Materials Selection For Transient Electronic Devices: Polymers And Composites

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transient Electronics Background and Objectives

Transient electronics represents a revolutionary paradigm shift in the field of electronic devices, characterized by their ability to dissolve, disintegrate, or degrade in a controlled manner after serving their intended functions. This emerging technology has evolved significantly over the past decade, transitioning from conceptual frameworks to practical applications across various sectors including healthcare, environmental monitoring, and security systems. The evolution of transient electronics has been driven by the growing need for sustainable electronic solutions that minimize electronic waste and address privacy concerns in an increasingly connected world.

The historical trajectory of transient electronics began with rudimentary water-soluble components in the early 2000s, progressing to more sophisticated systems capable of controlled degradation through various environmental triggers by the 2010s. Recent advancements have focused on developing materials with precise dissolution rates and enhanced functionality during their operational lifetime, particularly in the realm of polymers and composites that offer unique mechanical and electrical properties.

Current technological trends indicate a shift toward multifunctional transient materials that can simultaneously provide structural support, electrical conductivity, and controlled degradability. Polymers and polymer composites have emerged as particularly promising candidates due to their versatility, biocompatibility, and tunable degradation profiles. The integration of natural and synthetic polymers with various fillers and additives has opened new avenues for customizing transient behavior while maintaining essential electronic functionalities.

The primary objective of research in this field is to develop comprehensive material selection frameworks for transient electronic devices, with a specific focus on polymers and composites that balance performance requirements with controlled degradability. This includes identifying materials that offer optimal electrical properties, mechanical stability, and environmental responsiveness while maintaining predictable dissolution characteristics under specific triggers such as moisture, temperature, pH changes, or enzymatic activity.

Additional goals include establishing standardized testing protocols for evaluating transient materials, creating predictive models for degradation behavior under various environmental conditions, and developing scalable manufacturing processes that enable commercial viability. The ultimate aim is to create a new generation of electronic devices that can perform their functions reliably for predetermined periods before harmlessly disappearing, thereby addressing both environmental sustainability concerns and specialized application requirements in medical implants, environmental sensors, and secure hardware systems.

The convergence of materials science, electronics engineering, and environmental chemistry in this field presents unique interdisciplinary challenges that require innovative approaches to material design, characterization, and implementation. As the technology continues to mature, the focus increasingly shifts toward practical applications that can demonstrate real-world benefits and commercial potential.

The historical trajectory of transient electronics began with rudimentary water-soluble components in the early 2000s, progressing to more sophisticated systems capable of controlled degradation through various environmental triggers by the 2010s. Recent advancements have focused on developing materials with precise dissolution rates and enhanced functionality during their operational lifetime, particularly in the realm of polymers and composites that offer unique mechanical and electrical properties.

Current technological trends indicate a shift toward multifunctional transient materials that can simultaneously provide structural support, electrical conductivity, and controlled degradability. Polymers and polymer composites have emerged as particularly promising candidates due to their versatility, biocompatibility, and tunable degradation profiles. The integration of natural and synthetic polymers with various fillers and additives has opened new avenues for customizing transient behavior while maintaining essential electronic functionalities.

The primary objective of research in this field is to develop comprehensive material selection frameworks for transient electronic devices, with a specific focus on polymers and composites that balance performance requirements with controlled degradability. This includes identifying materials that offer optimal electrical properties, mechanical stability, and environmental responsiveness while maintaining predictable dissolution characteristics under specific triggers such as moisture, temperature, pH changes, or enzymatic activity.

Additional goals include establishing standardized testing protocols for evaluating transient materials, creating predictive models for degradation behavior under various environmental conditions, and developing scalable manufacturing processes that enable commercial viability. The ultimate aim is to create a new generation of electronic devices that can perform their functions reliably for predetermined periods before harmlessly disappearing, thereby addressing both environmental sustainability concerns and specialized application requirements in medical implants, environmental sensors, and secure hardware systems.

