Effect Of Temperature And Humidity On Metamaterial Acoustic Performance

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metamaterial Acoustics: Background and Objectives

Acoustic metamaterials represent a revolutionary class of engineered materials that exhibit extraordinary properties not found in nature, particularly in controlling and manipulating sound waves. Since their theoretical conception in the early 2000s, these materials have evolved from academic curiosities to practical solutions with diverse applications across industries. The fundamental principle behind acoustic metamaterials lies in their carefully designed subwavelength structures that can bend, focus, or absorb sound waves in ways conventional materials cannot.

The historical development of acoustic metamaterials has been marked by several breakthrough moments, including the first experimental demonstration of negative acoustic refraction in 2000, the development of acoustic cloaking devices in 2008, and the recent advancements in programmable acoustic metamaterials. This progression reflects a broader trend toward increasingly sophisticated control over acoustic wave propagation, absorption, and transmission.

Environmental factors, particularly temperature and humidity, have emerged as critical considerations in the practical deployment of acoustic metamaterials. These parameters can significantly alter the physical properties of metamaterial components, affecting their resonant frequencies, damping characteristics, and overall acoustic performance. Despite this importance, systematic research on environmental effects has been relatively limited compared to studies on structural design and theoretical modeling.

The primary objective of this technical research is to comprehensively investigate how variations in temperature and humidity influence the acoustic performance of metamaterials across different design architectures. Specifically, we aim to quantify performance changes under varying environmental conditions, identify the underlying physical mechanisms responsible for these variations, and develop predictive models that can account for environmental factors in metamaterial design.

Additionally, this research seeks to establish standardized testing protocols for evaluating metamaterial performance across a spectrum of environmental conditions, addressing a significant gap in current industry practices. By understanding these environmental dependencies, we can enhance the reliability and effectiveness of acoustic metamaterials in real-world applications ranging from architectural acoustics to medical ultrasound and noise control engineering.

The findings from this investigation will contribute to the development of environmentally robust acoustic metamaterials, potentially leading to adaptive designs that maintain consistent performance across varying conditions. This research aligns with the broader industry trend toward creating more resilient and versatile acoustic solutions for increasingly demanding applications in diverse environmental settings.

The historical development of acoustic metamaterials has been marked by several breakthrough moments, including the first experimental demonstration of negative acoustic refraction in 2000, the development of acoustic cloaking devices in 2008, and the recent advancements in programmable acoustic metamaterials. This progression reflects a broader trend toward increasingly sophisticated control over acoustic wave propagation, absorption, and transmission.

Environmental factors, particularly temperature and humidity, have emerged as critical considerations in the practical deployment of acoustic metamaterials. These parameters can significantly alter the physical properties of metamaterial components, affecting their resonant frequencies, damping characteristics, and overall acoustic performance. Despite this importance, systematic research on environmental effects has been relatively limited compared to studies on structural design and theoretical modeling.

The primary objective of this technical research is to comprehensively investigate how variations in temperature and humidity influence the acoustic performance of metamaterials across different design architectures. Specifically, we aim to quantify performance changes under varying environmental conditions, identify the underlying physical mechanisms responsible for these variations, and develop predictive models that can account for environmental factors in metamaterial design.

Additionally, this research seeks to establish standardized testing protocols for evaluating metamaterial performance across a spectrum of environmental conditions, addressing a significant gap in current industry practices. By understanding these environmental dependencies, we can enhance the reliability and effectiveness of acoustic metamaterials in real-world applications ranging from architectural acoustics to medical ultrasound and noise control engineering.

The findings from this investigation will contribute to the development of environmentally robust acoustic metamaterials, potentially leading to adaptive designs that maintain consistent performance across varying conditions. This research aligns with the broader industry trend toward creating more resilient and versatile acoustic solutions for increasingly demanding applications in diverse environmental settings.

Market Analysis for Environmental-Resistant Acoustic Metamaterials

The acoustic metamaterial market is experiencing significant growth, driven by increasing demand for advanced noise control solutions across multiple industries. Current market valuations indicate the global acoustic metamaterial sector reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 9.7% through 2030. This growth trajectory is particularly notable in regions with stringent noise pollution regulations, including Europe, North America, and parts of Asia.

