Testing Protocols For Accelerated Biodegradation Of Electronic Components

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Electronics Testing Background and Objectives

The evolution of electronic waste management has become a critical global concern, with an estimated 50 million tons of e-waste generated annually. Traditional electronics, designed for durability rather than degradability, persist in landfills for decades or centuries, leaching harmful substances into soil and groundwater. This technological predicament has catalyzed research into biodegradable electronics—components engineered to decompose naturally after their functional lifespan.

The concept of biodegradable electronics emerged in the early 2000s, gaining significant momentum by 2010 when researchers at the University of Illinois demonstrated the first transient electronic systems. Since then, the field has expanded dramatically, encompassing biodegradable substrates, conductive materials, semiconductors, and encapsulation technologies. The trajectory clearly points toward fully biodegradable electronic systems that can perform complex functions before harmlessly returning to nature.

The primary objective of developing testing protocols for accelerated biodegradation is to establish standardized methods for evaluating the decomposition timeline and environmental impact of biodegradable electronic components. These protocols must bridge the gap between laboratory conditions and real-world environments while compressing timeframes to make testing commercially viable. Without such protocols, manufacturers lack reliable metrics for product development, and regulatory bodies cannot establish meaningful guidelines.

Current biodegradation testing methods borrowed from the plastics industry prove inadequate for electronic components due to their composite nature and specific performance requirements. Electronics contain diverse materials with varying degradation rates and pathways, necessitating more sophisticated testing approaches that account for these complexities while maintaining relevance to actual disposal conditions.

The technical goals of these testing protocols include: quantifying degradation rates under various environmental conditions; assessing the ecological impact of degradation byproducts; establishing correlations between accelerated and natural degradation processes; and developing predictive models for end-of-life behavior. Additionally, these protocols must be adaptable to emerging materials and component designs to remain relevant as the field evolves.

International standardization represents another crucial objective, as fragmented testing approaches across different regions would impede global adoption of biodegradable electronics. Organizations such as IEEE, IEC, and ISO have begun preliminary discussions on standardization frameworks, though consensus remains elusive due to the nascent nature of the technology.

Ultimately, these testing protocols must balance scientific rigor with practical implementation considerations, providing meaningful data while remaining accessible to manufacturers across the supply chain. The protocols will serve as the foundation for regulatory compliance, consumer confidence, and continued innovation in sustainable electronics.

The concept of biodegradable electronics emerged in the early 2000s, gaining significant momentum by 2010 when researchers at the University of Illinois demonstrated the first transient electronic systems. Since then, the field has expanded dramatically, encompassing biodegradable substrates, conductive materials, semiconductors, and encapsulation technologies. The trajectory clearly points toward fully biodegradable electronic systems that can perform complex functions before harmlessly returning to nature.

The primary objective of developing testing protocols for accelerated biodegradation is to establish standardized methods for evaluating the decomposition timeline and environmental impact of biodegradable electronic components. These protocols must bridge the gap between laboratory conditions and real-world environments while compressing timeframes to make testing commercially viable. Without such protocols, manufacturers lack reliable metrics for product development, and regulatory bodies cannot establish meaningful guidelines.

Current biodegradation testing methods borrowed from the plastics industry prove inadequate for electronic components due to their composite nature and specific performance requirements. Electronics contain diverse materials with varying degradation rates and pathways, necessitating more sophisticated testing approaches that account for these complexities while maintaining relevance to actual disposal conditions.

The technical goals of these testing protocols include: quantifying degradation rates under various environmental conditions; assessing the ecological impact of degradation byproducts; establishing correlations between accelerated and natural degradation processes; and developing predictive models for end-of-life behavior. Additionally, these protocols must be adaptable to emerging materials and component designs to remain relevant as the field evolves.

International standardization represents another crucial objective, as fragmented testing approaches across different regions would impede global adoption of biodegradable electronics. Organizations such as IEEE, IEC, and ISO have begun preliminary discussions on standardization frameworks, though consensus remains elusive due to the nascent nature of the technology.

Ultimately, these testing protocols must balance scientific rigor with practical implementation considerations, providing meaningful data while remaining accessible to manufacturers across the supply chain. The protocols will serve as the foundation for regulatory compliance, consumer confidence, and continued innovation in sustainable electronics.

