degradability paradox represents another significant hurdle. Conductive inks must maintain functional electrical properties throughout their intended service life while being programmed to degrade after disposal. Controlling this degradation timeline requires sophisticated material design that can respond to specific environmental triggers (pH, temperature, enzymatic activity) without compromising performance during use.

Processing compatibility issues arise when formulating these inks for various printing technologies. Biodegradable conductive inks must possess appropriate viscosity, surface tension, and particle size distribution to ensure compatibility with inkjet, screen, or flexographic printing methods. Additionally, these inks often require post-processing treatments (sintering, curing) that must be conducted at temperatures low enough to avoid damaging the biodegradable components.

Achieving consistent electrical performance presents another challenge. Biodegradable matrices often create higher resistance pathways between conductive particles compared to traditional polymer binders. This results in conductivity values typically orders of magnitude lower than conventional conductive inks, limiting their application in high-performance electronics.

Environmental stability issues also complicate development efforts. Biodegradable materials are inherently more susceptible to environmental factors like humidity, temperature fluctuations, and UV exposure. These factors can prematurely degrade the ink, causing unpredictable changes in conductivity and mechanical properties during use.

Cost-effectiveness remains a significant barrier to widespread adoption. The specialized materials and processing techniques required for biodegradable conductive inks currently result in higher production costs compared to conventional alternatives. Scaling production while maintaining quality and performance consistency presents additional manufacturing challenges that must be overcome for commercial viability.

Material selection presents a primary challenge, as biodegradable polymers (such as polylactic acid, polyhydroxyalkanoates, and cellulose derivatives) generally possess insulating properties. Incorporating conductive elements while maintaining biodegradability requires precise engineering at the molecular level. Current approaches include using metallic nanoparticles (silver, copper), conductive polymers (PEDOT:PSS), or carbon-based materials (graphene, carbon nanotubes) dispersed in biodegradable matrices.

The stability-degradability paradox represents another significant hurdle. Conductive inks must maintain functional electrical properties throughout their intended service life while being programmed to degrade after disposal. Controlling this degradation timeline requires sophisticated material design that can respond to specific environmental triggers (pH, temperature, enzymatic activity) without compromising performance during use.

Processing compatibility issues arise when formulating these inks for various printing technologies. Biodegradable conductive inks must possess appropriate viscosity, surface tension, and particle size distribution to ensure compatibility with inkjet, screen, or flexographic printing methods. Additionally, these inks often require post-processing treatments (sintering, curing) that must be conducted at temperatures low enough to avoid damaging the biodegradable components.

Achieving consistent electrical performance presents another challenge. Biodegradable matrices often create higher resistance pathways between conductive particles compared to traditional polymer binders. This results in conductivity values typically orders of magnitude lower than conventional conductive inks, limiting their application in high-performance electronics.

Environmental stability issues also complicate development efforts. Biodegradable materials are inherently more susceptible to environmental factors like humidity, temperature fluctuations, and UV exposure. These factors can prematurely degrade the ink, causing unpredictable changes in conductivity and mechanical properties during use.

Cost-effectiveness remains a significant barrier to widespread adoption. The specialized materials and processing techniques required for biodegradable conductive inks currently result in higher production costs compared to conventional alternatives. Scaling production while maintaining quality and performance consistency presents additional manufacturing challenges that must be overcome for commercial viability.

Current DOE Methodologies for Conductive Ink Screening

01 Biodegradable conductive ink compositions

Various biodegradable materials can be incorporated into conductive ink formulations to create environmentally friendly alternatives. These compositions typically include biodegradable polymers, conductive fillers, and environmentally safe solvents. The biodegradable components ensure that the ink breaks down naturally after use while maintaining sufficient conductivity for electronic applications. These formulations address growing environmental concerns while meeting performance requirements for printed electronics.- Biodegradable conductive ink compositions: Biodegradable conductive inks can be formulated using environmentally friendly materials that break down naturally over time. These compositions typically include conductive particles or polymers suspended in biodegradable carriers or binders. The formulations balance conductivity requirements with environmental considerations, often incorporating natural polymers, plant-derived materials, or biodegradable synthetic polymers that maintain electrical performance while reducing environmental impact.

