Printed Transient Electronics For Agricultural Sensing Networks

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Printed Transient Electronics Background and Objectives

Printed transient electronics represent a revolutionary approach to electronic systems designed to degrade in a controlled manner after serving their intended purpose. This technology has emerged from the convergence of materials science, electronics engineering, and environmental sustainability concerns over the past decade. The evolution of this field has been driven by the growing need for sustainable electronic solutions that can address the mounting electronic waste crisis while offering new application possibilities in sectors where temporary functionality is advantageous.

The agricultural sector presents a particularly compelling use case for transient electronics, as it requires distributed sensing networks that can monitor environmental conditions, soil health, and crop status without creating persistent waste or requiring manual retrieval from vast fields. Traditional electronic sensors deployed in agricultural settings often become environmental contaminants or require resource-intensive collection efforts once their utility ends.

The technical trajectory of printed transient electronics has been marked by significant advancements in biodegradable substrates, environmentally benign conductive materials, and low-power sensing technologies. Early developments focused primarily on medical applications, but recent innovations have expanded the potential use cases to environmental monitoring, including agricultural applications.

The primary technical objective of printed transient electronics for agricultural sensing networks is to develop fully functional electronic systems that can accurately monitor critical agricultural parameters (such as soil moisture, nutrient levels, pH, and temperature) for a predetermined operational period before harmlessly degrading into environmentally benign components. This requires precise control over degradation timelines to ensure sensors remain functional throughout a growing season but decompose before the next planting cycle.

Secondary objectives include developing manufacturing processes that enable cost-effective mass production of these devices, ensuring sufficient durability to withstand agricultural environments while maintaining their transient properties, and creating energy harvesting or storage solutions compatible with biodegradable materials to power these sensing networks autonomously.

The field aims to achieve a balance between performance, longevity, and environmental impact—a challenging technical triad that necessitates innovative approaches to materials selection, circuit design, and system architecture. Current research trends indicate growing interest in water-soluble electronics, enzyme-triggered degradation mechanisms, and hybrid systems that combine permanent base stations with disposable transient sensors.

As climate change intensifies agricultural challenges and sustainability becomes increasingly critical to food security, printed transient electronics represent a promising technological pathway toward more environmentally responsible precision agriculture systems that can optimize resource use while minimizing ecological impact.

The agricultural sector presents a particularly compelling use case for transient electronics, as it requires distributed sensing networks that can monitor environmental conditions, soil health, and crop status without creating persistent waste or requiring manual retrieval from vast fields. Traditional electronic sensors deployed in agricultural settings often become environmental contaminants or require resource-intensive collection efforts once their utility ends.

The technical trajectory of printed transient electronics has been marked by significant advancements in biodegradable substrates, environmentally benign conductive materials, and low-power sensing technologies. Early developments focused primarily on medical applications, but recent innovations have expanded the potential use cases to environmental monitoring, including agricultural applications.

The primary technical objective of printed transient electronics for agricultural sensing networks is to develop fully functional electronic systems that can accurately monitor critical agricultural parameters (such as soil moisture, nutrient levels, pH, and temperature) for a predetermined operational period before harmlessly degrading into environmentally benign components. This requires precise control over degradation timelines to ensure sensors remain functional throughout a growing season but decompose before the next planting cycle.

Secondary objectives include developing manufacturing processes that enable cost-effective mass production of these devices, ensuring sufficient durability to withstand agricultural environments while maintaining their transient properties, and creating energy harvesting or storage solutions compatible with biodegradable materials to power these sensing networks autonomously.

The field aims to achieve a balance between performance, longevity, and environmental impact—a challenging technical triad that necessitates innovative approaches to materials selection, circuit design, and system architecture. Current research trends indicate growing interest in water-soluble electronics, enzyme-triggered degradation mechanisms, and hybrid systems that combine permanent base stations with disposable transient sensors.

