Energy Harvesting From Ambient Sound Using Metamaterial Resonators

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Energy Harvesting Background and Objectives

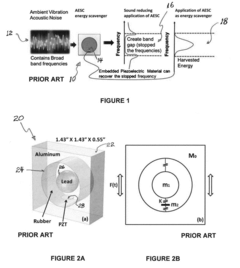

Acoustic energy harvesting represents a promising frontier in sustainable energy generation, focusing on capturing and converting ambient sound vibrations into usable electrical power. This technology has evolved significantly over the past two decades, transitioning from theoretical concepts to practical implementations. The fundamental principle involves harnessing acoustic pressure waves that propagate through various media and converting this mechanical energy into electrical energy through transduction mechanisms.

The historical trajectory of acoustic energy harvesting began with conventional piezoelectric materials in the early 2000s, which demonstrated limited efficiency in ambient conditions. The field experienced a paradigm shift with the introduction of metamaterial concepts around 2010, enabling enhanced energy capture through engineered resonance properties. Recent advancements have focused on nano-structured metamaterials that can respond to specific frequency ranges with unprecedented efficiency.

Current research indicates that ambient sound energy, particularly in urban and industrial environments, represents an untapped energy resource with power densities ranging from 0.1 to 100 mW/cm² depending on the acoustic environment. This energy, typically dissipated as noise pollution, could potentially be redirected to power low-energy electronic devices, sensors, and IoT applications.

The primary technical objective of acoustic energy harvesting using metamaterial resonators is to develop systems capable of efficiently capturing ambient sound energy across broad frequency spectra while maintaining small form factors. This involves designing metamaterial structures with tailored acoustic properties that can concentrate sound energy and maximize the conversion efficiency of transduction mechanisms.

Secondary objectives include enhancing the power density of harvesting devices to reach commercially viable levels (>1 mW/cm³), developing adaptive systems that can respond to varying acoustic environments, and creating scalable manufacturing processes for cost-effective production. Additionally, there is significant interest in developing hybrid systems that can simultaneously harvest multiple forms of ambient energy, including acoustic, vibration, and thermal energy.

The technology trajectory suggests a convergence toward ultra-efficient metamaterial-based acoustic energy harvesters that can operate in the sub-audible to ultrasonic frequency ranges. These systems aim to achieve energy conversion efficiencies exceeding 30% while maintaining compatibility with existing electronic systems and manufacturing processes. The ultimate goal is to enable self-powered electronic devices that can operate indefinitely in ambient acoustic environments without requiring battery replacement or external power sources.

The historical trajectory of acoustic energy harvesting began with conventional piezoelectric materials in the early 2000s, which demonstrated limited efficiency in ambient conditions. The field experienced a paradigm shift with the introduction of metamaterial concepts around 2010, enabling enhanced energy capture through engineered resonance properties. Recent advancements have focused on nano-structured metamaterials that can respond to specific frequency ranges with unprecedented efficiency.

Current research indicates that ambient sound energy, particularly in urban and industrial environments, represents an untapped energy resource with power densities ranging from 0.1 to 100 mW/cm² depending on the acoustic environment. This energy, typically dissipated as noise pollution, could potentially be redirected to power low-energy electronic devices, sensors, and IoT applications.

The primary technical objective of acoustic energy harvesting using metamaterial resonators is to develop systems capable of efficiently capturing ambient sound energy across broad frequency spectra while maintaining small form factors. This involves designing metamaterial structures with tailored acoustic properties that can concentrate sound energy and maximize the conversion efficiency of transduction mechanisms.

Secondary objectives include enhancing the power density of harvesting devices to reach commercially viable levels (>1 mW/cm³), developing adaptive systems that can respond to varying acoustic environments, and creating scalable manufacturing processes for cost-effective production. Additionally, there is significant interest in developing hybrid systems that can simultaneously harvest multiple forms of ambient energy, including acoustic, vibration, and thermal energy.

