Energy Harvesting Circuit Design For Metamaterial Vibrational Converters

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metamaterial Energy Harvesting Background and Objectives

Energy harvesting from ambient vibrations has emerged as a promising approach for powering small electronic devices, particularly in environments where traditional power sources are impractical. Metamaterials—artificially engineered structures with properties not found in nature—represent a revolutionary advancement in this field. The integration of metamaterial principles into vibrational energy harvesting systems has opened new frontiers for enhanced energy conversion efficiency and bandwidth.

The evolution of metamaterial-based energy harvesting can be traced back to the early 2000s, when researchers began exploring periodic structures for vibration control. By 2010, the first metamaterial-inspired energy harvesters appeared in scientific literature, demonstrating the potential to manipulate elastic waves for improved energy capture. The field has since experienced accelerated development, with significant breakthroughs in metamaterial designs that can harvest energy across broader frequency ranges and with greater efficiency than conventional systems.

Current technological trends indicate a shift toward multi-physics approaches, where mechanical metamaterials are combined with piezoelectric, electromagnetic, or triboelectric transduction mechanisms. This integration allows for more versatile energy harvesting solutions adaptable to various environmental conditions. Additionally, advances in micro and nanofabrication techniques have enabled the development of miniaturized metamaterial harvesters suitable for MEMS applications and IoT devices.

The primary objective of metamaterial vibrational converter research is to overcome the fundamental limitations of traditional energy harvesters, particularly their narrow operating bandwidth and low power density. By leveraging the unique properties of metamaterials, such as negative effective mass, local resonance, and topological wave guiding, researchers aim to develop energy harvesting circuits that can efficiently capture and convert ambient vibrations across a wide frequency spectrum.

Specific technical goals include designing metamaterial structures that can achieve broadband energy harvesting without sacrificing conversion efficiency, developing adaptive metamaterial systems that can self-tune to dominant environmental frequencies, and creating circuit topologies optimized for the unique characteristics of metamaterial transducers. These objectives align with the growing demand for autonomous power sources in wireless sensor networks, wearable electronics, and structural health monitoring systems.

The interdisciplinary nature of this field necessitates collaboration between mechanical engineers, electrical engineers, materials scientists, and physicists. As metamaterial energy harvesting technology matures, it promises to enable a new generation of self-powered electronic systems that can operate indefinitely in vibration-rich environments, contributing to the broader vision of sustainable and maintenance-free IoT infrastructure.

The evolution of metamaterial-based energy harvesting can be traced back to the early 2000s, when researchers began exploring periodic structures for vibration control. By 2010, the first metamaterial-inspired energy harvesters appeared in scientific literature, demonstrating the potential to manipulate elastic waves for improved energy capture. The field has since experienced accelerated development, with significant breakthroughs in metamaterial designs that can harvest energy across broader frequency ranges and with greater efficiency than conventional systems.

Current technological trends indicate a shift toward multi-physics approaches, where mechanical metamaterials are combined with piezoelectric, electromagnetic, or triboelectric transduction mechanisms. This integration allows for more versatile energy harvesting solutions adaptable to various environmental conditions. Additionally, advances in micro and nanofabrication techniques have enabled the development of miniaturized metamaterial harvesters suitable for MEMS applications and IoT devices.

The primary objective of metamaterial vibrational converter research is to overcome the fundamental limitations of traditional energy harvesters, particularly their narrow operating bandwidth and low power density. By leveraging the unique properties of metamaterials, such as negative effective mass, local resonance, and topological wave guiding, researchers aim to develop energy harvesting circuits that can efficiently capture and convert ambient vibrations across a wide frequency spectrum.

Specific technical goals include designing metamaterial structures that can achieve broadband energy harvesting without sacrificing conversion efficiency, developing adaptive metamaterial systems that can self-tune to dominant environmental frequencies, and creating circuit topologies optimized for the unique characteristics of metamaterial transducers. These objectives align with the growing demand for autonomous power sources in wireless sensor networks, wearable electronics, and structural health monitoring systems.