As climate change intensifies agricultural challenges and sustainability becomes increasingly critical to food security, printed transient electronics represent a promising technological pathway toward more environmentally responsible precision agriculture systems that can optimize resource use while minimizing ecological impact.

Agricultural Sensing Market Demand Analysis

The agricultural sensing market is experiencing significant growth driven by the increasing global demand for food security, sustainable farming practices, and precision agriculture. Current market analysis indicates that the global agricultural IoT market, which includes sensing technologies, is projected to reach $20.9 billion by 2024, with a compound annual growth rate of 11.3%. Within this broader market, agricultural sensors specifically represent approximately $3.8 billion, demonstrating the substantial economic potential for innovative sensing solutions like printed transient electronics.

The primary market drivers for agricultural sensing technologies include the pressing need to optimize resource utilization, particularly water and fertilizers, in the face of climate change and resource scarcity. Farmers worldwide are seeking technologies that can provide real-time soil moisture, nutrient levels, and environmental condition data to make informed decisions that maximize yield while minimizing input costs. This demand is particularly acute in regions facing water scarcity, where precise irrigation management can result in water savings of up to 30%.

Market research reveals distinct regional variations in agricultural sensing adoption. North America and Europe currently lead in market share due to higher technology adoption rates and larger average farm sizes that justify the investment in sensing infrastructure. However, the Asia-Pacific region is expected to show the fastest growth rate at 14.2% annually, driven by rapid modernization of agricultural practices in countries like China and India, which together account for over 36% of global agricultural land.

The market segmentation for agricultural sensing technologies shows demand across various application areas. Soil monitoring represents the largest segment at 42% of the market, followed by climate monitoring (28%), crop growth monitoring (18%), and livestock monitoring (12%). This distribution highlights the critical importance of soil-related parameters in agricultural decision-making processes, creating a significant opportunity for printed transient electronics that can be deployed directly in soil environments.

End-user analysis indicates that large commercial farms currently constitute 65% of the market, but small and medium-sized farms represent the fastest-growing segment with 16.7% annual growth. This trend suggests an increasing democratization of agricultural technology access, which aligns well with the potential cost advantages of printed electronics manufacturing techniques.

Consumer preference studies show that farmers prioritize sensing solutions with five key attributes: reliability in harsh field conditions, ease of deployment, minimal maintenance requirements, affordable initial investment, and clear return on investment through yield improvements or input cost reductions. Printed transient electronics that can be easily deployed and naturally decompose after their useful life address several of these key requirements, particularly regarding deployment simplicity and maintenance concerns.

The primary market drivers for agricultural sensing technologies include the pressing need to optimize resource utilization, particularly water and fertilizers, in the face of climate change and resource scarcity. Farmers worldwide are seeking technologies that can provide real-time soil moisture, nutrient levels, and environmental condition data to make informed decisions that maximize yield while minimizing input costs. This demand is particularly acute in regions facing water scarcity, where precise irrigation management can result in water savings of up to 30%.

Market research reveals distinct regional variations in agricultural sensing adoption. North America and Europe currently lead in market share due to higher technology adoption rates and larger average farm sizes that justify the investment in sensing infrastructure. However, the Asia-Pacific region is expected to show the fastest growth rate at 14.2% annually, driven by rapid modernization of agricultural practices in countries like China and India, which together account for over 36% of global agricultural land.

The market segmentation for agricultural sensing technologies shows demand across various application areas. Soil monitoring represents the largest segment at 42% of the market, followed by climate monitoring (28%), crop growth monitoring (18%), and livestock monitoring (12%). This distribution highlights the critical importance of soil-related parameters in agricultural decision-making processes, creating a significant opportunity for printed transient electronics that can be deployed directly in soil environments.

End-user analysis indicates that large commercial farms currently constitute 65% of the market, but small and medium-sized farms represent the fastest-growing segment with 16.7% annual growth. This trend suggests an increasing democratization of agricultural technology access, which aligns well with the potential cost advantages of printed electronics manufacturing techniques.

