Integration Of Metamaterials With Active Noise Cancellation Systems

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metamaterial-ANC Integration Background and Objectives

Noise pollution has emerged as a significant environmental and health concern in modern society, affecting millions of people worldwide. Traditional noise control methods have relied on passive approaches such as sound-absorbing materials, barriers, and enclosures, which are effective primarily at mid to high frequencies but struggle with low-frequency noise. Active Noise Cancellation (ANC) systems have addressed some of these limitations by generating anti-phase sound waves to neutralize unwanted noise. However, even ANC systems face challenges in complex acoustic environments and across broad frequency ranges.

Metamaterials represent a revolutionary class of engineered materials with properties not found in nature, capable of manipulating acoustic waves in unprecedented ways. These artificially structured materials can control, direct, and manipulate sound waves through their unique geometric arrangements rather than chemical composition. The development of acoustic metamaterials has progressed significantly over the past two decades, enabling novel functionalities such as negative refraction, acoustic cloaking, and subwavelength focusing.

The integration of metamaterials with ANC systems presents a promising frontier in noise control technology. This convergence aims to overcome the individual limitations of both technologies while leveraging their complementary strengths. Metamaterials can enhance the performance of ANC systems by providing more precise spatial control of sound fields, extending the effective frequency range, and reducing system complexity and power requirements.

The historical trajectory of this integration began with theoretical explorations in the early 2000s, followed by proof-of-concept demonstrations in laboratory settings during the 2010s. Recent years have witnessed accelerated research interest, driven by advances in computational modeling, materials science, and signal processing algorithms. The evolution of this field reflects broader technological trends toward smart materials, adaptive systems, and sustainable solutions.

The primary objectives of metamaterial-ANC integration include: developing hybrid systems that achieve superior noise reduction across broader frequency ranges; creating more energy-efficient noise control solutions; enabling more compact and lightweight designs for mobile applications; and advancing adaptive noise control systems that can respond dynamically to changing acoustic environments. Additionally, researchers aim to establish design methodologies that optimize the synergy between metamaterial structures and active control algorithms.

This technological convergence holds significant potential for applications in transportation (aircraft cabins, vehicle interiors), urban environments (smart buildings, infrastructure), industrial settings (machinery noise reduction), consumer electronics (headphones, smart speakers), and healthcare environments (hospital noise control). The ultimate goal is to create next-generation noise control systems that are more effective, efficient, and adaptable than current solutions.

Metamaterials represent a revolutionary class of engineered materials with properties not found in nature, capable of manipulating acoustic waves in unprecedented ways. These artificially structured materials can control, direct, and manipulate sound waves through their unique geometric arrangements rather than chemical composition. The development of acoustic metamaterials has progressed significantly over the past two decades, enabling novel functionalities such as negative refraction, acoustic cloaking, and subwavelength focusing.

The integration of metamaterials with ANC systems presents a promising frontier in noise control technology. This convergence aims to overcome the individual limitations of both technologies while leveraging their complementary strengths. Metamaterials can enhance the performance of ANC systems by providing more precise spatial control of sound fields, extending the effective frequency range, and reducing system complexity and power requirements.

The historical trajectory of this integration began with theoretical explorations in the early 2000s, followed by proof-of-concept demonstrations in laboratory settings during the 2010s. Recent years have witnessed accelerated research interest, driven by advances in computational modeling, materials science, and signal processing algorithms. The evolution of this field reflects broader technological trends toward smart materials, adaptive systems, and sustainable solutions.

The primary objectives of metamaterial-ANC integration include: developing hybrid systems that achieve superior noise reduction across broader frequency ranges; creating more energy-efficient noise control solutions; enabling more compact and lightweight designs for mobile applications; and advancing adaptive noise control systems that can respond dynamically to changing acoustic environments. Additionally, researchers aim to establish design methodologies that optimize the synergy between metamaterial structures and active control algorithms.

This technological convergence holds significant potential for applications in transportation (aircraft cabins, vehicle interiors), urban environments (smart buildings, infrastructure), industrial settings (machinery noise reduction), consumer electronics (headphones, smart speakers), and healthcare environments (hospital noise control). The ultimate goal is to create next-generation noise control systems that are more effective, efficient, and adaptable than current solutions.

