Biodegradable Conductors: From Carbon Inks To Biogenic Metals

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Conductors Background and Objectives

Biodegradable conductors represent a revolutionary frontier in sustainable electronics, emerging from the convergence of materials science, bioengineering, and environmental sustainability principles. The evolution of these materials has accelerated significantly over the past decade, driven by increasing environmental concerns regarding electronic waste and the growing demand for eco-friendly technological solutions. Traditional electronic conductors, predominantly composed of metals like copper, silver, and gold, present significant end-of-life challenges due to their persistence in the environment and associated toxicity concerns.

Carbon-based conductive inks emerged in the early 2000s as potential alternatives, with initial applications primarily in printed electronics. These materials have since evolved to incorporate various forms of carbon, including graphene, carbon nanotubes, and carbon black, suspended in biodegradable matrices. Parallel to this development, biogenic metals—metals produced through biological processes—have gained attention for their reduced environmental footprint and potential biodegradability.

The technical trajectory of biodegradable conductors has been characterized by progressive improvements in conductivity, mechanical flexibility, and degradation profiles. Early iterations exhibited conductivity values several orders of magnitude lower than conventional metals, limiting their practical applications. Recent advancements, however, have narrowed this performance gap substantially, with some biodegradable composites achieving conductivity values approaching 10^4 S/m.

The primary objective of current research in biodegradable conductors is to develop materials that maintain electrical performance comparable to conventional conductors while offering controlled degradation under specific environmental conditions. This includes optimizing the balance between electrical conductivity and degradation rate, enhancing mechanical properties for various application scenarios, and ensuring biocompatibility for potential biomedical applications.

Additional technical goals include developing scalable manufacturing processes for these materials, reducing production costs to competitive levels, and establishing standardized testing protocols for biodegradability assessment. The integration of these materials into functional electronic systems represents another critical objective, requiring innovations in circuit design, interconnection technologies, and encapsulation methods.

The environmental imperative driving this field cannot be overstated. With global electronic waste exceeding 50 million metric tons annually and growing at approximately 4-5% per year, biodegradable conductors offer a promising pathway toward more sustainable electronics. The ultimate technical vision encompasses fully biodegradable electronic systems that can safely return to the environment after their useful life, leaving minimal ecological footprint.

Carbon-based conductive inks emerged in the early 2000s as potential alternatives, with initial applications primarily in printed electronics. These materials have since evolved to incorporate various forms of carbon, including graphene, carbon nanotubes, and carbon black, suspended in biodegradable matrices. Parallel to this development, biogenic metals—metals produced through biological processes—have gained attention for their reduced environmental footprint and potential biodegradability.

The technical trajectory of biodegradable conductors has been characterized by progressive improvements in conductivity, mechanical flexibility, and degradation profiles. Early iterations exhibited conductivity values several orders of magnitude lower than conventional metals, limiting their practical applications. Recent advancements, however, have narrowed this performance gap substantially, with some biodegradable composites achieving conductivity values approaching 10^4 S/m.

The primary objective of current research in biodegradable conductors is to develop materials that maintain electrical performance comparable to conventional conductors while offering controlled degradation under specific environmental conditions. This includes optimizing the balance between electrical conductivity and degradation rate, enhancing mechanical properties for various application scenarios, and ensuring biocompatibility for potential biomedical applications.

Additional technical goals include developing scalable manufacturing processes for these materials, reducing production costs to competitive levels, and establishing standardized testing protocols for biodegradability assessment. The integration of these materials into functional electronic systems represents another critical objective, requiring innovations in circuit design, interconnection technologies, and encapsulation methods.

The environmental imperative driving this field cannot be overstated. With global electronic waste exceeding 50 million metric tons annually and growing at approximately 4-5% per year, biodegradable conductors offer a promising pathway toward more sustainable electronics. The ultimate technical vision encompasses fully biodegradable electronic systems that can safely return to the environment after their useful life, leaving minimal ecological footprint.

Market Demand Analysis for Eco-friendly Electronics

The global market for eco-friendly electronics is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures. The demand for biodegradable conductors, particularly carbon inks and biogenic metals, is rapidly expanding across multiple industries. Current market projections indicate that the sustainable electronics sector could reach $80 billion by 2028, with biodegradable components representing approximately 15% of this market.