The technology trajectory suggests a convergence toward ultra-efficient metamaterial-based acoustic energy harvesters that can operate in the sub-audible to ultrasonic frequency ranges. These systems aim to achieve energy conversion efficiencies exceeding 30% while maintaining compatibility with existing electronic systems and manufacturing processes. The ultimate goal is to enable self-powered electronic devices that can operate indefinitely in ambient acoustic environments without requiring battery replacement or external power sources.

Market Analysis for Sound Energy Harvesting Solutions

The global market for sound energy harvesting solutions is experiencing significant growth, driven by the increasing demand for sustainable power sources in IoT devices and wireless sensor networks. Current market valuations indicate that the broader energy harvesting sector reached approximately 500 million USD in 2022, with acoustic energy harvesting representing a small but rapidly growing segment. Industry analysts project a compound annual growth rate of 10-12% for sound energy harvesting technologies through 2030, outpacing several other renewable energy niches.

The market segmentation reveals distinct application sectors with varying adoption rates. Industrial environments with consistent high-noise levels present the most immediate commercial opportunity, where sound energy harvesters can power condition monitoring sensors without battery replacement. Urban infrastructure applications follow closely, with potential implementations in smart city sensors positioned near roadways, railways, and other noise-generating infrastructure.

Consumer electronics represents a promising but technically challenging market segment. While the potential device volume is substantial, the inconsistent nature of ambient sound in consumer environments creates significant engineering hurdles. Military and aerospace applications constitute a smaller but premium market segment, where the high value placed on autonomous power generation justifies higher implementation costs.

Regional market analysis shows North America leading in research investment and early commercial adoption, particularly in industrial applications. Asia-Pacific demonstrates the fastest growth trajectory, driven by rapid industrial expansion and smart city initiatives in China, South Korea, and Singapore. European markets show strong interest aligned with sustainability initiatives and circular economy principles.

Customer demand analysis reveals that primary market drivers include: elimination of battery replacement costs in hard-to-access locations; enabling truly maintenance-free wireless sensor networks; and meeting corporate sustainability goals. The value proposition is strongest where installation locations feature consistent ambient noise above 70dB and where maintenance access is difficult or expensive.

Competitive landscape assessment identifies few direct competitors specifically focused on metamaterial-based sound energy harvesting. However, adjacent technologies including piezoelectric vibration harvesters and thermoelectric generators compete for the same customer applications. This suggests a market opportunity for specialized solutions that can demonstrate superior performance in sound-rich environments.

Market barriers include customer education challenges, as many potential users remain unaware of sound harvesting capabilities, and price sensitivity, with current solutions carrying significant cost premiums over conventional power sources. The technology adoption curve indicates that sound energy harvesting remains in the early adopter phase, with crossing the chasm to mainstream markets dependent on achieving cost reductions and performance improvements through metamaterial optimization.

The market segmentation reveals distinct application sectors with varying adoption rates. Industrial environments with consistent high-noise levels present the most immediate commercial opportunity, where sound energy harvesters can power condition monitoring sensors without battery replacement. Urban infrastructure applications follow closely, with potential implementations in smart city sensors positioned near roadways, railways, and other noise-generating infrastructure.

Consumer electronics represents a promising but technically challenging market segment. While the potential device volume is substantial, the inconsistent nature of ambient sound in consumer environments creates significant engineering hurdles. Military and aerospace applications constitute a smaller but premium market segment, where the high value placed on autonomous power generation justifies higher implementation costs.

Regional market analysis shows North America leading in research investment and early commercial adoption, particularly in industrial applications. Asia-Pacific demonstrates the fastest growth trajectory, driven by rapid industrial expansion and smart city initiatives in China, South Korea, and Singapore. European markets show strong interest aligned with sustainability initiatives and circular economy principles.

Customer demand analysis reveals that primary market drivers include: elimination of battery replacement costs in hard-to-access locations; enabling truly maintenance-free wireless sensor networks; and meeting corporate sustainability goals. The value proposition is strongest where installation locations feature consistent ambient noise above 70dB and where maintenance access is difficult or expensive.