Consumer preference studies show that farmers prioritize sensing solutions with five key attributes: reliability in harsh field conditions, ease of deployment, minimal maintenance requirements, affordable initial investment, and clear return on investment through yield improvements or input cost reductions. Printed transient electronics that can be easily deployed and naturally decompose after their useful life address several of these key requirements, particularly regarding deployment simplicity and maintenance concerns.

Current State and Challenges in Biodegradable Electronics

Biodegradable electronics represent a significant advancement in the field of printed transient electronics for agricultural sensing networks. Currently, these technologies are evolving rapidly, with several research institutions and companies developing solutions that can monitor soil conditions, plant health, and environmental parameters before harmlessly degrading into the environment.

The global landscape of biodegradable electronics shows varying levels of development. North America and Europe lead in research output, with significant contributions from institutions like Stanford University, MIT, and the University of Illinois. Asia, particularly Japan, South Korea, and China, demonstrates growing expertise in manufacturing scalable biodegradable electronic components. This geographical distribution reflects both academic research concentration and industrial implementation capabilities.

A major technical challenge facing biodegradable electronics is the balance between operational lifetime and degradation rate. Agricultural sensors must function reliably for an entire growing season (typically 3-6 months) before beginning to degrade. Current materials struggle to maintain this precise timing, often degrading prematurely when exposed to unexpected environmental conditions like heavy rainfall or extreme temperature fluctuations.

Material limitations present another significant hurdle. Most biodegradable substrates, such as cellulose derivatives and poly(lactic-co-glycolic acid) (PLGA), exhibit inferior electrical properties compared to conventional electronics materials. This results in lower performance metrics, including reduced sensitivity, limited detection range, and inconsistent data transmission capabilities in field conditions.

Power supply remains a critical constraint. Biodegradable batteries typically offer limited energy density and shorter lifespans compared to conventional batteries. Alternative energy harvesting methods like biodegradable solar cells or piezoelectric generators show promise but currently lack the efficiency needed for continuous operation of sensing networks in variable agricultural environments.

Manufacturing scalability presents additional challenges. Current fabrication techniques for biodegradable electronics often involve complex, multi-step processes that are difficult to scale for mass production. This results in higher costs compared to conventional electronics, limiting widespread adoption despite the environmental benefits.

Data reliability and transmission represent emerging concerns. As biodegradable materials begin to break down, sensor accuracy and communication capabilities may deteriorate in unpredictable ways. This creates challenges for agricultural decision-making systems that rely on consistent, accurate data streams throughout the growing season.

Regulatory frameworks for biodegradable electronics in agricultural settings remain underdeveloped in most regions. This creates uncertainty regarding safety standards, environmental impact assessments, and end-of-life management protocols, potentially slowing commercial implementation despite technological readiness.

The global landscape of biodegradable electronics shows varying levels of development. North America and Europe lead in research output, with significant contributions from institutions like Stanford University, MIT, and the University of Illinois. Asia, particularly Japan, South Korea, and China, demonstrates growing expertise in manufacturing scalable biodegradable electronic components. This geographical distribution reflects both academic research concentration and industrial implementation capabilities.

A major technical challenge facing biodegradable electronics is the balance between operational lifetime and degradation rate. Agricultural sensors must function reliably for an entire growing season (typically 3-6 months) before beginning to degrade. Current materials struggle to maintain this precise timing, often degrading prematurely when exposed to unexpected environmental conditions like heavy rainfall or extreme temperature fluctuations.

Material limitations present another significant hurdle. Most biodegradable substrates, such as cellulose derivatives and poly(lactic-co-glycolic acid) (PLGA), exhibit inferior electrical properties compared to conventional electronics materials. This results in lower performance metrics, including reduced sensitivity, limited detection range, and inconsistent data transmission capabilities in field conditions.