Consumer electronics represents the largest application segment, with manufacturers increasingly incorporating biodegradable conductors into disposable or short-lifecycle products. Market research shows that 67% of consumers across major markets express willingness to pay premium prices for electronics with reduced environmental impact, creating a strong commercial incentive for manufacturers to adopt these technologies.

Healthcare applications constitute another significant market driver, particularly in wearable medical devices and disposable diagnostic equipment. The biodegradable sensors market alone is growing at 23% annually, with applications ranging from transient implantable devices to environmental monitoring systems. These technologies address the critical need for reducing medical waste while maintaining functionality and biocompatibility.

Regulatory frameworks worldwide are accelerating market adoption through both incentives and restrictions. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in Asia-Pacific regions have established concrete timelines for reducing electronic waste, creating immediate market opportunities for biodegradable alternatives to traditional conductors.

Supply chain considerations are reshaping market dynamics as well. The volatility in rare earth metal pricing and geopolitical concerns regarding critical minerals have intensified interest in biogenic metals derived from sustainable sources. Companies capable of establishing reliable, scalable production of these materials are positioned to capture significant market share.

Industry partnerships between material science companies and electronics manufacturers have increased by 45% in the past three years, indicating strong commercial interest in bringing biodegradable conductor technologies to market. These collaborations are essential for addressing the technical challenges of integrating novel materials into existing manufacturing processes.

Market penetration remains uneven across regions, with North America and Europe leading adoption rates while emerging economies present enormous growth potential. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 30% as manufacturing capabilities align with environmental priorities.

Price sensitivity remains a significant market barrier, with biodegradable conductors currently commanding a 30-40% premium over conventional materials. However, economies of scale and technological advancements are steadily reducing this gap, with price parity projected within 5-7 years for certain applications.

Consumer electronics represents the largest application segment, with manufacturers increasingly incorporating biodegradable conductors into disposable or short-lifecycle products. Market research shows that 67% of consumers across major markets express willingness to pay premium prices for electronics with reduced environmental impact, creating a strong commercial incentive for manufacturers to adopt these technologies.

Healthcare applications constitute another significant market driver, particularly in wearable medical devices and disposable diagnostic equipment. The biodegradable sensors market alone is growing at 23% annually, with applications ranging from transient implantable devices to environmental monitoring systems. These technologies address the critical need for reducing medical waste while maintaining functionality and biocompatibility.

Regulatory frameworks worldwide are accelerating market adoption through both incentives and restrictions. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in Asia-Pacific regions have established concrete timelines for reducing electronic waste, creating immediate market opportunities for biodegradable alternatives to traditional conductors.

Supply chain considerations are reshaping market dynamics as well. The volatility in rare earth metal pricing and geopolitical concerns regarding critical minerals have intensified interest in biogenic metals derived from sustainable sources. Companies capable of establishing reliable, scalable production of these materials are positioned to capture significant market share.

Industry partnerships between material science companies and electronics manufacturers have increased by 45% in the past three years, indicating strong commercial interest in bringing biodegradable conductor technologies to market. These collaborations are essential for addressing the technical challenges of integrating novel materials into existing manufacturing processes.

Market penetration remains uneven across regions, with North America and Europe leading adoption rates while emerging economies present enormous growth potential. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 30% as manufacturing capabilities align with environmental priorities.

Price sensitivity remains a significant market barrier, with biodegradable conductors currently commanding a 30-40% premium over conventional materials. However, economies of scale and technological advancements are steadily reducing this gap, with price parity projected within 5-7 years for certain applications.

Current Status and Challenges in Biodegradable Conductive Materials

Biodegradable conductive materials have gained significant attention globally, with research efforts intensifying over the past decade. Currently, the field is witnessing parallel development in both carbon-based inks and biogenic metals, each with distinct advantages and limitations. Carbon inks derived from sustainable sources have reached commercial viability in certain applications, particularly in low-power electronics and disposable sensors. Meanwhile, biogenic metals produced through microbial synthesis or extraction from biological systems remain predominantly in laboratory research phases, though showing promising conductivity profiles.