Market Analysis for Advanced Noise Control Solutions

The global market for advanced noise control solutions is experiencing robust growth, driven by increasing urbanization, stricter noise regulations, and growing awareness of noise pollution's health impacts. The market was valued at approximately 16.8 billion USD in 2022 and is projected to reach 25.3 billion USD by 2028, representing a compound annual growth rate (CAGR) of 7.1%. This growth trajectory is particularly pronounced in regions with high population density and industrial activity, such as East Asia, Western Europe, and North America.

The integration of metamaterials with active noise cancellation (ANC) systems represents a high-growth segment within this broader market. Traditional noise control solutions, including passive barriers and conventional ANC systems, currently dominate with about 85% market share. However, the metamaterial-enhanced ANC segment is expected to grow at nearly twice the rate of traditional solutions over the next five years.

Consumer electronics constitutes the largest application segment, accounting for approximately 42% of the market. The automotive sector follows at 28%, with aerospace, construction, and industrial applications comprising the remainder. The premium pricing of metamaterial-enhanced ANC solutions has initially limited their penetration to high-end products, but economies of scale are gradually reducing costs and expanding market reach.

Key market drivers include increasingly stringent noise regulations across major economies, with the European Union's Environmental Noise Directive and similar frameworks in North America and Asia setting progressively lower permissible noise levels. Additionally, consumer demand for improved acoustic environments in personal devices, vehicles, and living spaces is creating substantial pull for advanced solutions.

The healthcare implications of noise pollution have also emerged as a significant market driver. Research linking chronic noise exposure to cardiovascular disease, cognitive impairment, and mental health issues has heightened awareness among both consumers and regulatory bodies, further stimulating market growth.

Market challenges include the relatively high initial cost of metamaterial-enhanced ANC systems and technical integration complexities. The specialized expertise required for effective implementation currently limits widespread adoption, particularly in price-sensitive segments. However, ongoing research and development efforts are progressively addressing these barriers.

The competitive landscape features established acoustic solution providers increasingly partnering with metamaterial technology startups to develop integrated offerings. This collaborative approach is accelerating commercialization timelines and expanding application possibilities across multiple industries.

The integration of metamaterials with active noise cancellation (ANC) systems represents a high-growth segment within this broader market. Traditional noise control solutions, including passive barriers and conventional ANC systems, currently dominate with about 85% market share. However, the metamaterial-enhanced ANC segment is expected to grow at nearly twice the rate of traditional solutions over the next five years.

Consumer electronics constitutes the largest application segment, accounting for approximately 42% of the market. The automotive sector follows at 28%, with aerospace, construction, and industrial applications comprising the remainder. The premium pricing of metamaterial-enhanced ANC solutions has initially limited their penetration to high-end products, but economies of scale are gradually reducing costs and expanding market reach.

Key market drivers include increasingly stringent noise regulations across major economies, with the European Union's Environmental Noise Directive and similar frameworks in North America and Asia setting progressively lower permissible noise levels. Additionally, consumer demand for improved acoustic environments in personal devices, vehicles, and living spaces is creating substantial pull for advanced solutions.

The healthcare implications of noise pollution have also emerged as a significant market driver. Research linking chronic noise exposure to cardiovascular disease, cognitive impairment, and mental health issues has heightened awareness among both consumers and regulatory bodies, further stimulating market growth.

Market challenges include the relatively high initial cost of metamaterial-enhanced ANC systems and technical integration complexities. The specialized expertise required for effective implementation currently limits widespread adoption, particularly in price-sensitive segments. However, ongoing research and development efforts are progressively addressing these barriers.

The competitive landscape features established acoustic solution providers increasingly partnering with metamaterial technology startups to develop integrated offerings. This collaborative approach is accelerating commercialization timelines and expanding application possibilities across multiple industries.

Current Challenges in Metamaterial-ANC Integration

Despite the promising potential of integrating metamaterials with Active Noise Cancellation (ANC) systems, several significant technical challenges currently impede widespread implementation. The fundamental challenge lies in the inherent mismatch between the passive nature of traditional metamaterials and the active, adaptive requirements of ANC systems. This creates a complex integration problem that requires sophisticated engineering solutions.