The convergence of materials science, electronics engineering, and environmental chemistry in this field presents unique interdisciplinary challenges that require innovative approaches to material design, characterization, and implementation. As the technology continues to mature, the focus increasingly shifts toward practical applications that can demonstrate real-world benefits and commercial potential.

Market Analysis for Biodegradable Electronic Applications

The biodegradable electronics market is experiencing significant growth driven by increasing environmental concerns and regulatory pressures on electronic waste management. Current market valuations indicate that the global transient electronics sector is projected to reach approximately 3.5 billion USD by 2027, with a compound annual growth rate exceeding 20% between 2022 and 2027. This rapid expansion reflects the growing demand for environmentally responsible electronic solutions across multiple industries.

Healthcare applications currently dominate the biodegradable electronics market, accounting for nearly 40% of the total market share. Medical implants, drug delivery systems, and temporary diagnostic devices represent the primary applications in this sector. The ability of transient electronic devices to naturally degrade after serving their purpose eliminates the need for secondary surgical procedures for device removal, significantly reducing healthcare costs and patient discomfort.

Environmental monitoring represents another rapidly expanding application area, with an estimated market growth rate of 25% annually. Biodegradable sensors deployed in agricultural settings, natural habitats, and urban environments provide valuable data while minimizing ecological disruption. These devices offer particular advantages in remote or sensitive ecosystems where device retrieval would be impractical or potentially harmful.

Consumer electronics manufacturers are increasingly exploring biodegradable components to address mounting electronic waste concerns. Several major technology companies have launched research initiatives focused on developing partially biodegradable consumer products, particularly for short-lifecycle devices such as wearables and IoT sensors. Market research indicates that approximately 65% of consumers express willingness to pay premium prices for electronics with reduced environmental impact.

Regional market analysis reveals that North America and Europe currently lead in biodegradable electronics adoption, collectively accounting for over 60% of global market revenue. However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental regulations, and substantial government investments in sustainable technologies.

Key market challenges include the higher production costs of biodegradable materials compared to conventional electronics components, with current price premiums ranging from 30-80% depending on the specific application. Additionally, performance limitations and reliability concerns continue to restrict market penetration in certain high-demand applications requiring extended operational lifespans or extreme environmental conditions.

Despite these challenges, market forecasts remain highly positive as advances in polymer and composite materials continue to improve the performance-to-cost ratio of biodegradable electronic solutions. The convergence of environmental sustainability priorities with technological innovation is creating substantial market opportunities across multiple sectors.

Healthcare applications currently dominate the biodegradable electronics market, accounting for nearly 40% of the total market share. Medical implants, drug delivery systems, and temporary diagnostic devices represent the primary applications in this sector. The ability of transient electronic devices to naturally degrade after serving their purpose eliminates the need for secondary surgical procedures for device removal, significantly reducing healthcare costs and patient discomfort.

Environmental monitoring represents another rapidly expanding application area, with an estimated market growth rate of 25% annually. Biodegradable sensors deployed in agricultural settings, natural habitats, and urban environments provide valuable data while minimizing ecological disruption. These devices offer particular advantages in remote or sensitive ecosystems where device retrieval would be impractical or potentially harmful.

Consumer electronics manufacturers are increasingly exploring biodegradable components to address mounting electronic waste concerns. Several major technology companies have launched research initiatives focused on developing partially biodegradable consumer products, particularly for short-lifecycle devices such as wearables and IoT sensors. Market research indicates that approximately 65% of consumers express willingness to pay premium prices for electronics with reduced environmental impact.

Regional market analysis reveals that North America and Europe currently lead in biodegradable electronics adoption, collectively accounting for over 60% of global market revenue. However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental regulations, and substantial government investments in sustainable technologies.

Key market challenges include the higher production costs of biodegradable materials compared to conventional electronics components, with current price premiums ranging from 30-80% depending on the specific application. Additionally, performance limitations and reliability concerns continue to restrict market penetration in certain high-demand applications requiring extended operational lifespans or extreme environmental conditions.

Despite these challenges, market forecasts remain highly positive as advances in polymer and composite materials continue to improve the performance-to-cost ratio of biodegradable electronic solutions. The convergence of environmental sustainability priorities with technological innovation is creating substantial market opportunities across multiple sectors.