Power supply remains a critical constraint. Biodegradable batteries typically offer limited energy density and shorter lifespans compared to conventional batteries. Alternative energy harvesting methods like biodegradable solar cells or piezoelectric generators show promise but currently lack the efficiency needed for continuous operation of sensing networks in variable agricultural environments.

Manufacturing scalability presents additional challenges. Current fabrication techniques for biodegradable electronics often involve complex, multi-step processes that are difficult to scale for mass production. This results in higher costs compared to conventional electronics, limiting widespread adoption despite the environmental benefits.

Data reliability and transmission represent emerging concerns. As biodegradable materials begin to break down, sensor accuracy and communication capabilities may deteriorate in unpredictable ways. This creates challenges for agricultural decision-making systems that rely on consistent, accurate data streams throughout the growing season.

Regulatory frameworks for biodegradable electronics in agricultural settings remain underdeveloped in most regions. This creates uncertainty regarding safety standards, environmental impact assessments, and end-of-life management protocols, potentially slowing commercial implementation despite technological readiness.

Current Technical Solutions for Printed Transient Sensors

01 Biodegradable and transient electronic materials

Transient electronics are designed to dissolve or degrade after a predetermined period or under specific environmental conditions. These electronics use biodegradable substrates and conductive materials that can safely decompose in the environment or within the human body. This technology is particularly valuable for medical implants, environmental sensors, and secure devices that need to disappear after their useful life without leaving harmful residues.- Biodegradable and transient electronic components: Transient electronics that are designed to degrade or dissolve after a predetermined period or under specific environmental conditions. These components are typically made from biodegradable materials that can safely break down without leaving harmful residues. The technology enables applications in medical implants, environmental sensors, and temporary electronic devices that eliminate the need for retrieval or disposal procedures.

- Printing methods for flexible electronic circuits: Various printing techniques used to create flexible electronic circuits on different substrates. These methods include inkjet printing, screen printing, and roll-to-roll printing processes that enable the deposition of conductive, semiconductive, and dielectric materials to form functional electronic components. The printing approaches allow for cost-effective manufacturing of transient electronics on flexible substrates with controlled degradation properties.

- Materials for printed transient electronics: Specialized materials developed for transient electronic applications, including water-soluble conductors, biodegradable polymers, and environmentally responsive materials. These materials can be formulated as printable inks that maintain electronic functionality during their operational lifetime while being designed to degrade through hydrolysis, enzymatic processes, or other controlled mechanisms when exposed to specific triggers.

- Printing systems and device architecture: Advanced printing systems and architectural designs specifically developed for transient electronics manufacturing. These systems incorporate precise deposition control, multi-material printing capabilities, and specialized curing processes to create layered electronic structures with predetermined degradation profiles. The architecture includes design considerations for controlled dissolution rates and functional performance during the intended lifetime.

- Applications of printed transient electronics: Diverse applications of printed transient electronics across multiple fields including medical devices, environmental monitoring, security systems, and consumer electronics. These applications leverage the temporary nature of transient electronics to create devices that can perform their function for a predetermined period before harmlessly degrading. Examples include dissolvable medical sensors, environmentally degradable monitoring devices, and secure electronics that can be remotely triggered to deactivate.

02 Printing techniques for transient electronics

Various printing methods are employed to fabricate transient electronic devices, including inkjet printing, screen printing, and roll-to-roll processing. These techniques allow for the deposition of electronic materials onto biodegradable substrates in precise patterns. The printing processes must be optimized to ensure proper functionality while maintaining the transient properties of the final device. Advanced printing technologies enable the creation of complex circuit designs with controlled dissolution rates.Expand Specific Solutions03 Integration with conventional electronic systems

