Toxicology Testing Workflows For Degradation Products

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Toxicology Testing Background and Objectives

Toxicology testing for degradation products has evolved significantly over the past decades, transitioning from primarily animal-based methods to more sophisticated in vitro and computational approaches. This evolution has been driven by both ethical considerations regarding animal welfare and the scientific recognition that more targeted, mechanism-based testing strategies can provide more relevant human safety data. The field has progressed from observational toxicology to predictive toxicology, incorporating advances in molecular biology, computational modeling, and systems biology.

The pharmaceutical industry faces particular challenges in this domain, as drug degradation products can form during manufacturing, storage, or metabolism within the body. Regulatory frameworks such as ICH Q3A(R2) and Q3B(R2) have established thresholds for identification, qualification, and reporting of impurities, creating a structured approach to toxicological assessment of degradation products.

Current toxicology testing workflows typically follow a tiered approach, beginning with structural analysis and in silico predictions, followed by in vitro assays, and culminating in targeted in vivo studies when necessary. This progressive strategy aims to minimize animal testing while maximizing the scientific value of the data generated. The integration of high-throughput screening technologies has further enhanced the efficiency of early-stage toxicity assessment.

The primary objective of toxicology testing for degradation products is to ensure patient safety by identifying and characterizing potential toxicological risks associated with drug-related impurities. Secondary objectives include regulatory compliance, optimization of manufacturing processes to minimize harmful degradation, and development of analytical methods capable of detecting degradation products at relevant concentrations.

Recent technological advances have enabled more sensitive detection of degradation products, creating both opportunities and challenges. As analytical capabilities improve, increasingly minute quantities of degradation products can be detected, raising questions about the toxicological significance of these trace compounds and appropriate qualification strategies.

Looking forward, the field aims to develop more predictive, efficient, and humane testing paradigms. Key goals include establishing better in vitro-in vivo correlations, improving computational prediction models for toxicity, and developing integrated testing strategies that combine multiple lines of evidence. There is also growing interest in applying the adverse outcome pathway (AOP) framework to systematically link molecular initiating events to adverse outcomes at the organism level.

The ultimate vision is to create a comprehensive, mechanistically-based approach to toxicology testing that can accurately predict human safety risks from degradation products while minimizing resource requirements and ethical concerns associated with traditional testing methods.

The pharmaceutical industry faces particular challenges in this domain, as drug degradation products can form during manufacturing, storage, or metabolism within the body. Regulatory frameworks such as ICH Q3A(R2) and Q3B(R2) have established thresholds for identification, qualification, and reporting of impurities, creating a structured approach to toxicological assessment of degradation products.

Current toxicology testing workflows typically follow a tiered approach, beginning with structural analysis and in silico predictions, followed by in vitro assays, and culminating in targeted in vivo studies when necessary. This progressive strategy aims to minimize animal testing while maximizing the scientific value of the data generated. The integration of high-throughput screening technologies has further enhanced the efficiency of early-stage toxicity assessment.

The primary objective of toxicology testing for degradation products is to ensure patient safety by identifying and characterizing potential toxicological risks associated with drug-related impurities. Secondary objectives include regulatory compliance, optimization of manufacturing processes to minimize harmful degradation, and development of analytical methods capable of detecting degradation products at relevant concentrations.

Recent technological advances have enabled more sensitive detection of degradation products, creating both opportunities and challenges. As analytical capabilities improve, increasingly minute quantities of degradation products can be detected, raising questions about the toxicological significance of these trace compounds and appropriate qualification strategies.

Looking forward, the field aims to develop more predictive, efficient, and humane testing paradigms. Key goals include establishing better in vitro-in vivo correlations, improving computational prediction models for toxicity, and developing integrated testing strategies that combine multiple lines of evidence. There is also growing interest in applying the adverse outcome pathway (AOP) framework to systematically link molecular initiating events to adverse outcomes at the organism level.

The ultimate vision is to create a comprehensive, mechanistically-based approach to toxicology testing that can accurately predict human safety risks from degradation products while minimizing resource requirements and ethical concerns associated with traditional testing methods.