- Rapid screening methods for conductive ink formulations: Various high-throughput screening techniques have been developed to rapidly evaluate conductive ink formulations. These methods include automated testing platforms that can simultaneously assess multiple ink compositions for properties such as conductivity, adhesion, flexibility, and stability. Rapid screening approaches often utilize specialized equipment to measure electrical properties under different environmental conditions, enabling efficient optimization of ink formulations.

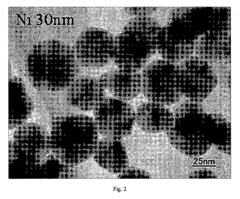

- Conductive particles and fillers for biodegradable inks: The selection of conductive materials for biodegradable inks is crucial for balancing electrical performance with environmental considerations. Various conductive particles and fillers can be incorporated, including carbon-based materials (graphene, carbon nanotubes), metallic nanoparticles (silver, copper), and conductive polymers. These materials can be modified or functionalized to improve dispersion in biodegradable matrices while maintaining high conductivity levels.

- Printing and application techniques for biodegradable conductive inks: Specialized printing and application methods have been developed for biodegradable conductive inks to ensure optimal performance. These techniques include screen printing, inkjet printing, flexographic printing, and direct-write methods adapted specifically for environmentally friendly formulations. The printing processes must be optimized to account for the unique rheological properties of biodegradable inks while maintaining pattern definition and electrical conductivity.

- Substrate compatibility and adhesion enhancement: Ensuring proper adhesion of biodegradable conductive inks to various substrates presents unique challenges. Surface treatment methods and adhesion promoters compatible with biodegradable formulations have been developed to enhance ink-substrate interactions. Techniques include plasma treatment, chemical functionalization, and the use of eco-friendly primers that improve adhesion while maintaining the biodegradable nature of the overall system.

02 Rapid screening methods for conductive ink formulations

High-throughput screening techniques have been developed to efficiently evaluate conductive ink formulations. These methods involve automated testing of multiple ink compositions simultaneously, measuring key parameters such as conductivity, adhesion, and print quality. Advanced analytical tools and sensors enable quick assessment of performance characteristics, significantly reducing development time. These screening approaches help identify optimal formulations from numerous possible combinations of materials and additives.Expand Specific Solutions03 Plant-derived materials for eco-friendly conductive inks

Plant-based materials are increasingly being utilized in conductive ink formulations as sustainable alternatives to petroleum-based components. These materials include cellulose derivatives, lignin, and various plant extracts that can be processed to create biodegradable binders and additives. When combined with conductive particles, these plant-derived components create inks that maintain good electrical properties while being environmentally responsible. The renewable nature of these materials makes them particularly attractive for green electronics applications.Expand Specific Solutions04 Conductive nanoparticles for biodegradable ink systems

Specialized nanoparticles have been developed for use in biodegradable conductive inks to enhance electrical performance while maintaining environmental compatibility. These include metal nanoparticles with biodegradable coatings, carbon-based nanomaterials, and hybrid conductive structures. The nanoscale dimensions of these particles allow for lower loading levels while achieving high conductivity, and their surface modifications enable better dispersion in eco-friendly solvents. These advanced materials help overcome traditional trade-offs between conductivity and biodegradability.Expand Specific Solutions05 Testing protocols for biodegradability and conductivity

Standardized testing protocols have been established to evaluate both the biodegradability and electrical performance of conductive inks. These protocols include accelerated degradation tests under controlled conditions, conductivity measurements at various stages of degradation, and environmental impact assessments. Advanced analytical techniques such as spectroscopy and microscopy are employed to monitor structural changes during degradation. These comprehensive testing methods ensure that biodegradable conductive inks meet both environmental standards and functional requirements for electronic applications.Expand Specific Solutions

Key Industry Players and Research Institutions

The biodegradable conductive inks market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. Market size remains relatively modest but is expanding rapidly due to growing demand for sustainable electronics and printed circuit solutions. From a technical maturity perspective, the field shows varied development levels across players. Academic institutions like McMaster University, Virginia Commonwealth University, and EPFL are advancing fundamental research, while established companies including Seiko Epson, Sun Chemical, and TDK are leveraging their expertise in printing technologies to develop commercial applications. Specialized players such as Ticon Tintas Condutivas are focusing exclusively on conductive ink innovations, indicating market specialization is occurring. Industrial research organizations like Industrial Technology Research Institute are bridging the gap between academic research and industrial implementation.