Current Challenges in Polymer-Based Transient Electronics

Despite significant advancements in polymer-based transient electronics, several critical challenges continue to impede widespread implementation and commercialization. The fundamental challenge lies in achieving the delicate balance between functional stability during operational lifetime and complete degradation after triggering. Current polymer matrices often exhibit inconsistent degradation rates, leading to unpredictable device performance and reliability issues in real-world applications.

Material selection presents a significant hurdle as polymers with excellent electronic properties typically demonstrate poor degradability, while highly degradable polymers often lack the necessary mechanical and electrical characteristics. This inverse relationship between functionality and transience creates a complex materials engineering problem that has not been fully resolved.

Environmental sensitivity remains problematic for polymer-based transient electronics. Many current polymer systems are highly susceptible to ambient conditions such as humidity, temperature fluctuations, and UV exposure, which can trigger premature degradation or significantly alter device performance parameters. This environmental vulnerability severely limits deployment in harsh or unpredictable environments.

Interfacial compatibility between polymer substrates and electronic components presents another major challenge. Poor adhesion and mechanical mismatch between organic and inorganic materials often lead to delamination, cracking, and premature device failure. These interface issues become particularly pronounced during the degradation phase, where differential dissolution rates can cause unpredictable device behavior.

Scalable manufacturing remains elusive for many polymer-based transient electronic systems. Current fabrication techniques often involve complex, multi-step processes that are difficult to scale while maintaining consistent material properties and device performance. The lack of standardized manufacturing protocols further complicates industrial adoption and commercialization efforts.

Biocompatibility concerns persist for biomedical applications, where polymer degradation byproducts may cause inflammatory responses or other adverse biological reactions. The toxicological profiles of novel polymer composites and their degradation products require extensive evaluation before clinical implementation can be considered.

Additionally, the development of precise, reliable triggering mechanisms for controlled transience remains challenging. Current approaches often lack specificity or require conditions that may compromise device functionality. The ability to precisely control when and how quickly a device degrades represents a critical frontier in transient electronics research.

Material selection presents a significant hurdle as polymers with excellent electronic properties typically demonstrate poor degradability, while highly degradable polymers often lack the necessary mechanical and electrical characteristics. This inverse relationship between functionality and transience creates a complex materials engineering problem that has not been fully resolved.

Environmental sensitivity remains problematic for polymer-based transient electronics. Many current polymer systems are highly susceptible to ambient conditions such as humidity, temperature fluctuations, and UV exposure, which can trigger premature degradation or significantly alter device performance parameters. This environmental vulnerability severely limits deployment in harsh or unpredictable environments.

Interfacial compatibility between polymer substrates and electronic components presents another major challenge. Poor adhesion and mechanical mismatch between organic and inorganic materials often lead to delamination, cracking, and premature device failure. These interface issues become particularly pronounced during the degradation phase, where differential dissolution rates can cause unpredictable device behavior.

Scalable manufacturing remains elusive for many polymer-based transient electronic systems. Current fabrication techniques often involve complex, multi-step processes that are difficult to scale while maintaining consistent material properties and device performance. The lack of standardized manufacturing protocols further complicates industrial adoption and commercialization efforts.

Biocompatibility concerns persist for biomedical applications, where polymer degradation byproducts may cause inflammatory responses or other adverse biological reactions. The toxicological profiles of novel polymer composites and their degradation products require extensive evaluation before clinical implementation can be considered.

Additionally, the development of precise, reliable triggering mechanisms for controlled transience remains challenging. Current approaches often lack specificity or require conditions that may compromise device functionality. The ability to precisely control when and how quickly a device degrades represents a critical frontier in transient electronics research.