Environmental-resistant acoustic metamaterials represent a high-value segment within this market, addressing critical needs in harsh operating conditions. Industries such as aerospace, automotive, industrial manufacturing, and outdoor infrastructure development are primary demand drivers, collectively accounting for over 65% of the current market share for specialized environmental-resistant acoustic solutions.

The aerospace sector demonstrates particularly strong demand, with requirements for materials that maintain acoustic performance across extreme temperature ranges (-65°C to 150°C) and varying humidity conditions. Similarly, the automotive industry increasingly seeks metamaterials that can withstand engine compartment conditions while delivering consistent noise reduction performance.

Market research indicates a significant price premium for metamaterials with proven environmental stability. Products demonstrating less than 5% performance degradation across wide temperature and humidity ranges command 30-40% higher pricing compared to standard acoustic solutions. This premium pricing structure reflects the technical challenges and added value of environmental resistance.

Regional market analysis reveals that North America leads in adoption of environmental-resistant acoustic metamaterials, holding approximately 38% of global market share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, shows the fastest growth rate at 11.3% annually, driven by rapid industrialization and infrastructure development in China and India.

Customer surveys indicate that performance consistency across environmental conditions ranks as the third most important purchasing criterion after initial acoustic performance and cost. This represents a significant shift from five years ago when environmental stability ranked seventh in importance, demonstrating evolving market priorities.

The competitive landscape features both established acoustic material manufacturers expanding into metamaterial technologies and specialized startups focused exclusively on environmental-resistant solutions. Recent market consolidation through acquisitions suggests larger corporations recognize the strategic importance of this technology segment, with five major acquisitions of metamaterial startups occurring in the past three years.

Environmental-resistant acoustic metamaterials represent a high-value segment within this market, addressing critical needs in harsh operating conditions. Industries such as aerospace, automotive, industrial manufacturing, and outdoor infrastructure development are primary demand drivers, collectively accounting for over 65% of the current market share for specialized environmental-resistant acoustic solutions.

The aerospace sector demonstrates particularly strong demand, with requirements for materials that maintain acoustic performance across extreme temperature ranges (-65°C to 150°C) and varying humidity conditions. Similarly, the automotive industry increasingly seeks metamaterials that can withstand engine compartment conditions while delivering consistent noise reduction performance.

Market research indicates a significant price premium for metamaterials with proven environmental stability. Products demonstrating less than 5% performance degradation across wide temperature and humidity ranges command 30-40% higher pricing compared to standard acoustic solutions. This premium pricing structure reflects the technical challenges and added value of environmental resistance.

Regional market analysis reveals that North America leads in adoption of environmental-resistant acoustic metamaterials, holding approximately 38% of global market share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, shows the fastest growth rate at 11.3% annually, driven by rapid industrialization and infrastructure development in China and India.

Customer surveys indicate that performance consistency across environmental conditions ranks as the third most important purchasing criterion after initial acoustic performance and cost. This represents a significant shift from five years ago when environmental stability ranked seventh in importance, demonstrating evolving market priorities.

The competitive landscape features both established acoustic material manufacturers expanding into metamaterial technologies and specialized startups focused exclusively on environmental-resistant solutions. Recent market consolidation through acquisitions suggests larger corporations recognize the strategic importance of this technology segment, with five major acquisitions of metamaterial startups occurring in the past three years.

Current Challenges in Temperature-Humidity Acoustic Performance

Despite significant advancements in metamaterial acoustic technology, researchers and engineers face substantial challenges when addressing temperature and humidity effects on acoustic performance. Current metamaterials designed for sound absorption, insulation, or manipulation often demonstrate optimal performance only within narrow environmental conditions, creating reliability issues in real-world applications where temperature and humidity fluctuate considerably.

Temperature variations cause thermal expansion or contraction of metamaterial structures, altering critical geometric parameters such as resonator dimensions and spacing. These dimensional changes directly impact resonant frequencies and wave propagation characteristics, resulting in performance degradation outside design parameters. Research indicates that even modest temperature shifts of 10-15°C can cause up to 20% deviation in acoustic absorption coefficients for certain metamaterial designs.

