Mitigating Environmental Risks Of Metal Electrodes In Biodegradable Designs

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Metal Electrodes Background and Objectives

Biodegradable electronics represent a revolutionary approach to sustainable technology development, addressing the growing concern of electronic waste accumulation. Metal electrodes are fundamental components in these systems, serving as conductive pathways for electrical signals. The evolution of biodegradable metal electrodes has progressed significantly over the past decade, transitioning from theoretical concepts to practical implementations in various biomedical and environmental applications.

Historically, conventional electronics relied on non-degradable metals such as gold, platinum, and copper, which persist indefinitely in the environment. The paradigm shift toward biodegradable alternatives began in the early 2000s, driven by increasing environmental awareness and regulatory pressures. This technological trajectory has been characterized by the exploration of metals and alloys that can maintain functionality during their operational lifetime while safely degrading afterward.

Magnesium, zinc, iron, and their alloys have emerged as promising candidates for biodegradable electrodes due to their essential biological roles and controlled degradation profiles. These metals undergo corrosion processes in physiological or environmental conditions, eventually breaking down into non-toxic byproducts. However, this very property presents a significant technical challenge: balancing functional stability during use with predictable degradation post-use.

The primary objective of current research in biodegradable metal electrodes is to mitigate environmental risks while maintaining performance integrity. This involves developing electrodes that minimize toxic ion release, control degradation rates, and ensure complete biodegradation without harmful residues. Additionally, researchers aim to establish standardized testing protocols for assessing the environmental impact of these materials throughout their lifecycle.

Another critical goal is to enhance the compatibility of these electrodes with various biodegradable substrates and encapsulation materials, creating fully integrated systems that degrade harmoniously. This requires interdisciplinary collaboration between materials scientists, electrical engineers, and environmental toxicologists to comprehensively address the complex interactions between degrading metals and their surroundings.

The technological landscape is further shaped by emerging applications in environmental sensing, agricultural monitoring, and temporary medical implants, each presenting unique requirements for electrode performance and degradation profiles. These diverse application scenarios necessitate customizable approaches to electrode design and composition.

Looking forward, the field is moving toward smart biodegradable electrodes with programmable degradation timelines, allowing precise control over when and how quickly the materials break down. This advancement would significantly reduce environmental risks by ensuring that devices degrade only after fulfilling their intended purpose, thereby minimizing premature failure and unnecessary replacement.

Historically, conventional electronics relied on non-degradable metals such as gold, platinum, and copper, which persist indefinitely in the environment. The paradigm shift toward biodegradable alternatives began in the early 2000s, driven by increasing environmental awareness and regulatory pressures. This technological trajectory has been characterized by the exploration of metals and alloys that can maintain functionality during their operational lifetime while safely degrading afterward.

Magnesium, zinc, iron, and their alloys have emerged as promising candidates for biodegradable electrodes due to their essential biological roles and controlled degradation profiles. These metals undergo corrosion processes in physiological or environmental conditions, eventually breaking down into non-toxic byproducts. However, this very property presents a significant technical challenge: balancing functional stability during use with predictable degradation post-use.

The primary objective of current research in biodegradable metal electrodes is to mitigate environmental risks while maintaining performance integrity. This involves developing electrodes that minimize toxic ion release, control degradation rates, and ensure complete biodegradation without harmful residues. Additionally, researchers aim to establish standardized testing protocols for assessing the environmental impact of these materials throughout their lifecycle.

Another critical goal is to enhance the compatibility of these electrodes with various biodegradable substrates and encapsulation materials, creating fully integrated systems that degrade harmoniously. This requires interdisciplinary collaboration between materials scientists, electrical engineers, and environmental toxicologists to comprehensively address the complex interactions between degrading metals and their surroundings.

The technological landscape is further shaped by emerging applications in environmental sensing, agricultural monitoring, and temporary medical implants, each presenting unique requirements for electrode performance and degradation profiles. These diverse application scenarios necessitate customizable approaches to electrode design and composition.

Looking forward, the field is moving toward smart biodegradable electrodes with programmable degradation timelines, allowing precise control over when and how quickly the materials break down. This advancement would significantly reduce environmental risks by ensuring that devices degrade only after fulfilling their intended purpose, thereby minimizing premature failure and unnecessary replacement.