The interdisciplinary nature of this field necessitates collaboration between mechanical engineers, electrical engineers, materials scientists, and physicists. As metamaterial energy harvesting technology matures, it promises to enable a new generation of self-powered electronic systems that can operate indefinitely in vibration-rich environments, contributing to the broader vision of sustainable and maintenance-free IoT infrastructure.

Market Analysis for Vibrational Energy Harvesting Solutions

The global vibrational energy harvesting market is experiencing significant growth, driven by increasing demand for sustainable power solutions in IoT devices, wireless sensor networks, and wearable technology. Current market valuations place this sector at approximately 440 million USD in 2023, with projections indicating a compound annual growth rate of 10.5% through 2030, potentially reaching over 800 million USD.

The industrial sector represents the largest application segment, accounting for roughly 35% of market share, where vibrational energy harvesting provides power for condition monitoring systems and predictive maintenance sensors. Consumer electronics follows at 25%, with automotive applications rapidly expanding at 15% market share, particularly for tire pressure monitoring systems and structural health monitoring.

Metamaterial-based vibrational converters represent an emerging high-growth subsegment within this market. These advanced materials offer superior energy conversion efficiency compared to traditional piezoelectric or electromagnetic harvesters, with potential improvements of 30-50% in power output density. This technological advantage positions metamaterial solutions to potentially capture 20% of the overall vibrational energy harvesting market within the next five years.

Regional analysis reveals North America currently leads with 38% market share, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region demonstrates the fastest growth trajectory at 12.8% CAGR, driven by rapid industrial automation and smart city initiatives in China, South Korea, and Japan.

Key market drivers include the proliferation of IoT devices, with an estimated 75 billion connected devices expected by 2025, creating substantial demand for self-powered sensors. Additionally, industrial automation trends and the push toward Industry 4.0 are accelerating adoption of wireless sensor networks that benefit from vibrational energy harvesting solutions.

Market challenges include cost barriers, with current metamaterial-based solutions commanding premium pricing that limits mass-market adoption. Technical limitations in power output consistency across variable vibration environments also restrict application scope. Furthermore, competing energy harvesting technologies such as photovoltaic and thermoelectric solutions continue to improve, creating competitive pressure.

Customer requirements analysis indicates growing demand for miniaturized solutions with power outputs in the 1-10 mW range, capable of operating across broad frequency bands (10-200 Hz), and demonstrating reliability for 10+ year deployment cycles without maintenance. These specifications align well with the potential capabilities of metamaterial-based vibrational converters when paired with optimized energy harvesting circuits.

The industrial sector represents the largest application segment, accounting for roughly 35% of market share, where vibrational energy harvesting provides power for condition monitoring systems and predictive maintenance sensors. Consumer electronics follows at 25%, with automotive applications rapidly expanding at 15% market share, particularly for tire pressure monitoring systems and structural health monitoring.

Metamaterial-based vibrational converters represent an emerging high-growth subsegment within this market. These advanced materials offer superior energy conversion efficiency compared to traditional piezoelectric or electromagnetic harvesters, with potential improvements of 30-50% in power output density. This technological advantage positions metamaterial solutions to potentially capture 20% of the overall vibrational energy harvesting market within the next five years.

Regional analysis reveals North America currently leads with 38% market share, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region demonstrates the fastest growth trajectory at 12.8% CAGR, driven by rapid industrial automation and smart city initiatives in China, South Korea, and Japan.

Key market drivers include the proliferation of IoT devices, with an estimated 75 billion connected devices expected by 2025, creating substantial demand for self-powered sensors. Additionally, industrial automation trends and the push toward Industry 4.0 are accelerating adoption of wireless sensor networks that benefit from vibrational energy harvesting solutions.