Current Polymer and Composite Solutions for Transient Devices

01 Biodegradable polymer composites

Biodegradable polymers and composites are increasingly being selected for environmentally friendly applications. These materials combine natural fibers or fillers with biodegradable polymer matrices to create composites with reduced environmental impact. The selection criteria include biodegradation rate, mechanical properties, and processing characteristics. These materials are particularly valuable in packaging, agriculture, and consumer goods where end-of-life considerations are important.- Biodegradable polymer composites: Biodegradable polymers and their composites are increasingly being selected for various applications due to environmental concerns. These materials are designed to break down naturally after their useful life, reducing environmental impact. Selection criteria include degradation rate, mechanical properties, and compatibility with fillers such as natural fibers or minerals. These composites often incorporate renewable resources and are suitable for packaging, agricultural applications, and consumer goods where end-of-life considerations are important.

- High-performance polymer composites for structural applications: Selection of high-performance polymer composites focuses on materials with exceptional mechanical properties, including strength, stiffness, and impact resistance. These materials often incorporate reinforcing fibers such as carbon, glass, or aramid to enhance structural performance. Selection criteria include fiber orientation, matrix compatibility, and processing requirements. These composites are typically chosen for aerospace, automotive, and construction applications where weight reduction and structural integrity are critical factors.

- Functional polymer composites with specialized properties: Functional polymer composites are selected based on their ability to provide specialized properties beyond mechanical performance. These include electrical conductivity, thermal management, electromagnetic shielding, or optical characteristics. Material selection involves consideration of additives such as conductive fillers, phase change materials, or specialty particles that impart the desired functionality. These composites are used in electronics, sensors, energy storage, and smart materials applications where specific functional properties are required.

- Polymer blends and alloys for enhanced performance: Polymer blends and alloys are selected to combine the beneficial properties of multiple polymers into a single material system. Selection criteria include compatibility between polymers, phase morphology, and processing conditions. These materials often provide a balance of properties that cannot be achieved with a single polymer, such as improved impact resistance without sacrificing stiffness. Applications include automotive components, consumer products, and industrial parts where a specific combination of properties is required.

- Sustainable and bio-based polymer composites: Selection of sustainable polymer composites focuses on materials derived from renewable resources or designed for reduced environmental impact. These include bio-based polymers from plant sources, composites with natural fibers, and materials designed for recyclability or circular economy approaches. Selection criteria include carbon footprint, renewable content, and end-of-life considerations. These materials are increasingly chosen for packaging, consumer goods, and building materials where sustainability is a key requirement.

02 High-performance engineering polymers

High-performance engineering polymers are selected for demanding applications requiring exceptional mechanical, thermal, or chemical resistance properties. These include polyetheretherketone (PEEK), polyimides, polysulfones, and liquid crystal polymers. Material selection criteria focus on strength-to-weight ratio, heat deflection temperature, chemical resistance, and long-term durability. These polymers are often used in aerospace, automotive, and industrial applications where traditional materials would fail.Expand Specific Solutions03 Polymer nanocomposites

Polymer nanocomposites incorporate nanoscale fillers such as carbon nanotubes, graphene, clay, or metal nanoparticles into polymer matrices. The selection of these materials is based on the dramatic property improvements achieved with minimal filler content. These nanocomposites offer enhanced mechanical strength, barrier properties, electrical conductivity, or thermal stability compared to conventional composites. The interface between the nanofiller and polymer matrix is critical to performance optimization.Expand Specific Solutions04 Fiber-reinforced polymer composites

Fiber-reinforced polymer composites combine high-strength fibers with polymer matrices to create materials with exceptional strength-to-weight ratios. Material selection involves choosing appropriate fiber types (glass, carbon, aramid, natural), fiber orientation, and compatible polymer matrices. Design considerations include fiber volume fraction, interfacial adhesion, and processing methods. These composites are widely used in structural applications where weight reduction and high performance are required.Expand Specific Solutions05 Functional and smart polymers

Functional and smart polymers exhibit responsive behaviors to external stimuli such as temperature, pH, light, or electrical fields. Material selection focuses on the specific responsive mechanism required for the application. These include shape-memory polymers, self-healing materials, and polymers with switchable properties. Applications range from medical devices and drug delivery systems to sensors and actuators. The selection criteria balance the functional response with mechanical properties and processing requirements.Expand Specific Solutions