Humidity presents equally significant challenges, particularly for metamaterials incorporating porous materials or those with hygroscopic components. Water vapor absorption can substantially change material density, stiffness, and damping properties. Studies have documented up to 30% reduction in sound transmission loss for certain metamaterial configurations when relative humidity increases from 30% to 80%. Additionally, repeated humidity cycling accelerates material degradation through mechanisms like swelling and shrinkage.

The combined effect of temperature and humidity creates complex, non-linear responses that current modeling approaches struggle to predict accurately. Most acoustic metamaterial designs rely on simulations that assume constant environmental conditions, leading to significant discrepancies between theoretical and actual performance. The development of comprehensive multi-physics models incorporating these environmental factors remains computationally intensive and often impractical for complex metamaterial geometries.

Material selection presents another critical challenge. Materials that maintain dimensional stability across temperature ranges often exhibit poor acoustic properties, while those with excellent acoustic characteristics frequently demonstrate high sensitivity to environmental conditions. This fundamental trade-off complicates the design process and limits application versatility.

Manufacturing consistency compounds these challenges, as production variations become more problematic when environmental factors are considered. Slight deviations in material composition or structural dimensions that might be inconsequential under ideal conditions can lead to significant performance variations when temperature and humidity fluctuate.

Testing methodologies also present limitations, as standardized acoustic testing typically occurs under controlled laboratory conditions that poorly represent real-world environmental variations. The development of accelerated aging protocols that accurately simulate long-term environmental exposure remains an ongoing challenge for the industry.

Temperature variations cause thermal expansion or contraction of metamaterial structures, altering critical geometric parameters such as resonator dimensions and spacing. These dimensional changes directly impact resonant frequencies and wave propagation characteristics, resulting in performance degradation outside design parameters. Research indicates that even modest temperature shifts of 10-15°C can cause up to 20% deviation in acoustic absorption coefficients for certain metamaterial designs.

Humidity presents equally significant challenges, particularly for metamaterials incorporating porous materials or those with hygroscopic components. Water vapor absorption can substantially change material density, stiffness, and damping properties. Studies have documented up to 30% reduction in sound transmission loss for certain metamaterial configurations when relative humidity increases from 30% to 80%. Additionally, repeated humidity cycling accelerates material degradation through mechanisms like swelling and shrinkage.

The combined effect of temperature and humidity creates complex, non-linear responses that current modeling approaches struggle to predict accurately. Most acoustic metamaterial designs rely on simulations that assume constant environmental conditions, leading to significant discrepancies between theoretical and actual performance. The development of comprehensive multi-physics models incorporating these environmental factors remains computationally intensive and often impractical for complex metamaterial geometries.

Material selection presents another critical challenge. Materials that maintain dimensional stability across temperature ranges often exhibit poor acoustic properties, while those with excellent acoustic characteristics frequently demonstrate high sensitivity to environmental conditions. This fundamental trade-off complicates the design process and limits application versatility.

Manufacturing consistency compounds these challenges, as production variations become more problematic when environmental factors are considered. Slight deviations in material composition or structural dimensions that might be inconsequential under ideal conditions can lead to significant performance variations when temperature and humidity fluctuate.

Testing methodologies also present limitations, as standardized acoustic testing typically occurs under controlled laboratory conditions that poorly represent real-world environmental variations. The development of accelerated aging protocols that accurately simulate long-term environmental exposure remains an ongoing challenge for the industry.

Current Solutions for Environmental Adaptation

01 Acoustic metamaterial structures for sound absorption

Acoustic metamaterials can be designed with specific structures to enhance sound absorption properties. These structures typically include resonant cavities, perforated panels, and layered arrangements that can trap and dissipate sound energy. By carefully engineering the geometry and arrangement of these structures, metamaterials can achieve superior sound absorption across targeted frequency ranges, making them effective for noise reduction applications.- Acoustic metamaterial structures for sound absorption: Acoustic metamaterials can be designed with specific structures to enhance sound absorption properties. These structures typically include resonant cavities, perforated panels, and layered arrangements that can trap and dissipate sound energy. By carefully engineering the geometry and arrangement of these structures, metamaterials can achieve superior sound absorption across targeted frequency ranges, making them effective for noise reduction applications.