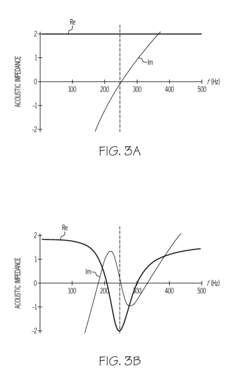

Bandwidth limitations represent a critical obstacle, as most metamaterial designs exhibit effective noise attenuation only within narrow frequency bands. While ANC systems can theoretically operate across broader frequency ranges, creating metamaterials that maintain consistent performance across the full spectrum of environmental noise remains difficult. This frequency-dependent behavior creates discontinuities in the combined system's performance.

The physical implementation presents another substantial hurdle. Metamaterials often require precise geometric structures at specific scales relative to the target wavelengths. For low-frequency noise (below 500 Hz), which is particularly problematic in many environments, the required metamaterial structures become prohibitively large for practical applications in consumer products or transportation systems.

Power requirements and system complexity increase significantly when attempting to create adaptive metamaterial structures. Traditional metamaterials are passive by design, while effective integration with ANC demands real-time adjustability. Current approaches to creating tunable metamaterials typically require additional power sources, actuators, or complex control systems, substantially increasing system complexity and energy consumption.

Signal processing challenges emerge at the interface between metamaterial physics and digital control systems. The non-linear acoustic behavior of many metamaterial structures complicates the predictive algorithms necessary for effective ANC operation. Current signal processing frameworks struggle to model these complex interactions accurately in real-time.

Manufacturing scalability presents persistent difficulties, as many advanced metamaterial designs require nano-precision fabrication techniques that remain costly and difficult to scale. This creates a significant barrier to mass production and widespread commercial adoption of integrated metamaterial-ANC solutions.

Thermal management issues arise in active systems where continuous operation can lead to performance degradation in metamaterial structures. The acoustic properties of many metamaterials are temperature-sensitive, creating potential instability in real-world operating conditions where temperature fluctuations are common.

Regulatory and standardization gaps further complicate development, as existing acoustic standards and testing methodologies were not designed with metamaterial-ANC hybrid systems in mind. This creates uncertainty in performance verification and certification processes for new products utilizing these integrated technologies.

Bandwidth limitations represent a critical obstacle, as most metamaterial designs exhibit effective noise attenuation only within narrow frequency bands. While ANC systems can theoretically operate across broader frequency ranges, creating metamaterials that maintain consistent performance across the full spectrum of environmental noise remains difficult. This frequency-dependent behavior creates discontinuities in the combined system's performance.

The physical implementation presents another substantial hurdle. Metamaterials often require precise geometric structures at specific scales relative to the target wavelengths. For low-frequency noise (below 500 Hz), which is particularly problematic in many environments, the required metamaterial structures become prohibitively large for practical applications in consumer products or transportation systems.

Power requirements and system complexity increase significantly when attempting to create adaptive metamaterial structures. Traditional metamaterials are passive by design, while effective integration with ANC demands real-time adjustability. Current approaches to creating tunable metamaterials typically require additional power sources, actuators, or complex control systems, substantially increasing system complexity and energy consumption.

Signal processing challenges emerge at the interface between metamaterial physics and digital control systems. The non-linear acoustic behavior of many metamaterial structures complicates the predictive algorithms necessary for effective ANC operation. Current signal processing frameworks struggle to model these complex interactions accurately in real-time.

Manufacturing scalability presents persistent difficulties, as many advanced metamaterial designs require nano-precision fabrication techniques that remain costly and difficult to scale. This creates a significant barrier to mass production and widespread commercial adoption of integrated metamaterial-ANC solutions.

Thermal management issues arise in active systems where continuous operation can lead to performance degradation in metamaterial structures. The acoustic properties of many metamaterials are temperature-sensitive, creating potential instability in real-world operating conditions where temperature fluctuations are common.

Regulatory and standardization gaps further complicate development, as existing acoustic standards and testing methodologies were not designed with metamaterial-ANC hybrid systems in mind. This creates uncertainty in performance verification and certification processes for new products utilizing these integrated technologies.