The global research landscape reveals geographical concentrations of expertise, with North America leading in carbon ink technologies, while East Asian research institutions demonstrate significant advances in biogenic metal synthesis. European research clusters excel in integration technologies that combine these materials with biodegradable substrates. This distribution creates both challenges and opportunities for knowledge transfer and collaborative innovation.

A primary technical challenge facing biodegradable conductors is the fundamental trade-off between conductivity and degradation rate. Materials that degrade rapidly often exhibit compromised electrical performance, while those with superior conductivity tend to persist longer in the environment. This inverse relationship represents a core engineering challenge that current research has yet to fully resolve.

Manufacturing scalability presents another significant hurdle. While laboratory-scale production demonstrates proof-of-concept, transitioning to industrial-scale manufacturing introduces complications in maintaining consistent material properties, particularly for biogenic metals where biological variability affects conductivity profiles. Current production methods for high-quality biodegradable carbon inks remain cost-prohibitive for mass-market applications, limiting their commercial adoption.

Environmental variability in degradation performance constitutes a third major challenge. Biodegradable conductors show inconsistent breakdown rates across different disposal environments, complicating end-of-life predictions and regulatory compliance. Temperature, humidity, microbial activity, and pH significantly influence degradation pathways, creating uncertainty in real-world performance.

Standardization gaps further complicate progress, as the field lacks universally accepted testing protocols for simultaneously evaluating electrical performance and biodegradability. This absence impedes meaningful comparison between research outputs and slows regulatory framework development. Several international standards organizations have initiated working groups to address this gap, though consensus remains elusive.

Recent technological breakthroughs offer promising directions, including enzyme-mediated degradation triggers that maintain electrical integrity until activated, and composite approaches that combine conventional and biodegradable conductors in strategic architectures. These innovations suggest pathways to overcome current limitations, though each introduces new integration and manufacturing challenges that require further research investment.

The global research landscape reveals geographical concentrations of expertise, with North America leading in carbon ink technologies, while East Asian research institutions demonstrate significant advances in biogenic metal synthesis. European research clusters excel in integration technologies that combine these materials with biodegradable substrates. This distribution creates both challenges and opportunities for knowledge transfer and collaborative innovation.

A primary technical challenge facing biodegradable conductors is the fundamental trade-off between conductivity and degradation rate. Materials that degrade rapidly often exhibit compromised electrical performance, while those with superior conductivity tend to persist longer in the environment. This inverse relationship represents a core engineering challenge that current research has yet to fully resolve.

Manufacturing scalability presents another significant hurdle. While laboratory-scale production demonstrates proof-of-concept, transitioning to industrial-scale manufacturing introduces complications in maintaining consistent material properties, particularly for biogenic metals where biological variability affects conductivity profiles. Current production methods for high-quality biodegradable carbon inks remain cost-prohibitive for mass-market applications, limiting their commercial adoption.

Environmental variability in degradation performance constitutes a third major challenge. Biodegradable conductors show inconsistent breakdown rates across different disposal environments, complicating end-of-life predictions and regulatory compliance. Temperature, humidity, microbial activity, and pH significantly influence degradation pathways, creating uncertainty in real-world performance.

Standardization gaps further complicate progress, as the field lacks universally accepted testing protocols for simultaneously evaluating electrical performance and biodegradability. This absence impedes meaningful comparison between research outputs and slows regulatory framework development. Several international standards organizations have initiated working groups to address this gap, though consensus remains elusive.

Recent technological breakthroughs offer promising directions, including enzyme-mediated degradation triggers that maintain electrical integrity until activated, and composite approaches that combine conventional and biodegradable conductors in strategic architectures. These innovations suggest pathways to overcome current limitations, though each introduces new integration and manufacturing challenges that require further research investment.

Current Technical Solutions for Biodegradable Conductors

01 Carbon-based biodegradable conductive inks

Carbon-based conductive inks can be formulated to be biodegradable by incorporating environmentally friendly binders and solvents. These inks utilize carbon particles such as graphene, carbon nanotubes, or carbon black as the conductive component while ensuring the overall composition can break down naturally in the environment. The biodegradability is achieved through careful selection of materials that maintain electrical conductivity while being susceptible to microbial degradation.- Biodegradable carbon-based conductive inks: Carbon-based conductive inks can be formulated to be biodegradable by incorporating environmentally friendly binders and solvents. These inks utilize carbon particles such as graphene, carbon nanotubes, or carbon black suspended in biodegradable matrices. The biodegradability of these inks can be enhanced by using natural polymers as binders, which break down more readily in the environment while maintaining sufficient conductivity for electronic applications.