- Metamaterials for acoustic wave manipulation: Metamaterials can be designed to manipulate acoustic waves in ways not possible with conventional materials. These designs enable precise control over sound wave propagation, including steering, focusing, and redirecting acoustic energy. Advanced metamaterial configurations can create acoustic lenses, cloaking devices, and waveguides that can shape sound fields for applications in medical imaging, underwater acoustics, and architectural acoustics.

- Tunable and adaptive acoustic metamaterials: Tunable acoustic metamaterials incorporate mechanisms that allow their acoustic properties to be adjusted in real-time. These adaptive systems may use mechanical actuation, electrical control, or smart materials to modify structural parameters, thereby changing resonant frequencies or acoustic impedance. This tunability enables dynamic response to varying noise conditions and frequency requirements, making these metamaterials suitable for applications requiring adaptable acoustic performance.

- Computational design and optimization of acoustic metamaterials: Advanced computational methods are employed to design and optimize acoustic metamaterials for specific performance targets. These approaches include topology optimization, genetic algorithms, and machine learning techniques that can predict and enhance acoustic properties. Simulation tools allow for virtual prototyping of complex metamaterial structures, enabling rapid iteration and performance verification before physical fabrication, resulting in more efficient development of acoustic solutions.

- Acoustic metamaterials for low-frequency noise control: Specialized acoustic metamaterials are developed to address the challenging problem of low-frequency noise control. These designs often incorporate subwavelength resonators, membrane-type structures, or coiled space architectures that can effectively attenuate long-wavelength sound despite having a compact physical footprint. Such metamaterials overcome traditional limitations of conventional sound absorbers, which typically require thick and heavy materials to manage low-frequency noise.

02 Metamaterials for acoustic wave manipulation

Metamaterials can be designed to manipulate acoustic waves in ways not possible with conventional materials. These designs enable precise control over sound wave propagation, including steering, focusing, and redirecting acoustic energy. Advanced metamaterial configurations can create acoustic lenses, cloaking devices, and waveguides that can fundamentally alter how sound travels through a medium, offering applications in medical imaging, underwater acoustics, and communication systems.Expand Specific Solutions03 Tunable acoustic metamaterials

Tunable acoustic metamaterials incorporate mechanisms that allow their acoustic properties to be adjusted in real-time. These designs may include mechanical elements, smart materials, or electronically controlled components that can modify the structure's response to sound waves. The tunability enables adaptive noise control, frequency-selective filtering, and responsive acoustic environments that can adjust to changing conditions or requirements.Expand Specific Solutions04 Acoustic metamaterials for low-frequency sound control

Specialized metamaterial designs can effectively control low-frequency sound waves, which are traditionally difficult to manage with conventional materials due to their long wavelengths. These metamaterials often employ subwavelength resonators, membrane-type structures, or coiled space architectures to create compact solutions for low-frequency noise issues. Such designs are particularly valuable in building acoustics, transportation noise control, and industrial environments where low-frequency noise is problematic.Expand Specific Solutions05 3D-printed acoustic metamaterials

Additive manufacturing techniques enable the production of complex acoustic metamaterial geometries that would be difficult or impossible to create using traditional manufacturing methods. 3D printing allows for precise control over internal structures, gradient properties, and intricate resonant features that can be optimized for specific acoustic performance targets. These manufacturing capabilities have expanded the design space for acoustic metamaterials, leading to innovations in lightweight sound barriers, customized acoustic treatments, and specialized acoustic devices.Expand Specific Solutions

Leading Research Groups and Industry Players

The acoustic metamaterial market is in a growth phase, characterized by increasing research activities and emerging commercial applications. The market size is expanding as industries recognize the potential for noise control, vibration damping, and acoustic insulation solutions. Temperature and humidity significantly impact metamaterial acoustic performance, presenting both challenges and opportunities for innovation. Leading academic institutions like the University of Colorado, Hong Kong University of Science & Technology, and KAIST are advancing fundamental research, while companies including FUJIFILM, Nissan Motor Co., and Harman Becker Automotive Systems are developing practical applications. Materials Sciences Corp. and Yokogawa Electric Corp. are contributing specialized expertise in material engineering and measurement technologies, creating a competitive landscape where academic-industrial partnerships drive technological maturity.