Leading Companies and Research Institutions in Transient Electronics

The transient electronics market is in its early growth phase, characterized by rapid technological advancement and expanding applications across medical, environmental, and consumer sectors. Current market size is modest but projected to grow significantly as biodegradable and environmentally friendly electronic solutions gain traction. From a technical maturity perspective, polymer and composite materials development is advancing through collaborative research between academic institutions (University of Illinois, Cambridge Enterprise, Tufts College) and commercial entities (DuPont, Solvay Specialty Polymers, Huawei). Leading companies like Semiconductor Energy Laboratory and BASF are developing innovative substrate materials, while Fraunhofer-Gesellschaft and Industrial Technology Research Institute focus on manufacturing processes. The competitive landscape shows a balance between established chemical companies and emerging specialized players, with increasing interest from electronics manufacturers seeking sustainable solutions.

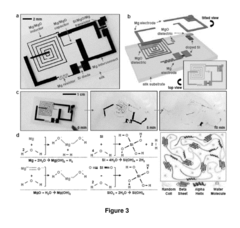

The Board of Trustees of the University of Illinois

Technical Solution: The University of Illinois has pioneered significant advancements in transient electronics through their development of water-soluble polymers and silk-based substrates. Their research team led by Professor John Rogers has created biodegradable electronic systems using silk fibroin as a substrate material combined with magnesium conductors and silicon semiconductors. These materials dissolve in biofluids at controlled rates, enabling applications in implantable medical devices. Their technology incorporates specialized polymer composites that can be triggered to degrade through environmental stimuli such as pH changes, temperature variations, or exposure to specific enzymes. The university has demonstrated functional transient electronic devices including sensors, actuators, and wireless power systems that completely dissolve after their useful lifetime, leaving no harmful residues in the body or environment.

Strengths: Leading academic research in biodegradable electronics with numerous high-impact publications; strong focus on biomedical applications; established collaboration network with medical institutions. Weaknesses: As an academic institution, may face challenges in scaling manufacturing processes for commercial production; potential intellectual property complexities when transferring technology to industry partners.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed proprietary polymer systems specifically engineered for transient electronics applications. Their technology platform includes water-soluble polymers like polyvinyl alcohol (PVA) derivatives and polylactic acid (PLA) composites with controlled degradation profiles. DuPont's materials feature customizable dissolution rates through molecular weight adjustments and specialized additives that can trigger degradation under specific environmental conditions. Their polymer composites provide excellent substrate properties including flexibility, thermal stability during device fabrication, and controlled mechanical properties. DuPont has created specialized encapsulation materials that protect electronic components during operation while enabling complete dissolution when exposed to targeted solvents or environmental conditions. Their materials support conventional electronics manufacturing processes including printing, lamination, and photolithography, making them compatible with existing production infrastructure while enabling next-generation transient functionality.

Strengths: Extensive polymer chemistry expertise; established manufacturing infrastructure; strong intellectual property portfolio in specialty polymers; global distribution network. Weaknesses: Primary focus on industrial applications may limit innovation in emerging biomedical applications; potential higher material costs compared to conventional electronics materials.

Key Patents and Research on Degradable Electronic Materials

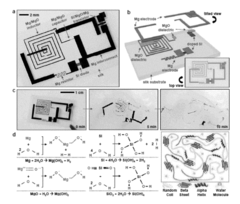

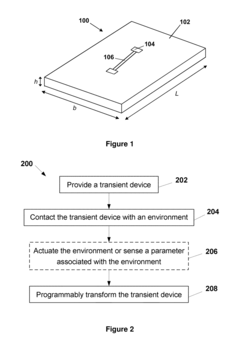

Transient Devices Designed to Undergo Programmable Transformations

PatentActiveUS20180175158A1

Innovation

- Development of transient electronic devices using degradable silicon components and substrates with selectively transformable materials, allowing for controlled transformation through stimuli such as bioresorption, hydrolysis, or chemical changes, enabling programmable changes in device function over time.

