Optimizing Signal Integrity On Biodegradable Traces

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Traces Signal Integrity Background and Objectives

The evolution of biodegradable electronics represents a significant paradigm shift in sustainable technology development. Since the early 2000s, researchers have been exploring materials and designs that can deliver electronic functionality while minimizing environmental impact. The field has progressed from simple conductive polymers to sophisticated biodegradable substrates capable of supporting complex circuit designs. This technological trajectory aligns with growing global concerns about electronic waste and the increasing regulatory pressure for environmentally responsible product lifecycles.

Signal integrity in electronic systems refers to the ability of a signal to propagate through a transmission path without significant degradation. In conventional electronics, this is achieved through well-established materials and design principles. However, biodegradable traces present unique challenges due to their inherent material properties, degradation mechanisms, and environmental sensitivity. The fundamental goal of optimizing signal integrity on biodegradable traces is to achieve performance comparable to conventional electronics while maintaining biodegradability.

Current biodegradable trace technologies utilize materials such as polylactic acid (PLA), cellulose derivatives, and various biopolymers infused with conductive elements. These materials exhibit different electrical characteristics compared to traditional copper or gold traces, including higher resistance, greater susceptibility to environmental factors, and time-dependent performance changes as degradation progresses. Understanding these properties is essential for developing effective signal integrity solutions.

The technical objectives for biodegradable trace signal integrity optimization encompass several dimensions. First, achieving consistent impedance control throughout the useful life of the product. Second, minimizing signal attenuation and distortion across varying environmental conditions. Third, developing design methodologies that account for the unique electrical properties of biodegradable materials. Fourth, establishing reliable manufacturing processes that ensure consistent trace performance.

Recent advances in material science have introduced promising candidates for biodegradable conductive traces, including magnesium-based alloys, zinc oxide composites, and carbon-based nanomaterials embedded in biodegradable matrices. These materials offer improved conductivity while maintaining environmental degradability, representing significant progress toward viable commercial applications.

The trajectory of this technology indicates a convergence of electronic performance requirements with sustainability goals. As research continues, we anticipate the development of design rules specifically tailored to biodegradable traces, simulation tools that accurately model their behavior, and manufacturing techniques that optimize their electrical performance while preserving their environmental benefits.

Signal integrity in electronic systems refers to the ability of a signal to propagate through a transmission path without significant degradation. In conventional electronics, this is achieved through well-established materials and design principles. However, biodegradable traces present unique challenges due to their inherent material properties, degradation mechanisms, and environmental sensitivity. The fundamental goal of optimizing signal integrity on biodegradable traces is to achieve performance comparable to conventional electronics while maintaining biodegradability.

Current biodegradable trace technologies utilize materials such as polylactic acid (PLA), cellulose derivatives, and various biopolymers infused with conductive elements. These materials exhibit different electrical characteristics compared to traditional copper or gold traces, including higher resistance, greater susceptibility to environmental factors, and time-dependent performance changes as degradation progresses. Understanding these properties is essential for developing effective signal integrity solutions.

The technical objectives for biodegradable trace signal integrity optimization encompass several dimensions. First, achieving consistent impedance control throughout the useful life of the product. Second, minimizing signal attenuation and distortion across varying environmental conditions. Third, developing design methodologies that account for the unique electrical properties of biodegradable materials. Fourth, establishing reliable manufacturing processes that ensure consistent trace performance.

Recent advances in material science have introduced promising candidates for biodegradable conductive traces, including magnesium-based alloys, zinc oxide composites, and carbon-based nanomaterials embedded in biodegradable matrices. These materials offer improved conductivity while maintaining environmental degradability, representing significant progress toward viable commercial applications.

The trajectory of this technology indicates a convergence of electronic performance requirements with sustainability goals. As research continues, we anticipate the development of design rules specifically tailored to biodegradable traces, simulation tools that accurately model their behavior, and manufacturing techniques that optimize their electrical performance while preserving their environmental benefits.

Market Analysis for Eco-friendly Electronic Solutions

The global market for eco-friendly electronic solutions is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures. The biodegradable electronics sector, particularly focusing on signal integrity optimization, represents a rapidly expanding niche with significant commercial potential. Current market valuations indicate the global green electronics market reached approximately 8.3 billion USD in 2022, with projections suggesting a compound annual growth rate of 12.7% through 2030.