Market Demand Analysis for Degradation Product Testing

The global market for toxicology testing of degradation products has experienced significant growth in recent years, driven primarily by increasing regulatory requirements and growing awareness of potential health risks associated with pharmaceutical, food, and environmental contaminants. Current market estimates value this sector at approximately 3.5 billion USD, with projections indicating a compound annual growth rate of 7.8% through 2028.

Pharmaceutical companies represent the largest market segment, accounting for nearly 45% of the total demand. This dominance stems from stringent regulatory frameworks such as the ICH Q3B guidelines, which mandate thorough characterization and toxicological assessment of drug degradation products. The FDA's increasing focus on degradants in both new and generic drug applications has further accelerated market growth in this segment.

The food and beverage industry constitutes the second-largest market segment, driven by consumer demand for safer products and regulatory bodies implementing more comprehensive testing requirements for food additives, packaging materials, and processing aids. Particular attention is being paid to compounds that may form during storage or preparation, such as acrylamide in baked goods or bisphenol derivatives from packaging.

Geographically, North America leads the market with approximately 38% share, followed by Europe at 32% and Asia-Pacific at 22%. However, the Asia-Pacific region is experiencing the fastest growth rate, particularly in China and India, where expanding pharmaceutical manufacturing capabilities and strengthening regulatory frameworks are creating substantial demand for advanced toxicology testing services.

Contract research organizations (CROs) have emerged as key beneficiaries of this market trend, with many pharmaceutical and food companies outsourcing their degradation product testing to specialized laboratories. This has created a robust service sector within the broader toxicology testing market, estimated to be growing at 9.2% annually.

The demand for more efficient, cost-effective testing methodologies represents a significant market driver. Traditional animal-based toxicology testing is increasingly being supplemented or replaced by in vitro and in silico approaches, creating market opportunities for companies developing innovative testing platforms. High-throughput screening technologies and computational toxicology tools are experiencing particularly strong demand growth as they enable faster assessment of multiple degradation products.

Regulatory trends indicate continued market expansion, with authorities worldwide implementing more comprehensive requirements for degradation product characterization. The European Chemicals Agency's REACH regulations and similar frameworks in other regions are extending testing requirements beyond pharmaceuticals to a broader range of chemical products, further expanding the potential market.

Pharmaceutical companies represent the largest market segment, accounting for nearly 45% of the total demand. This dominance stems from stringent regulatory frameworks such as the ICH Q3B guidelines, which mandate thorough characterization and toxicological assessment of drug degradation products. The FDA's increasing focus on degradants in both new and generic drug applications has further accelerated market growth in this segment.

The food and beverage industry constitutes the second-largest market segment, driven by consumer demand for safer products and regulatory bodies implementing more comprehensive testing requirements for food additives, packaging materials, and processing aids. Particular attention is being paid to compounds that may form during storage or preparation, such as acrylamide in baked goods or bisphenol derivatives from packaging.

Geographically, North America leads the market with approximately 38% share, followed by Europe at 32% and Asia-Pacific at 22%. However, the Asia-Pacific region is experiencing the fastest growth rate, particularly in China and India, where expanding pharmaceutical manufacturing capabilities and strengthening regulatory frameworks are creating substantial demand for advanced toxicology testing services.

Contract research organizations (CROs) have emerged as key beneficiaries of this market trend, with many pharmaceutical and food companies outsourcing their degradation product testing to specialized laboratories. This has created a robust service sector within the broader toxicology testing market, estimated to be growing at 9.2% annually.

The demand for more efficient, cost-effective testing methodologies represents a significant market driver. Traditional animal-based toxicology testing is increasingly being supplemented or replaced by in vitro and in silico approaches, creating market opportunities for companies developing innovative testing platforms. High-throughput screening technologies and computational toxicology tools are experiencing particularly strong demand growth as they enable faster assessment of multiple degradation products.

Regulatory trends indicate continued market expansion, with authorities worldwide implementing more comprehensive requirements for degradation product characterization. The European Chemicals Agency's REACH regulations and similar frameworks in other regions are extending testing requirements beyond pharmaceuticals to a broader range of chemical products, further expanding the potential market.