Market Analysis for Eco-friendly Electronic Components

The market for eco-friendly electronic components has experienced significant growth in recent years, driven by increasing environmental regulations, consumer awareness, and corporate sustainability initiatives. The global green electronics market was valued at approximately $8.8 billion in 2022 and is projected to reach $18.6 billion by 2028, representing a compound annual growth rate of 13.2% during the forecast period.

Biodegradable electronics, particularly those addressing metal electrode environmental risks, represent a rapidly expanding segment within this market. This growth is primarily fueled by the escalating electronic waste crisis, with over 50 million metric tons of e-waste generated annually worldwide, of which less than 20% is formally recycled.

Consumer electronics manufacturers are increasingly seeking sustainable alternatives to traditional metal electrodes containing toxic elements such as lead, mercury, and cadmium. This demand is particularly strong in regions with stringent environmental regulations, including the European Union with its Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives.

Healthcare applications represent another significant market driver, with biodegradable implantable devices projected to grow at 15.7% annually through 2030. These devices require electrodes that can safely degrade within the human body without releasing harmful metal ions or residues.

The automotive sector is also emerging as a key market for eco-friendly electronic components, particularly as electric vehicles gain market share. Sustainable battery technologies and biodegradable sensors are in high demand as manufacturers seek to improve their environmental credentials.

Regional analysis indicates that North America and Europe currently lead in adoption of eco-friendly electronic components, accounting for approximately 65% of the global market. However, the Asia-Pacific region is expected to witness the fastest growth rate of 16.8% annually, driven by increasing environmental regulations in China and Japan, coupled with the region's dominant position in electronics manufacturing.

Key customer segments include consumer electronics manufacturers (38% market share), medical device companies (27%), automotive manufacturers (18%), and industrial electronics producers (12%). The remaining 5% is distributed across various smaller applications including aerospace and defense.

Price sensitivity remains a significant market challenge, with eco-friendly components typically commanding a 15-30% premium over conventional alternatives. However, this price gap is narrowing as production scales up and new manufacturing techniques emerge. Market research indicates that 62% of electronics manufacturers are willing to absorb higher component costs to meet sustainability goals and regulatory requirements.

Biodegradable electronics, particularly those addressing metal electrode environmental risks, represent a rapidly expanding segment within this market. This growth is primarily fueled by the escalating electronic waste crisis, with over 50 million metric tons of e-waste generated annually worldwide, of which less than 20% is formally recycled.

Consumer electronics manufacturers are increasingly seeking sustainable alternatives to traditional metal electrodes containing toxic elements such as lead, mercury, and cadmium. This demand is particularly strong in regions with stringent environmental regulations, including the European Union with its Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives.

Healthcare applications represent another significant market driver, with biodegradable implantable devices projected to grow at 15.7% annually through 2030. These devices require electrodes that can safely degrade within the human body without releasing harmful metal ions or residues.

The automotive sector is also emerging as a key market for eco-friendly electronic components, particularly as electric vehicles gain market share. Sustainable battery technologies and biodegradable sensors are in high demand as manufacturers seek to improve their environmental credentials.

Regional analysis indicates that North America and Europe currently lead in adoption of eco-friendly electronic components, accounting for approximately 65% of the global market. However, the Asia-Pacific region is expected to witness the fastest growth rate of 16.8% annually, driven by increasing environmental regulations in China and Japan, coupled with the region's dominant position in electronics manufacturing.

Key customer segments include consumer electronics manufacturers (38% market share), medical device companies (27%), automotive manufacturers (18%), and industrial electronics producers (12%). The remaining 5% is distributed across various smaller applications including aerospace and defense.

Price sensitivity remains a significant market challenge, with eco-friendly components typically commanding a 15-30% premium over conventional alternatives. However, this price gap is narrowing as production scales up and new manufacturing techniques emerge. Market research indicates that 62% of electronics manufacturers are willing to absorb higher component costs to meet sustainability goals and regulatory requirements.