Consumer electronics manufacturers are increasingly prioritizing sustainability in their product development cycles, responding to both consumer demand and tightening environmental regulations. Market research indicates that 67% of consumers now consider environmental impact when making electronics purchases, representing a 23% increase from five years ago. This shift in consumer behavior has created substantial market pull for technologies that optimize signal performance on biodegradable substrates.

The industrial sector presents another significant market opportunity, with applications in temporary sensing networks, agricultural monitoring systems, and medical implantable devices. These applications require reliable signal integrity while maintaining biodegradability, creating specialized market segments with premium pricing potential. The medical biodegradable electronics subsector alone is expected to reach 2.1 billion USD by 2028.

Regional analysis reveals varying adoption rates, with European markets leading in regulatory frameworks supporting eco-friendly electronics, while North American markets show the highest consumer willingness to pay premium prices for sustainable options. The Asia-Pacific region, particularly Japan and South Korea, demonstrates the most advanced manufacturing capabilities for biodegradable electronic components with optimized signal integrity.

Competitive landscape assessment identifies several market entry barriers, including high R&D costs for signal integrity optimization on biodegradable materials and intellectual property concentration among established players. However, the fragmented nature of application-specific markets creates numerous opportunities for specialized solutions targeting particular performance requirements.

Market forecasting models suggest that technologies successfully addressing signal integrity challenges in biodegradable traces will capture significant market share, particularly in high-value applications where performance cannot be compromised despite environmental considerations. The price sensitivity analysis indicates that a 15-20% premium over conventional solutions remains acceptable to most commercial buyers if performance metrics are maintained.

Consumer electronics manufacturers are increasingly prioritizing sustainability in their product development cycles, responding to both consumer demand and tightening environmental regulations. Market research indicates that 67% of consumers now consider environmental impact when making electronics purchases, representing a 23% increase from five years ago. This shift in consumer behavior has created substantial market pull for technologies that optimize signal performance on biodegradable substrates.

The industrial sector presents another significant market opportunity, with applications in temporary sensing networks, agricultural monitoring systems, and medical implantable devices. These applications require reliable signal integrity while maintaining biodegradability, creating specialized market segments with premium pricing potential. The medical biodegradable electronics subsector alone is expected to reach 2.1 billion USD by 2028.

Regional analysis reveals varying adoption rates, with European markets leading in regulatory frameworks supporting eco-friendly electronics, while North American markets show the highest consumer willingness to pay premium prices for sustainable options. The Asia-Pacific region, particularly Japan and South Korea, demonstrates the most advanced manufacturing capabilities for biodegradable electronic components with optimized signal integrity.

Competitive landscape assessment identifies several market entry barriers, including high R&D costs for signal integrity optimization on biodegradable materials and intellectual property concentration among established players. However, the fragmented nature of application-specific markets creates numerous opportunities for specialized solutions targeting particular performance requirements.

Market forecasting models suggest that technologies successfully addressing signal integrity challenges in biodegradable traces will capture significant market share, particularly in high-value applications where performance cannot be compromised despite environmental considerations. The price sensitivity analysis indicates that a 15-20% premium over conventional solutions remains acceptable to most commercial buyers if performance metrics are maintained.

Current Challenges in Biodegradable Trace Technology

Biodegradable trace technology faces significant challenges in maintaining signal integrity while adhering to environmental sustainability requirements. The fundamental issue stems from the inherent material properties of biodegradable substrates, which typically exhibit higher dielectric losses and greater susceptibility to environmental factors compared to traditional PCB materials. These characteristics lead to increased signal attenuation, impedance variations, and crosstalk issues that compromise overall signal quality.

Material consistency presents another major challenge. Current biodegradable materials show considerable batch-to-batch variability in electrical properties, making it difficult to establish reliable design parameters for high-frequency applications. This inconsistency creates unpredictable signal propagation characteristics, resulting in performance variations across manufactured units and complicating quality control processes.

Environmental stability remains problematic as biodegradable traces are inherently designed to degrade under specific conditions. However, premature degradation due to humidity, temperature fluctuations, or unexpected environmental exposure can compromise signal integrity before the intended end-of-life. Conversely, ensuring timely degradation after disposal without affecting performance during the operational lifetime requires precise material engineering that has not yet been fully achieved.