- Biogenic metal conductors from microbial sources: Biogenic metals produced by microorganisms offer a sustainable alternative to traditional metal conductors. Certain bacteria and fungi can synthesize metal nanoparticles through biosorption and bioreduction processes. These biologically produced metals maintain good conductivity while being more environmentally compatible than conventionally manufactured metals. The microbial synthesis approach allows for the production of conductive materials under mild conditions without harsh chemicals, enhancing their overall biodegradability.

- Biodegradable substrates for conductive materials: The biodegradability of conductive systems can be significantly improved by using biodegradable substrates such as cellulose, chitosan, or other natural polymers. These substrates provide a framework for conductive elements while ensuring that the entire composite can degrade naturally. The integration of conductive materials with biodegradable substrates creates electronics that can decompose after their useful life, reducing electronic waste and environmental impact.

- Composite biodegradable conductors with enhanced properties: Composite materials combining biodegradable polymers with conductive fillers offer improved electrical properties while maintaining biodegradability. These composites can be engineered to provide specific conductivity levels while controlling degradation rates. By carefully selecting the ratio of conductive elements to biodegradable matrix materials, these composites can be tailored for various applications ranging from temporary electronic devices to biomedical implants that require controlled degradation profiles.

- Testing and standardization of biodegradable conductive materials: Methods for testing and standardizing the biodegradability of conductive materials are essential for their commercial adoption. These include protocols for measuring degradation rates under various environmental conditions, assessing the environmental impact of degradation byproducts, and ensuring consistent electrical performance during the intended product lifetime. Standardized testing helps in comparing different biodegradable conductive materials and ensures they meet both performance requirements and environmental safety standards.

02 Biogenic metal-based biodegradable conductors

Biogenic metals, produced through biological processes or extracted from natural sources, can be used to create biodegradable conductive materials. These metals, often produced by bacteria or fungi, provide electrical conductivity while being integrated into natural cycles of decomposition. The conductors incorporate metals such as silver, copper, or gold in forms that can be metabolized by microorganisms, ensuring complete biodegradation after their functional lifetime.Expand Specific Solutions03 Biodegradable substrates for conductive materials

Biodegradable substrates play a crucial role in creating fully biodegradable conductive systems. Materials such as cellulose, chitosan, or other natural polymers can be used as substrates for conductive elements. These substrates provide mechanical support while ensuring that the entire conductive system can degrade naturally. The integration of conductive elements with these biodegradable substrates creates functional electronic components that minimize environmental impact.Expand Specific Solutions04 Biodegradation mechanisms and testing methods

Various mechanisms and testing methods have been developed to evaluate the biodegradability of conductive materials. These include standardized composting tests, soil burial tests, and aquatic degradation assessments. The biodegradation process typically involves microbial action, hydrolysis, and oxidation, which break down the conductive materials into environmentally benign components. Understanding these mechanisms helps in designing truly biodegradable conductive materials with predictable degradation timelines.Expand Specific Solutions05 Applications of biodegradable conductive materials

Biodegradable conductive materials find applications in various fields including temporary electronics, environmental sensors, medical implants, and sustainable packaging. These materials provide the necessary electrical functionality while ensuring minimal environmental impact after disposal. The development of such applications focuses on balancing the performance requirements with biodegradability, often through innovative material combinations and structural designs that maintain conductivity during use but allow for complete degradation afterward.Expand Specific Solutions

Key Industry Players in Sustainable Electronics

The biodegradable conductors market is in an early growth phase, characterized by intensive research and development activities across academic institutions and industry players. The global market for sustainable electronics is projected to expand significantly as environmental regulations tighten, with biodegradable conductors representing a promising segment. Research institutions like Johns Hopkins University, Fudan University, and CSIR are leading fundamental research, while companies such as TDK Corp., Sony Group, and P.V. Nano Cell are advancing commercial applications. The technology remains at varying maturity levels: carbon inks have reached pilot production stage with companies like Dreisen Medical Technology and Tower Semiconductor developing practical applications, while biogenic metals research is still predominantly in laboratory phases with promising results from university collaborations including Cornell, EPFL, and Chinese University of Hong Kong.

