Design For Manufacturability In Acoustic Metamaterial Panels

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterial Manufacturing Background and Objectives

Acoustic metamaterials represent a revolutionary advancement in sound engineering, emerging from theoretical physics concepts in the early 2000s to practical applications in the 2010s. These engineered structures manipulate sound waves in ways conventional materials cannot, offering unprecedented control over acoustic properties through their unique microstructural design rather than chemical composition. The evolution of acoustic metamaterials has been driven by increasing demands for noise reduction solutions in urban environments, transportation, industrial settings, and architectural acoustics.

The manufacturing of acoustic metamaterial panels has progressed from laboratory prototypes to early commercial applications, though significant challenges remain in scaling production while maintaining acoustic performance. Traditional manufacturing methods often struggle with the complex geometries and precise structural requirements that give these materials their unique properties. Current manufacturing approaches include 3D printing, precision molding, and advanced composite fabrication techniques, each with distinct advantages and limitations in terms of cost, scalability, and performance.

The primary objective of Design for Manufacturability (DFM) in acoustic metamaterial panels is to bridge the gap between theoretical acoustic performance and practical, cost-effective production methods. This involves developing design principles that maintain the desired acoustic properties while accommodating manufacturing constraints and economic viability. The goal is to transition acoustic metamaterials from specialized, high-cost applications to mainstream acoustic solutions accessible across multiple industries.

Recent technological advancements in additive manufacturing, computational design tools, and material science have created new opportunities for optimizing acoustic metamaterial designs for manufacturability. Machine learning algorithms are increasingly being employed to navigate the complex relationship between structural design, acoustic performance, and manufacturing parameters, enabling more efficient exploration of the design space.

Global research institutions and industry leaders are actively pursuing innovations in this field, with significant progress in developing metamaterial designs that can be manufactured using modified conventional production methods. The trend is moving toward modular and scalable designs that can be adapted to different acoustic requirements while maintaining manufacturing efficiency.

The convergence of acoustic engineering principles with advanced manufacturing capabilities represents a critical juncture in the evolution of noise control solutions. Success in this domain could revolutionize industries ranging from automotive and aerospace to construction and consumer electronics, offering unprecedented acoustic performance with practical implementation pathways.

The manufacturing of acoustic metamaterial panels has progressed from laboratory prototypes to early commercial applications, though significant challenges remain in scaling production while maintaining acoustic performance. Traditional manufacturing methods often struggle with the complex geometries and precise structural requirements that give these materials their unique properties. Current manufacturing approaches include 3D printing, precision molding, and advanced composite fabrication techniques, each with distinct advantages and limitations in terms of cost, scalability, and performance.

The primary objective of Design for Manufacturability (DFM) in acoustic metamaterial panels is to bridge the gap between theoretical acoustic performance and practical, cost-effective production methods. This involves developing design principles that maintain the desired acoustic properties while accommodating manufacturing constraints and economic viability. The goal is to transition acoustic metamaterials from specialized, high-cost applications to mainstream acoustic solutions accessible across multiple industries.

Recent technological advancements in additive manufacturing, computational design tools, and material science have created new opportunities for optimizing acoustic metamaterial designs for manufacturability. Machine learning algorithms are increasingly being employed to navigate the complex relationship between structural design, acoustic performance, and manufacturing parameters, enabling more efficient exploration of the design space.

Global research institutions and industry leaders are actively pursuing innovations in this field, with significant progress in developing metamaterial designs that can be manufactured using modified conventional production methods. The trend is moving toward modular and scalable designs that can be adapted to different acoustic requirements while maintaining manufacturing efficiency.

The convergence of acoustic engineering principles with advanced manufacturing capabilities represents a critical juncture in the evolution of noise control solutions. Success in this domain could revolutionize industries ranging from automotive and aerospace to construction and consumer electronics, offering unprecedented acoustic performance with practical implementation pathways.

Market Analysis for Manufacturable Acoustic Metamaterial Panels

The global market for acoustic metamaterial panels is experiencing significant growth, driven by increasing demand for noise control solutions across various industries. The market size for advanced acoustic materials was valued at approximately $7.6 billion in 2022 and is projected to reach $11.8 billion by 2028, with acoustic metamaterials representing an emerging segment with accelerated growth potential.