Competitive landscape assessment identifies few direct competitors specifically focused on metamaterial-based sound energy harvesting. However, adjacent technologies including piezoelectric vibration harvesters and thermoelectric generators compete for the same customer applications. This suggests a market opportunity for specialized solutions that can demonstrate superior performance in sound-rich environments.

Market barriers include customer education challenges, as many potential users remain unaware of sound harvesting capabilities, and price sensitivity, with current solutions carrying significant cost premiums over conventional power sources. The technology adoption curve indicates that sound energy harvesting remains in the early adopter phase, with crossing the chasm to mainstream markets dependent on achieving cost reductions and performance improvements through metamaterial optimization.

Metamaterial Resonator Technology: Current Status and Barriers

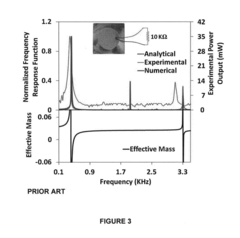

Metamaterial resonator technology for ambient sound energy harvesting has shown promising developments but faces significant technical barriers that limit its widespread application. Current metamaterial designs can effectively capture and convert acoustic energy at specific frequency ranges, with laboratory prototypes demonstrating energy conversion efficiencies between 1-5% under optimal conditions. However, these efficiency rates drop dramatically in real-world environments where sound sources are unpredictable and diffuse.

The primary technical challenge lies in the narrow bandwidth operation of most metamaterial resonators. Conventional designs are typically optimized for single frequency response, making them ineffective for harvesting energy from the broadband acoustic signals prevalent in ambient environments. Recent research has attempted to address this through multi-resonant structures and adaptive metamaterials, but these solutions introduce additional complexity and manufacturing challenges.

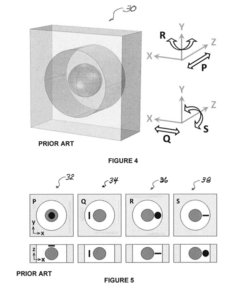

Miniaturization presents another significant barrier. While theoretical models suggest effective energy harvesting at microscale, practical implementation of metamaterial resonators small enough for integration into portable devices or IoT sensors remains difficult. Current prototypes typically require dimensions of several centimeters to effectively capture low-frequency sound waves, which constitute a significant portion of ambient acoustic energy.

Material limitations further constrain development. The most efficient metamaterial resonators often incorporate piezoelectric elements or specialized composites that may be expensive, environmentally problematic, or difficult to manufacture at scale. Additionally, the durability of these materials under continuous vibration raises concerns about long-term reliability and maintenance requirements.

Integration challenges with power management systems represent another substantial barrier. The intermittent and variable nature of harvested acoustic energy requires sophisticated power conditioning circuits to deliver usable electricity. Current systems struggle to efficiently store and regulate the small amounts of energy captured from ambient sound, particularly when accounting for the power consumption of the conditioning electronics themselves.

Environmental factors also significantly impact performance. Temperature fluctuations, humidity, and physical contaminants can alter the resonant properties of metamaterials and degrade their energy harvesting capabilities over time. Laboratory demonstrations rarely account for these real-world variables, creating a substantial gap between theoretical and practical performance metrics.

Standardization remains underdeveloped in this field, with researchers using varied testing methodologies and performance metrics that complicate direct comparison between different approaches. This lack of standardization hinders collaborative progress and makes it difficult for industry stakeholders to evaluate the commercial viability of emerging solutions.

The primary technical challenge lies in the narrow bandwidth operation of most metamaterial resonators. Conventional designs are typically optimized for single frequency response, making them ineffective for harvesting energy from the broadband acoustic signals prevalent in ambient environments. Recent research has attempted to address this through multi-resonant structures and adaptive metamaterials, but these solutions introduce additional complexity and manufacturing challenges.