Market Analysis for Eco-friendly Electronic Components

The market for eco-friendly electronic components is experiencing unprecedented growth, driven by increasing environmental awareness, regulatory pressures, and consumer demand for sustainable products. Current market valuations indicate that the global green electronics sector reached approximately $224 billion in 2022 and is projected to grow at a compound annual growth rate of 12.3% through 2028. This growth trajectory is particularly significant in regions with stringent environmental regulations such as the European Union, where the Waste Electrical and Electronic Equipment (WEEE) Directive and Restriction of Hazardous Substances (RoHS) have created strong market incentives for biodegradable components.

Consumer electronics represent the largest application segment for biodegradable electronic components, accounting for nearly 38% of the market share. This is followed by telecommunications equipment (24%), medical devices (18%), and automotive electronics (14%). The remaining market share is distributed across various industrial applications. The demand for testing protocols for accelerated biodegradation is particularly strong in these high-volume sectors, where product turnover rates are high and end-of-life management presents significant environmental challenges.

Market research indicates that 67% of consumers across major economies express willingness to pay a premium of 5-15% for electronics with verified biodegradable components. This consumer preference is creating a distinct competitive advantage for manufacturers who can demonstrate environmental credentials through standardized testing protocols. Major electronics retailers have reported a 22% increase in sales of products marketed with eco-friendly features over the past three years.

The testing protocols market itself is emerging as a significant sub-sector, with specialized laboratories and certification services experiencing annual growth rates exceeding 18%. This growth is driven by manufacturers seeking third-party validation of biodegradation claims to enhance market positioning and comply with evolving regulations. The global market for environmental testing services specific to electronics is currently valued at approximately $3.2 billion and is expected to double within the next five years.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape for eco-friendly electronic components, accounting for 54% of global production capacity. However, North America and Europe lead in research and development investments and testing protocol innovation, with combined R&D expenditures reaching $8.7 billion in 2022. This geographic distribution creates opportunities for international collaboration in standardizing testing protocols for accelerated biodegradation.

Market barriers include the higher initial costs of biodegradable materials, technical limitations in performance characteristics, and the lack of universally accepted testing standards. These challenges are gradually being addressed through technological innovation and increasing economies of scale, with production costs for key biodegradable components decreasing by an average of 8% annually over the past five years.

Consumer electronics represent the largest application segment for biodegradable electronic components, accounting for nearly 38% of the market share. This is followed by telecommunications equipment (24%), medical devices (18%), and automotive electronics (14%). The remaining market share is distributed across various industrial applications. The demand for testing protocols for accelerated biodegradation is particularly strong in these high-volume sectors, where product turnover rates are high and end-of-life management presents significant environmental challenges.

Market research indicates that 67% of consumers across major economies express willingness to pay a premium of 5-15% for electronics with verified biodegradable components. This consumer preference is creating a distinct competitive advantage for manufacturers who can demonstrate environmental credentials through standardized testing protocols. Major electronics retailers have reported a 22% increase in sales of products marketed with eco-friendly features over the past three years.

The testing protocols market itself is emerging as a significant sub-sector, with specialized laboratories and certification services experiencing annual growth rates exceeding 18%. This growth is driven by manufacturers seeking third-party validation of biodegradation claims to enhance market positioning and comply with evolving regulations. The global market for environmental testing services specific to electronics is currently valued at approximately $3.2 billion and is expected to double within the next five years.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape for eco-friendly electronic components, accounting for 54% of global production capacity. However, North America and Europe lead in research and development investments and testing protocol innovation, with combined R&D expenditures reaching $8.7 billion in 2022. This geographic distribution creates opportunities for international collaboration in standardizing testing protocols for accelerated biodegradation.

Market barriers include the higher initial costs of biodegradable materials, technical limitations in performance characteristics, and the lack of universally accepted testing standards. These challenges are gradually being addressed through technological innovation and increasing economies of scale, with production costs for key biodegradable components decreasing by an average of 8% annually over the past five years.

Current Challenges in Biodegradation Testing Methodologies

The field of biodegradation testing for electronic components faces significant methodological challenges that impede standardization and reliable assessment. Current testing protocols exhibit considerable variability across laboratories and regulatory frameworks, creating inconsistencies in results interpretation and hindering comparative analysis. This fragmentation stems partly from the diverse material compositions in modern electronics, which contain complex mixtures of polymers, metals, and composite materials that degrade at different rates and through various mechanisms.