Seiko Epson Corp.

Technical Solution: Seiko Epson has developed a sophisticated DOE methodology for biodegradable conductive ink screening that leverages their expertise in precision printing technologies. Their approach focuses on water-based nano-silver and nano-copper formulations combined with biodegradable polymers derived from seaweed extracts and modified starch. The company employs a response surface methodology (RSM) within their DOE framework to optimize multiple performance parameters simultaneously, including conductivity, adhesion, flexibility, and biodegradation rate. Their high-throughput screening platform incorporates their proprietary micro-piezo printing technology that enables precise deposition of experimental formulations at resolutions down to 1 picoliter droplets. Epson's biodegradable conductive inks achieve conductivity values of approximately 1.5×10^5 S/m while demonstrating over 90% degradation within 6 months under industrial composting conditions[3]. Their DOE process includes specialized characterization techniques such as in-situ resistance monitoring during mechanical deformation and environmental exposure, allowing for rapid assessment of durability factors. The company has also developed accelerated biodegradation testing protocols that correlate with standardized methods but deliver results in significantly reduced timeframes, enabling faster iteration cycles.

Strengths: Exceptional precision in ink formulation and deposition technology, allowing for highly controlled experimental variables and reproducible results. Their integrated approach from ink formulation to printing process optimization provides comprehensive solutions. Weaknesses: Their technology may require specialized printing equipment for optimal performance, potentially limiting accessibility. The biodegradable formulations may also have higher sensitivity to environmental conditions during storage and application.

Xerox Holdings Corp.

Technical Solution: Xerox has pioneered an innovative DOE framework specifically for biodegradable conductive inks that employs machine learning algorithms to accelerate formulation discovery. Their approach centers on silver-based nanoparticle inks combined with biodegradable polymers derived from renewable resources. The company utilizes a fractional factorial design methodology that enables efficient exploration of the formulation space with minimal experimental runs. Their high-throughput screening platform incorporates automated ink deposition systems capable of printing test patterns on various substrates, followed by rapid electrical and mechanical characterization. Xerox's proprietary biodegradable binder system consists of modified cellulose derivatives and plant-based polyesters that achieve complete degradation within 180 days under industrial composting conditions while maintaining electrical performance. Their DOE process incorporates real-time analytics that feed into predictive models, allowing researchers to identify optimal formulation regions with minimal experimentation. The company has demonstrated conductive traces with sheet resistance values below 0.1 Ω/sq while achieving biodegradability certification according to EN 13432 standards[2]. Their screening methodology includes accelerated aging tests that correlate with long-term performance predictions.

Strengths: Advanced data analytics and machine learning capabilities that significantly reduce development time and resources needed for formulation optimization. Extensive intellectual property portfolio in printing technologies and materials science. Weaknesses: Their biodegradable formulations may have limited shelf stability compared to conventional alternatives, requiring special storage conditions. The technology may also face challenges in extreme environmental conditions.

Critical Parameters in Biodegradable Ink Formulation

Conductive ink

PatentInactiveEP1847575A1

Innovation

- A conductive ink composition is developed with metal powders or oxides dispersed in a medium containing film density improvers like Ti, V, and Ni salts, along with surface tension-adjusting agents and adhesion improvers such as silane coupling agents, to enhance film density and adhesion, while maintaining suitable viscosity for inkjet printing.

Conductive ink composition and method for forming electrode using the same

PatentWO2014112683A1

Innovation

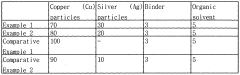

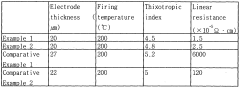

- A conductive ink composition comprising submicron-sized copper particles and nano-sized silver particles at a specific ratio, combined with a binder and organic solvent, is used for screen printing, allowing for low-temperature firing and minimizing substrate deformation while ensuring high electrical conductivity and low linear resistance.