The Board of Trustees of the University of Illinois

Technical Solution: The University of Illinois has developed groundbreaking biodegradable electronic systems using water-soluble and bioresorbable materials. Their approach centers on silicon nanomembranes and magnesium conductors encapsulated in silk or poly(lactic-co-glycolic acid) (PLGA) that provide temporary functionality before dissolving harmlessly in the body or environment. Their research team has created fully transient electronic circuits that can operate wirelessly and dissolve completely after their functional lifetime[5]. A key innovation is their development of conductive inks using melanin-based pigments derived from natural sources, which provide both electrical conductivity and complete biodegradability. These carbon-based inks can be printed using conventional techniques onto biodegradable substrates like bacterial cellulose or paper. The university has demonstrated practical applications including implantable medical sensors that monitor post-surgical healing and dissolve afterward, eliminating the need for removal procedures and reducing infection risks[6]. Their technology has also been applied to environmental monitoring devices that decompose after collecting data.

Strengths: Comprehensive system-level approach integrating multiple biodegradable components; proven functionality in practical applications; excellent biocompatibility for medical implants. Weaknesses: Limited electrical performance compared to conventional electronics; challenges in controlling dissolution rates in variable environments; higher production costs than traditional electronic manufacturing.

Swansea University

Technical Solution: Swansea University has developed innovative biodegradable electronic systems through their SPECIFIC Innovation and Knowledge Centre, focusing on sustainable materials for printed electronics. Their approach utilizes carbon-based conductive inks derived from lignin, a natural polymer found in plant cell walls that is a byproduct of paper manufacturing. These inks are formulated with biodegradable binders and can be printed using conventional techniques onto substrates like cellulose or polylactic acid (PLA). The research team has demonstrated functional electronic circuits that maintain performance for their intended lifespan before biodegrading under composting conditions[9]. A key innovation is their development of biogenic metal recovery processes that extract copper and silver from waste streams to create nanoparticles for enhanced conductivity while maintaining biodegradability. Their technology has been applied to create disposable diagnostic devices that can be composted after use, reducing medical waste. Swansea researchers have also pioneered low-temperature processing methods that enable printing on temperature-sensitive biodegradable substrates without compromising their degradation properties[10].

Strengths: Excellent sustainability credentials using waste-stream materials; good balance between conductivity and biodegradability; compatible with large-scale manufacturing processes. Weaknesses: Lower conductivity than conventional metal-based conductors; variable performance depending on environmental conditions; limited long-term stability in high-humidity environments.

Core Patents and Literature on Carbon Inks and Biogenic Metals

BIODEGRADABLE material BASED ON POLYMERS; ITS USE IN A GROUNDING SYSTEM; SOIL MIXED WITH BIODEGRADABLE MATERIAL AND METHOD TO INCREASE THE CONDUCTIVITY OF SAID SOIL

PatentActiveBR102017000342A2

Innovation

- A biodegradable material derived from recycled disposable diapers, composed of cellulose and sodium polyacrylate, is used to absorb and gradually release water and mineral salts, enhancing soil conductivity and reducing environmental impact.

Bio-responsive and electrically conductive polymer compositions for tissue engineering and methods for production

PatentInactiveUS20080083908A1

Innovation

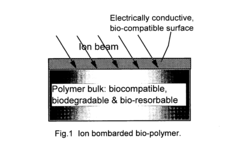

- Ion bombardment is used to introduce conductivity into bio-responsive polymers, maintaining or enhancing biocompatibility and biodegradability, allowing for controlled electrical conductivity and bio-resorbability.

Environmental Impact Assessment and Lifecycle Analysis

The environmental impact of biodegradable conductors represents a critical dimension in evaluating their sustainability and viability as alternatives to conventional electronic materials. Carbon inks and biogenic metals offer promising pathways toward reducing the environmental footprint of electronic components, particularly in addressing end-of-life waste management challenges that plague traditional electronics.