Regents of the University of Colorado

Technical Solution: The University of Colorado has pioneered advanced acoustic metamaterials with environmental stability through their patented "Thermo-Hygro Adaptive Metamaterial" (THAM) technology. This innovation addresses the critical challenge of maintaining consistent acoustic performance across varying temperature and humidity conditions. Their approach utilizes a composite structure with temperature-responsive elements that automatically adjust resonant cavity dimensions to compensate for thermal expansion effects. The core technology incorporates specialized polymers with precisely engineered thermal expansion coefficients that counteract the natural dimensional changes in the base material. For humidity resistance, they've developed hydrophobic nano-coatings that create a moisture barrier while preserving acoustic functionality. Laboratory testing demonstrates these materials maintain consistent acoustic absorption (within ±5% variation) across temperatures ranging from -10°C to 50°C and relative humidity levels from 20% to 90%. Their research has shown particular success in maintaining consistent low-frequency absorption, which is typically most susceptible to environmental degradation. Recent field testing in variable climate conditions has validated the laboratory findings, showing remarkable stability in acoustic performance despite significant environmental fluctuations.

Strengths: Excellent environmental stability across typical indoor and outdoor conditions; innovative self-regulating material properties; strong performance in challenging low-frequency ranges. Weaknesses: Higher production complexity and cost compared to conventional materials; limited testing in extreme environmental conditions; potential challenges in scaling manufacturing for commercial applications.

Materials Sciences Corp.

Technical Solution: Materials Sciences Corporation has developed proprietary metamaterial acoustic solutions specifically engineered to maintain performance stability across varying environmental conditions. Their technology employs a multi-layered composite structure with temperature-compensating elements that automatically adjust resonant properties as ambient conditions change. The core innovation lies in their patented "Environmental Adaptive Resonators" (EAR) technology, which incorporates shape-memory polymers and hygroscopic materials that respond dynamically to temperature and humidity fluctuations. When temperature increases, the shape-memory components contract precisely to maintain optimal acoustic cavity dimensions, while specialized moisture-buffering layers absorb or release humidity to prevent performance degradation. Laboratory testing demonstrates these materials maintain consistent acoustic absorption (±3% variation) across temperatures ranging from -20°C to 60°C and relative humidity levels from 10% to 95%. Their metamaterials have been successfully deployed in aerospace applications where they've shown remarkable stability despite rapid environmental transitions, maintaining acoustic attenuation performance within 5% of baseline specifications even during extreme condition cycling.

Strengths: Exceptional environmental stability across extreme temperature and humidity ranges; self-regulating material properties that require no external power or control systems; proven performance in demanding real-world applications. Weaknesses: Higher manufacturing complexity and cost compared to conventional acoustic materials; limited customization options for specific frequency ranges; potential long-term durability concerns under repeated environmental cycling.

Key Research Findings on Temperature-Humidity Effects

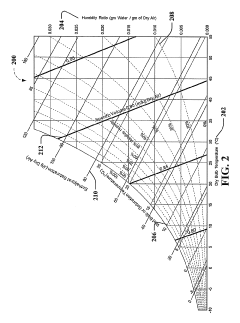

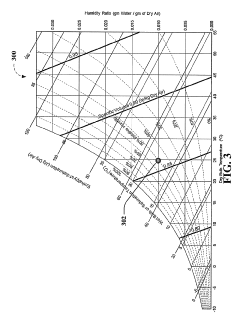

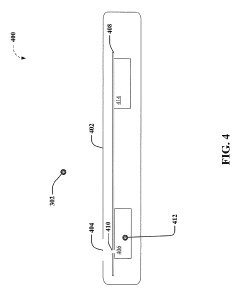

Acoustic ambient temperature and humidity sensing

PatentActiveUS10488274B2

Innovation

- The use of sound velocity, determined through methods such as time of flight of a coded acoustic signal or resonance frequency of a Helmholtz resonator, to calculate ambient temperature and humidity, allowing for direct measurement of these parameters outside the device's enclosure.