Construction and building sectors currently dominate the application landscape, accounting for nearly 38% of market share. These industries seek innovative sound insulation solutions that are thinner and lighter than traditional materials while offering superior acoustic performance. The automotive industry follows closely, representing about 27% of the market, where weight reduction and space optimization are critical factors driving adoption.

Consumer electronics manufacturers are increasingly exploring acoustic metamaterial panels for speakers, headphones, and smart devices, creating a rapidly expanding market segment with an estimated annual growth rate of 14.3%. Aerospace applications, though smaller in volume, offer premium pricing opportunities due to stringent performance requirements and regulatory standards.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid industrialization, infrastructure development, and increasing awareness about noise pollution control.

Key market drivers include increasingly stringent noise regulations across developed economies, growing awareness of noise pollution's health impacts, and the push for sustainable building materials. The trend toward urban densification has further accelerated demand for effective soundproofing solutions in residential and commercial spaces.

Customer preferences are shifting toward multifunctional materials that offer not only acoustic benefits but also thermal insulation, fire resistance, and aesthetic appeal. This trend presents significant opportunities for manufacturers who can develop integrated solutions that address multiple performance criteria simultaneously.

Price sensitivity varies significantly across market segments, with industrial and infrastructure applications being more cost-conscious, while high-end consumer electronics and aerospace sectors prioritize performance over price. The average price premium that customers are willing to pay for acoustic metamaterial panels over traditional solutions ranges from 15-40%, depending on the application and performance advantages.

Construction and building sectors currently dominate the application landscape, accounting for nearly 38% of market share. These industries seek innovative sound insulation solutions that are thinner and lighter than traditional materials while offering superior acoustic performance. The automotive industry follows closely, representing about 27% of the market, where weight reduction and space optimization are critical factors driving adoption.

Consumer electronics manufacturers are increasingly exploring acoustic metamaterial panels for speakers, headphones, and smart devices, creating a rapidly expanding market segment with an estimated annual growth rate of 14.3%. Aerospace applications, though smaller in volume, offer premium pricing opportunities due to stringent performance requirements and regulatory standards.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid industrialization, infrastructure development, and increasing awareness about noise pollution control.

Key market drivers include increasingly stringent noise regulations across developed economies, growing awareness of noise pollution's health impacts, and the push for sustainable building materials. The trend toward urban densification has further accelerated demand for effective soundproofing solutions in residential and commercial spaces.

Customer preferences are shifting toward multifunctional materials that offer not only acoustic benefits but also thermal insulation, fire resistance, and aesthetic appeal. This trend presents significant opportunities for manufacturers who can develop integrated solutions that address multiple performance criteria simultaneously.

Price sensitivity varies significantly across market segments, with industrial and infrastructure applications being more cost-conscious, while high-end consumer electronics and aerospace sectors prioritize performance over price. The average price premium that customers are willing to pay for acoustic metamaterial panels over traditional solutions ranges from 15-40%, depending on the application and performance advantages.

Technical Barriers in Acoustic Metamaterial Mass Production

Despite the promising acoustic properties of metamaterial panels, their transition from laboratory prototypes to mass-produced products faces significant manufacturing challenges. Current production methods remain largely experimental and lab-based, utilizing techniques such as 3D printing, precision CNC machining, and micro-fabrication processes that are inherently time-consuming and cost-prohibitive at scale. These methods, while suitable for creating precise research specimens, lack the throughput capacity necessary for commercial viability.

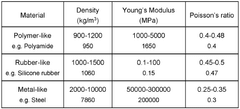

Material selection presents another substantial barrier, as acoustic metamaterials often require specialized composites with precise mechanical properties. These materials must simultaneously satisfy acoustic performance requirements while meeting manufacturing constraints related to moldability, thermal stability, and production consistency. The complex geometrical structures that give metamaterials their unique acoustic properties—including resonant cavities, Helmholtz resonators, and phononic crystals—demand manufacturing precision at micro and sometimes nano scales.

Dimensional tolerance control represents a critical challenge, as even minor deviations can significantly alter the acoustic performance of metamaterial panels. The resonant frequencies and bandgap properties are highly sensitive to geometric precision, requiring manufacturing processes with exceptional repeatability and quality control systems. This precision requirement conflicts with the need for high-volume production methods.

Scalability issues further complicate mass production efforts. Laboratory-proven designs often incorporate features that cannot be directly translated to conventional manufacturing processes like injection molding or stamping. The transition requires substantial redesign work to maintain acoustic performance while adapting to manufacturing constraints, a process that few companies have successfully navigated.