Transient electrochemical devices

PatentActiveHK1221597A

Innovation

- Development of transient electronic devices that incorporate degradable components and substrates with programmable degradation rates, combining high-performance single crystalline inorganic materials with biodegradable substrates, allowing for controlled transformation in response to internal or external stimuli, enabling applications like bio-resorbable medical implants and eco-resorbable environmental sensors.

Environmental Impact Assessment of Transient Electronic Materials

The environmental impact of transient electronic materials represents a critical dimension in evaluating their sustainability and long-term viability. Polymers and composites used in transient electronics demonstrate significantly different environmental footprints compared to conventional electronic materials, primarily due to their designed degradability and reduced persistence in ecosystems.

Life cycle assessment (LCA) studies indicate that biodegradable polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and silk fibroin demonstrate substantially lower environmental impacts during end-of-life phases. These materials naturally decompose into non-toxic components, reducing waste accumulation and ecosystem contamination. However, their production phase often requires more energy and resources compared to conventional polymers, creating a complex environmental trade-off scenario.

Water-soluble polymers like polyvinyl alcohol (PVA) and polyethylene oxide (PEO) show promising environmental profiles when their dissolution products are non-toxic. Research indicates that these materials can reduce electronic waste volume by up to 90% compared to traditional electronics. Nevertheless, concerns remain regarding the potential introduction of microplastics into aquatic ecosystems if dissolution is incomplete.

Composite materials incorporating natural fibers (cellulose, chitin) demonstrate enhanced biodegradability while maintaining functional performance. These bio-based composites typically reduce carbon footprint by 30-45% compared to petroleum-based alternatives. However, the environmental benefits are often offset by complex manufacturing processes that may involve toxic solvents or energy-intensive conditions.

The environmental impact of conductive fillers within transient composites presents particular challenges. While metals like magnesium and zinc offer biodegradability, their extraction and processing carry significant environmental burdens. Alternative conductive materials such as carbon-based nanomaterials and conductive polymers show promise but require further assessment regarding their long-term environmental fate and ecotoxicity.

Regulatory frameworks increasingly emphasize the importance of comprehensive environmental impact assessments for transient electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are beginning to incorporate specific provisions for transient electronics, focusing on both material composition and degradation pathways.

Future environmental assessment methodologies must address the unique characteristics of transient materials, particularly their transformation products and degradation intermediates. Current standardized testing protocols often fail to capture the dynamic nature of these materials, necessitating the development of specialized assessment frameworks that consider temporal dimensions and varying environmental conditions.

Life cycle assessment (LCA) studies indicate that biodegradable polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and silk fibroin demonstrate substantially lower environmental impacts during end-of-life phases. These materials naturally decompose into non-toxic components, reducing waste accumulation and ecosystem contamination. However, their production phase often requires more energy and resources compared to conventional polymers, creating a complex environmental trade-off scenario.

Water-soluble polymers like polyvinyl alcohol (PVA) and polyethylene oxide (PEO) show promising environmental profiles when their dissolution products are non-toxic. Research indicates that these materials can reduce electronic waste volume by up to 90% compared to traditional electronics. Nevertheless, concerns remain regarding the potential introduction of microplastics into aquatic ecosystems if dissolution is incomplete.

Composite materials incorporating natural fibers (cellulose, chitin) demonstrate enhanced biodegradability while maintaining functional performance. These bio-based composites typically reduce carbon footprint by 30-45% compared to petroleum-based alternatives. However, the environmental benefits are often offset by complex manufacturing processes that may involve toxic solvents or energy-intensive conditions.

The environmental impact of conductive fillers within transient composites presents particular challenges. While metals like magnesium and zinc offer biodegradability, their extraction and processing carry significant environmental burdens. Alternative conductive materials such as carbon-based nanomaterials and conductive polymers show promise but require further assessment regarding their long-term environmental fate and ecotoxicity.

Regulatory frameworks increasingly emphasize the importance of comprehensive environmental impact assessments for transient electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are beginning to incorporate specific provisions for transient electronics, focusing on both material composition and degradation pathways.