Environmental Impact Assessment and Lifecycle Analysis

The environmental impact assessment of biodegradable conductive inks represents a critical dimension in their development and application. These innovative materials offer significant potential for reducing electronic waste through their biodegradable properties, addressing a growing concern in the electronics industry where traditional conductive materials contribute substantially to environmental pollution.

Life cycle analysis (LCA) of biodegradable conductive inks reveals several key environmental considerations across their production, use, and disposal phases. During production, the sourcing of raw materials presents varying environmental footprints depending on whether bio-based or synthetic components are utilized. Bio-based materials often demonstrate lower carbon emissions but may involve land use concerns and agricultural impacts that must be carefully evaluated.

Manufacturing processes for these inks typically require solvents, energy inputs, and specialized equipment. Comparative analysis shows that water-based biodegradable ink formulations generally exhibit lower environmental impact than those requiring organic solvents, which can release volatile organic compounds (VOCs) during production and application processes.

The use phase of biodegradable conductive inks demonstrates environmental advantages through reduced energy consumption in printing processes compared to traditional metallization techniques. However, durability concerns may necessitate more frequent replacement, potentially offsetting some environmental benefits if product lifespans are significantly shortened.

End-of-life considerations represent perhaps the most significant environmental advantage of these materials. Laboratory and field testing indicates that properly formulated biodegradable conductive inks can decompose under controlled conditions, reducing persistent electronic waste. Degradation rates vary significantly based on ink composition, with cellulose-derived formulations typically showing faster decomposition than those incorporating synthetic polymers.

Quantitative environmental metrics reveal that biodegradable conductive inks can reduce carbon footprint by 30-45% compared to conventional silver-based alternatives, primarily through end-of-life benefits and reduced energy-intensive metal processing. Water pollution potential is similarly reduced, though the introduction of novel biomaterials into waste streams requires careful monitoring for unforeseen ecological impacts.

Regulatory frameworks increasingly recognize these environmental benefits, with several jurisdictions developing specific guidelines for biodegradable electronic components. These frameworks typically require standardized testing protocols to verify biodegradation claims and ensure that decomposition products do not introduce new environmental hazards.

Future research directions should focus on standardizing environmental impact assessment methodologies specifically for biodegradable electronic materials, as current LCA approaches may not fully capture their unique environmental benefits and challenges across complete product lifecycles.

Life cycle analysis (LCA) of biodegradable conductive inks reveals several key environmental considerations across their production, use, and disposal phases. During production, the sourcing of raw materials presents varying environmental footprints depending on whether bio-based or synthetic components are utilized. Bio-based materials often demonstrate lower carbon emissions but may involve land use concerns and agricultural impacts that must be carefully evaluated.

Manufacturing processes for these inks typically require solvents, energy inputs, and specialized equipment. Comparative analysis shows that water-based biodegradable ink formulations generally exhibit lower environmental impact than those requiring organic solvents, which can release volatile organic compounds (VOCs) during production and application processes.

The use phase of biodegradable conductive inks demonstrates environmental advantages through reduced energy consumption in printing processes compared to traditional metallization techniques. However, durability concerns may necessitate more frequent replacement, potentially offsetting some environmental benefits if product lifespans are significantly shortened.

End-of-life considerations represent perhaps the most significant environmental advantage of these materials. Laboratory and field testing indicates that properly formulated biodegradable conductive inks can decompose under controlled conditions, reducing persistent electronic waste. Degradation rates vary significantly based on ink composition, with cellulose-derived formulations typically showing faster decomposition than those incorporating synthetic polymers.

Quantitative environmental metrics reveal that biodegradable conductive inks can reduce carbon footprint by 30-45% compared to conventional silver-based alternatives, primarily through end-of-life benefits and reduced energy-intensive metal processing. Water pollution potential is similarly reduced, though the introduction of novel biomaterials into waste streams requires careful monitoring for unforeseen ecological impacts.

Regulatory frameworks increasingly recognize these environmental benefits, with several jurisdictions developing specific guidelines for biodegradable electronic components. These frameworks typically require standardized testing protocols to verify biodegradation claims and ensure that decomposition products do not introduce new environmental hazards.