Environmental Challenges and Technical Limitations

The integration of metal electrodes in biodegradable designs presents significant environmental challenges that require careful consideration. Traditional metal electrodes contain elements such as gold, platinum, and copper that persist in the environment long after the biodegradable components have decomposed. This persistence creates a fundamental contradiction to the core purpose of biodegradable electronics, which aims to minimize environmental impact through complete degradation.

Heavy metals from electrodes can leach into soil and water systems, potentially causing bioaccumulation in organisms and disrupting ecosystem functions. Studies have shown that even trace amounts of certain metals can have toxic effects on aquatic organisms and soil microbiota, affecting biodiversity and ecological balance. The environmental risk is particularly pronounced in applications where biodegradable electronics might be deployed in large numbers, such as environmental sensors or agricultural monitoring systems.

Technical limitations further complicate the development of environmentally safe biodegradable electrodes. Current biodegradable metal alternatives, such as magnesium, zinc, and iron alloys, often exhibit inferior electrical conductivity compared to conventional electrode materials. This reduced performance creates a significant trade-off between environmental safety and device functionality that engineers must navigate.

Corrosion control presents another major challenge. While controlled degradation is desirable for biodegradable electronics, premature corrosion of metal components can lead to device failure before the intended lifespan is reached. Conversely, corrosion-resistant coatings may impede the eventual biodegradation process, creating a technical paradox that requires sophisticated materials engineering solutions.

The manufacturing processes for biodegradable metal electrodes often require specialized techniques that are not yet optimized for mass production. This limitation restricts scalability and increases production costs, creating barriers to widespread adoption. Additionally, quality control for biodegradable metals is more complex than for conventional materials, as degradation rates can vary significantly based on minor compositional differences.

Regulatory frameworks for assessing the environmental impact of biodegradable electronics remain underdeveloped. The lack of standardized testing protocols for evaluating the long-term environmental effects of degrading metal components creates uncertainty for manufacturers and potential adopters. This regulatory gap slows innovation and market penetration of environmentally safer alternatives.

The interface between biodegradable substrates and metal electrodes presents additional technical challenges. Differences in degradation rates between organic substrates and metal components can lead to structural integrity issues, affecting device reliability and potentially releasing electrode fragments into the environment prematurely.

Heavy metals from electrodes can leach into soil and water systems, potentially causing bioaccumulation in organisms and disrupting ecosystem functions. Studies have shown that even trace amounts of certain metals can have toxic effects on aquatic organisms and soil microbiota, affecting biodiversity and ecological balance. The environmental risk is particularly pronounced in applications where biodegradable electronics might be deployed in large numbers, such as environmental sensors or agricultural monitoring systems.

Technical limitations further complicate the development of environmentally safe biodegradable electrodes. Current biodegradable metal alternatives, such as magnesium, zinc, and iron alloys, often exhibit inferior electrical conductivity compared to conventional electrode materials. This reduced performance creates a significant trade-off between environmental safety and device functionality that engineers must navigate.

Corrosion control presents another major challenge. While controlled degradation is desirable for biodegradable electronics, premature corrosion of metal components can lead to device failure before the intended lifespan is reached. Conversely, corrosion-resistant coatings may impede the eventual biodegradation process, creating a technical paradox that requires sophisticated materials engineering solutions.

The manufacturing processes for biodegradable metal electrodes often require specialized techniques that are not yet optimized for mass production. This limitation restricts scalability and increases production costs, creating barriers to widespread adoption. Additionally, quality control for biodegradable metals is more complex than for conventional materials, as degradation rates can vary significantly based on minor compositional differences.

Regulatory frameworks for assessing the environmental impact of biodegradable electronics remain underdeveloped. The lack of standardized testing protocols for evaluating the long-term environmental effects of degrading metal components creates uncertainty for manufacturers and potential adopters. This regulatory gap slows innovation and market penetration of environmentally safer alternatives.

The interface between biodegradable substrates and metal electrodes presents additional technical challenges. Differences in degradation rates between organic substrates and metal components can lead to structural integrity issues, affecting device reliability and potentially releasing electrode fragments into the environment prematurely.