Market challenges include cost barriers, with current metamaterial-based solutions commanding premium pricing that limits mass-market adoption. Technical limitations in power output consistency across variable vibration environments also restrict application scope. Furthermore, competing energy harvesting technologies such as photovoltaic and thermoelectric solutions continue to improve, creating competitive pressure.

Customer requirements analysis indicates growing demand for miniaturized solutions with power outputs in the 1-10 mW range, capable of operating across broad frequency bands (10-200 Hz), and demonstrating reliability for 10+ year deployment cycles without maintenance. These specifications align well with the potential capabilities of metamaterial-based vibrational converters when paired with optimized energy harvesting circuits.

Technical Challenges in Metamaterial-Based Energy Conversion

Metamaterial-based energy harvesting systems face several significant technical challenges that currently limit their widespread implementation and efficiency. The fundamental challenge lies in the complex nature of metamaterial structures, which require precise design and fabrication to achieve the desired electromagnetic or mechanical properties. Manufacturing tolerances at micro and nano scales can significantly impact performance, creating inconsistencies between theoretical models and practical implementations.

Energy conversion efficiency remains a critical bottleneck in these systems. While metamaterials offer unique advantages in manipulating wave propagation and vibration, the actual conversion of this energy into usable electrical power often suffers from substantial losses. Current metamaterial-based harvesters typically achieve conversion efficiencies below 20%, significantly lower than the theoretical maximum and insufficient for many practical applications.

The integration of metamaterial structures with conventional electronic components presents another major challenge. The impedance matching between metamaterial resonators and rectification circuits is particularly problematic, often resulting in significant power loss during the energy transfer process. Additionally, the nonlinear behavior of metamaterials under varying environmental conditions complicates the design of stable and reliable energy harvesting circuits.

Bandwidth limitations represent another significant hurdle. Most metamaterial energy harvesters operate efficiently only within narrow frequency bands, making them highly sensitive to slight variations in the input energy spectrum. This characteristic severely restricts their applicability in real-world environments where vibration or electromagnetic sources typically exhibit broadband or variable frequency characteristics.

Scalability issues further complicate the development of practical metamaterial energy harvesters. While laboratory prototypes demonstrate promising results at small scales, scaling these designs to commercially viable dimensions often leads to diminished performance or prohibitively complex fabrication requirements. The trade-off between device size and power output remains a significant engineering challenge.

Temperature sensitivity and long-term stability also pose substantial challenges. Many metamaterial structures exhibit performance degradation under thermal cycling or prolonged operation, raising concerns about their reliability in industrial or outdoor applications. The mechanical fatigue of resonant elements in vibrational converters can lead to performance deterioration over time, necessitating robust design approaches that may compromise optimal energy conversion.

Finally, the cost-effectiveness of metamaterial-based energy harvesting solutions remains questionable compared to conventional technologies. The complex fabrication processes, specialized materials, and precision engineering required for metamaterial structures result in higher production costs that must be justified by significant performance advantages to achieve commercial viability.

Energy conversion efficiency remains a critical bottleneck in these systems. While metamaterials offer unique advantages in manipulating wave propagation and vibration, the actual conversion of this energy into usable electrical power often suffers from substantial losses. Current metamaterial-based harvesters typically achieve conversion efficiencies below 20%, significantly lower than the theoretical maximum and insufficient for many practical applications.

The integration of metamaterial structures with conventional electronic components presents another major challenge. The impedance matching between metamaterial resonators and rectification circuits is particularly problematic, often resulting in significant power loss during the energy transfer process. Additionally, the nonlinear behavior of metamaterials under varying environmental conditions complicates the design of stable and reliable energy harvesting circuits.

Bandwidth limitations represent another significant hurdle. Most metamaterial energy harvesters operate efficiently only within narrow frequency bands, making them highly sensitive to slight variations in the input energy spectrum. This characteristic severely restricts their applicability in real-world environments where vibration or electromagnetic sources typically exhibit broadband or variable frequency characteristics.