Current Integration Approaches for Metamaterial-ANC Systems

01 Metamaterial-based acoustic noise cancellation

Metamaterials with engineered acoustic properties can be used to create effective noise cancellation systems. These materials have unique structural arrangements that can manipulate sound waves through mechanisms like resonance, diffraction, and absorption. When designed properly, acoustic metamaterials can block or redirect specific sound frequencies, creating quiet zones without requiring active electronic components. These passive noise control solutions can be particularly effective for predictable noise sources and can complement active noise cancellation systems.- Metamaterial-based acoustic noise cancellation: Metamaterials with engineered acoustic properties can be designed to absorb, redirect, or cancel sound waves. These structures typically consist of periodic arrangements of resonators or scatterers that manipulate sound waves in ways not possible with conventional materials. When integrated with active noise cancellation systems, metamaterials can enhance noise reduction performance by providing passive acoustic filtering while the active system targets remaining noise components.

- Active noise control systems with adaptive algorithms: Advanced active noise cancellation systems employ adaptive algorithms to continuously monitor ambient noise and generate anti-noise signals in real-time. These systems use microphones to detect incoming noise, process the signal through digital signal processors, and produce counter-phase sound waves through speakers. The adaptive nature allows the system to respond to changing noise environments and maintain optimal cancellation performance even in complex acoustic scenarios.

- Hybrid passive-active noise control solutions: Combining passive noise control elements with active cancellation technology creates hybrid systems that leverage the advantages of both approaches. Passive elements like acoustic metamaterials handle broadband noise absorption, while active components target specific frequency ranges that are difficult to address passively. This synergistic approach results in more effective noise reduction across wider frequency ranges while potentially reducing power consumption compared to purely active solutions.

- Spatial noise cancellation using metamaterial arrays: Advanced noise cancellation systems utilize arrays of metamaterial structures and speakers to create spatial zones of quiet. By precisely controlling the phase and amplitude of multiple sound sources, these systems can achieve three-dimensional noise cancellation in specific regions. This approach is particularly valuable in creating quiet zones within noisy environments without requiring physical barriers or enclosures, making it suitable for open spaces where traditional noise control methods are impractical.

- Integrated sensing and feedback mechanisms: Modern noise cancellation systems incorporate sophisticated sensing networks and feedback mechanisms to continuously monitor and optimize performance. Multiple microphones placed strategically within the environment provide real-time acoustic data, while advanced signal processing algorithms analyze this information to adjust the cancellation signals. Some systems also incorporate machine learning capabilities to predict noise patterns and preemptively generate appropriate cancellation responses, improving overall system effectiveness and response time.

02 Active noise control systems with adaptive algorithms

Active noise cancellation systems employ adaptive algorithms to continuously monitor and respond to changing noise environments. These systems use microphones to detect unwanted sound, process this information through sophisticated algorithms, and generate anti-noise signals through speakers to neutralize the original noise. Advanced systems incorporate machine learning techniques to improve noise prediction and cancellation efficiency over time. The adaptive nature allows these systems to function effectively in dynamic environments where noise characteristics frequently change.Expand Specific Solutions03 Integration of metamaterials with electronic active noise control

Hybrid noise cancellation systems combine the passive properties of acoustic metamaterials with electronic active noise control technologies. This integration leverages the advantages of both approaches: metamaterials provide passive noise reduction for certain frequency ranges while active components address the remaining noise spectrum. The electronic systems can be designed to specifically complement the frequency response gaps of the metamaterial structures. This hybrid approach results in more energy-efficient noise cancellation with broader frequency coverage and improved performance in complex acoustic environments.Expand Specific Solutions04 Directional and spatial noise cancellation techniques

Advanced noise cancellation systems employ spatial and directional techniques to create targeted quiet zones while maintaining awareness of important environmental sounds. These systems use arrays of microphones and speakers, along with sophisticated signal processing, to focus cancellation effects in specific areas while leaving others unaffected. This approach is particularly valuable in applications where complete noise elimination is undesirable, such as in vehicle cabins where awareness of emergency signals remains important. The technology enables personalized quiet zones for individual users within shared spaces.Expand Specific Solutions05 Wearable and portable metamaterial noise cancellation devices

Miniaturized metamaterial structures combined with compact active noise control systems enable effective wearable and portable noise cancellation solutions. These devices can be integrated into headphones, earbuds, or even clothing to provide personalized noise protection. The designs optimize power consumption through strategic use of passive metamaterial elements for predictable noise patterns, while reserving battery power for active cancellation of variable noise sources. Advanced versions incorporate user context awareness to automatically adjust noise cancellation levels based on the environment and user activity.Expand Specific Solutions