Miniaturization presents another significant barrier. While theoretical models suggest effective energy harvesting at microscale, practical implementation of metamaterial resonators small enough for integration into portable devices or IoT sensors remains difficult. Current prototypes typically require dimensions of several centimeters to effectively capture low-frequency sound waves, which constitute a significant portion of ambient acoustic energy.

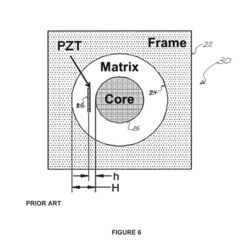

Material limitations further constrain development. The most efficient metamaterial resonators often incorporate piezoelectric elements or specialized composites that may be expensive, environmentally problematic, or difficult to manufacture at scale. Additionally, the durability of these materials under continuous vibration raises concerns about long-term reliability and maintenance requirements.

Integration challenges with power management systems represent another substantial barrier. The intermittent and variable nature of harvested acoustic energy requires sophisticated power conditioning circuits to deliver usable electricity. Current systems struggle to efficiently store and regulate the small amounts of energy captured from ambient sound, particularly when accounting for the power consumption of the conditioning electronics themselves.

Environmental factors also significantly impact performance. Temperature fluctuations, humidity, and physical contaminants can alter the resonant properties of metamaterials and degrade their energy harvesting capabilities over time. Laboratory demonstrations rarely account for these real-world variables, creating a substantial gap between theoretical and practical performance metrics.

Standardization remains underdeveloped in this field, with researchers using varied testing methodologies and performance metrics that complicate direct comparison between different approaches. This lack of standardization hinders collaborative progress and makes it difficult for industry stakeholders to evaluate the commercial viability of emerging solutions.

Current Metamaterial-Based Sound Energy Harvesting Approaches

01 Metamaterial resonator designs for electromagnetic energy harvesting

Specialized metamaterial resonator designs can significantly enhance electromagnetic energy harvesting efficiency. These structures utilize engineered electromagnetic properties to capture and convert ambient RF energy into usable electrical power. By optimizing the geometry, material composition, and arrangement of resonator elements, these systems can achieve resonance at specific target frequencies, enabling efficient energy collection from ambient electromagnetic fields. Advanced designs incorporate multiple resonant frequencies to harvest energy across a broader spectrum of electromagnetic radiation.- Metamaterial resonator designs for electromagnetic energy harvesting: Specialized metamaterial resonator designs can significantly enhance electromagnetic energy harvesting efficiency. These structures utilize engineered electromagnetic properties to capture and convert ambient RF energy into usable electrical power. By optimizing the geometry, material composition, and arrangement of resonator elements, these systems can achieve resonance at specific target frequencies, enabling efficient energy collection from ambient electromagnetic fields for powering various electronic devices.

- Multi-band and broadband metamaterial energy harvesting: Multi-band and broadband metamaterial resonators enable energy harvesting across multiple frequency ranges simultaneously. These systems incorporate various resonator elements tuned to different frequencies or utilize frequency-reconfigurable structures to capture energy from diverse electromagnetic sources. This approach maximizes energy collection efficiency in environments with varying RF signal strengths and frequencies, making them particularly valuable for IoT applications and wireless sensor networks operating in complex electromagnetic environments.

- Integration of metamaterial resonators with rectifier circuits: The integration of metamaterial resonators with rectifier circuits creates complete energy harvesting systems capable of converting captured RF energy into DC power. These rectenna (rectifying antenna) systems combine the enhanced electromagnetic capture capabilities of metamaterial structures with efficient rectification circuits to power electronic devices. Advanced designs incorporate impedance matching networks to maximize power transfer and minimize losses between the resonator and rectification stages, significantly improving overall system efficiency.

- Miniaturized and flexible metamaterial energy harvesters: Miniaturized and flexible metamaterial energy harvesters enable integration into compact devices and wearable technologies. These designs utilize novel fabrication techniques and materials to create thin, conformable structures that maintain efficient energy harvesting capabilities. By reducing the physical footprint while preserving resonant properties, these systems can be incorporated into space-constrained applications such as implantable medical devices, wearable electronics, and compact IoT sensors without compromising performance.