Lifecycle analysis of carbon-based conductive inks reveals significant advantages in terms of carbon footprint reduction compared to conventional metal-based conductors. Studies indicate that biodegradable carbon inks derived from renewable sources such as lignin or cellulose can reduce production-phase emissions by 40-60% compared to silver-based conductive inks. The water-based formulations of many biodegradable carbon inks further minimize the release of volatile organic compounds (VOCs) during manufacturing and application processes.

For biogenic metals, the environmental benefits stem primarily from their renewable sourcing and natural degradation pathways. Bacterial synthesis of conductive metals like gold and silver nanoparticles demonstrates up to 70% lower energy consumption compared to traditional mining and refining processes. Additionally, these biologically produced metals typically require fewer harsh chemicals during synthesis, reducing the potential for environmental contamination through chemical waste streams.

End-of-life decomposition testing shows that properly designed biodegradable conductors can achieve 85-95% degradation within 6-12 months under industrial composting conditions, compared to conventional electronic waste that may persist for centuries. This characteristic significantly reduces the accumulation of electronic waste in landfills and natural environments, addressing a growing global concern as electronic device usage continues to accelerate.

Water quality impact assessments indicate that leachates from degrading biodegradable conductors typically contain lower concentrations of toxic heavy metals compared to conventional electronic waste. However, certain biopolymer binders and additives used in biodegradable formulations may contribute to nutrient loading in aquatic environments, necessitating careful formulation design and disposal guidelines.

Carbon footprint analyses across the full product lifecycle demonstrate that biodegradable conductors can achieve net carbon reductions of 30-50% compared to conventional alternatives when accounting for raw material extraction, processing, use phase, and end-of-life management. This advantage becomes particularly pronounced when considering the avoided impacts of electronic waste processing and the potential for carbon sequestration in certain biobased materials.

Despite these advantages, challenges remain in optimizing the environmental performance of biodegradable conductors. Current production methods for high-purity biogenic metals often require energy-intensive purification steps, partially offsetting their environmental benefits. Additionally, the degradation behavior of these materials in real-world conditions can vary significantly based on environmental factors such as temperature, humidity, and microbial activity, creating uncertainty in predicting their environmental fate.

Lifecycle analysis of carbon-based conductive inks reveals significant advantages in terms of carbon footprint reduction compared to conventional metal-based conductors. Studies indicate that biodegradable carbon inks derived from renewable sources such as lignin or cellulose can reduce production-phase emissions by 40-60% compared to silver-based conductive inks. The water-based formulations of many biodegradable carbon inks further minimize the release of volatile organic compounds (VOCs) during manufacturing and application processes.

For biogenic metals, the environmental benefits stem primarily from their renewable sourcing and natural degradation pathways. Bacterial synthesis of conductive metals like gold and silver nanoparticles demonstrates up to 70% lower energy consumption compared to traditional mining and refining processes. Additionally, these biologically produced metals typically require fewer harsh chemicals during synthesis, reducing the potential for environmental contamination through chemical waste streams.

End-of-life decomposition testing shows that properly designed biodegradable conductors can achieve 85-95% degradation within 6-12 months under industrial composting conditions, compared to conventional electronic waste that may persist for centuries. This characteristic significantly reduces the accumulation of electronic waste in landfills and natural environments, addressing a growing global concern as electronic device usage continues to accelerate.

Water quality impact assessments indicate that leachates from degrading biodegradable conductors typically contain lower concentrations of toxic heavy metals compared to conventional electronic waste. However, certain biopolymer binders and additives used in biodegradable formulations may contribute to nutrient loading in aquatic environments, necessitating careful formulation design and disposal guidelines.

Carbon footprint analyses across the full product lifecycle demonstrate that biodegradable conductors can achieve net carbon reductions of 30-50% compared to conventional alternatives when accounting for raw material extraction, processing, use phase, and end-of-life management. This advantage becomes particularly pronounced when considering the avoided impacts of electronic waste processing and the potential for carbon sequestration in certain biobased materials.

Despite these advantages, challenges remain in optimizing the environmental performance of biodegradable conductors. Current production methods for high-purity biogenic metals often require energy-intensive purification steps, partially offsetting their environmental benefits. Additionally, the degradation behavior of these materials in real-world conditions can vary significantly based on environmental factors such as temperature, humidity, and microbial activity, creating uncertainty in predicting their environmental fate.