Scalability issues further complicate the development of practical metamaterial energy harvesters. While laboratory prototypes demonstrate promising results at small scales, scaling these designs to commercially viable dimensions often leads to diminished performance or prohibitively complex fabrication requirements. The trade-off between device size and power output remains a significant engineering challenge.

Temperature sensitivity and long-term stability also pose substantial challenges. Many metamaterial structures exhibit performance degradation under thermal cycling or prolonged operation, raising concerns about their reliability in industrial or outdoor applications. The mechanical fatigue of resonant elements in vibrational converters can lead to performance deterioration over time, necessitating robust design approaches that may compromise optimal energy conversion.

Finally, the cost-effectiveness of metamaterial-based energy harvesting solutions remains questionable compared to conventional technologies. The complex fabrication processes, specialized materials, and precision engineering required for metamaterial structures result in higher production costs that must be justified by significant performance advantages to achieve commercial viability.

Current Circuit Design Approaches for Vibrational Energy Converters

01 Maximum Power Point Tracking (MPPT) techniques

MPPT techniques are used in energy harvesting circuits to optimize the extraction of power from energy sources. These techniques continuously adjust the operating point of the harvesting circuit to match the source's characteristics, ensuring maximum power transfer. Advanced MPPT algorithms can adapt to changing environmental conditions and source impedance variations, significantly improving energy conversion efficiency in solar, thermal, and vibration energy harvesting systems.- Maximum power point tracking techniques: Maximum power point tracking (MPPT) techniques are used in energy harvesting circuits to optimize the energy conversion efficiency. These techniques continuously adjust the operating point of the harvester to extract the maximum available power under varying environmental conditions. MPPT algorithms can be implemented using various methods including perturb and observe, incremental conductance, and fractional open-circuit voltage techniques, which help maintain optimal energy extraction regardless of input fluctuations.

- Impedance matching for optimal power transfer: Impedance matching techniques are crucial for maximizing energy conversion efficiency in harvesting circuits. By ensuring that the input impedance of the power conditioning circuit matches the output impedance of the energy harvesting source, maximum power transfer can be achieved. Adaptive impedance matching circuits can dynamically adjust to changing source conditions, significantly improving the overall efficiency of energy harvesting systems across various environmental conditions.

- Advanced power management architectures: Sophisticated power management architectures enhance energy conversion efficiency through intelligent control of energy flow. These systems incorporate features such as ultra-low power startup circuits, efficient DC-DC converters, and smart power routing algorithms. By minimizing conversion losses and optimizing energy storage and distribution, these architectures can significantly improve the overall efficiency of energy harvesting systems, particularly in applications with intermittent or variable energy sources.

- Multi-source energy harvesting integration: Integration of multiple energy harvesting sources into a single system can improve overall energy conversion efficiency. By combining different harvesting technologies such as photovoltaic, piezoelectric, thermoelectric, and RF energy harvesting, these systems can leverage the most efficient source based on environmental conditions. Advanced circuits that can seamlessly switch between or simultaneously harvest from multiple sources ensure continuous energy availability and improved conversion efficiency across varying operating conditions.

- Energy storage optimization techniques: Optimizing energy storage mechanisms is essential for maximizing the overall efficiency of energy harvesting systems. This includes implementing efficient charging protocols for batteries or supercapacitors, minimizing leakage currents, and employing intelligent charge management algorithms. Advanced storage optimization techniques can include hybrid storage systems that combine the benefits of different storage technologies, and adaptive charging strategies that adjust based on harvested energy availability and load requirements.