Future environmental assessment methodologies must address the unique characteristics of transient materials, particularly their transformation products and degradation intermediates. Current standardized testing protocols often fail to capture the dynamic nature of these materials, necessitating the development of specialized assessment frameworks that consider temporal dimensions and varying environmental conditions.

Biocompatibility and Safety Standards for Medical Applications

The integration of transient electronic devices into medical applications necessitates rigorous adherence to biocompatibility and safety standards. For polymers and composites used in these devices, compliance with ISO 10993 series is fundamental, particularly ISO 10993-1 which outlines the biological evaluation framework for medical devices. These standards require comprehensive testing for cytotoxicity, sensitization, irritation, and systemic toxicity to ensure patient safety during the functional lifetime of the device.

FDA guidelines further specify requirements for materials intended for implantation or direct contact with biological tissues. For transient electronics, the FDA's guidance on Biocompatibility Testing of Medical Devices (2020) provides specific protocols for evaluating materials that are designed to degrade in physiological environments. These guidelines emphasize the importance of characterizing degradation products and their potential biological impacts.

Materials selection must also consider the European Medical Device Regulation (MDR 2017/745), which imposes stringent requirements on materials that come into contact with the human body. For polymers like poly(lactic-co-glycolic acid) (PLGA) and polycaprolactone (PCL) commonly used in transient electronics, documentation of their degradation kinetics and metabolic pathways is essential for regulatory approval.

The biocompatibility assessment must account for the unique characteristics of transient devices, including controlled dissolution rates and potential interactions between degradation products and surrounding tissues. ASTM F748 provides standard practice for selecting biological tests for materials and devices, while ASTM F2475 specifically addresses the degradation testing of absorbable polymers.

Recent developments in safety standards have begun to address nanomaterials incorporated into polymeric composites, with ISO/TR 10993-22:2017 providing guidance on nanomaterial considerations. This is particularly relevant for transient electronics that may incorporate conductive nanoparticles or carbon-based nanomaterials to enhance functionality.

For implantable transient devices, long-term safety monitoring protocols must be established according to ISO 14155, which governs clinical investigations of medical devices. These protocols should include assessment of local tissue response, systemic effects, and potential immunological reactions throughout the degradation process.

Emerging standards are also beginning to address the environmental impact of medical materials, with ISO 14001 providing a framework for environmental management systems. This is increasingly important for transient electronics, as their end-of-life characteristics and environmental footprint become considerations in material selection and device design.

FDA guidelines further specify requirements for materials intended for implantation or direct contact with biological tissues. For transient electronics, the FDA's guidance on Biocompatibility Testing of Medical Devices (2020) provides specific protocols for evaluating materials that are designed to degrade in physiological environments. These guidelines emphasize the importance of characterizing degradation products and their potential biological impacts.

Materials selection must also consider the European Medical Device Regulation (MDR 2017/745), which imposes stringent requirements on materials that come into contact with the human body. For polymers like poly(lactic-co-glycolic acid) (PLGA) and polycaprolactone (PCL) commonly used in transient electronics, documentation of their degradation kinetics and metabolic pathways is essential for regulatory approval.

The biocompatibility assessment must account for the unique characteristics of transient devices, including controlled dissolution rates and potential interactions between degradation products and surrounding tissues. ASTM F748 provides standard practice for selecting biological tests for materials and devices, while ASTM F2475 specifically addresses the degradation testing of absorbable polymers.

Recent developments in safety standards have begun to address nanomaterials incorporated into polymeric composites, with ISO/TR 10993-22:2017 providing guidance on nanomaterial considerations. This is particularly relevant for transient electronics that may incorporate conductive nanoparticles or carbon-based nanomaterials to enhance functionality.

For implantable transient devices, long-term safety monitoring protocols must be established according to ISO 14155, which governs clinical investigations of medical devices. These protocols should include assessment of local tissue response, systemic effects, and potential immunological reactions throughout the degradation process.

Emerging standards are also beginning to address the environmental impact of medical materials, with ISO 14001 providing a framework for environmental management systems. This is increasingly important for transient electronics, as their end-of-life characteristics and environmental footprint become considerations in material selection and device design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!