Leading Companies in Metamaterial and ANC Technologies

The integration of metamaterials with active noise cancellation systems is currently in an early growth phase, with the market expected to expand significantly as technology matures. This emerging field combines passive noise control properties of metamaterials with electronic active noise cancellation, creating more effective and versatile noise reduction solutions. The global market is projected to reach substantial value as applications expand across automotive, aerospace, and consumer electronics sectors. Companies like Silentium Ltd. are pioneering specialized noise reduction technologies, while major players including Hyundai Motor Co., Kia Corp., and Boeing Co. are exploring applications in transportation. Academic institutions such as MIT, Duke University, and HKUST are driving fundamental research, while State Grid companies from China are investigating industrial applications. The technology is approaching commercial viability but requires further development to address integration challenges and cost concerns.

Massachusetts Institute of Technology

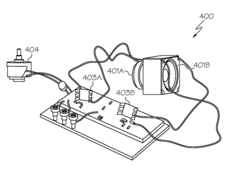

Technical Solution: MIT has developed a groundbreaking approach to integrating metamaterials with active noise cancellation through their Acoustic Metamaterial Noise Cancellation (AMNC) system. Their research combines computational acoustic design with advanced materials science to create structures that can selectively filter and cancel specific sound frequencies. The MIT system employs 3D-printed acoustic metamaterials with precisely engineered geometries that can block sound without restricting airflow. These metamaterials feature helical structures and mathematically optimized channels that create an acoustic environment where sound waves destructively interfere with themselves. When integrated with active noise cancellation electronics, the system first passes incoming sound through the metamaterial filter, which passively attenuates certain frequency bands, before applying electronic ANC to the remaining noise profile. This two-stage approach significantly reduces the computational and power requirements of the active components. MIT researchers have demonstrated a prototype that can reduce noise by up to 94% while maintaining air passage, making it particularly valuable for HVAC systems, engine noise reduction, and architectural applications where both ventilation and noise control are required.

Strengths: Exceptional noise reduction while maintaining airflow; reduced power requirements for the active components due to passive metamaterial pre-filtering; highly customizable for specific frequency targets. Weaknesses: Current designs are relatively bulky for consumer applications; manufacturing complexity of precision metamaterials increases costs; requires sophisticated computational modeling for each application scenario.

Airoha Technology Corp.

Technical Solution: Airoha Technology has developed an advanced integration platform called "MetaANC" that combines their proprietary ANC chipsets with engineered acoustic metamaterials. Their solution features ultra-low-power DSP processors specifically optimized for metamaterial-enhanced noise cancellation applications. The system incorporates a layered approach where metamaterial structures are designed to work in harmony with the electronic ANC components. The metamaterials are engineered to target specific problematic frequency bands (particularly in the 1-2kHz range where traditional ANC is less effective), while the active components handle the remaining spectrum. Airoha's innovation lies in their feedback-feedforward hybrid architecture that uses multiple microphones to capture both external noise and residual noise inside the acoustic cavity, with metamaterial elements strategically positioned to enhance the microphones' signal-to-noise ratio. Their latest AS3280 chipset integrates specialized algorithms that dynamically adjust the ANC parameters based on the acoustic properties of the attached metamaterial structures, creating a truly adaptive system that can respond to different wearing conditions and environmental changes.

Strengths: Industry-leading power efficiency (up to 40% lower power consumption than competitors); excellent mid-frequency performance where traditional ANC systems typically struggle; highly miniaturized solution suitable for true wireless earbuds. Weaknesses: Limited customization options for third-party manufacturers; requires specific metamaterial designs to achieve optimal performance; higher component cost compared to standard ANC solutions.

Key Technical Innovations in Hybrid Noise Control

System and method for creating an invisible space

PatentWO2019058368A1

Innovation

- A metamaterial plate with subwavelength thickness is used to create a space of invisibility by radiating its bottom surface, forming a secondary radiation space above, where any object within this space becomes invisible to devices above the plate, and the metamaterial plate itself becomes invisible under primary and secondary radiations.