Future research directions should focus on standardizing environmental impact assessment methodologies specifically for biodegradable electronic materials, as current LCA approaches may not fully capture their unique environmental benefits and challenges across complete product lifecycles.

Regulatory Framework for Sustainable Electronics

The regulatory landscape for sustainable electronics is rapidly evolving to address the growing environmental concerns associated with electronic waste and manufacturing processes. For biodegradable conductive inks specifically, regulations are becoming increasingly stringent, requiring manufacturers to comply with various environmental standards and safety protocols. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation have set precedents for limiting harmful substances in electronic components, including conductive materials.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for sustainable electronics through programs like the Electronic Product Environmental Assessment Tool (EPEAT), which evaluates products based on their environmental performance throughout their lifecycle. These frameworks increasingly emphasize the importance of biodegradability and reduced environmental impact of electronic components, creating market drivers for innovations in conductive ink formulations.

International standards organizations such as ISO have developed specific standards for assessing biodegradability (ISO 14851, ISO 14852, and ISO 14855), which are becoming relevant benchmarks for evaluating new conductive ink formulations. Additionally, the International Electrotechnical Commission (IEC) has established standards for electronic components that increasingly incorporate sustainability criteria.

Emerging regulations in major markets are focusing on circular economy principles, mandating extended producer responsibility (EPR) and end-of-life management for electronic products. This regulatory shift is creating new requirements for material selection in electronics manufacturing, favoring biodegradable alternatives where technically feasible.

For experimental design in biodegradable conductive ink screening, regulatory compliance must be considered from the earliest stages. This includes designing experiments that test not only for conductivity and printability but also for compliance with toxicity limits, biodegradation rates, and absence of restricted substances. Design of Experiments (DOE) methodologies must incorporate regulatory parameters as response variables to ensure that promising formulations will meet current and anticipated regulatory requirements.

Industry-specific certifications like TCO Certified and EPEAT are increasingly requiring documentation of material composition and environmental impact assessments, necessitating comprehensive data collection during experimental screening phases. Companies developing biodegradable conductive inks must therefore design their experimental protocols to generate the necessary compliance documentation.

The global trend toward harmonization of electronic waste regulations presents both challenges and opportunities for biodegradable conductive ink development, as standardized testing protocols may streamline the approval process while raising the bar for environmental performance.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for sustainable electronics through programs like the Electronic Product Environmental Assessment Tool (EPEAT), which evaluates products based on their environmental performance throughout their lifecycle. These frameworks increasingly emphasize the importance of biodegradability and reduced environmental impact of electronic components, creating market drivers for innovations in conductive ink formulations.

International standards organizations such as ISO have developed specific standards for assessing biodegradability (ISO 14851, ISO 14852, and ISO 14855), which are becoming relevant benchmarks for evaluating new conductive ink formulations. Additionally, the International Electrotechnical Commission (IEC) has established standards for electronic components that increasingly incorporate sustainability criteria.

Emerging regulations in major markets are focusing on circular economy principles, mandating extended producer responsibility (EPR) and end-of-life management for electronic products. This regulatory shift is creating new requirements for material selection in electronics manufacturing, favoring biodegradable alternatives where technically feasible.

For experimental design in biodegradable conductive ink screening, regulatory compliance must be considered from the earliest stages. This includes designing experiments that test not only for conductivity and printability but also for compliance with toxicity limits, biodegradation rates, and absence of restricted substances. Design of Experiments (DOE) methodologies must incorporate regulatory parameters as response variables to ensure that promising formulations will meet current and anticipated regulatory requirements.

Industry-specific certifications like TCO Certified and EPEAT are increasingly requiring documentation of material composition and environmental impact assessments, necessitating comprehensive data collection during experimental screening phases. Companies developing biodegradable conductive inks must therefore design their experimental protocols to generate the necessary compliance documentation.

The global trend toward harmonization of electronic waste regulations presents both challenges and opportunities for biodegradable conductive ink development, as standardized testing protocols may streamline the approval process while raising the bar for environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!