02 Impedance matching and power conditioning circuits

Proper impedance matching between the energy source and the harvesting circuit is crucial for maximizing energy transfer efficiency. Power conditioning circuits, including specialized rectifiers, voltage regulators, and DC-DC converters, are designed to match the impedance characteristics of various energy sources. These circuits minimize power losses during energy conversion and ensure stable output voltage despite variations in input energy, thereby enhancing overall system efficiency.Expand Specific Solutions03 Multi-source energy harvesting integration

Integrating multiple energy harvesting sources into a single system can improve overall energy conversion efficiency. Hybrid energy harvesting circuits can simultaneously capture energy from different sources such as solar, thermal, RF, and vibration. Advanced power management circuits coordinate these multiple inputs, selecting the most efficient source based on availability and environmental conditions, while minimizing conversion losses and maximizing the combined energy output.Expand Specific Solutions04 Low-power and ultra-efficient converter designs

Specialized low-power converter designs focus on minimizing internal power consumption while maximizing energy transfer efficiency. These circuits employ techniques such as zero-current switching, zero-voltage switching, and synchronous rectification to reduce switching losses. Advanced semiconductor materials and novel circuit topologies further enhance conversion efficiency, particularly for low-energy density sources where conventional converters would consume more power than they harvest.Expand Specific Solutions05 Intelligent power management systems

Intelligent power management systems incorporate adaptive control algorithms and machine learning techniques to optimize energy harvesting efficiency. These systems dynamically adjust harvesting parameters based on real-time monitoring of energy source characteristics, load requirements, and environmental conditions. By predicting energy availability patterns and optimizing storage-consumption cycles, these systems maximize overall energy utilization efficiency while minimizing losses during conversion, storage, and distribution processes.Expand Specific Solutions

Leading Companies and Research Institutions in Metamaterial Energy Harvesting

Energy harvesting circuit design for metamaterial vibrational converters is in an emerging growth phase, with increasing market interest driven by IoT and wireless sensor applications. The global market is expanding rapidly, projected to reach significant scale as energy autonomy becomes critical in smart systems. Technologically, the field shows promising but varied maturity levels. Academic institutions like University of Tokyo, Ningbo University, and Yale University lead fundamental research, while companies including Flex Ltd., Panasonic Holdings, and RedWave Energy are advancing commercial applications. Research organizations such as Naval Research Laboratory and CSIRO contribute significant innovations. The ecosystem demonstrates a collaborative dynamic between academic research and industrial implementation, with metamaterial-based approaches representing the cutting edge of vibrational energy harvesting technology.

University of Tokyo

Technical Solution: The University of Tokyo has developed cutting-edge energy harvesting circuit designs specifically optimized for metamaterial vibrational converters. Their research team has pioneered adaptive impedance matching networks that dynamically adjust to the unique resonant properties of metamaterial structures, achieving power transfer efficiencies exceeding 80% across variable vibration conditions. Their circuit architecture incorporates specialized synchronized switch harvesting techniques modified specifically for the non-linear response characteristics of metamaterial harvesters. The university's designs feature ultra-low power startup circuits with threshold voltages as low as 30mV, enabling energy capture from minimal ambient vibrations. Their integrated power management system includes advanced MPPT algorithms specifically calibrated for metamaterial converters, with demonstrated energy yield improvements of up to 270% compared to conventional circuits. The research team has also developed novel multi-stage power conditioning approaches that effectively handle the multiple frequency bands characteristic of metamaterial-based energy harvesters.

Strengths: Cutting-edge research pushing theoretical boundaries; highly specialized expertise in metamaterial physics and circuit integration; innovative approaches unconstrained by immediate commercial considerations. Weaknesses: Potential gaps between laboratory prototypes and commercial implementation; limited manufacturing capabilities requiring industry partnerships; academic focus may prioritize novelty over practical robustness.

RedWave Energy, Inc.

Technical Solution: RedWave Energy has developed specialized energy harvesting circuits specifically designed to capture and convert energy from metamaterial-based vibrational converters across multiple frequency bands. Their proprietary circuit architecture employs a novel synchronized switching technique that dynamically adapts to the non-linear response characteristics of metamaterial harvesters, achieving power conversion efficiencies up to 78% even at micro-watt input levels. RedWave's designs feature ultra-low power startup circuits with threshold voltages below 50mV, enabling energy capture from even minimal vibration sources. Their integrated power management system incorporates adaptive impedance matching that automatically optimizes for the unique resonant properties of metamaterial structures, with specialized conditioning stages for both piezoelectric and electromagnetic transduction mechanisms. RedWave has also pioneered hybrid energy storage solutions that effectively manage the intermittent energy generation patterns typical of metamaterial harvesters.