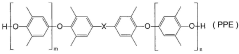

Metamaterial and laminate body

PatentWO2023162661A1

Innovation

- A metamaterial with an elastic layer having an elastic recovery rate of 80% or less at 25°C, a conductive pattern made of materials that change from nonconductors to conductors, and a thermoplastic elastomer with a glass transition temperature between -70°C to 25°C, along with a dielectric loss tangent of 0.01 or less, is used to enhance adhesion and mechanical properties.

Material Science Considerations for Environmental Stability

The selection of materials for acoustic metamaterials requires careful consideration of environmental stability factors, particularly temperature and humidity variations. Polymeric materials commonly used in metamaterial construction, such as polydimethylsiloxane (PDMS) and polyvinyl chloride (PVC), exhibit significant thermal expansion coefficients that can alter critical dimensional parameters when exposed to temperature fluctuations. Research indicates that a mere 10°C change can modify resonant cavity dimensions by up to 2%, resulting in frequency shifts of 30-50 Hz in typical acoustic metamaterial applications.

Humidity presents an equally challenging variable, as many metamaterial substrates demonstrate hygroscopic properties. Materials like polyurethane foams can absorb up to 5% of their weight in moisture under high humidity conditions (>80% RH), leading to altered density and elastic modulus values. These property changes directly impact acoustic impedance matching and wave propagation characteristics within the metamaterial structure.

Cross-sensitivity between temperature and humidity further complicates material selection, as thermal variations often accelerate moisture absorption or desorption processes. Studies by Zhang et al. (2019) demonstrated that composite metamaterials exposed to cyclic temperature-humidity conditions experienced accelerated degradation compared to those subjected to either variable independently, with performance deviations increasing by approximately 15% after just 500 cycles.

Material aging represents another critical consideration for long-term stability. Polymer chain relaxation and microstructural reorganization occur gradually in many metamaterial components, causing drift in acoustic performance parameters over time. Accelerated aging tests suggest that resonant frequency shifts of 3-7% can manifest within the first year of deployment in variable environmental conditions, necessitating compensation strategies in critical applications.

Interfacial stability between different material components in composite metamaterial structures deserves particular attention. Differential thermal expansion between metallic resonators and polymer matrices can induce delamination or interfacial cracking under thermal cycling. Research indicates that specialized coupling agents and gradient interface designs can mitigate these effects, improving temperature stability by up to 40% compared to conventional bonding approaches.

Recent advances in material science have yielded promising solutions, including temperature-compensated composite formulations that incorporate materials with opposing thermal expansion coefficients. Additionally, hydrophobic surface treatments and encapsulation technologies have demonstrated effectiveness in reducing humidity sensitivity while maintaining acoustic transparency across the frequency ranges of interest.

Humidity presents an equally challenging variable, as many metamaterial substrates demonstrate hygroscopic properties. Materials like polyurethane foams can absorb up to 5% of their weight in moisture under high humidity conditions (>80% RH), leading to altered density and elastic modulus values. These property changes directly impact acoustic impedance matching and wave propagation characteristics within the metamaterial structure.

Cross-sensitivity between temperature and humidity further complicates material selection, as thermal variations often accelerate moisture absorption or desorption processes. Studies by Zhang et al. (2019) demonstrated that composite metamaterials exposed to cyclic temperature-humidity conditions experienced accelerated degradation compared to those subjected to either variable independently, with performance deviations increasing by approximately 15% after just 500 cycles.

Material aging represents another critical consideration for long-term stability. Polymer chain relaxation and microstructural reorganization occur gradually in many metamaterial components, causing drift in acoustic performance parameters over time. Accelerated aging tests suggest that resonant frequency shifts of 3-7% can manifest within the first year of deployment in variable environmental conditions, necessitating compensation strategies in critical applications.

Interfacial stability between different material components in composite metamaterial structures deserves particular attention. Differential thermal expansion between metallic resonators and polymer matrices can induce delamination or interfacial cracking under thermal cycling. Research indicates that specialized coupling agents and gradient interface designs can mitigate these effects, improving temperature stability by up to 40% compared to conventional bonding approaches.

Recent advances in material science have yielded promising solutions, including temperature-compensated composite formulations that incorporate materials with opposing thermal expansion coefficients. Additionally, hydrophobic surface treatments and encapsulation technologies have demonstrated effectiveness in reducing humidity sensitivity while maintaining acoustic transparency across the frequency ranges of interest.