Transient electronics can be integrated with conventional, permanent electronic systems to create hybrid devices with both persistent and temporary components. This integration allows for the development of systems where certain parts remain functional indefinitely while others disappear after completing their tasks. Communication protocols and interfaces between transient and permanent components are crucial for ensuring seamless operation during the device's intended lifetime.Expand Specific Solutions04 Monitoring and control systems for dissolution

Advanced transient electronics incorporate monitoring and control systems that can trigger or regulate the dissolution process. These systems may include sensors that detect environmental conditions or timers that activate dissolution after a predetermined period. Some designs feature remote triggering capabilities, allowing external control over when the device begins to degrade. This controlled dissolution is essential for applications requiring precise timing of the device's end-of-life.Expand Specific Solutions05 Display and imaging applications

Transient display and imaging technologies enable the creation of temporary visual interfaces that can dissolve or degrade when no longer needed. These displays utilize materials that maintain optical clarity and electronic functionality during operation but can safely decompose afterward. Applications include temporary information displays, single-use medical imaging devices, and secure visual communication systems that leave no permanent record after use.Expand Specific Solutions

Key Industry Players in Agricultural IoT and Printed Electronics

Printed Transient Electronics for Agricultural Sensing Networks is in an early growth phase, with the market expanding as sustainable agriculture demands increase. The technology is approaching early maturity, with academic institutions (University of Illinois, Huazhong Agricultural University, China Agricultural University) leading research while commercial players (NthDegree Technologies, Saralon GmbH) begin developing practical applications. Major technology corporations (Intel, Apple, Sony, LG Electronics) are exploring integration possibilities, while agricultural equipment manufacturers (Deere & Co., State Grid) investigate implementation pathways. The market shows promising growth potential as biodegradable electronics address environmental concerns in agricultural monitoring, though widespread commercial deployment remains several years away.

The Board of Trustees of the University of Illinois

Technical Solution: The University of Illinois has pioneered transient electronics for agricultural sensing networks through their development of water-soluble printed circuit boards (PCBs) that naturally decompose after fulfilling their monitoring functions. Their technology utilizes biodegradable polymers like poly(vinyl alcohol) and poly(lactic-co-glycolic acid) as substrates, combined with water-soluble or biodegradable conductive inks containing magnesium, zinc, or iron microparticles. These materials enable the creation of sensors that can monitor soil moisture, nutrient levels, and plant health parameters while completely dissolving into non-toxic components within predetermined timeframes (typically 3-6 months). The university has demonstrated field deployments where networks of these sensors communicate wirelessly to central hubs, providing real-time agricultural data without requiring physical retrieval, as the devices safely decompose into the soil after their operational period.

Strengths: Completely eliminates e-waste concerns through full biodegradability; tailorable dissolution rates to match growing seasons; minimal environmental impact. Weaknesses: Lower performance metrics compared to conventional electronics; limited operational lifespan; potentially higher initial production costs; signal transmission challenges in dense vegetation environments.

Huazhong Agricultural University

Technical Solution: Huazhong Agricultural University has developed a comprehensive printed transient electronics platform specifically designed for agricultural monitoring applications. Their approach integrates cellulose-based substrates derived from agricultural waste with silver nanoparticle inks modified for enhanced biodegradability. The university's system features multi-parameter sensing capabilities including soil moisture detection at multiple depths, temperature monitoring, and specialized nutrient sensors for nitrogen, phosphorus, and potassium levels. A distinguishing feature of their technology is the implementation of a hierarchical network architecture where numerous low-cost transient sensor nodes communicate with slightly more durable "aggregator" nodes that process data before transmission to central systems. Their sensors are designed to operate for one growing season (approximately 4-5 months) before degrading into environmentally benign components, with degradation triggered by soil enzymes and microbial activity. Field trials across various crop types have demonstrated 92% accuracy in moisture detection and 87% accuracy in nutrient monitoring compared to conventional laboratory testing methods.