Assembly complexity adds another layer of difficulty, particularly for metamaterial designs requiring multiple components or layers. The integration of these elements must maintain precise alignment and spacing to preserve acoustic functionality, necessitating specialized assembly techniques and quality verification methods that are difficult to implement in high-volume production environments.

Cost factors remain perhaps the most significant barrier to widespread adoption. Current manufacturing approaches result in per-unit costs that are prohibitively high for most commercial applications, limiting market penetration. The specialized equipment, materials, and expertise required for production create significant capital investment hurdles for manufacturers considering entry into this space.

Standardization is notably absent in the field, with no established industry standards for testing, performance metrics, or manufacturing processes specific to acoustic metamaterials. This lack of standardization complicates quality control efforts and creates uncertainty for potential manufacturers and end-users alike.

Material selection presents another substantial barrier, as acoustic metamaterials often require specialized composites with precise mechanical properties. These materials must simultaneously satisfy acoustic performance requirements while meeting manufacturing constraints related to moldability, thermal stability, and production consistency. The complex geometrical structures that give metamaterials their unique acoustic properties—including resonant cavities, Helmholtz resonators, and phononic crystals—demand manufacturing precision at micro and sometimes nano scales.

Dimensional tolerance control represents a critical challenge, as even minor deviations can significantly alter the acoustic performance of metamaterial panels. The resonant frequencies and bandgap properties are highly sensitive to geometric precision, requiring manufacturing processes with exceptional repeatability and quality control systems. This precision requirement conflicts with the need for high-volume production methods.

Scalability issues further complicate mass production efforts. Laboratory-proven designs often incorporate features that cannot be directly translated to conventional manufacturing processes like injection molding or stamping. The transition requires substantial redesign work to maintain acoustic performance while adapting to manufacturing constraints, a process that few companies have successfully navigated.

Assembly complexity adds another layer of difficulty, particularly for metamaterial designs requiring multiple components or layers. The integration of these elements must maintain precise alignment and spacing to preserve acoustic functionality, necessitating specialized assembly techniques and quality verification methods that are difficult to implement in high-volume production environments.

Cost factors remain perhaps the most significant barrier to widespread adoption. Current manufacturing approaches result in per-unit costs that are prohibitively high for most commercial applications, limiting market penetration. The specialized equipment, materials, and expertise required for production create significant capital investment hurdles for manufacturers considering entry into this space.

Standardization is notably absent in the field, with no established industry standards for testing, performance metrics, or manufacturing processes specific to acoustic metamaterials. This lack of standardization complicates quality control efforts and creates uncertainty for potential manufacturers and end-users alike.

Current DFM Approaches for Acoustic Metamaterial Panels

01 Additive manufacturing techniques for acoustic metamaterials

Additive manufacturing technologies, such as 3D printing, enable the fabrication of complex acoustic metamaterial structures with precise geometries that would be difficult to achieve using conventional manufacturing methods. These techniques allow for the creation of intricate internal structures, resonators, and lattices that are essential for the desired acoustic properties. The layer-by-layer building process facilitates the production of customized acoustic panels with specific sound absorption, reflection, or transmission characteristics.- Additive Manufacturing Techniques for Acoustic Metamaterials: Additive manufacturing techniques, such as 3D printing, enable the fabrication of complex acoustic metamaterial structures with precise control over geometry and material properties. These techniques allow for the creation of intricate resonant cavities, lattice structures, and periodic arrangements that are essential for achieving desired acoustic properties. The layer-by-layer building process facilitates the production of metamaterials with tailored acoustic impedance and sound absorption characteristics that would be difficult to achieve using conventional manufacturing methods.