Current Approaches to Metal Electrode Biodegradability

01 Heavy metal contamination and leaching

Metal electrodes, particularly those containing heavy metals like lead, cadmium, and mercury, pose significant environmental risks through leaching into soil and water systems. When improperly disposed of or exposed to environmental conditions, these electrodes can release toxic metals that contaminate groundwater, disrupt ecosystems, and potentially enter the food chain. This contamination can persist in the environment for extended periods, causing long-term ecological damage and potential human health hazards.- Heavy metal contamination and leaching: Metal electrodes, particularly those containing heavy metals like lead, cadmium, and mercury, pose significant environmental risks through leaching into soil and water systems. When improperly disposed of or exposed to environmental conditions, these electrodes can release toxic metals that contaminate groundwater, disrupt ecosystems, and potentially enter the food chain. This contamination can persist for extended periods and spread beyond the initial contamination site, creating long-term environmental hazards.

- Energy consumption and carbon footprint: The manufacturing, operation, and disposal of metal electrodes contribute significantly to energy consumption and carbon emissions. The extraction of raw materials, processing of metals, and fabrication of electrodes require substantial energy inputs, often from fossil fuel sources. Additionally, electrochemical processes utilizing these electrodes may consume considerable electricity during operation. This energy-intensive lifecycle results in a substantial carbon footprint, contributing to climate change and related environmental impacts.

- End-of-life disposal challenges: Metal electrodes present significant challenges for environmentally responsible disposal at the end of their useful life. Conventional disposal methods like landfilling can lead to soil and water contamination as metals degrade and leach into the environment. Recycling processes for complex electrode materials may be energy-intensive or technically challenging, particularly for composite or coated electrodes. Improper disposal practices can result in hazardous waste sites and long-term environmental liabilities that require costly remediation efforts.

- Monitoring and risk assessment technologies: Advanced technologies for monitoring and assessing environmental risks associated with metal electrodes are being developed to mitigate potential hazards. These include sensor systems for real-time detection of metal leaching, computational models for predicting environmental fate and transport of contaminants, and risk assessment frameworks specific to electrode materials. These technologies enable better understanding of exposure pathways, facilitate early intervention when contamination occurs, and support the development of safer electrode designs and materials.

- Eco-friendly alternatives and design improvements: Research is advancing toward developing environmentally safer alternatives to conventional metal electrodes and improving existing designs to reduce environmental risks. This includes exploring biodegradable electrode materials, utilizing less toxic metals, implementing protective coatings to prevent leaching, and designing electrodes for easier recycling and material recovery. Additionally, green manufacturing processes are being developed to reduce the environmental impact during production, while maintaining or enhancing the electrochemical performance required for specific applications.

02 Environmental monitoring and risk assessment

Advanced monitoring systems and risk assessment methodologies have been developed to evaluate the environmental impact of metal electrodes throughout their lifecycle. These approaches include sensor networks for real-time detection of metal contamination, predictive modeling of environmental dispersion, and comprehensive lifecycle assessment frameworks. By implementing these monitoring strategies, industries can better understand and mitigate the environmental risks associated with metal electrode production, use, and disposal.Expand Specific Solutions03 Sustainable electrode materials and green alternatives

Research has focused on developing environmentally friendly alternatives to traditional metal electrodes. These include biodegradable electrode materials, electrodes made from abundant and non-toxic metals, and carbon-based alternatives. These sustainable materials aim to maintain or improve electrode performance while significantly reducing environmental impact through decreased toxicity, improved recyclability, and reduced resource depletion.Expand Specific Solutions04 Recycling and waste management strategies

Specialized recycling processes and waste management protocols have been established to address the environmental risks of metal electrode disposal. These include hydrometallurgical and pyrometallurgical recovery methods, selective extraction techniques for valuable metals, and closed-loop manufacturing systems. Proper implementation of these strategies can significantly reduce the environmental footprint of metal electrodes by preventing toxic materials from entering ecosystems and conserving valuable resources.Expand Specific Solutions05 Regulatory frameworks and compliance systems