Strengths: Utilizes agricultural waste as raw material for substrates; comprehensive multi-parameter sensing capabilities; hierarchical network design optimizes power consumption and data transmission. Weaknesses: Requires careful calibration for different soil types; degradation rate can be unpredictable in extreme weather conditions; limited processing capabilities compared to permanent electronics.

Core Patents and Research in Degradable Electronic Materials

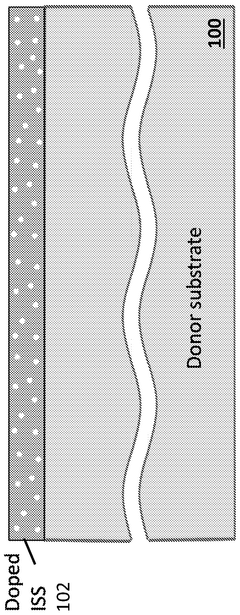

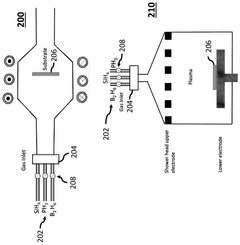

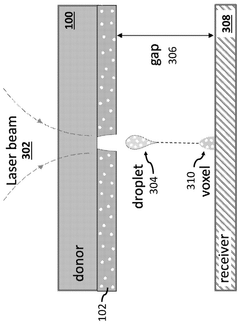

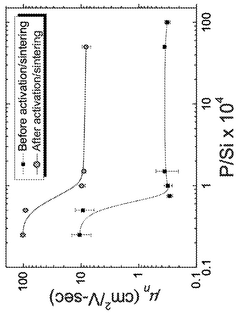

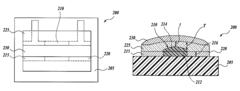

Semiconductor donor substrates for laser-transfer printing

PatentWO2025046453A1

Innovation

- The development of donor substrates with a transparent substrate and a thin film of inorganic semiconductor material containing dopant atoms, allowing for direct laser transfer of inorganic semiconductor patterns with controlled electrical conductivity onto receiving substrates.

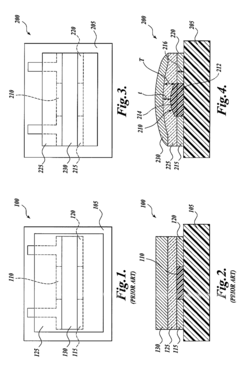

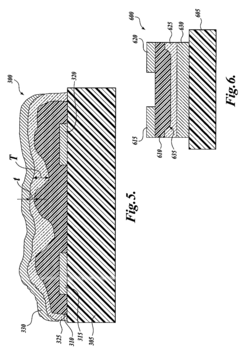

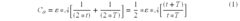

Organic transistor having a non-planar semiconductor-insulating layer interface

PatentInactiveUS7834347B2

Innovation

- The development of OFETs with non-planar semiconductor layers, achieved through multiple deposition stages and curing processes, results in variable thicknesses of the insulating layer and increased interface area, enhancing charge carrier mobility and capacitance.

Environmental Impact Assessment and Sustainability Metrics

The environmental impact of printed transient electronics for agricultural sensing networks represents a critical dimension in evaluating their overall viability and sustainability. These biodegradable electronic systems offer significant environmental advantages compared to conventional electronic devices, primarily through their ability to naturally decompose after fulfilling their intended functions.

The life cycle assessment of printed transient electronics reveals substantially reduced environmental footprints. Traditional electronic waste contributes approximately 50 million tons annually to global waste streams, with less than 20% being properly recycled. In contrast, transient electronics can decompose within weeks to months depending on environmental conditions and material composition, leaving minimal or no toxic residues in agricultural soils.

Material selection plays a pivotal role in determining environmental performance. Biodegradable polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives serve as substrates with decomposition rates ranging from 3-24 months under typical agricultural conditions. Conductive inks utilizing silver nanoparticles or carbon-based materials present varying environmental profiles, with water-based formulations demonstrating 40-60% lower ecotoxicity compared to solvent-based alternatives.