Current Challenges in Degradation Product Toxicology

The toxicology testing landscape for degradation products faces numerous significant challenges that impede efficient safety assessment and regulatory compliance. One primary obstacle is the sheer complexity of identifying all relevant degradation products in pharmaceutical compounds, food additives, and industrial chemicals. These degradation pathways are often influenced by multiple environmental factors including light, temperature, pH, and biological processes, creating a vast array of potential compounds requiring toxicological evaluation.

Analytical limitations present another substantial hurdle. Current detection methods often struggle with the identification of low-concentration degradation products that may nonetheless pose significant toxicological risks. The sensitivity threshold of many analytical techniques fails to capture compounds present at parts per billion or trillion levels, potentially missing toxicologically relevant degradation products.

Resource constraints significantly impact toxicology testing workflows. Traditional animal-based toxicology studies are time-consuming, expensive, and increasingly subject to ethical concerns and regulatory restrictions. This creates a bottleneck in the assessment process, particularly when multiple degradation products require evaluation. The pharmaceutical industry alone estimates that comprehensive toxicology testing for all potential degradation products could increase development costs by 15-25%.

Regulatory inconsistency across different jurisdictions creates additional complexity. The European Medicines Agency, US FDA, and regulatory bodies in Asia often have divergent requirements for degradation product toxicology testing, forcing companies to navigate multiple compliance pathways. This regulatory fragmentation leads to duplicative testing and delays in product approvals.

The absence of standardized risk assessment frameworks specifically designed for degradation products represents a critical gap. Current approaches often apply general toxicology principles without accounting for the unique characteristics of degradation products, including their formation conditions, concentration patterns, and potential co-occurrence effects.

Emerging concerns about combination effects further complicate testing workflows. Degradation products rarely exist in isolation, yet current toxicology paradigms predominantly evaluate compounds individually. The potential synergistic or antagonistic effects between multiple degradation products or between degradation products and parent compounds remain poorly understood and inadequately tested in current workflows.

Data integration challenges also hinder effective risk assessment. Information about degradation pathways, analytical chemistry results, and toxicological findings often exists in separate systems without effective integration mechanisms, limiting holistic safety evaluations and knowledge transfer between similar compounds.

Analytical limitations present another substantial hurdle. Current detection methods often struggle with the identification of low-concentration degradation products that may nonetheless pose significant toxicological risks. The sensitivity threshold of many analytical techniques fails to capture compounds present at parts per billion or trillion levels, potentially missing toxicologically relevant degradation products.

Resource constraints significantly impact toxicology testing workflows. Traditional animal-based toxicology studies are time-consuming, expensive, and increasingly subject to ethical concerns and regulatory restrictions. This creates a bottleneck in the assessment process, particularly when multiple degradation products require evaluation. The pharmaceutical industry alone estimates that comprehensive toxicology testing for all potential degradation products could increase development costs by 15-25%.

Regulatory inconsistency across different jurisdictions creates additional complexity. The European Medicines Agency, US FDA, and regulatory bodies in Asia often have divergent requirements for degradation product toxicology testing, forcing companies to navigate multiple compliance pathways. This regulatory fragmentation leads to duplicative testing and delays in product approvals.

The absence of standardized risk assessment frameworks specifically designed for degradation products represents a critical gap. Current approaches often apply general toxicology principles without accounting for the unique characteristics of degradation products, including their formation conditions, concentration patterns, and potential co-occurrence effects.

Emerging concerns about combination effects further complicate testing workflows. Degradation products rarely exist in isolation, yet current toxicology paradigms predominantly evaluate compounds individually. The potential synergistic or antagonistic effects between multiple degradation products or between degradation products and parent compounds remain poorly understood and inadequately tested in current workflows.

Data integration challenges also hinder effective risk assessment. Information about degradation pathways, analytical chemistry results, and toxicological findings often exists in separate systems without effective integration mechanisms, limiting holistic safety evaluations and knowledge transfer between similar compounds.