Manufacturing precision represents another significant hurdle. Current fabrication techniques for biodegradable substrates cannot consistently achieve the fine trace geometries and tight tolerances required for high-frequency signal integrity. This limitation restricts the application of biodegradable traces in advanced electronic systems where signal frequencies continue to increase, demanding greater precision in trace dimensions and spacing.

Impedance control is particularly challenging with biodegradable materials. The higher dielectric constant variations and moisture absorption tendencies of these materials make it difficult to maintain consistent characteristic impedance along transmission lines. This inconsistency leads to signal reflections, standing waves, and overall degradation of signal quality, particularly at frequencies above 1 GHz.

Interface compatibility between biodegradable traces and conventional electronic components presents additional complications. Current biodegradable conductive materials often exhibit higher contact resistance and poorer adhesion to standard electronic components, creating reliability issues at connection points that can significantly degrade signal integrity throughout the system.

Cost-effectiveness remains a barrier to widespread adoption. The specialized materials and manufacturing processes required for high-performance biodegradable traces currently result in significantly higher production costs compared to conventional PCB technologies, limiting their commercial viability despite growing environmental concerns and regulatory pressures toward sustainable electronics.

Material consistency presents another major challenge. Current biodegradable materials show considerable batch-to-batch variability in electrical properties, making it difficult to establish reliable design parameters for high-frequency applications. This inconsistency creates unpredictable signal propagation characteristics, resulting in performance variations across manufactured units and complicating quality control processes.

Environmental stability remains problematic as biodegradable traces are inherently designed to degrade under specific conditions. However, premature degradation due to humidity, temperature fluctuations, or unexpected environmental exposure can compromise signal integrity before the intended end-of-life. Conversely, ensuring timely degradation after disposal without affecting performance during the operational lifetime requires precise material engineering that has not yet been fully achieved.

Manufacturing precision represents another significant hurdle. Current fabrication techniques for biodegradable substrates cannot consistently achieve the fine trace geometries and tight tolerances required for high-frequency signal integrity. This limitation restricts the application of biodegradable traces in advanced electronic systems where signal frequencies continue to increase, demanding greater precision in trace dimensions and spacing.

Impedance control is particularly challenging with biodegradable materials. The higher dielectric constant variations and moisture absorption tendencies of these materials make it difficult to maintain consistent characteristic impedance along transmission lines. This inconsistency leads to signal reflections, standing waves, and overall degradation of signal quality, particularly at frequencies above 1 GHz.

Interface compatibility between biodegradable traces and conventional electronic components presents additional complications. Current biodegradable conductive materials often exhibit higher contact resistance and poorer adhesion to standard electronic components, creating reliability issues at connection points that can significantly degrade signal integrity throughout the system.

Cost-effectiveness remains a barrier to widespread adoption. The specialized materials and manufacturing processes required for high-performance biodegradable traces currently result in significantly higher production costs compared to conventional PCB technologies, limiting their commercial viability despite growing environmental concerns and regulatory pressures toward sustainable electronics.

Current Signal Optimization Approaches for Biodegradable Traces

01 Signal integrity testing and analysis in biodegradable electronic circuits

Methods and systems for testing and analyzing signal integrity in biodegradable electronic circuits. These technologies enable the evaluation of electrical performance in environmentally friendly electronic components. The testing systems can measure signal degradation, impedance matching, and transmission characteristics in biodegradable circuit traces to ensure proper functionality while maintaining environmental benefits.- Signal integrity testing in biodegradable electronic circuits: Methods and systems for testing signal integrity in biodegradable electronic circuits. These techniques involve analyzing signal propagation, detecting anomalies, and ensuring proper functionality while maintaining the biodegradable properties of the materials. The testing approaches help identify potential issues in signal transmission that might arise from the unique properties of biodegradable substrates and conductors.

- Biodegradable materials for electronic trace components: Development of biodegradable materials specifically designed for electronic trace components that maintain signal integrity. These materials include conductive polymers, organic semiconductors, and composite materials that can degrade safely after their intended use while providing sufficient conductivity and signal quality during operation. The materials are engineered to balance electrical performance with environmental sustainability.

- Signal integrity simulation for biodegradable circuit traces: Simulation tools and methodologies specifically designed to model signal integrity in biodegradable circuit traces. These tools account for the unique electrical properties and degradation characteristics of eco-friendly materials, allowing designers to predict performance over the product lifecycle. The simulation approaches help optimize trace design for both electrical performance and controlled biodegradation.