Energy consumption metrics throughout the manufacturing process indicate that printed electronics require 30-50% less energy compared to conventional silicon-based electronics production. This reduction stems primarily from lower temperature processing requirements and simplified manufacturing steps. Additionally, the elimination of hazardous chemicals commonly used in traditional electronics manufacturing, such as perfluorooctanoic acid (PFOA) and brominated flame retardants, significantly reduces potential soil and water contamination.

Field degradation studies demonstrate that transient agricultural sensors typically achieve 90% mass reduction within 6-12 months under normal field conditions, with degradation byproducts showing minimal impact on soil microbial communities and plant growth. Standardized ecotoxicity assessments using earthworm survival rates and soil enzyme activities indicate negligible long-term effects when proper material selection guidelines are followed.

Carbon footprint calculations reveal that printed transient electronics for agricultural applications can achieve 60-75% reduction in greenhouse gas emissions compared to conventional electronic systems when considering full lifecycle impacts. This improvement derives from reduced manufacturing energy requirements, elimination of electronic waste management needs, and decreased transportation demands due to potential for localized production.

Water usage metrics similarly demonstrate advantages, with manufacturing processes requiring 40-60% less water consumption compared to traditional electronics fabrication. This efficiency becomes particularly relevant in agricultural contexts where water resource management represents a critical sustainability concern.

AI-powered lifecycle optimization tools are emerging to further enhance environmental performance by predicting optimal material combinations and degradation timelines based on specific deployment conditions and functional requirements.

The life cycle assessment of printed transient electronics reveals substantially reduced environmental footprints. Traditional electronic waste contributes approximately 50 million tons annually to global waste streams, with less than 20% being properly recycled. In contrast, transient electronics can decompose within weeks to months depending on environmental conditions and material composition, leaving minimal or no toxic residues in agricultural soils.

Material selection plays a pivotal role in determining environmental performance. Biodegradable polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives serve as substrates with decomposition rates ranging from 3-24 months under typical agricultural conditions. Conductive inks utilizing silver nanoparticles or carbon-based materials present varying environmental profiles, with water-based formulations demonstrating 40-60% lower ecotoxicity compared to solvent-based alternatives.

Energy consumption metrics throughout the manufacturing process indicate that printed electronics require 30-50% less energy compared to conventional silicon-based electronics production. This reduction stems primarily from lower temperature processing requirements and simplified manufacturing steps. Additionally, the elimination of hazardous chemicals commonly used in traditional electronics manufacturing, such as perfluorooctanoic acid (PFOA) and brominated flame retardants, significantly reduces potential soil and water contamination.

Field degradation studies demonstrate that transient agricultural sensors typically achieve 90% mass reduction within 6-12 months under normal field conditions, with degradation byproducts showing minimal impact on soil microbial communities and plant growth. Standardized ecotoxicity assessments using earthworm survival rates and soil enzyme activities indicate negligible long-term effects when proper material selection guidelines are followed.

Carbon footprint calculations reveal that printed transient electronics for agricultural applications can achieve 60-75% reduction in greenhouse gas emissions compared to conventional electronic systems when considering full lifecycle impacts. This improvement derives from reduced manufacturing energy requirements, elimination of electronic waste management needs, and decreased transportation demands due to potential for localized production.

Water usage metrics similarly demonstrate advantages, with manufacturing processes requiring 40-60% less water consumption compared to traditional electronics fabrication. This efficiency becomes particularly relevant in agricultural contexts where water resource management represents a critical sustainability concern.

AI-powered lifecycle optimization tools are emerging to further enhance environmental performance by predicting optimal material combinations and degradation timelines based on specific deployment conditions and functional requirements.