Comprehensive regulatory frameworks have been developed to govern the environmental aspects of metal electrode manufacturing, use, and disposal. These include restrictions on hazardous substances, mandatory environmental impact assessments, and extended producer responsibility programs. Compliance systems incorporate environmental management standards, certification processes, and reporting requirements to ensure that industries adequately address the environmental risks associated with metal electrodes throughout their lifecycle.Expand Specific Solutions

Leading Companies in Sustainable Electronics Manufacturing

The biodegradable electronics market is currently in its early growth phase, with increasing attention to mitigating environmental risks of metal electrodes. This emerging field represents a market estimated at $500-700 million, expected to grow significantly as sustainability concerns drive adoption. Academic institutions lead research efforts, with Zhejiang University, University of Massachusetts, and Arizona State University pioneering biodegradable electrode materials. Companies like Bayer AG, LG Chem, and Sony Group are beginning to commercialize these technologies, focusing on reducing toxicity and improving degradation profiles. The technology remains in early-to-mid maturity, with significant challenges in balancing performance with environmental safety, though recent innovations from National Institute for Materials Science and Cambrian Innovation demonstrate promising advances in electrode design that minimize ecological impact.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative biodegradable metal electrode systems using magnesium-based alloys with controlled degradation rates. Their approach incorporates protective polymer coatings infused with anti-inflammatory agents that create a barrier between the metal and surrounding tissue. The university has pioneered a multi-layer encapsulation technique that allows for predictable dissolution timelines while minimizing toxic byproduct formation. Their research includes in-vivo testing demonstrating significantly reduced inflammatory responses compared to conventional metal electrodes. Additionally, they've developed composite structures where magnesium is alloyed with zinc and calcium in precise ratios to optimize both electrical conductivity and degradation characteristics, allowing for complete absorption by the body within predetermined timeframes while maintaining functional performance during the required operational period.

Strengths: Superior control over degradation rates and excellent biocompatibility through innovative alloy formulations. Weaknesses: Higher manufacturing complexity and potential challenges in scaling production to commercial levels.

University of Massachusetts

Technical Solution: The University of Massachusetts has developed a groundbreaking approach to biodegradable electronics using silk fibroin as a substrate for metal electrodes. Their technology incorporates ultrathin metal films (gold, magnesium, zinc) on silk substrates that can dissolve harmlessly in biological environments. The research team has created a proprietary process for controlling dissolution rates through precise manipulation of metal film thickness and crystallinity. Their electrodes feature a unique layered architecture where the metal is sandwiched between protective silk layers with engineered porosity that regulates fluid access to the metal components. This design allows for programmable degradation timelines ranging from days to months depending on the application requirements. The university has also developed environmentally responsive triggers that can accelerate electrode dissolution based on specific physiological signals, enabling smart biodegradable implants.

Strengths: Excellent biocompatibility with programmable degradation timelines and minimal toxic byproducts. Weaknesses: Limited electrical performance compared to conventional metal electrodes and potential challenges with long-term stability in certain biological environments.

Key Innovations in Eco-compatible Electrode Materials

Biodegradable metal alloy with multiple properties

PatentActiveUS20200173000A1

Innovation

- A biodegradable metal alloy composition incorporating 0.05-0.15 wt% calcium and a metal element with a HCP structure, such as Sc, Gd, or Zn, which has high solid solubility with magnesium, is used to improve mechanical properties and corrosion resistance, with a method involving extrusion after casting to refine the alloy texture.

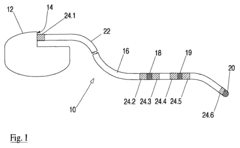

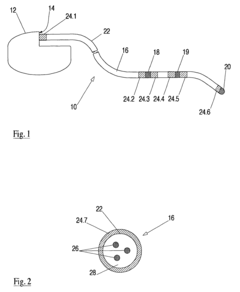

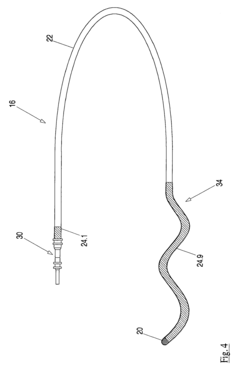

Implantable electrode

PatentInactiveEP1618918A1

Innovation

- Incorporating elemental magnesium, particularly in biodegradable magnesium alloys with rare earth metals and yttrium, into the electrode sections to reduce immunological and inflammatory responses by promoting biodegradation and anti-proliferative effects.