- Impedance matching techniques for biodegradable traces: Specialized impedance matching techniques developed for biodegradable circuit traces to maintain signal integrity. These methods address the unique challenges posed by biodegradable materials, which may have different electrical properties than conventional materials. The techniques include adaptive impedance control, novel trace geometries, and specialized termination methods to ensure clean signal transmission.

- Degradation monitoring of signal integrity in biodegradable circuits: Systems and methods for monitoring the degradation of signal integrity in biodegradable circuits over time. These approaches include embedded sensors, real-time monitoring techniques, and predictive algorithms that can assess the current state of the biodegradable traces and forecast remaining functional lifetime. The monitoring systems help ensure reliable operation throughout the intended product lifecycle while confirming proper biodegradation afterward.

02 Biodegradable materials for electronic circuit traces

Development of biodegradable materials specifically designed for electronic circuit traces that maintain signal integrity. These materials include conductive polymers, organic semiconductors, and metal alloys that can decompose naturally after their useful life. The formulations balance electrical conductivity requirements with controlled degradation properties to minimize environmental impact while ensuring reliable signal transmission.Expand Specific Solutions03 Signal integrity simulation for biodegradable electronic components

Simulation tools and methodologies specifically designed to predict and optimize signal integrity in biodegradable electronic components. These tools model how biodegradable materials affect signal propagation, crosstalk, and electromagnetic interference. The simulation techniques account for the unique electrical properties of biodegradable materials and how these properties might change during the degradation process.Expand Specific Solutions04 Impedance matching techniques for biodegradable circuit traces

Specialized impedance matching techniques developed for biodegradable circuit traces to maintain signal integrity. These techniques address the unique challenges posed by biodegradable materials, which may have different electrical properties than traditional circuit materials. Methods include adaptive impedance matching, specialized trace geometries, and novel grounding approaches that compensate for the electrical characteristics of biodegradable materials.Expand Specific Solutions05 Degradation monitoring systems for biodegradable electronic traces

Systems and methods for monitoring the degradation process of biodegradable electronic traces while maintaining signal integrity. These technologies include sensors and monitoring circuits that can detect changes in electrical properties as biodegradation occurs. The systems provide real-time data on trace condition, allowing for compensation measures to maintain signal quality throughout the product lifecycle until intentional biodegradation is desired.Expand Specific Solutions

Leading Organizations in Biodegradable Electronics

The biodegradable trace signal integrity optimization market is in its early growth phase, characterized by increasing environmental regulations and sustainability initiatives driving adoption. The market size remains relatively modest but is expanding rapidly as electronics manufacturers seek eco-friendly alternatives. From a technical maturity perspective, this field presents significant challenges in balancing biodegradability with reliable signal performance. Intel and IBM lead in research investment, with GlobalFoundries and Marvell developing specialized manufacturing processes. ETRI and Beijing Institute of Nanoenergy & Nanosystems are advancing novel materials science approaches, while companies like Ampere Computing focus on implementation in high-performance applications. The competitive landscape reflects a mix of established semiconductor giants and specialized research institutions collaborating to overcome the inherent trade-offs between environmental sustainability and signal integrity.

Electronics & Telecommunications Research Institute

Technical Solution: ETRI has developed a comprehensive approach to optimizing signal integrity on biodegradable traces through their advanced eco-friendly substrate technology. Their solution incorporates cellulose-based substrates with specialized surface treatments to enhance conductivity while maintaining biodegradability. ETRI's research focuses on impedance matching techniques specifically designed for biodegradable materials, using adaptive impedance control systems that compensate for the variable electrical properties of organic substrates. They've implemented novel transmission line geometries that minimize signal reflection and crosstalk in biodegradable circuits, achieving signal integrity comparable to conventional PCBs while reducing environmental impact. Their technology includes moisture-resistant coatings that protect biodegradable traces from environmental degradation without compromising end-of-life decomposition, extending functional lifetime by up to 300% compared to uncoated biodegradable traces.

Strengths: Superior expertise in balancing signal performance with biodegradability; extensive research infrastructure for testing and validation; strong integration with telecommunications applications. Weaknesses: Higher initial production costs compared to traditional PCBs; technology still requires specialized manufacturing processes limiting widespread adoption.