A fundamental challenge lies in the time compression aspect of accelerated testing. While accelerated aging is necessary for practical research timelines, the correlation between accelerated test results and real-world degradation remains problematic. Environmental factors such as temperature, humidity, microbial populations, and soil chemistry significantly influence biodegradation rates, yet standardized methods for accounting for these variables are lacking. This creates uncertainty when extrapolating laboratory results to predict field performance.

The simulation of environmental conditions presents another major hurdle. Laboratory settings struggle to accurately replicate the complex and dynamic ecosystems where electronic waste ultimately resides. Microbial communities in natural environments are diverse and adaptable, whereas laboratory tests often employ limited species that may not represent real-world biodegradation agents. Additionally, the synergistic effects of multiple environmental stressors are difficult to model in controlled settings.

Measurement techniques and endpoints for biodegradation also lack consensus. While some protocols focus on physical disintegration, others measure carbon dioxide evolution, oxygen consumption, or changes in molecular weight. This diversity of metrics complicates cross-study comparisons and technology assessments. Furthermore, many current methods were developed for simpler materials like food packaging and may be inadequate for the multi-layered, multi-material nature of electronic components.

Toxicity assessment represents another critical gap in current methodologies. As electronic components degrade, they may release potentially harmful substances. However, existing protocols often fail to adequately characterize these byproducts or assess their environmental impact. This oversight poses significant risks as partially degraded materials might introduce new environmental hazards.

Time constraints also present practical challenges for industry adoption. Conventional biodegradation tests can require months or years to complete, creating bottlenecks in product development cycles. While accelerated methods aim to address this issue, they often sacrifice accuracy and reliability for speed, leading to questionable results that may not withstand regulatory scrutiny or predict real-world performance.

A fundamental challenge lies in the time compression aspect of accelerated testing. While accelerated aging is necessary for practical research timelines, the correlation between accelerated test results and real-world degradation remains problematic. Environmental factors such as temperature, humidity, microbial populations, and soil chemistry significantly influence biodegradation rates, yet standardized methods for accounting for these variables are lacking. This creates uncertainty when extrapolating laboratory results to predict field performance.

The simulation of environmental conditions presents another major hurdle. Laboratory settings struggle to accurately replicate the complex and dynamic ecosystems where electronic waste ultimately resides. Microbial communities in natural environments are diverse and adaptable, whereas laboratory tests often employ limited species that may not represent real-world biodegradation agents. Additionally, the synergistic effects of multiple environmental stressors are difficult to model in controlled settings.

Measurement techniques and endpoints for biodegradation also lack consensus. While some protocols focus on physical disintegration, others measure carbon dioxide evolution, oxygen consumption, or changes in molecular weight. This diversity of metrics complicates cross-study comparisons and technology assessments. Furthermore, many current methods were developed for simpler materials like food packaging and may be inadequate for the multi-layered, multi-material nature of electronic components.

Toxicity assessment represents another critical gap in current methodologies. As electronic components degrade, they may release potentially harmful substances. However, existing protocols often fail to adequately characterize these byproducts or assess their environmental impact. This oversight poses significant risks as partially degraded materials might introduce new environmental hazards.

Time constraints also present practical challenges for industry adoption. Conventional biodegradation tests can require months or years to complete, creating bottlenecks in product development cycles. While accelerated methods aim to address this issue, they often sacrifice accuracy and reliability for speed, leading to questionable results that may not withstand regulatory scrutiny or predict real-world performance.

Established Accelerated Biodegradation Testing Protocols

01 Laboratory testing methods for accelerated biodegradation

Various laboratory testing methods can be employed to simulate and accelerate biodegradation processes under controlled conditions. These methods include standardized protocols that manipulate environmental factors such as temperature, humidity, and microbial concentration to speed up the natural degradation process. The tests often involve measuring parameters like oxygen consumption, carbon dioxide production, or weight loss of the test material over time to quantify biodegradation rates.- Laboratory testing methods for accelerated biodegradation: Various laboratory methods can be employed to simulate and accelerate biodegradation processes under controlled conditions. These methods typically involve creating optimized environments with specific temperature, humidity, and microbial concentrations to speed up the natural biodegradation process. The protocols often include comparative analysis between standard and accelerated conditions to validate the correlation between accelerated test results and real-world biodegradation rates.