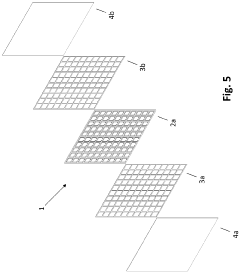

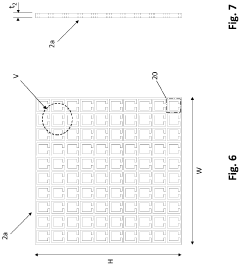

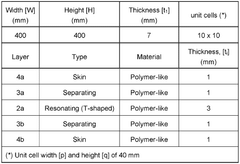

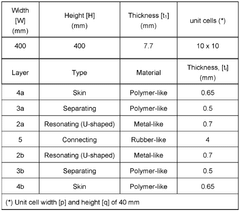

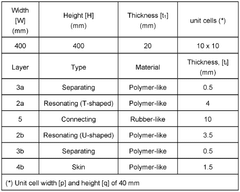

- Multi-layer Panel Construction Methods: Multi-layer construction approaches involve combining different material layers with varying acoustic properties to create metamaterial panels with enhanced performance. These methods typically include the integration of resonant cavities, perforated plates, and porous materials arranged in specific configurations. The manufacturing process often requires precise bonding techniques between layers to maintain structural integrity while preserving the acoustic functionality. This approach allows for the development of panels with broadband sound absorption and targeted frequency response characteristics.

- Micro-machining and Precision Fabrication Processes: Micro-machining and precision fabrication processes are employed to create acoustic metamaterial panels with features at the micro and nano scales. These techniques include laser cutting, micro-drilling, and precision milling to produce accurately dimensioned resonators, channels, and membranes. The manufacturing process requires tight tolerances to ensure that the acoustic metamaterial performs according to design specifications. Advanced quality control methods are implemented throughout production to verify dimensional accuracy and structural integrity of the microscale features that are critical to the acoustic performance.

- Scalable Production Methods for Industrial Applications: Scalable production methods have been developed to manufacture acoustic metamaterial panels in quantities suitable for industrial applications. These methods include roll-to-roll processing, injection molding, and automated assembly techniques that maintain the acoustic properties while increasing production efficiency. The manufacturing processes incorporate quality control systems to ensure consistency across large production runs. Considerations for cost-effectiveness and material optimization are integrated into the production workflow to make acoustic metamaterial panels commercially viable for various applications including automotive, construction, and aerospace industries.

- Integration of Smart Materials and Adaptive Features: Advanced manufacturing techniques enable the integration of smart materials and adaptive features into acoustic metamaterial panels. These methods involve embedding sensors, actuators, and tunable elements during the fabrication process to create panels with adjustable acoustic properties. The manufacturing challenges include ensuring proper electrical connections, maintaining material compatibility, and preserving the functionality of the smart components throughout the production process. These techniques allow for the development of acoustic panels that can dynamically respond to changing environmental conditions or user requirements, offering enhanced performance in noise control applications.

02 Multi-layer panel construction methods

Manufacturing acoustic metamaterial panels often involves multi-layer construction techniques where different materials and structures are combined to achieve the desired acoustic performance. These methods include lamination processes, adhesive bonding, and mechanical fastening of various layers with specific acoustic properties. The multi-layer approach allows for the integration of resonant cavities, perforated sheets, and porous materials to create panels that can effectively control sound across different frequency ranges.Expand Specific Solutions03 Micro-perforation and precision machining techniques

Micro-perforation and precision machining are critical manufacturing processes for acoustic metamaterial panels. These techniques involve creating precisely sized and spaced holes, channels, or cavities in panel materials to achieve specific acoustic resonance properties. Advanced CNC machining, laser cutting, and micro-drilling technologies enable manufacturers to produce panels with the exact dimensions and patterns required for targeted sound absorption or diffusion characteristics. The precision of these processes directly impacts the acoustic performance of the final product.Expand Specific Solutions04 Composite material formulation and processing

The development and processing of composite materials play a significant role in acoustic metamaterial panel manufacturability. These composites often combine rigid and flexible components, or dense and lightweight materials, to achieve specific acoustic impedance characteristics. Manufacturing processes include compression molding, injection molding, and extrusion techniques adapted for acoustic applications. The selection and processing of these materials must balance acoustic performance with structural integrity, durability, and cost-effectiveness for commercial viability.Expand Specific Solutions05 Scalable production and industrial implementation

Scaling up the production of acoustic metamaterial panels from laboratory prototypes to industrial manufacturing presents significant challenges. Innovations in this area focus on adapting existing production lines, developing specialized equipment, and creating standardized processes for consistent quality. These approaches include automated assembly systems, quality control methods specific to acoustic properties, and modular design strategies that facilitate mass production while maintaining the precise geometric features necessary for acoustic performance. Cost-effective manufacturing methods are essential for the widespread adoption of acoustic metamaterial panels in commercial applications.Expand Specific Solutions