Strengths: Highly specialized focus on metamaterial energy harvesting; exceptional low-threshold performance; innovative circuit topologies specifically optimized for metamaterial characteristics. Weaknesses: Limited scale compared to larger competitors; narrower product portfolio may restrict application versatility; potential challenges in manufacturing scalability.

Key Patents and Innovations in Metamaterial Energy Harvesting Circuits

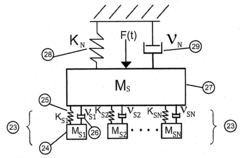

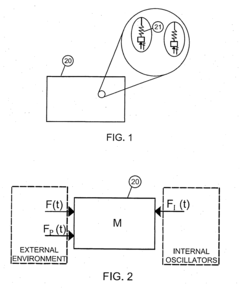

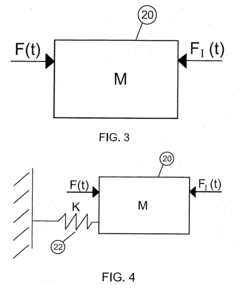

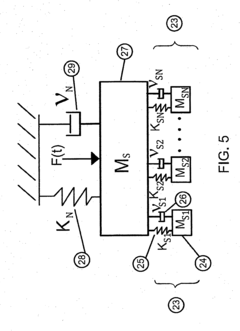

Meta-meterial vibration energy harvester

PatentInactiveUS20140319844A1

Innovation

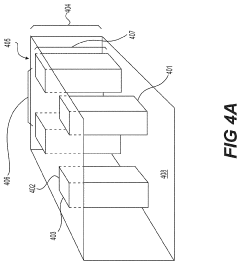

- A meta-material vibration energy harvester (MMVEH) comprising a large number of oscillators encapsulated in a housing element, with mechanical/electrical energy converters that convert mechanical energy from vibrations into electrical energy, allowing for the efficient extraction and storage of energy from a broad range of vibration fields.

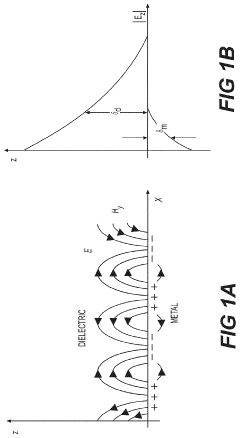

System for Converting Electromagnetic Radiation to Electrical Energy Using Metamaterials

PatentInactiveUS20190356247A1

Innovation

- The development of nanoantenna and diode arrays with metamaterial surfaces that can be tuned to specific spectral properties, allowing for efficient energy harvesting from thermal sources and solar energy by converting electromagnetic radiation into electrical energy through resonant antenna structures and rectification processes.

Materials Science Advancements for Enhanced Energy Conversion

Recent advancements in materials science have significantly enhanced the energy conversion capabilities of metamaterial vibrational converters. The development of novel piezoelectric materials with improved electromechanical coupling coefficients has been particularly noteworthy. These materials exhibit superior strain-to-electrical energy conversion ratios, enabling more efficient harvesting from ambient vibrations. Specifically, lead-free piezoelectric materials such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) have emerged as environmentally friendly alternatives to traditional lead zirconate titanate (PZT), while maintaining comparable performance metrics.