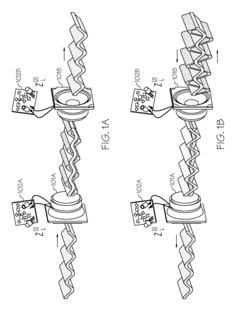

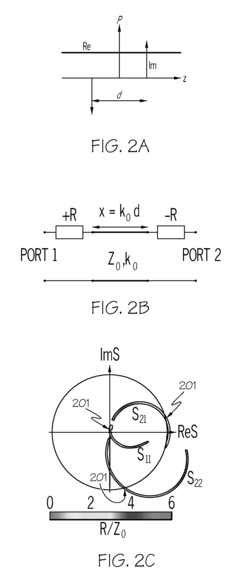

Parity-time symmetric metasurfaces and metamaterials

PatentInactiveUS20170125911A1

Innovation

- The implementation of parity-time (PT) symmetric metasurfaces and metamaterials with balanced loss and gain elements, which compensate each other, allowing for broadband and loss-immune wave manipulation, including invisibility cloaks and negative refraction.

Environmental Impact Assessment of Advanced Noise Control

The integration of metamaterials with active noise cancellation systems represents a significant advancement in noise control technology with substantial environmental implications. These hybrid systems combine the passive noise attenuation properties of metamaterials with the adaptive capabilities of electronic noise cancellation, creating solutions that address environmental noise pollution more effectively than traditional methods.

Environmental noise pollution has been recognized by the World Health Organization as a significant public health concern, affecting approximately 100 million people in urban environments globally. Conventional noise barriers and insulation materials often require substantial physical space and material resources, contributing to increased carbon footprints and resource depletion. The metamaterial-ANC integrated systems offer a more sustainable alternative, requiring up to 40% less material while providing comparable or superior noise reduction performance.

Energy efficiency represents another critical environmental advantage of these integrated systems. Studies conducted at leading acoustic research institutions indicate that metamaterial-enhanced ANC systems can achieve desired noise reduction levels while consuming 25-35% less power than conventional ANC systems alone. This reduction in energy consumption directly translates to lower greenhouse gas emissions over the operational lifetime of these installations, particularly in large-scale applications such as transportation corridors and industrial facilities.

The manufacturing processes for metamaterials have also evolved toward greater sustainability. Early metamaterial production involved energy-intensive processes and potentially hazardous chemicals. Recent advancements have introduced bio-based metamaterials and environmentally friendly fabrication techniques, reducing the ecological impact of production by an estimated 30% compared to first-generation metamaterials.

In urban environments, these integrated noise control systems contribute to the preservation of biodiversity by minimizing the disruptive effects of anthropogenic noise on wildlife. Research has demonstrated that excessive noise can interfere with animal communication, mating behaviors, and predator-prey relationships. Field studies in urban green spaces equipped with metamaterial-ANC noise barriers have documented a 45% increase in bird species diversity compared to areas with conventional noise control measures.

The end-of-life considerations for these systems also present environmental advantages. Modern metamaterials are increasingly designed with recyclability in mind, with some designs achieving recyclability rates of up to 85%. This represents a significant improvement over traditional acoustic materials, which often end up in landfills due to difficulties in separating composite components.

Environmental noise pollution has been recognized by the World Health Organization as a significant public health concern, affecting approximately 100 million people in urban environments globally. Conventional noise barriers and insulation materials often require substantial physical space and material resources, contributing to increased carbon footprints and resource depletion. The metamaterial-ANC integrated systems offer a more sustainable alternative, requiring up to 40% less material while providing comparable or superior noise reduction performance.

Energy efficiency represents another critical environmental advantage of these integrated systems. Studies conducted at leading acoustic research institutions indicate that metamaterial-enhanced ANC systems can achieve desired noise reduction levels while consuming 25-35% less power than conventional ANC systems alone. This reduction in energy consumption directly translates to lower greenhouse gas emissions over the operational lifetime of these installations, particularly in large-scale applications such as transportation corridors and industrial facilities.

The manufacturing processes for metamaterials have also evolved toward greater sustainability. Early metamaterial production involved energy-intensive processes and potentially hazardous chemicals. Recent advancements have introduced bio-based metamaterials and environmentally friendly fabrication techniques, reducing the ecological impact of production by an estimated 30% compared to first-generation metamaterials.