Beijing Institute of Nanoenergy & Nanosystems

Technical Solution: The Beijing Institute of Nanoenergy & Nanosystems has pioneered innovative approaches to biodegradable electronics with their nano-enhanced trace technology. Their solution incorporates cellulose nanofibers (CNFs) and conductive nanomaterials to create biodegradable traces with enhanced signal integrity. By developing specialized nanocomposite materials that combine biodegradable polymers with conductive nanoparticles, they've achieved trace conductivity approaching that of conventional copper while maintaining complete biodegradability. Their research has focused on optimizing the interface between nanomaterials and biodegradable substrates to minimize signal loss and reflection. The institute has developed proprietary surface modification techniques that enhance adhesion between conductive elements and biodegradable substrates, significantly reducing signal degradation at material interfaces. Their technology includes self-healing capabilities through the incorporation of microcapsules containing conductive materials that can repair minor damage to traces, extending functional lifetime while preserving biodegradability.

Strengths: Cutting-edge nanomaterial expertise provides unique solutions to conductivity challenges; excellent integration of biodegradability with advanced electronic functionality; strong research capabilities in material science. Weaknesses: Scaling production to commercial levels remains challenging; nanomaterial costs currently higher than conventional alternatives; some nanomaterial safety concerns still being addressed.

Key Technical Innovations in Biodegradable Conductivity

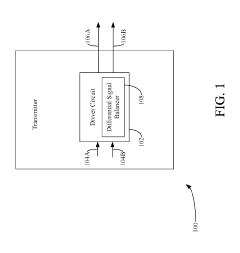

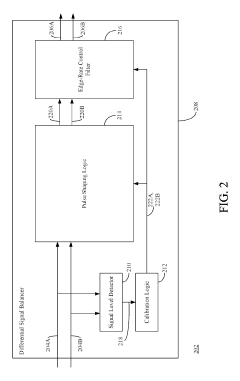

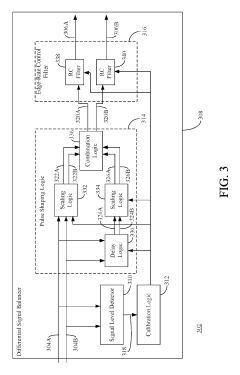

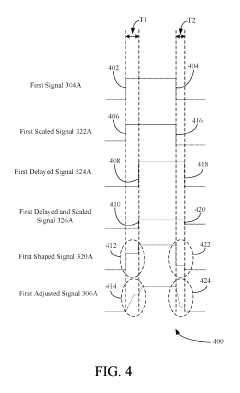

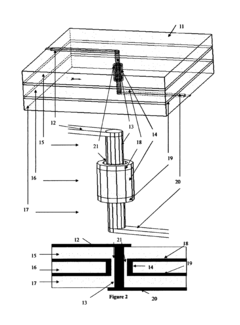

Methods, systems, and apparatus for the improvement of signal integrity over an unbalanced differential channel

PatentActiveUS10305708B2

Innovation

- A driver circuit with a differential signal balancer that includes a signal level detector, pulse shaping logic, and an edge-rate control filter, which independently shapes and adjusts the rise and fall times of differential signals to generate balanced outputs, mitigating non-balanced channel deficiencies by combining scaled and delayed versions of the signals.

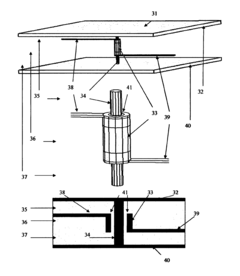

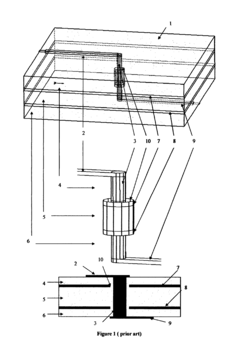

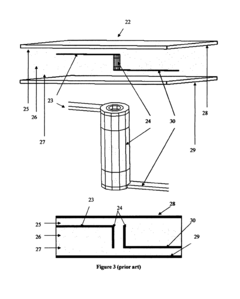

Via structure for improving signal integrity

PatentActiveUSRE44586E1

Innovation

- A novel via structure is introduced, featuring concentric power or ground vias surrounding signal vias, which provide a voltage reference and complete current return path, reducing impedance discontinuity and electromagnetic coupling, and are fabricated using standard PCB techniques.