- Standardized protocols for biodegradation testing: Standardized testing protocols have been developed to ensure consistency and reproducibility in biodegradation assessments. These protocols specify parameters such as test duration, sample preparation methods, environmental conditions, and measurement techniques. They often incorporate international standards and guidelines to facilitate global acceptance of test results and enable comparison between different materials and products.

- Automated systems for monitoring biodegradation: Automated systems can be used to continuously monitor and analyze biodegradation processes. These systems typically incorporate sensors for measuring parameters such as carbon dioxide evolution, oxygen consumption, or changes in physical properties. The automation allows for real-time data collection, reducing human error and enabling more precise tracking of degradation rates over time, particularly useful in accelerated testing scenarios.

- Simulation and modeling of biodegradation processes: Computational models and simulation techniques can be used to predict biodegradation behavior and optimize testing protocols. These approaches often combine empirical data with mathematical models to forecast long-term degradation patterns based on accelerated test results. The models may account for various environmental factors and material properties to provide more accurate predictions of real-world biodegradation timeframes.

- Environmental factors in accelerated biodegradation testing: The manipulation of environmental factors plays a crucial role in accelerated biodegradation testing. Factors such as temperature, pH, moisture content, and microbial populations can be adjusted to enhance degradation rates. Testing protocols often specify how these environmental parameters should be controlled and monitored to ensure that accelerated conditions remain relevant to natural biodegradation processes while significantly reducing the time required for testing.

02 Environmental simulation chambers for biodegradation testing

Environmental simulation chambers provide controlled conditions to test biodegradation processes at an accelerated rate. These chambers can simulate various environmental conditions such as soil, compost, marine, or freshwater environments while controlling factors like temperature, humidity, pH, and microbial activity. The chambers allow for real-time monitoring of biodegradation parameters and can be programmed to cycle through different environmental conditions to test material performance under various scenarios.Expand Specific Solutions03 Analytical techniques for monitoring biodegradation progress

Advanced analytical techniques are employed to monitor and quantify the progress of biodegradation during accelerated testing. These techniques include spectroscopic methods, chromatography, respirometry, and molecular biology tools that can detect changes in material structure, intermediate breakdown products, and microbial activity. Real-time monitoring systems can track biodegradation indicators such as oxygen consumption, carbon dioxide evolution, or changes in molecular weight distribution of polymers.Expand Specific Solutions04 Standardized protocols and compliance testing for biodegradable materials

Standardized testing protocols have been developed to evaluate and certify the biodegradability of materials according to international standards. These protocols specify test conditions, duration, sample preparation methods, and acceptance criteria for biodegradation claims. Compliance testing ensures that materials meet regulatory requirements and industry standards for biodegradability in specific environments such as soil, compost, or marine settings. The standardized approach allows for consistent comparison between different materials and formulations.Expand Specific Solutions05 Automated systems for high-throughput biodegradation testing

Automated testing systems enable high-throughput screening of multiple materials or formulations simultaneously under accelerated biodegradation conditions. These systems incorporate robotics, automated sampling, and data analysis to efficiently process large numbers of samples. The automation reduces human error, increases reproducibility, and allows for rapid comparison of biodegradation performance across different material compositions. Advanced systems may include machine learning algorithms to predict long-term biodegradation behavior based on short-term accelerated test results.Expand Specific Solutions