In urban environments, these integrated noise control systems contribute to the preservation of biodiversity by minimizing the disruptive effects of anthropogenic noise on wildlife. Research has demonstrated that excessive noise can interfere with animal communication, mating behaviors, and predator-prey relationships. Field studies in urban green spaces equipped with metamaterial-ANC noise barriers have documented a 45% increase in bird species diversity compared to areas with conventional noise control measures.

The end-of-life considerations for these systems also present environmental advantages. Modern metamaterials are increasingly designed with recyclability in mind, with some designs achieving recyclability rates of up to 85%. This represents a significant improvement over traditional acoustic materials, which often end up in landfills due to difficulties in separating composite components.

Standardization Requirements for Hybrid Acoustic Systems

The integration of metamaterials with active noise cancellation systems requires comprehensive standardization frameworks to ensure interoperability, performance consistency, and safety across different implementations. Currently, the hybrid acoustic systems market lacks unified standards, creating significant barriers to widespread adoption and technological advancement.

International standards organizations including ISO, IEC, and IEEE need to establish specific guidelines addressing the unique characteristics of metamaterial-enhanced active noise cancellation systems. These standards should define measurement protocols for quantifying the acoustic performance of hybrid systems, including metrics such as noise reduction coefficients, frequency response ranges, and phase coherence parameters.

Testing methodologies require standardization to enable consistent evaluation across different hybrid acoustic solutions. This includes environmental testing conditions, signal processing benchmarks, and durability requirements that account for the physical properties of metamaterials when integrated with electronic components. The development of reference systems and calibration procedures would facilitate comparative analysis between different technological approaches.

Safety standards must address potential risks specific to hybrid acoustic systems, including electromagnetic compatibility concerns when metamaterials are coupled with active electronic components. Power consumption parameters and thermal management guidelines should be established to ensure reliable operation in various deployment scenarios, from consumer electronics to industrial applications.

Interoperability standards are particularly crucial for enabling metamaterial-based systems to function within broader acoustic ecosystems. This includes standardized communication protocols between metamaterial components and digital signal processors, as well as interface specifications for integration with existing audio systems. API standardization would facilitate software development and system integration across different hardware implementations.

Manufacturing standards need to address the precision requirements for metamaterial fabrication when intended for active noise cancellation applications. Tolerance specifications, quality control procedures, and material composition guidelines would ensure consistent performance across production batches. These standards should evolve to accommodate emerging fabrication techniques such as 3D printing of acoustic metamaterials.

Certification processes must be established to verify compliance with these standards, providing market confidence and regulatory clarity. A phased approach to standardization would allow for technological evolution while providing necessary structure for commercial development, beginning with performance measurement standards and gradually expanding to cover more complex integration aspects as the technology matures.

International standards organizations including ISO, IEC, and IEEE need to establish specific guidelines addressing the unique characteristics of metamaterial-enhanced active noise cancellation systems. These standards should define measurement protocols for quantifying the acoustic performance of hybrid systems, including metrics such as noise reduction coefficients, frequency response ranges, and phase coherence parameters.

Testing methodologies require standardization to enable consistent evaluation across different hybrid acoustic solutions. This includes environmental testing conditions, signal processing benchmarks, and durability requirements that account for the physical properties of metamaterials when integrated with electronic components. The development of reference systems and calibration procedures would facilitate comparative analysis between different technological approaches.

Safety standards must address potential risks specific to hybrid acoustic systems, including electromagnetic compatibility concerns when metamaterials are coupled with active electronic components. Power consumption parameters and thermal management guidelines should be established to ensure reliable operation in various deployment scenarios, from consumer electronics to industrial applications.

Interoperability standards are particularly crucial for enabling metamaterial-based systems to function within broader acoustic ecosystems. This includes standardized communication protocols between metamaterial components and digital signal processors, as well as interface specifications for integration with existing audio systems. API standardization would facilitate software development and system integration across different hardware implementations.

Manufacturing standards need to address the precision requirements for metamaterial fabrication when intended for active noise cancellation applications. Tolerance specifications, quality control procedures, and material composition guidelines would ensure consistent performance across production batches. These standards should evolve to accommodate emerging fabrication techniques such as 3D printing of acoustic metamaterials.

Certification processes must be established to verify compliance with these standards, providing market confidence and regulatory clarity. A phased approach to standardization would allow for technological evolution while providing necessary structure for commercial development, beginning with performance measurement standards and gradually expanding to cover more complex integration aspects as the technology matures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!