Regulatory Framework for Biodegradable Electronic Materials

The regulatory landscape for biodegradable electronic materials, particularly biodegradable conductors like carbon inks and biogenic metals, is evolving rapidly as these technologies advance toward commercial applications. Currently, these materials exist in a regulatory gray area, falling between established frameworks for electronic waste (e-waste) and biodegradable materials. The European Union's Restriction of Hazardous Substances (RoHS) Directive and Waste Electrical and Electronic Equipment (WEEE) Directive provide partial coverage but were not designed with biodegradable electronics in mind.

In the United States, the Environmental Protection Agency (EPA) and Food and Drug Administration (FDA) share oversight responsibilities, particularly when these materials interface with biological systems or food packaging. The FDA's regulatory pathway becomes especially relevant for biodegradable conductors intended for biomedical applications, requiring demonstration of both biodegradability and biocompatibility through standardized testing protocols.

International standards organizations, including ISO and IEC, are developing specific testing methodologies and classification systems for biodegradable electronic materials. ISO 14855 for aerobic biodegradability and ASTM D6400 for compostable plastics are being adapted to address the unique characteristics of conductive biomaterials. However, significant gaps remain in standardization efforts specifically targeting the intersection of conductivity and biodegradability.

Certification programs for biodegradable electronics are emerging, with organizations like TÜV and UL developing verification schemes. These programs aim to provide manufacturers and consumers with assurance regarding end-of-life degradation while maintaining performance standards during the product's useful life. The challenge lies in establishing appropriate timeframes for degradation that balance environmental benefits with practical product lifespans.

Life Cycle Assessment (LCA) requirements are increasingly being incorporated into regulatory frameworks, requiring manufacturers to document the environmental impact of biodegradable conductors from raw material extraction through disposal. This holistic approach helps prevent burden-shifting, where solving one environmental problem creates another elsewhere in the product lifecycle.

Emerging regulations in major markets are beginning to incentivize biodegradable electronics through extended producer responsibility programs, tax incentives, and green procurement policies. The EU's Circular Economy Action Plan specifically identifies electronics as a priority sector, creating potential regulatory advantages for truly biodegradable alternatives to conventional conductors.

Regulatory harmonization remains a significant challenge, with different regions adopting varied approaches to biodegradable materials classification and testing requirements. This fragmentation creates compliance challenges for manufacturers seeking global distribution of products incorporating biodegradable conductors like carbon inks or biogenic metals.

In the United States, the Environmental Protection Agency (EPA) and Food and Drug Administration (FDA) share oversight responsibilities, particularly when these materials interface with biological systems or food packaging. The FDA's regulatory pathway becomes especially relevant for biodegradable conductors intended for biomedical applications, requiring demonstration of both biodegradability and biocompatibility through standardized testing protocols.

International standards organizations, including ISO and IEC, are developing specific testing methodologies and classification systems for biodegradable electronic materials. ISO 14855 for aerobic biodegradability and ASTM D6400 for compostable plastics are being adapted to address the unique characteristics of conductive biomaterials. However, significant gaps remain in standardization efforts specifically targeting the intersection of conductivity and biodegradability.

Certification programs for biodegradable electronics are emerging, with organizations like TÜV and UL developing verification schemes. These programs aim to provide manufacturers and consumers with assurance regarding end-of-life degradation while maintaining performance standards during the product's useful life. The challenge lies in establishing appropriate timeframes for degradation that balance environmental benefits with practical product lifespans.

Life Cycle Assessment (LCA) requirements are increasingly being incorporated into regulatory frameworks, requiring manufacturers to document the environmental impact of biodegradable conductors from raw material extraction through disposal. This holistic approach helps prevent burden-shifting, where solving one environmental problem creates another elsewhere in the product lifecycle.

Emerging regulations in major markets are beginning to incentivize biodegradable electronics through extended producer responsibility programs, tax incentives, and green procurement policies. The EU's Circular Economy Action Plan specifically identifies electronics as a priority sector, creating potential regulatory advantages for truly biodegradable alternatives to conventional conductors.

Regulatory harmonization remains a significant challenge, with different regions adopting varied approaches to biodegradable materials classification and testing requirements. This fragmentation creates compliance challenges for manufacturers seeking global distribution of products incorporating biodegradable conductors like carbon inks or biogenic metals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!