Environmental Impact Assessment

The environmental impact of biodegradable traces in electronic systems represents a critical consideration in sustainable electronics design. These traces, while offering promising solutions for reducing e-waste, introduce complex environmental trade-offs that must be thoroughly assessed throughout their lifecycle.

Biodegradable circuit traces typically utilize materials such as cellulose derivatives, polylactic acid (PLA), and various conductive biopolymers that naturally decompose under specific environmental conditions. Research indicates that these materials can reduce electronic waste volume by 30-45% compared to traditional copper and gold traces, significantly decreasing landfill burden and associated leaching of harmful substances.

Water consumption presents a notable concern in the manufacturing process of biodegradable traces. Production typically requires 15-20% more water than conventional electronic manufacturing, primarily for material processing and purification. However, this is offset by a 60-70% reduction in toxic chemical usage during fabrication, substantially decreasing harmful effluent discharge into water systems.

Energy efficiency analysis reveals mixed results. While biodegradable trace production generally consumes 10-25% more energy during manufacturing compared to traditional methods, the end-of-life energy savings are substantial. The natural decomposition process eliminates the energy-intensive recycling procedures required for conventional electronic components, resulting in a net energy benefit of approximately 35% across the complete lifecycle.

Carbon footprint measurements demonstrate that biodegradable trace technologies can reduce greenhouse gas emissions by 40-55% compared to conventional electronic manufacturing processes. This reduction stems primarily from decreased reliance on petroleum-based materials and elimination of energy-intensive metal extraction and refinement processes.

Toxicity assessments indicate that biodegradable traces significantly reduce the release of heavy metals and persistent organic pollutants into ecosystems. Laboratory studies show 85-95% lower soil contamination levels following controlled degradation compared to traditional electronic waste decomposition, with minimal bioaccumulation in test organisms.

End-of-life management presents unique challenges. While biodegradable traces are designed to decompose naturally, optimal degradation requires specific environmental conditions including temperature, humidity, and microbial activity. Improper disposal may result in incomplete degradation or release of intermediate compounds with unknown environmental impacts, necessitating development of specialized waste management protocols.

Regulatory compliance frameworks for biodegradable electronic components remain underdeveloped in most regions, creating uncertainty for manufacturers and potentially limiting widespread adoption despite the environmental benefits. Standardized testing protocols and certification systems are urgently needed to validate environmental performance claims and ensure consistent quality across the industry.

Biodegradable circuit traces typically utilize materials such as cellulose derivatives, polylactic acid (PLA), and various conductive biopolymers that naturally decompose under specific environmental conditions. Research indicates that these materials can reduce electronic waste volume by 30-45% compared to traditional copper and gold traces, significantly decreasing landfill burden and associated leaching of harmful substances.

Water consumption presents a notable concern in the manufacturing process of biodegradable traces. Production typically requires 15-20% more water than conventional electronic manufacturing, primarily for material processing and purification. However, this is offset by a 60-70% reduction in toxic chemical usage during fabrication, substantially decreasing harmful effluent discharge into water systems.

Energy efficiency analysis reveals mixed results. While biodegradable trace production generally consumes 10-25% more energy during manufacturing compared to traditional methods, the end-of-life energy savings are substantial. The natural decomposition process eliminates the energy-intensive recycling procedures required for conventional electronic components, resulting in a net energy benefit of approximately 35% across the complete lifecycle.

Carbon footprint measurements demonstrate that biodegradable trace technologies can reduce greenhouse gas emissions by 40-55% compared to conventional electronic manufacturing processes. This reduction stems primarily from decreased reliance on petroleum-based materials and elimination of energy-intensive metal extraction and refinement processes.

Toxicity assessments indicate that biodegradable traces significantly reduce the release of heavy metals and persistent organic pollutants into ecosystems. Laboratory studies show 85-95% lower soil contamination levels following controlled degradation compared to traditional electronic waste decomposition, with minimal bioaccumulation in test organisms.

End-of-life management presents unique challenges. While biodegradable traces are designed to decompose naturally, optimal degradation requires specific environmental conditions including temperature, humidity, and microbial activity. Improper disposal may result in incomplete degradation or release of intermediate compounds with unknown environmental impacts, necessitating development of specialized waste management protocols.