Current Workflows for Degradation Product Analysis

01 Automated toxicology testing platforms

Advanced automated platforms have been developed to enhance toxicology testing efficiency. These systems integrate robotics, high-throughput screening technologies, and automated sample handling to process multiple samples simultaneously. By reducing manual intervention, these platforms minimize human error, increase throughput, and standardize testing procedures. The automation of routine tasks allows for continuous operation and optimization of laboratory resources, significantly improving overall testing efficiency.- Automated toxicology testing systems: Automated systems for toxicology testing can significantly improve workflow efficiency by reducing manual intervention and human error. These systems incorporate robotics, automated sample handling, and integrated analytical instruments to streamline the testing process. Automation allows for higher throughput, consistent methodology application, and more reliable results in toxicological assessments. These systems can handle multiple samples simultaneously and operate continuously, greatly enhancing testing capacity and efficiency.

- AI and machine learning in toxicology workflows: Artificial intelligence and machine learning technologies are being integrated into toxicology testing workflows to improve efficiency and predictive capabilities. These technologies can analyze complex datasets, identify patterns, and predict toxicological outcomes with reduced need for extensive laboratory testing. AI systems can process historical toxicology data to develop predictive models that accelerate the assessment of new compounds. Machine learning algorithms can also optimize testing protocols by identifying the most informative assays for specific compounds or toxicity endpoints.

- High-throughput screening methodologies: High-throughput screening approaches enable rapid assessment of multiple compounds or samples simultaneously, dramatically increasing toxicology testing efficiency. These methodologies typically utilize miniaturized assay formats, parallel processing techniques, and advanced detection systems to evaluate toxicological endpoints quickly. Microplate-based assays, microfluidic devices, and cell-based reporter systems allow for testing of numerous conditions with minimal reagent consumption. These approaches reduce the time and resources required for comprehensive toxicological evaluation while maintaining or improving the quality of the data generated.

- Integrated data management systems: Specialized data management systems designed for toxicology testing workflows improve efficiency by streamlining data collection, analysis, and reporting processes. These systems integrate laboratory information management, electronic lab notebooks, and analytical software to create seamless workflows from sample receipt to final report generation. Centralized data repositories enable better tracking of samples, improved collaboration among team members, and more efficient regulatory compliance documentation. Advanced analytics capabilities within these systems allow for rapid identification of trends, anomalies, and correlations in toxicological data.

- In vitro and alternative testing methods: In vitro and alternative testing methods are being developed to replace or reduce traditional animal testing approaches, offering improvements in both ethical considerations and workflow efficiency. These methods include cell-based assays, organ-on-chip technologies, and computational toxicology approaches that can provide faster results with fewer resources. By focusing on specific toxicological mechanisms and pathways, these alternative methods can deliver more targeted and relevant information. The development of standardized protocols for these methods further enhances their reliability and efficiency in toxicological assessment workflows.

02 AI and machine learning in toxicology workflows

Artificial intelligence and machine learning algorithms are revolutionizing toxicology testing workflows by predicting toxicity profiles, identifying patterns in complex datasets, and optimizing testing protocols. These computational approaches can analyze historical toxicology data to develop predictive models that reduce the need for extensive laboratory testing. Machine learning systems can also prioritize compounds for testing based on their predicted toxicity, allowing researchers to focus resources on substances with the highest risk profiles, thereby improving testing efficiency.Expand Specific Solutions03 Integrated data management systems for toxicology testing

Comprehensive data management systems specifically designed for toxicology testing workflows enable efficient data collection, analysis, and reporting. These systems integrate laboratory information management systems (LIMS) with electronic laboratory notebooks (ELNs) and analytical instruments to create seamless data flows. By automating data transfer between different stages of testing, these integrated systems eliminate manual data entry, reduce transcription errors, and provide real-time access to testing results, significantly enhancing workflow efficiency and data integrity.Expand Specific Solutions04 High-throughput in vitro and alternative testing methods

Novel high-throughput in vitro testing methods and alternative approaches to traditional animal testing have been developed to increase toxicology testing efficiency. These methods include cell-based assays, organ-on-a-chip technologies, and computational toxicology approaches that can rapidly screen multiple compounds simultaneously. By replacing or reducing traditional animal testing, these alternative methods not only address ethical concerns but also provide faster results, require smaller sample volumes, and allow for higher throughput screening, ultimately improving the efficiency of toxicology testing workflows.Expand Specific Solutions05 Workflow optimization and quality control systems