Industry Leaders in Acoustic Metamaterial Panel Production

The acoustic metamaterial panels market is in a growth phase, characterized by increasing adoption across aerospace, defense, and construction sectors. The market is projected to expand significantly due to rising demand for noise reduction solutions in urban environments and transportation. Technologically, the field is advancing rapidly but faces manufacturability challenges. Leading players include established aerospace giants like Airbus Operations SAS, Boeing, and Safran SA, who are integrating these materials into aircraft components for weight reduction and acoustic performance. Research institutions like CNRS and specialized companies such as Pixie Dust Technologies are driving innovation in metamaterial design. Chinese entities including Kuang-Chi Innovative Technology are emerging as significant competitors, particularly in novel applications. The industry is transitioning from laboratory concepts to scalable manufacturing processes, with companies like Jabil and USG Interiors working to overcome production constraints.

Airbus Operations SAS

Technical Solution: Airbus has developed advanced acoustic metamaterial panels specifically designed for aircraft noise reduction. Their approach integrates metamaterial structures into composite panels that can be manufactured using existing aerospace production lines. The technology employs periodic arrangements of resonators embedded within lightweight composite structures, creating frequency bandgaps that effectively block sound transmission. Airbus has optimized these designs for mass production by developing specialized tooling and automated layup processes that maintain precise geometric tolerances required for acoustic performance while meeting aerospace manufacturing standards. Their DFM approach includes simulation-based optimization that accounts for manufacturing variability, ensuring consistent acoustic performance across production units. The company has successfully implemented these panels in A350 and A320neo aircraft, achieving up to 3dB noise reduction compared to conventional solutions while maintaining structural integrity and meeting weight constraints[1][3].

Strengths: Integration with existing aerospace manufacturing infrastructure; proven implementation in commercial aircraft; excellent weight-to-performance ratio. Weaknesses: High initial tooling costs; limited to aerospace-grade materials which increases production costs; requires tight manufacturing tolerances that can be challenging to maintain in high-volume production.

Kuang-Chi Institute of Advanced Technology

Technical Solution: Kuang-Chi has developed a novel approach to acoustic metamaterial panel manufacturing focused on scalability and cost-effectiveness. Their technology utilizes 3D-printed micro-lattice structures with precisely engineered acoustic properties that can be manufactured using modified commercial 3D printing systems. The company has created a proprietary design methodology that optimizes metamaterial geometries specifically for additive manufacturing constraints, ensuring that theoretical acoustic performance translates to manufactured products. Their panels incorporate gradient-index metamaterial designs that provide broadband noise reduction across multiple frequency ranges simultaneously. Kuang-Chi has developed specialized post-processing techniques to ensure consistent acoustic performance across large panel areas, addressing common challenges in metamaterial manufacturing uniformity. Their manufacturing process allows for customization of acoustic properties without tooling changes, making it suitable for diverse applications from transportation to architectural acoustics. The company has demonstrated production capabilities of up to 500 square meters of acoustic metamaterial panels monthly using their current manufacturing setup[5][6].

Strengths: Highly customizable acoustic properties; minimal tooling costs; excellent scalability from prototype to production. Weaknesses: Higher unit production time compared to traditional manufacturing methods; limited panel size due to 3D printing bed constraints; requires specialized post-processing expertise.

Key Patents in Acoustic Metamaterial Manufacturing Processes

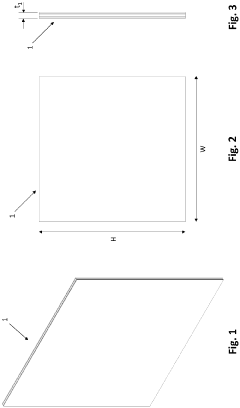

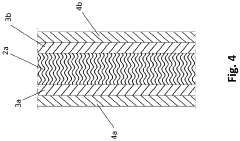

Acoustic metamaterial and process for manufacturing the same

PatentActiveEP4030420A1

Innovation

- The Multi-resonant Layered Acoustic Metamaterial (MLAM) features a simplified configuration with coplanar resonating elements and layers, allowing for easy manufacturing through lamination and die cutting, and coupling of internal modes to produce extended attenuation bands without undesired effects.

Acoustic metamaterial and process for manufacturing the same

PatentWO2022152449A1

Innovation

- The Multi-resonant Layered Acoustic Metamaterial (MLAM) features a simplified configuration with layers of constant thickness, utilizing resonating and separating units to couple internal modes for extended attenuation bands, manufactured via lamination and die cutting for ease and scalability.