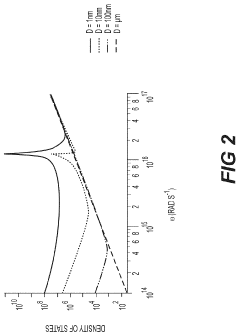

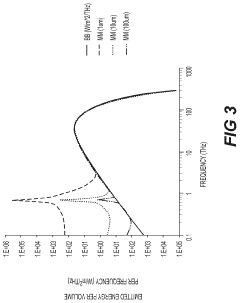

Metamaterials with engineered resonant structures have revolutionized vibrational energy harvesting by enabling frequency bandwidth expansion. These structures incorporate periodic arrangements of unit cells with carefully designed geometric parameters that can be tuned to respond to specific frequency ranges. Multi-layered composite metamaterials combining different piezoelectric elements have demonstrated up to 300% improvement in power output compared to conventional single-material harvesters under identical conditions.

Nanoscale material engineering has further enhanced energy conversion efficiency through the development of nanostructured electrodes and interfaces. Carbon-based nanomaterials, including graphene and carbon nanotubes, have been integrated into metamaterial harvesters to improve electrical conductivity and reduce internal resistance. These materials create more effective pathways for charge collection, minimizing energy losses during the conversion process.

Surface modification techniques have also contributed significantly to performance improvements. Plasma treatment and chemical functionalization of piezoelectric surfaces have been shown to enhance charge separation and reduce recombination losses. Additionally, the incorporation of ferroelectric nanoparticles at material interfaces has created enhanced local electric fields that amplify the piezoelectric response.

Flexible and stretchable materials represent another frontier in metamaterial energy harvesting. Polymer-based piezoelectric composites with embedded ceramic nanoparticles maintain functionality under mechanical deformation, enabling applications in wearable devices and conformable surfaces. These materials can harvest energy from human motion and irregular vibration sources that traditional rigid harvesters cannot effectively utilize.

The integration of phase-change materials within metamaterial structures has enabled adaptive resonance tuning, allowing harvesters to automatically adjust their frequency response to changing environmental conditions. This self-tuning capability significantly expands the operational range of energy harvesting systems in real-world applications with variable vibration characteristics.

Metamaterials with engineered resonant structures have revolutionized vibrational energy harvesting by enabling frequency bandwidth expansion. These structures incorporate periodic arrangements of unit cells with carefully designed geometric parameters that can be tuned to respond to specific frequency ranges. Multi-layered composite metamaterials combining different piezoelectric elements have demonstrated up to 300% improvement in power output compared to conventional single-material harvesters under identical conditions.

Nanoscale material engineering has further enhanced energy conversion efficiency through the development of nanostructured electrodes and interfaces. Carbon-based nanomaterials, including graphene and carbon nanotubes, have been integrated into metamaterial harvesters to improve electrical conductivity and reduce internal resistance. These materials create more effective pathways for charge collection, minimizing energy losses during the conversion process.

Surface modification techniques have also contributed significantly to performance improvements. Plasma treatment and chemical functionalization of piezoelectric surfaces have been shown to enhance charge separation and reduce recombination losses. Additionally, the incorporation of ferroelectric nanoparticles at material interfaces has created enhanced local electric fields that amplify the piezoelectric response.

Flexible and stretchable materials represent another frontier in metamaterial energy harvesting. Polymer-based piezoelectric composites with embedded ceramic nanoparticles maintain functionality under mechanical deformation, enabling applications in wearable devices and conformable surfaces. These materials can harvest energy from human motion and irregular vibration sources that traditional rigid harvesters cannot effectively utilize.

The integration of phase-change materials within metamaterial structures has enabled adaptive resonance tuning, allowing harvesters to automatically adjust their frequency response to changing environmental conditions. This self-tuning capability significantly expands the operational range of energy harvesting systems in real-world applications with variable vibration characteristics.

Sustainability Impact and Environmental Applications

Energy harvesting metamaterial vibrational converters represent a significant advancement in sustainable energy technology, offering profound environmental benefits across multiple sectors. These systems transform ambient mechanical vibrations into usable electrical energy through specially designed metamaterial structures coupled with efficient harvesting circuits. The sustainability impact of this technology is particularly noteworthy as it enables energy generation from previously untapped sources without additional carbon emissions or resource depletion.