Specialized workflow optimization and quality control systems have been developed to enhance toxicology testing efficiency. These systems employ process analysis tools to identify bottlenecks, standardize procedures, and implement continuous improvement methodologies. Quality control mechanisms are integrated throughout the testing workflow to ensure data reliability and compliance with regulatory standards. By systematically analyzing and refining each step of the toxicology testing process, these systems minimize redundancies, reduce turnaround times, and maximize resource utilization while maintaining high-quality results.Expand Specific Solutions

Key Industry Players in Toxicology Testing

The toxicology testing workflows for degradation products market is currently in a growth phase, characterized by increasing regulatory scrutiny and expanding applications across pharmaceutical, chemical, and environmental sectors. The market is estimated to reach approximately $2.5-3 billion globally, driven by stringent safety requirements and growing awareness of degradation-related risks. Technologically, the field shows varying maturity levels with established players like BASF Corp., Saudi Arabian Oil Co., and Air Products & Chemicals offering comprehensive solutions, while research institutions such as North Carolina State University and Agency for Science, Technology & Research are advancing novel methodologies. Pharmaceutical companies like Amgen are investing in specialized workflows, while government agencies including the US Government and Agency for Defense Development are developing regulatory frameworks and standardized protocols to address emerging concerns in degradation product toxicology assessment.

BASF Corp.

Technical Solution: BASF has established a comprehensive toxicology testing platform for degradation products that integrates computational prediction, analytical chemistry, and biological testing. Their workflow begins with in silico modeling to predict potential degradation pathways and identify structures of concern. This is followed by forced degradation studies under various conditions (heat, light, pH, oxidation) to generate relevant degradation products. BASF employs state-of-the-art analytical techniques including UHPLC-QTOF-MS and NMR for structural elucidation of degradation products. Their biological assessment incorporates both traditional toxicology endpoints and newer approach methodologies (NAMs) such as high-content imaging and transcriptomics to evaluate potential toxicity mechanisms. BASF has particularly focused on developing specialized workflows for agrochemical degradation products in soil and water systems, as well as for polymer additives that may leach into food or environmental matrices.

Strengths: Extensive chemical expertise across multiple industries; integrated testing approach combining computational, analytical and biological methods; strong regulatory knowledge and compliance capabilities. Weaknesses: Testing workflows may be optimized primarily for their own product portfolio; potential conflicts of interest when evaluating their own products versus independent third-party assessment.

Battelle Memorial Institute

Technical Solution: Battelle has developed sophisticated toxicology testing workflows for degradation products with particular emphasis on environmental contaminants and pharmaceutical compounds. Their approach integrates environmental fate modeling with advanced analytical chemistry and ecotoxicology testing. Battelle's workflow begins with prediction of degradation pathways using computational tools, followed by controlled laboratory studies to generate relevant degradation products. They employ high-resolution mass spectrometry techniques coupled with advanced data processing algorithms to identify unknown degradation products in complex matrices. Their biological testing cascade includes both in vitro screening assays (cell-based reporter assays, zebrafish embryo tests) and targeted in vivo studies when necessary. Battelle has pioneered the use of effect-directed analysis (EDA) to identify toxic fractions in complex mixtures of degradation products, allowing for prioritization of compounds requiring further investigation. Their integrated approach enables comprehensive risk assessment of degradation products across multiple environmental compartments and exposure scenarios.

Strengths: Independent research organization with extensive government and industry experience; multidisciplinary expertise spanning environmental science, chemistry and toxicology; advanced analytical capabilities for complex environmental samples. Weaknesses: As a contract research organization, may have less specialized focus on specific industries compared to dedicated companies; testing workflows may require customization for unique client needs.

Critical Technologies in Degradation Product Detection

Method and system for development of forced degradation and stability indicating studies of drugs with defined parameters

PatentPendingIN202441033742A

Innovation

- A method and system that subject drug samples to specific stress conditions like temperature, humidity, light exposure, and oxidative environments, using integrated laboratory equipment and advanced analytical techniques such as HPLC, LC-MS, FTIR, and NMR spectroscopy, with software modules for automated control and data acquisition to ensure reproducibility and accuracy.