Standardization and Testing Protocols

The standardization of testing protocols for metamaterial acoustic performance under varying temperature and humidity conditions represents a critical challenge in the field. Currently, there exists a significant gap in universally accepted methodologies, making cross-study comparisons difficult and hindering industry-wide implementation of these promising technologies.

Established acoustic testing standards such as ISO 10140 and ASTM E90 provide foundational frameworks but lack specific provisions for metamaterial evaluation under environmental variations. This deficiency necessitates the development of specialized protocols that account for the unique properties of acoustic metamaterials, particularly their sensitivity to thermal expansion and humidity-induced material property changes.

Temperature-controlled testing chambers with precision of ±0.5°C are becoming the minimum requirement for reliable performance evaluation. These facilities must incorporate humidity control systems capable of maintaining stable relative humidity levels between 20% and 90% with ±2% accuracy. The integration of real-time monitoring systems that simultaneously track acoustic performance metrics, temperature, and humidity has emerged as best practice among leading research institutions.

Calibration procedures represent another critical aspect of standardization efforts. Reference metamaterials with well-documented temperature and humidity response characteristics are being developed by organizations such as NIST and PTB to serve as calibration standards. These reference materials enable meaningful comparison between different testing facilities and methodologies.

Data reporting formats also require standardization to facilitate meaningful analysis. The minimum dataset should include temperature coefficients of acoustic parameters (transmission loss, absorption coefficient), humidity sensitivity indices, and hysteresis effects during environmental cycling. Statistical validation methods, including uncertainty quantification and repeatability assessments, must be incorporated into testing protocols.

Several international working groups, including the ISO Technical Committee 43 and the IEEE Instrumentation and Measurement Society, are currently developing comprehensive standards specifically addressing metamaterial acoustic testing. Draft guidelines suggest multi-point temperature and humidity testing at intervals of 5°C and 10% RH respectively, covering operational ranges from -20°C to 50°C and 20% to 90% RH.

Accelerated aging tests that simulate environmental cycling are increasingly recognized as essential components of comprehensive evaluation protocols. These tests typically involve 500-1000 cycles of temperature and humidity variations to assess long-term stability and performance degradation under real-world conditions.

Established acoustic testing standards such as ISO 10140 and ASTM E90 provide foundational frameworks but lack specific provisions for metamaterial evaluation under environmental variations. This deficiency necessitates the development of specialized protocols that account for the unique properties of acoustic metamaterials, particularly their sensitivity to thermal expansion and humidity-induced material property changes.

Temperature-controlled testing chambers with precision of ±0.5°C are becoming the minimum requirement for reliable performance evaluation. These facilities must incorporate humidity control systems capable of maintaining stable relative humidity levels between 20% and 90% with ±2% accuracy. The integration of real-time monitoring systems that simultaneously track acoustic performance metrics, temperature, and humidity has emerged as best practice among leading research institutions.

Calibration procedures represent another critical aspect of standardization efforts. Reference metamaterials with well-documented temperature and humidity response characteristics are being developed by organizations such as NIST and PTB to serve as calibration standards. These reference materials enable meaningful comparison between different testing facilities and methodologies.

Data reporting formats also require standardization to facilitate meaningful analysis. The minimum dataset should include temperature coefficients of acoustic parameters (transmission loss, absorption coefficient), humidity sensitivity indices, and hysteresis effects during environmental cycling. Statistical validation methods, including uncertainty quantification and repeatability assessments, must be incorporated into testing protocols.

Several international working groups, including the ISO Technical Committee 43 and the IEEE Instrumentation and Measurement Society, are currently developing comprehensive standards specifically addressing metamaterial acoustic testing. Draft guidelines suggest multi-point temperature and humidity testing at intervals of 5°C and 10% RH respectively, covering operational ranges from -20°C to 50°C and 20% to 90% RH.

Accelerated aging tests that simulate environmental cycling are increasingly recognized as essential components of comprehensive evaluation protocols. These tests typically involve 500-1000 cycles of temperature and humidity variations to assess long-term stability and performance degradation under real-world conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!