In urban environments, metamaterial vibrational converters can be integrated into infrastructure such as bridges, buildings, and roadways to capture energy from traffic-induced vibrations, pedestrian movement, and structural oscillations. This passive energy generation reduces dependence on conventional power sources, potentially decreasing urban carbon footprints while providing supplementary power for smart city applications including environmental monitoring systems and public lighting.

The environmental applications extend to remote ecological monitoring, where these harvesters can power sensor networks in protected natural areas without intrusive power infrastructure. By eliminating the need for battery replacement in hard-to-reach locations, these systems reduce maintenance-related disruptions to sensitive ecosystems while enabling continuous data collection for climate research, wildlife tracking, and pollution monitoring.

Manufacturing processes for metamaterial vibrational converters demonstrate favorable life-cycle assessments compared to traditional energy technologies. The materials utilized—primarily silicon, piezoelectric ceramics, and specialized polymers—require less energy-intensive production than conventional solar panels or wind turbines. Additionally, these systems contain fewer toxic components than batteries, presenting reduced end-of-life disposal challenges and opportunities for component recycling.

Water management systems benefit significantly from this technology, with applications in pipeline monitoring and water quality assessment. Self-powered sensors utilizing metamaterial harvesters can detect leaks, measure flow rates, and analyze contaminant levels without external power sources, contributing to more efficient water resource management and conservation efforts.

The scalability of metamaterial vibrational converters further enhances their sustainability profile. From microscale biomedical implants to large industrial machinery monitoring, these systems can be tailored to specific environmental applications while maintaining energy efficiency. This adaptability positions the technology as a versatile tool in addressing diverse sustainability challenges across different ecosystems and human environments.

As climate change intensifies the need for resilient energy systems, metamaterial vibrational converters offer a promising approach to distributed, low-impact power generation that complements broader renewable energy strategies while providing unique environmental monitoring capabilities in previously inaccessible contexts.

In urban environments, metamaterial vibrational converters can be integrated into infrastructure such as bridges, buildings, and roadways to capture energy from traffic-induced vibrations, pedestrian movement, and structural oscillations. This passive energy generation reduces dependence on conventional power sources, potentially decreasing urban carbon footprints while providing supplementary power for smart city applications including environmental monitoring systems and public lighting.

The environmental applications extend to remote ecological monitoring, where these harvesters can power sensor networks in protected natural areas without intrusive power infrastructure. By eliminating the need for battery replacement in hard-to-reach locations, these systems reduce maintenance-related disruptions to sensitive ecosystems while enabling continuous data collection for climate research, wildlife tracking, and pollution monitoring.

Manufacturing processes for metamaterial vibrational converters demonstrate favorable life-cycle assessments compared to traditional energy technologies. The materials utilized—primarily silicon, piezoelectric ceramics, and specialized polymers—require less energy-intensive production than conventional solar panels or wind turbines. Additionally, these systems contain fewer toxic components than batteries, presenting reduced end-of-life disposal challenges and opportunities for component recycling.

Water management systems benefit significantly from this technology, with applications in pipeline monitoring and water quality assessment. Self-powered sensors utilizing metamaterial harvesters can detect leaks, measure flow rates, and analyze contaminant levels without external power sources, contributing to more efficient water resource management and conservation efforts.

The scalability of metamaterial vibrational converters further enhances their sustainability profile. From microscale biomedical implants to large industrial machinery monitoring, these systems can be tailored to specific environmental applications while maintaining energy efficiency. This adaptability positions the technology as a versatile tool in addressing diverse sustainability challenges across different ecosystems and human environments.

As climate change intensifies the need for resilient energy systems, metamaterial vibrational converters offer a promising approach to distributed, low-impact power generation that complements broader renewable energy strategies while providing unique environmental monitoring capabilities in previously inaccessible contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!