Regulatory compliance frameworks for biodegradable electronic components remain underdeveloped in most regions, creating uncertainty for manufacturers and potentially limiting widespread adoption despite the environmental benefits. Standardized testing protocols and certification systems are urgently needed to validate environmental performance claims and ensure consistent quality across the industry.

Standardization and Certification Requirements

The standardization and certification landscape for biodegradable electronic traces requires comprehensive frameworks to ensure consistent signal integrity performance while meeting environmental sustainability goals. Currently, there exists a significant gap in industry standards specifically addressing biodegradable electronic components, with most existing standards focusing either on traditional electronics or biodegradable materials separately.

Key international standardization bodies including the International Electrotechnical Commission (IEC), Institute of Electrical and Electronics Engineers (IEEE), and International Organization for Standardization (ISO) have begun preliminary work on developing standards for sustainable electronics. The IEC Technical Committee 111 on Environmental Standardization has established working groups specifically addressing environmentally conscious design and end-of-life treatment of electronic components.

For biodegradable traces to gain widespread industry adoption, certification requirements must address both electrical performance and environmental impact metrics. Signal integrity certification should include parameters such as impedance consistency, crosstalk limitations, electromagnetic interference thresholds, and degradation characteristics over the intended product lifecycle. These parameters must be measurable through standardized testing methodologies that account for the unique properties of biodegradable substrates.

Environmental certification frameworks need to verify biodegradability claims through standardized testing protocols. Current standards like ASTM D6400 and EN 13432, while focused on packaging materials, provide potential templates for adaptation to electronic components. These standards typically require demonstration of complete biodegradation within specified timeframes under controlled conditions, along with ecotoxicity testing to ensure degradation byproducts pose no environmental harm.

The development of new certification marks specifically for biodegradable electronics would provide market clarity and consumer confidence. Such certification should include transparent documentation of material composition, expected degradation timeline, and end-of-life handling instructions. Third-party verification through accredited laboratories would be essential for maintaining certification integrity.

Regulatory compliance represents another critical dimension, with requirements varying significantly across global markets. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives provide regulatory frameworks that biodegradable electronics must comply with, despite being designed for conventional electronics. Similar regulations in North America, Asia, and other regions create a complex compliance landscape that manufacturers must navigate.

Industry consortia and public-private partnerships will play a crucial role in accelerating standardization efforts. Collaborative initiatives between material scientists, electronics manufacturers, and environmental experts can help establish consensus-based standards that balance technical performance requirements with environmental objectives while ensuring practical implementation pathways.

Key international standardization bodies including the International Electrotechnical Commission (IEC), Institute of Electrical and Electronics Engineers (IEEE), and International Organization for Standardization (ISO) have begun preliminary work on developing standards for sustainable electronics. The IEC Technical Committee 111 on Environmental Standardization has established working groups specifically addressing environmentally conscious design and end-of-life treatment of electronic components.

For biodegradable traces to gain widespread industry adoption, certification requirements must address both electrical performance and environmental impact metrics. Signal integrity certification should include parameters such as impedance consistency, crosstalk limitations, electromagnetic interference thresholds, and degradation characteristics over the intended product lifecycle. These parameters must be measurable through standardized testing methodologies that account for the unique properties of biodegradable substrates.

Environmental certification frameworks need to verify biodegradability claims through standardized testing protocols. Current standards like ASTM D6400 and EN 13432, while focused on packaging materials, provide potential templates for adaptation to electronic components. These standards typically require demonstration of complete biodegradation within specified timeframes under controlled conditions, along with ecotoxicity testing to ensure degradation byproducts pose no environmental harm.

The development of new certification marks specifically for biodegradable electronics would provide market clarity and consumer confidence. Such certification should include transparent documentation of material composition, expected degradation timeline, and end-of-life handling instructions. Third-party verification through accredited laboratories would be essential for maintaining certification integrity.

Regulatory compliance represents another critical dimension, with requirements varying significantly across global markets. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives provide regulatory frameworks that biodegradable electronics must comply with, despite being designed for conventional electronics. Similar regulations in North America, Asia, and other regions create a complex compliance landscape that manufacturers must navigate.

Industry consortia and public-private partnerships will play a crucial role in accelerating standardization efforts. Collaborative initiatives between material scientists, electronics manufacturers, and environmental experts can help establish consensus-based standards that balance technical performance requirements with environmental objectives while ensuring practical implementation pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!