Lifecycle Assessment Methodologies

Lifecycle Assessment Methodologies for biodegradable electronic designs with metal electrodes require comprehensive frameworks to evaluate environmental impacts throughout the product's existence. Traditional LCA approaches must be adapted to address the unique challenges posed by these hybrid materials that combine biodegradable substrates with potentially toxic metal components.

The ISO 14040 and 14044 standards provide the foundational structure for these assessments, but specialized protocols have emerged specifically for biodegradable electronics. These methodologies typically divide the product lifecycle into five key phases: raw material extraction, manufacturing, distribution, use, and end-of-life management. For metal electrodes in biodegradable designs, particular emphasis must be placed on leaching potential and bioaccumulation risks during degradation.

Recent advancements in LCA methodologies include the integration of Material Flow Analysis (MFA) with environmental risk assessment frameworks. This combined approach enables researchers to track the fate of metals from electrodes as they transition through environmental compartments after disposal. The USEtox model has been adapted specifically for biodegradable electronics to provide characterization factors for metal toxicity in various ecosystems.

Cradle-to-cradle assessment frameworks have gained prominence for biodegradable electronics, focusing on material recovery potential and circular economy principles. These methodologies evaluate not only environmental impacts but also resource efficiency and potential for material recirculation. For metal electrodes, this includes assessing the feasibility of recovery processes and the environmental footprint of recycling operations.

Dynamic LCA approaches are particularly valuable for biodegradable electronics, as they account for temporal variations in impact. This is crucial when evaluating metal electrodes that may release compounds at different rates depending on environmental conditions. These methodologies incorporate time-dependent release models and exposure scenarios to provide more accurate risk assessments than static approaches.

Uncertainty analysis has become an integral component of LCA methodologies for biodegradable electronics. Monte Carlo simulations and sensitivity analyses help quantify confidence levels in environmental impact predictions, particularly important when dealing with variable degradation rates and metal leaching behaviors in different disposal environments.

Standardized testing protocols have been developed to generate consistent input data for these LCA methodologies. These include accelerated aging tests under various environmental conditions, leachate analysis protocols, and bioavailability assessments that specifically target metal components in biodegradable matrices. The Environmental Fate and Transport Model (EFTM) has been adapted to predict the movement of metals from electrodes through soil, water, and biological systems.

The ISO 14040 and 14044 standards provide the foundational structure for these assessments, but specialized protocols have emerged specifically for biodegradable electronics. These methodologies typically divide the product lifecycle into five key phases: raw material extraction, manufacturing, distribution, use, and end-of-life management. For metal electrodes in biodegradable designs, particular emphasis must be placed on leaching potential and bioaccumulation risks during degradation.

Recent advancements in LCA methodologies include the integration of Material Flow Analysis (MFA) with environmental risk assessment frameworks. This combined approach enables researchers to track the fate of metals from electrodes as they transition through environmental compartments after disposal. The USEtox model has been adapted specifically for biodegradable electronics to provide characterization factors for metal toxicity in various ecosystems.

Cradle-to-cradle assessment frameworks have gained prominence for biodegradable electronics, focusing on material recovery potential and circular economy principles. These methodologies evaluate not only environmental impacts but also resource efficiency and potential for material recirculation. For metal electrodes, this includes assessing the feasibility of recovery processes and the environmental footprint of recycling operations.

Dynamic LCA approaches are particularly valuable for biodegradable electronics, as they account for temporal variations in impact. This is crucial when evaluating metal electrodes that may release compounds at different rates depending on environmental conditions. These methodologies incorporate time-dependent release models and exposure scenarios to provide more accurate risk assessments than static approaches.

Uncertainty analysis has become an integral component of LCA methodologies for biodegradable electronics. Monte Carlo simulations and sensitivity analyses help quantify confidence levels in environmental impact predictions, particularly important when dealing with variable degradation rates and metal leaching behaviors in different disposal environments.