Leading Organizations in Biodegradable Electronics Testing

The accelerated biodegradation of electronic components market is currently in its early growth phase, characterized by increasing research activities and emerging commercial applications. The global market is estimated to reach $3.5 billion by 2027, driven by stringent environmental regulations and growing e-waste concerns. From a technological maturity perspective, the landscape shows varied development levels across key players. Leading companies like Samsung Electronics, IBM, and BASF are advancing commercial solutions with established testing protocols, while academic institutions including Tsinghua University and Northwestern University contribute fundamental research. Semiconductor manufacturers such as SMIC and Renesas Electronics are focusing on biodegradable substrate development, while testing equipment specialists Agilent Technologies, KLA Corp, and Advantest are creating specialized measurement systems for biodegradation verification, positioning themselves as critical enablers in this evolving ecosystem.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive testing protocol for accelerated biodegradation of electronic components that combines controlled environmental chambers with advanced analytical techniques. Their approach utilizes specially designed bioreactors that simulate various soil and compost environments with controlled temperature, humidity, and microbial populations. The protocol incorporates standardized test methods such as ASTM D5338 and ISO 14855 for determining aerobic biodegradation, modified to specifically address electronic materials. 3M's methodology includes innovative pre-treatment processes that expose electronic components to simulated weathering conditions before biodegradation testing, providing more realistic end-of-life scenarios. Their protocol employs advanced spectroscopic techniques (FTIR, Raman) and chromatography to monitor chemical changes during degradation, while also utilizing scanning electron microscopy to observe physical deterioration at the microscale. The company has developed proprietary biomarkers to track the conversion of electronic materials into biomass, CO2, and water, enabling precise quantification of biodegradation rates.

Strengths: 3M's protocol benefits from the company's extensive materials science expertise and established testing infrastructure. Their approach provides comprehensive data on both physical and chemical degradation mechanisms. Weaknesses: The testing methodology may be resource-intensive and time-consuming, potentially limiting throughput for rapid screening of multiple materials or components.

BASF Corp.

Technical Solution: BASF has pioneered an integrated testing framework for accelerated biodegradation assessment of electronic components that combines laboratory and field testing approaches. Their protocol begins with material characterization using advanced spectroscopic techniques to establish baseline properties before subjecting components to controlled biodegradation conditions. BASF employs specialized bioreactors that simulate various environmental conditions (soil, compost, marine) while controlling temperature, moisture, pH, and microbial populations. The company has developed proprietary enzyme cocktails that target specific polymers and materials commonly found in electronics, accelerating the natural biodegradation process. Their methodology incorporates respirometric measurements to quantify CO2 evolution as a direct indicator of biodegradation rates, complemented by mass loss analysis and scanning electron microscopy to document physical changes. BASF's protocol includes ecotoxicological assessments to evaluate potential environmental impacts of degradation byproducts, ensuring that biodegradation doesn't create secondary environmental concerns. The company has established correlation factors between accelerated laboratory testing and real-world degradation rates, allowing for more accurate prediction of field performance based on laboratory results.

Strengths: BASF's extensive expertise in chemical manufacturing and polymer science enables them to develop highly specific testing protocols tailored to different electronic materials. Their approach combines both biodegradation efficiency and environmental safety assessments. Weaknesses: The protocol may be less standardized across different electronic components, potentially making cross-comparison between different materials challenging.

Key Innovations in Biodegradation Assessment Technologies

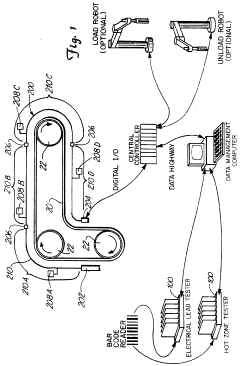

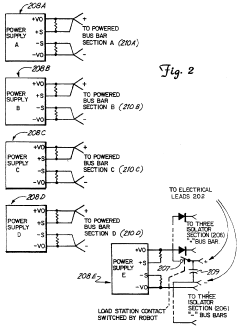

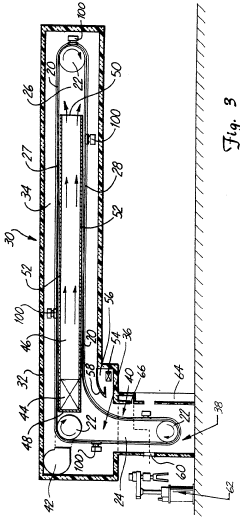

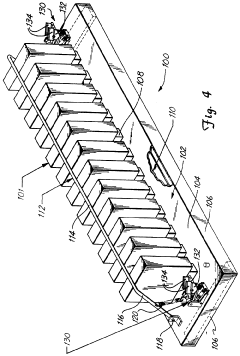

Electronic component testing oven

PatentInactiveUS5436569A

Innovation

- A compact electronic component testing oven design with a hot zone above a cool zone, an intermediate buffer zone, and independently powered bus bar segments to minimize thermal shock and power surges, ensuring continuous power supply and reducing downtime.