RP-HPLC stability-indicating assay

PatentInactiveIN3877DEL2011A

Innovation

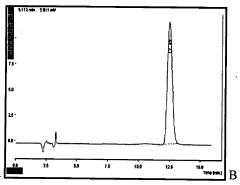

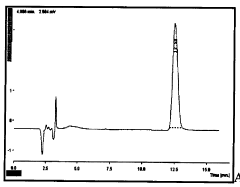

- A reverse phase high performance liquid chromatographic (RP-HPLC) method is developed for the separation, identification, and quantitative determination of talinolol and its degradation products, involving forced degradation under acidic, alkaline, neutral, thermal, oxidative, and photolytic conditions, with characterization using TOF/MS, NMR, and IR spectroscopy.

Regulatory Framework for Degradation Product Safety

The regulatory landscape governing toxicology testing for degradation products is complex and multifaceted, with frameworks varying across regions and industries. In the pharmaceutical sector, the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) provides critical guidelines, particularly ICH Q3A(R2) and ICH Q3B(R2), which establish thresholds for reporting, identification, and qualification of impurities in new drug substances and products.

The U.S. Food and Drug Administration (FDA) has implemented these ICH guidelines while adding specific requirements through guidance documents that address degradation product safety assessment. Similarly, the European Medicines Agency (EMA) enforces stringent regulations through its Committee for Medicinal Products for Human Use (CHMP), which has established detailed protocols for toxicological evaluation of degradation products.

For food contact materials, the European Food Safety Authority (EFSA) and FDA have developed comprehensive frameworks that include specific migration limits and toxicological assessment requirements for degradation products. These regulations typically employ a tiered approach based on exposure levels, with increasing testing requirements as exposure thresholds are exceeded.

Environmental regulations present another critical dimension, with the Environmental Protection Agency (EPA) in the U.S. and the European Chemicals Agency (ECHA) under REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) legislation requiring extensive toxicological data for degradation products of chemicals released into the environment. These frameworks often incorporate the principles of the 3Rs (Replacement, Reduction, Refinement) to minimize animal testing while ensuring safety.

Recent regulatory trends show increasing emphasis on in silico methods and alternative testing strategies. The FDA's Predictive Toxicology Roadmap and the EU's promotion of New Approach Methodologies (NAMs) reflect growing regulatory acceptance of computational toxicology, high-throughput screening, and organ-on-chip technologies as complementary or alternative approaches to traditional animal testing for degradation products.

Compliance challenges arise from the varying thresholds and requirements across different regulatory bodies. For instance, qualification thresholds for degradation products can differ between ICH, FDA, and EMA guidelines, creating complexity for global product development. Additionally, emerging markets are developing their own regulatory frameworks, often adapting elements from established systems while introducing unique requirements.

The U.S. Food and Drug Administration (FDA) has implemented these ICH guidelines while adding specific requirements through guidance documents that address degradation product safety assessment. Similarly, the European Medicines Agency (EMA) enforces stringent regulations through its Committee for Medicinal Products for Human Use (CHMP), which has established detailed protocols for toxicological evaluation of degradation products.

For food contact materials, the European Food Safety Authority (EFSA) and FDA have developed comprehensive frameworks that include specific migration limits and toxicological assessment requirements for degradation products. These regulations typically employ a tiered approach based on exposure levels, with increasing testing requirements as exposure thresholds are exceeded.

Environmental regulations present another critical dimension, with the Environmental Protection Agency (EPA) in the U.S. and the European Chemicals Agency (ECHA) under REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) legislation requiring extensive toxicological data for degradation products of chemicals released into the environment. These frameworks often incorporate the principles of the 3Rs (Replacement, Reduction, Refinement) to minimize animal testing while ensuring safety.

Recent regulatory trends show increasing emphasis on in silico methods and alternative testing strategies. The FDA's Predictive Toxicology Roadmap and the EU's promotion of New Approach Methodologies (NAMs) reflect growing regulatory acceptance of computational toxicology, high-throughput screening, and organ-on-chip technologies as complementary or alternative approaches to traditional animal testing for degradation products.