Cost-Benefit Analysis of Manufacturing Methods

The manufacturing of acoustic metamaterial panels presents a complex cost-benefit landscape that varies significantly across different production methods. Traditional manufacturing techniques such as CNC machining offer high precision but at substantial cost, particularly for complex geometries characteristic of metamaterial structures. The unit cost typically ranges from $500-1,500 per square meter depending on material selection and geometric complexity, with setup costs averaging $2,000-5,000 per production run.

Additive manufacturing technologies, particularly 3D printing, have revolutionized the production economics of acoustic metamaterials. While the equipment investment remains high ($50,000-200,000 for industrial-grade printers), the per-unit costs can be reduced to $200-600 per square meter for polymer-based materials. However, this advantage diminishes with scale, as the production speed remains relatively slow compared to molding techniques.

Injection molding represents the most cost-effective solution for high-volume production, with per-unit costs potentially dropping below $100 per square meter after amortizing the substantial initial tooling investment ($15,000-50,000). The economic crossover point typically occurs between 500-1,000 units, making this approach viable primarily for standardized designs in mass production.

Material selection significantly impacts both manufacturing costs and acoustic performance. While polymers offer cost advantages ($5-15/kg), their acoustic properties may be inferior to specialized composites ($20-50/kg) or engineered ceramics ($40-100/kg). This creates a critical performance-cost tradeoff that must be evaluated against specific application requirements.

Labor costs vary dramatically across manufacturing methods, with additive manufacturing requiring minimal supervision (5-10% of total cost) compared to traditional fabrication techniques (20-30% of total cost). This differential becomes particularly significant in high-wage regions, potentially altering the optimal manufacturing strategy based on geographic location.

Energy consumption analysis reveals that injection molding typically consumes 4-8 kWh per kilogram of material processed, compared to 10-15 kWh for additive manufacturing and 12-20 kWh for CNC machining. At industrial electricity rates, this translates to operational cost differentials of $0.50-2.00 per unit, which accumulates significantly in large-scale production scenarios.

Quality control considerations introduce additional cost factors, with rejection rates averaging 2-5% for established molding processes versus 8-15% for newer additive techniques. These rejection costs must be factored into comprehensive manufacturing economics, particularly for applications with stringent acoustic performance requirements.

Additive manufacturing technologies, particularly 3D printing, have revolutionized the production economics of acoustic metamaterials. While the equipment investment remains high ($50,000-200,000 for industrial-grade printers), the per-unit costs can be reduced to $200-600 per square meter for polymer-based materials. However, this advantage diminishes with scale, as the production speed remains relatively slow compared to molding techniques.

Injection molding represents the most cost-effective solution for high-volume production, with per-unit costs potentially dropping below $100 per square meter after amortizing the substantial initial tooling investment ($15,000-50,000). The economic crossover point typically occurs between 500-1,000 units, making this approach viable primarily for standardized designs in mass production.

Material selection significantly impacts both manufacturing costs and acoustic performance. While polymers offer cost advantages ($5-15/kg), their acoustic properties may be inferior to specialized composites ($20-50/kg) or engineered ceramics ($40-100/kg). This creates a critical performance-cost tradeoff that must be evaluated against specific application requirements.

Labor costs vary dramatically across manufacturing methods, with additive manufacturing requiring minimal supervision (5-10% of total cost) compared to traditional fabrication techniques (20-30% of total cost). This differential becomes particularly significant in high-wage regions, potentially altering the optimal manufacturing strategy based on geographic location.

Energy consumption analysis reveals that injection molding typically consumes 4-8 kWh per kilogram of material processed, compared to 10-15 kWh for additive manufacturing and 12-20 kWh for CNC machining. At industrial electricity rates, this translates to operational cost differentials of $0.50-2.00 per unit, which accumulates significantly in large-scale production scenarios.

Quality control considerations introduce additional cost factors, with rejection rates averaging 2-5% for established molding processes versus 8-15% for newer additive techniques. These rejection costs must be factored into comprehensive manufacturing economics, particularly for applications with stringent acoustic performance requirements.