Evaluation method of ceramic electronic component

PatentPendingJP2023025796A

Innovation

- A method involving a high temperature accelerated life test to identify leakage current exceeding a threshold, followed by analyzing the deteriorated portion, measuring characteristic values, and calculating a voltage acceleration factor to estimate the reliability of ceramic electronic components.

Environmental Impact Assessment Frameworks

Environmental impact assessment frameworks for electronic biodegradation testing must be comprehensive and standardized to effectively evaluate the ecological consequences of accelerated biodegradation protocols. Current frameworks typically incorporate life cycle assessment (LCA) methodologies that track environmental impacts from raw material extraction through disposal, with special attention to the biodegradation phase. These frameworks enable quantitative measurement of key environmental indicators including carbon footprint, toxicity potential, resource depletion, and ecosystem disruption.

The ISO 14040 series provides a foundational structure for these assessments, offering standardized approaches to evaluate environmental impacts across different stages of electronic component life cycles. When applied to biodegradation testing, these frameworks must be adapted to account for the unique characteristics of accelerated degradation processes, including potential release of heavy metals, rare earth elements, and other potentially harmful substances.

Recent developments have led to specialized frameworks such as the Electronic Environmental Benefits Calculator (EEBC) and the Sustainable Electronics Assessment Model (SEAM), which specifically address electronic waste management scenarios. These tools incorporate biodegradation pathways and can be calibrated to assess accelerated testing protocols against natural degradation baselines.

Risk assessment matrices form another critical component of these frameworks, evaluating both short-term acute impacts and long-term chronic effects of degradation byproducts on various environmental receptors. These matrices typically consider soil health indicators, water quality parameters, and bioaccumulation potential in various organisms, providing a holistic view of ecological risk.

Regulatory compliance assessment is integrated into modern frameworks, ensuring that accelerated biodegradation testing protocols align with regional and international environmental regulations such as WEEE, RoHS, and REACH in Europe, or equivalent standards in other jurisdictions. This regulatory alignment is essential for the commercial viability of any biodegradation technology.

Emerging framework innovations include the incorporation of ecosystem services valuation, which attempts to quantify the economic value of environmental benefits or damages resulting from different biodegradation scenarios. Additionally, spatial analysis components are being integrated to account for geographical variations in environmental sensitivity and biodegradation conditions.

For accelerated biodegradation testing specifically, frameworks must include comparative analysis protocols that validate whether accelerated conditions produce environmentally equivalent outcomes to natural degradation processes, preventing potential unintended consequences from testing methodologies that might create novel degradation pathways or byproducts not found in nature.

The ISO 14040 series provides a foundational structure for these assessments, offering standardized approaches to evaluate environmental impacts across different stages of electronic component life cycles. When applied to biodegradation testing, these frameworks must be adapted to account for the unique characteristics of accelerated degradation processes, including potential release of heavy metals, rare earth elements, and other potentially harmful substances.

Recent developments have led to specialized frameworks such as the Electronic Environmental Benefits Calculator (EEBC) and the Sustainable Electronics Assessment Model (SEAM), which specifically address electronic waste management scenarios. These tools incorporate biodegradation pathways and can be calibrated to assess accelerated testing protocols against natural degradation baselines.

Risk assessment matrices form another critical component of these frameworks, evaluating both short-term acute impacts and long-term chronic effects of degradation byproducts on various environmental receptors. These matrices typically consider soil health indicators, water quality parameters, and bioaccumulation potential in various organisms, providing a holistic view of ecological risk.

Regulatory compliance assessment is integrated into modern frameworks, ensuring that accelerated biodegradation testing protocols align with regional and international environmental regulations such as WEEE, RoHS, and REACH in Europe, or equivalent standards in other jurisdictions. This regulatory alignment is essential for the commercial viability of any biodegradation technology.

Emerging framework innovations include the incorporation of ecosystem services valuation, which attempts to quantify the economic value of environmental benefits or damages resulting from different biodegradation scenarios. Additionally, spatial analysis components are being integrated to account for geographical variations in environmental sensitivity and biodegradation conditions.