Regulatory Framework for Agricultural Sensing Technologies

The regulatory landscape for printed transient electronics in agricultural sensing networks is complex and evolving rapidly as these innovative technologies enter the market. Currently, regulatory frameworks addressing these technologies span multiple domains including environmental protection, electronic waste management, agricultural standards, and data privacy. The U.S. Environmental Protection Agency (EPA) has established guidelines for biodegradable materials in agricultural settings, requiring comprehensive ecological impact assessments before deployment. Similarly, the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive has begun incorporating provisions for transient electronics, recognizing their unique position between traditional electronics and biodegradable materials.

Food safety regulations administered by agencies such as the FDA in the United States and EFSA in Europe impose strict requirements on materials that may come into contact with soil or crops. Printed transient electronics must demonstrate non-toxicity and minimal environmental persistence to gain regulatory approval. The materials used in these sensors—including conductive inks, substrates, and encapsulation materials—must undergo rigorous testing to ensure they do not introduce harmful substances into the food chain.

Data collection and privacy regulations present another significant regulatory consideration. Agricultural sensing networks generate substantial data about farm operations, soil conditions, and crop performance. Regulations such as the General Data Protection Regulation (GDPR) in Europe and various state-level privacy laws in the United States impose requirements on data collection, storage, and sharing practices. Manufacturers and deployers of agricultural sensing networks must implement appropriate data governance frameworks to ensure compliance.

Certification standards specifically for transient electronics remain underdeveloped. Industry stakeholders are working with organizations such as IEEE, ISO, and ASTM International to establish standardized testing protocols for biodegradability, functionality duration, and environmental impact. The lack of unified standards creates market uncertainty and potential barriers to widespread adoption.

Regulatory compliance costs represent a significant consideration for technology developers. Small and medium enterprises face particular challenges navigating the complex regulatory landscape across different jurisdictions. Several countries have begun implementing regulatory sandboxes to allow controlled testing of transient electronics in agricultural settings while regulatory frameworks mature.

Looking forward, regulatory harmonization efforts are emerging through international bodies such as the International Telecommunication Union (ITU) and the Food and Agriculture Organization (FAO). These initiatives aim to create consistent global standards that balance innovation with environmental protection and food safety concerns, potentially accelerating the responsible deployment of printed transient electronics in agricultural applications worldwide.

Food safety regulations administered by agencies such as the FDA in the United States and EFSA in Europe impose strict requirements on materials that may come into contact with soil or crops. Printed transient electronics must demonstrate non-toxicity and minimal environmental persistence to gain regulatory approval. The materials used in these sensors—including conductive inks, substrates, and encapsulation materials—must undergo rigorous testing to ensure they do not introduce harmful substances into the food chain.

Data collection and privacy regulations present another significant regulatory consideration. Agricultural sensing networks generate substantial data about farm operations, soil conditions, and crop performance. Regulations such as the General Data Protection Regulation (GDPR) in Europe and various state-level privacy laws in the United States impose requirements on data collection, storage, and sharing practices. Manufacturers and deployers of agricultural sensing networks must implement appropriate data governance frameworks to ensure compliance.

Certification standards specifically for transient electronics remain underdeveloped. Industry stakeholders are working with organizations such as IEEE, ISO, and ASTM International to establish standardized testing protocols for biodegradability, functionality duration, and environmental impact. The lack of unified standards creates market uncertainty and potential barriers to widespread adoption.

Regulatory compliance costs represent a significant consideration for technology developers. Small and medium enterprises face particular challenges navigating the complex regulatory landscape across different jurisdictions. Several countries have begun implementing regulatory sandboxes to allow controlled testing of transient electronics in agricultural settings while regulatory frameworks mature.

Looking forward, regulatory harmonization efforts are emerging through international bodies such as the International Telecommunication Union (ITU) and the Food and Agriculture Organization (FAO). These initiatives aim to create consistent global standards that balance innovation with environmental protection and food safety concerns, potentially accelerating the responsible deployment of printed transient electronics in agricultural applications worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!