Standardized testing protocols have been developed to generate consistent input data for these LCA methodologies. These include accelerated aging tests under various environmental conditions, leachate analysis protocols, and bioavailability assessments that specifically target metal components in biodegradable matrices. The Environmental Fate and Transport Model (EFTM) has been adapted to predict the movement of metals from electrodes through soil, water, and biological systems.

Regulatory Compliance and Safety Standards

The regulatory landscape for biodegradable electronics incorporating metal electrodes is complex and evolving rapidly as environmental concerns gain prominence. Currently, several key regulatory frameworks govern this space, including the European Union's Restriction of Hazardous Substances (RoHS) Directive, which limits the use of certain hazardous materials in electrical and electronic equipment. Similarly, the WEEE (Waste Electrical and Electronic Equipment) Directive establishes collection, recycling, and recovery targets for electronic waste, directly impacting biodegradable design considerations.

In the United States, the Environmental Protection Agency (EPA) regulates electronic waste under the Resource Conservation and Recovery Act (RCRA), while the FDA maintains oversight for biodegradable medical devices containing metal components. These regulations establish thresholds for metal leaching and bioaccumulation that must be addressed in biodegradable designs.

Safety standards for biodegradable electronics with metal electrodes are primarily developed by international organizations such as ISO, IEC, and ASTM. ISO 10993 series specifically addresses the biocompatibility evaluation of medical devices, providing crucial guidelines for biodegradable electronics intended for medical applications. ASTM D6400 and D6868 standards, though focused on compostable plastics, offer relevant frameworks for testing biodegradation characteristics.

Compliance testing protocols typically involve leaching tests (TCLP - Toxicity Characteristic Leaching Procedure), bioaccumulation assessments, and ecotoxicity evaluations. These tests measure the potential environmental impact of metals as they degrade, with particular attention to heavy metals like lead, mercury, cadmium, and chromium that pose significant environmental risks.

Emerging regulatory trends indicate a shift toward more stringent requirements for end-of-life management of electronic components. The concept of "extended producer responsibility" is gaining traction globally, placing greater onus on manufacturers to consider the full lifecycle environmental impact of their products. Several jurisdictions are developing specific regulations for biodegradable electronics, recognizing their unique characteristics and potential environmental benefits when properly designed.

Certification pathways for biodegradable electronics with metal components remain fragmented, with various ecolabels and certification schemes emerging. The EU Ecolabel, EPEAT, and TCO Certified programs are beginning to incorporate criteria relevant to biodegradable electronics, though specific standards for metal electrode degradation are still developing.

In the United States, the Environmental Protection Agency (EPA) regulates electronic waste under the Resource Conservation and Recovery Act (RCRA), while the FDA maintains oversight for biodegradable medical devices containing metal components. These regulations establish thresholds for metal leaching and bioaccumulation that must be addressed in biodegradable designs.

Safety standards for biodegradable electronics with metal electrodes are primarily developed by international organizations such as ISO, IEC, and ASTM. ISO 10993 series specifically addresses the biocompatibility evaluation of medical devices, providing crucial guidelines for biodegradable electronics intended for medical applications. ASTM D6400 and D6868 standards, though focused on compostable plastics, offer relevant frameworks for testing biodegradation characteristics.

Compliance testing protocols typically involve leaching tests (TCLP - Toxicity Characteristic Leaching Procedure), bioaccumulation assessments, and ecotoxicity evaluations. These tests measure the potential environmental impact of metals as they degrade, with particular attention to heavy metals like lead, mercury, cadmium, and chromium that pose significant environmental risks.

Emerging regulatory trends indicate a shift toward more stringent requirements for end-of-life management of electronic components. The concept of "extended producer responsibility" is gaining traction globally, placing greater onus on manufacturers to consider the full lifecycle environmental impact of their products. Several jurisdictions are developing specific regulations for biodegradable electronics, recognizing their unique characteristics and potential environmental benefits when properly designed.

Certification pathways for biodegradable electronics with metal components remain fragmented, with various ecolabels and certification schemes emerging. The EU Ecolabel, EPEAT, and TCO Certified programs are beginning to incorporate criteria relevant to biodegradable electronics, though specific standards for metal electrode degradation are still developing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!