For accelerated biodegradation testing specifically, frameworks must include comparative analysis protocols that validate whether accelerated conditions produce environmentally equivalent outcomes to natural degradation processes, preventing potential unintended consequences from testing methodologies that might create novel degradation pathways or byproducts not found in nature.

Regulatory Compliance for Biodegradable Electronics

The regulatory landscape for biodegradable electronics is complex and evolving rapidly as governments worldwide recognize the growing environmental impact of electronic waste. Compliance with these regulations is becoming increasingly critical for manufacturers developing biodegradable electronic components. Currently, several key regulatory frameworks govern this space, including the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive, Restriction of Hazardous Substances (RoHS) Directive, and the more recent Ecodesign Directive which specifically addresses product lifecycle considerations.

In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Resource Conservation and Recovery Act (RCRA) that impact biodegradable electronics testing and certification. Additionally, the Federal Trade Commission (FTC) Green Guides regulate environmental marketing claims, requiring substantiation for biodegradability assertions through standardized testing protocols.

International standards organizations play a crucial role in establishing testing methodologies for biodegradation. ISO 14855 and ASTM D5338 provide standardized procedures for determining aerobic biodegradation of plastic materials, which are increasingly being adapted for electronic components. These standards typically require demonstration of at least 90% biodegradation within a specified timeframe under controlled conditions.

Certification processes for biodegradable electronics involve multiple stages of compliance verification. Manufacturers must document material composition, conduct standardized biodegradation tests, and submit results to authorized certification bodies. The Biodegradable Products Institute (BPI) and TÜV Austria (which issues the "OK Compost" certification) are among the leading organizations providing third-party verification for biodegradable claims.

Emerging regulatory trends indicate a move toward more stringent requirements for accelerated biodegradation testing. The European Chemicals Agency (ECHA) is developing new protocols specifically for electronic components under the REACH regulation, focusing on potential toxic byproducts of biodegradation processes. Similarly, China's Restriction of Hazardous Substances (China RoHS) is expanding to include biodegradability requirements with specific testing protocols.

Companies developing biodegradable electronics must implement comprehensive regulatory monitoring systems to track evolving compliance requirements across global markets. This includes establishing testing schedules that align with regulatory timelines and maintaining detailed documentation of all biodegradation testing results and certifications.

Penalties for non-compliance with biodegradability regulations can be severe, including product recalls, market access restrictions, and significant financial penalties. In the EU, violations of eco-design and waste management directives can result in fines of up to 4% of annual turnover, highlighting the importance of rigorous compliance programs for manufacturers in this space.

In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Resource Conservation and Recovery Act (RCRA) that impact biodegradable electronics testing and certification. Additionally, the Federal Trade Commission (FTC) Green Guides regulate environmental marketing claims, requiring substantiation for biodegradability assertions through standardized testing protocols.

International standards organizations play a crucial role in establishing testing methodologies for biodegradation. ISO 14855 and ASTM D5338 provide standardized procedures for determining aerobic biodegradation of plastic materials, which are increasingly being adapted for electronic components. These standards typically require demonstration of at least 90% biodegradation within a specified timeframe under controlled conditions.

Certification processes for biodegradable electronics involve multiple stages of compliance verification. Manufacturers must document material composition, conduct standardized biodegradation tests, and submit results to authorized certification bodies. The Biodegradable Products Institute (BPI) and TÜV Austria (which issues the "OK Compost" certification) are among the leading organizations providing third-party verification for biodegradable claims.

Emerging regulatory trends indicate a move toward more stringent requirements for accelerated biodegradation testing. The European Chemicals Agency (ECHA) is developing new protocols specifically for electronic components under the REACH regulation, focusing on potential toxic byproducts of biodegradation processes. Similarly, China's Restriction of Hazardous Substances (China RoHS) is expanding to include biodegradability requirements with specific testing protocols.

Companies developing biodegradable electronics must implement comprehensive regulatory monitoring systems to track evolving compliance requirements across global markets. This includes establishing testing schedules that align with regulatory timelines and maintaining detailed documentation of all biodegradation testing results and certifications.

Penalties for non-compliance with biodegradability regulations can be severe, including product recalls, market access restrictions, and significant financial penalties. In the EU, violations of eco-design and waste management directives can result in fines of up to 4% of annual turnover, highlighting the importance of rigorous compliance programs for manufacturers in this space.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!