Compliance challenges arise from the varying thresholds and requirements across different regulatory bodies. For instance, qualification thresholds for degradation products can differ between ICH, FDA, and EMA guidelines, creating complexity for global product development. Additionally, emerging markets are developing their own regulatory frameworks, often adapting elements from established systems while introducing unique requirements.

Risk Assessment Strategies for Novel Degradation Products

Risk assessment for novel degradation products requires a structured approach that balances scientific rigor with practical implementation. The assessment typically begins with a comprehensive hazard identification process, where potential degradation products are cataloged based on chemical structure analysis and reaction pathway predictions. This initial screening helps prioritize compounds that warrant further toxicological evaluation based on structural alerts, known toxicity of similar compounds, or predicted bioactivity profiles.

Quantitative structure-activity relationship (QSAR) models serve as valuable tools in the early stages of risk assessment, enabling rapid screening of numerous degradation products without extensive laboratory testing. These computational approaches can predict potential toxicological endpoints such as mutagenicity, carcinogenicity, and organ-specific toxicities based on molecular structure alone, providing a cost-effective first line of evaluation.

The threshold of toxicological concern (TTC) concept represents another critical strategy in risk assessment workflows. This approach establishes exposure thresholds below which the risk to human health is considered negligible, even in the absence of compound-specific toxicity data. For degradation products detected at levels below their respective TTC values, further toxicological testing may be deemed unnecessary, allowing resources to be directed toward higher-risk compounds.

For degradation products requiring more detailed assessment, a tiered testing approach is typically employed. Initial in vitro assays focus on fundamental toxicological endpoints such as genotoxicity, cytotoxicity, and receptor binding potential. Only compounds showing concerning results in these preliminary screens proceed to more resource-intensive in vivo studies, optimizing both ethical and economic considerations in the assessment process.

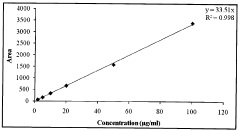

Exposure assessment forms an essential component of the risk characterization framework. This involves determining the concentration of degradation products in the final product, estimating human exposure scenarios, and calculating safety margins. Advanced analytical techniques such as high-resolution mass spectrometry coupled with liquid chromatography enable precise quantification of degradation products, even at trace levels, supporting accurate exposure assessments.

Regulatory acceptance represents the final hurdle in risk assessment strategies. Different regulatory bodies may require varying levels of evidence regarding the safety of novel degradation products. A well-designed risk assessment strategy anticipates these requirements and generates appropriate data packages that address specific regulatory concerns while avoiding unnecessary testing, ultimately facilitating efficient product approval processes.

Quantitative structure-activity relationship (QSAR) models serve as valuable tools in the early stages of risk assessment, enabling rapid screening of numerous degradation products without extensive laboratory testing. These computational approaches can predict potential toxicological endpoints such as mutagenicity, carcinogenicity, and organ-specific toxicities based on molecular structure alone, providing a cost-effective first line of evaluation.

The threshold of toxicological concern (TTC) concept represents another critical strategy in risk assessment workflows. This approach establishes exposure thresholds below which the risk to human health is considered negligible, even in the absence of compound-specific toxicity data. For degradation products detected at levels below their respective TTC values, further toxicological testing may be deemed unnecessary, allowing resources to be directed toward higher-risk compounds.

For degradation products requiring more detailed assessment, a tiered testing approach is typically employed. Initial in vitro assays focus on fundamental toxicological endpoints such as genotoxicity, cytotoxicity, and receptor binding potential. Only compounds showing concerning results in these preliminary screens proceed to more resource-intensive in vivo studies, optimizing both ethical and economic considerations in the assessment process.

Exposure assessment forms an essential component of the risk characterization framework. This involves determining the concentration of degradation products in the final product, estimating human exposure scenarios, and calculating safety margins. Advanced analytical techniques such as high-resolution mass spectrometry coupled with liquid chromatography enable precise quantification of degradation products, even at trace levels, supporting accurate exposure assessments.

Regulatory acceptance represents the final hurdle in risk assessment strategies. Different regulatory bodies may require varying levels of evidence regarding the safety of novel degradation products. A well-designed risk assessment strategy anticipates these requirements and generates appropriate data packages that address specific regulatory concerns while avoiding unnecessary testing, ultimately facilitating efficient product approval processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!