Sustainability Considerations in Metamaterial Panel Production

The sustainability of acoustic metamaterial panel production represents a critical dimension in the evolution of this technology. As environmental concerns gain prominence across industries, manufacturers must balance innovative acoustic performance with ecological responsibility. Current production methods for metamaterial panels often involve energy-intensive processes and materials with significant environmental footprints, necessitating a comprehensive sustainability assessment.

Material selection emerges as a primary sustainability consideration. Traditional metamaterial fabrication frequently relies on petroleum-based polymers and rare metals that present end-of-life disposal challenges. Recent research indicates promising alternatives through bio-based polymers, recycled composites, and renewable materials that maintain acoustic performance while reducing environmental impact. These sustainable material substitutions must be evaluated not only for their acoustic properties but also for their complete lifecycle implications.

Energy consumption during manufacturing presents another significant sustainability challenge. The precision required for metamaterial microstructures often demands energy-intensive processes including high-temperature curing, laser cutting, and advanced 3D printing. Innovations in low-energy manufacturing techniques, such as room-temperature curing resins and energy-efficient additive manufacturing, demonstrate potential for reducing the carbon footprint of production while maintaining design integrity.

Waste minimization strategies have gained traction in metamaterial panel production. Design approaches that optimize material usage through computational modeling can significantly reduce manufacturing waste. Additionally, closed-loop production systems that incorporate production scrap back into the manufacturing process show promise for minimizing landfill contributions while potentially reducing raw material costs.

Longevity and end-of-life considerations must be integrated into sustainable metamaterial design. Panels engineered for disassembly facilitate component separation for recycling or reuse. Some manufacturers have implemented take-back programs where panels are refurbished or recycled after their service life, creating circular economy opportunities within the acoustic materials sector.

Regulatory compliance and certification systems increasingly influence production decisions. Standards such as Environmental Product Declarations (EPDs) and Life Cycle Assessments (LCAs) provide frameworks for quantifying environmental impacts. Forward-thinking manufacturers are proactively pursuing certifications like Cradle to Cradle, which evaluates products across multiple sustainability dimensions including material health, material reutilization, renewable energy use, water stewardship, and social fairness.

Economic viability remains essential for sustainable manufacturing practices to achieve widespread adoption. While sustainable materials and processes may carry higher initial costs, they often deliver long-term benefits through reduced regulatory compliance expenses, enhanced brand reputation, and improved market positioning as sustainability becomes a competitive differentiator in the building materials sector.

Material selection emerges as a primary sustainability consideration. Traditional metamaterial fabrication frequently relies on petroleum-based polymers and rare metals that present end-of-life disposal challenges. Recent research indicates promising alternatives through bio-based polymers, recycled composites, and renewable materials that maintain acoustic performance while reducing environmental impact. These sustainable material substitutions must be evaluated not only for their acoustic properties but also for their complete lifecycle implications.

Energy consumption during manufacturing presents another significant sustainability challenge. The precision required for metamaterial microstructures often demands energy-intensive processes including high-temperature curing, laser cutting, and advanced 3D printing. Innovations in low-energy manufacturing techniques, such as room-temperature curing resins and energy-efficient additive manufacturing, demonstrate potential for reducing the carbon footprint of production while maintaining design integrity.

Waste minimization strategies have gained traction in metamaterial panel production. Design approaches that optimize material usage through computational modeling can significantly reduce manufacturing waste. Additionally, closed-loop production systems that incorporate production scrap back into the manufacturing process show promise for minimizing landfill contributions while potentially reducing raw material costs.

Longevity and end-of-life considerations must be integrated into sustainable metamaterial design. Panels engineered for disassembly facilitate component separation for recycling or reuse. Some manufacturers have implemented take-back programs where panels are refurbished or recycled after their service life, creating circular economy opportunities within the acoustic materials sector.

Regulatory compliance and certification systems increasingly influence production decisions. Standards such as Environmental Product Declarations (EPDs) and Life Cycle Assessments (LCAs) provide frameworks for quantifying environmental impacts. Forward-thinking manufacturers are proactively pursuing certifications like Cradle to Cradle, which evaluates products across multiple sustainability dimensions including material health, material reutilization, renewable energy use, water stewardship, and social fairness.

Economic viability remains essential for sustainable manufacturing practices to achieve widespread adoption. While sustainable materials and processes may carry higher initial costs, they often deliver long-term benefits through reduced regulatory compliance expenses, enhanced brand reputation, and improved market positioning as sustainability becomes a competitive differentiator in the building materials sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!