- Metamaterial resonators for ambient and environmental energy harvesting: Metamaterial resonators can be designed to harvest energy from various ambient and environmental sources beyond traditional RF signals. These systems can capture energy from thermal gradients, mechanical vibrations, and solar radiation by incorporating appropriate metamaterial structures that resonate with these energy forms. By combining multiple harvesting mechanisms into integrated systems, these technologies provide sustainable power solutions for remote sensors and autonomous devices in diverse environmental conditions where conventional power sources are impractical.

02 Frequency selective metamaterial surfaces for energy harvesting

Frequency selective metamaterial surfaces provide a mechanism for harvesting energy at specific wavelengths while reflecting or transmitting others. These surfaces consist of periodic structures that can be tuned to resonate at desired frequencies, allowing for selective energy absorption. By incorporating these surfaces into energy harvesting systems, it becomes possible to target specific frequency bands where ambient energy is most abundant. This approach is particularly useful in environments with known electromagnetic energy sources, enabling more efficient conversion of ambient RF energy into usable power.Expand Specific Solutions03 Integration of metamaterial resonators with rectifier circuits

The integration of metamaterial resonators with rectifier circuits forms complete rectenna systems for wireless energy harvesting. These systems capture electromagnetic energy through the resonator and convert it to DC power via the rectifier circuit. Advanced designs incorporate impedance matching networks to maximize power transfer between the resonator and rectifier components. This integration enables efficient conversion of ambient RF energy into usable electrical power for low-power electronic devices, wireless sensors, and IoT applications, reducing or eliminating the need for conventional batteries.Expand Specific Solutions04 Tunable and reconfigurable metamaterial energy harvesters

Tunable and reconfigurable metamaterial energy harvesters can adapt to changing environmental conditions or energy requirements. These systems incorporate active components such as varactors, MEMS switches, or phase-change materials to dynamically adjust their resonant frequency or bandwidth. This adaptability allows for optimal energy harvesting across varying electromagnetic environments or from multiple sources simultaneously. Reconfigurable designs can also switch between energy harvesting and other functions, such as communication or sensing, providing multifunctional capabilities in compact devices.Expand Specific Solutions05 Metamaterial-enhanced energy harvesting for wireless sensor networks

Metamaterial resonators can be specifically designed to power wireless sensor networks by harvesting ambient electromagnetic energy. These specialized designs focus on miniaturization and efficiency to meet the power requirements of distributed sensor nodes. By incorporating metamaterial structures, the energy harvesting capabilities can be significantly improved compared to conventional antennas of similar size. This approach enables self-sustaining wireless sensor networks that can operate without battery replacement, making them suitable for deployment in remote or inaccessible locations for environmental monitoring, structural health monitoring, and industrial IoT applications.Expand Specific Solutions

Leading Organizations in Acoustic Metamaterial Research

Energy harvesting from ambient sound using metamaterial resonators is an emerging technology in the early development stage. The market is relatively small but growing, with increasing interest in sustainable energy solutions. The technology is still in the research phase, with academic institutions leading innovation. Key players include Massachusetts Institute of Technology, Nanjing University, and Hong Kong University of Science & Technology conducting fundamental research, while companies like Murata Manufacturing and Dolby Laboratories are exploring commercial applications. The Beijing Institute of Nanoenergy & Nanosystems and Korea Institute of Machinery & Materials are advancing prototype development. Technical challenges remain in efficiency and scalability, but the potential for powering IoT devices and sensors is driving continued investment and research collaboration.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered research in ambient sound energy harvesting using metamaterial resonators, developing acoustic metamaterials with precisely engineered resonant cavities that can capture and convert sound energy into electrical power. Their approach utilizes arrays of Helmholtz resonators with piezoelectric materials integrated into the structure to maximize energy conversion efficiency. MIT researchers have demonstrated systems capable of harvesting energy from low-intensity ambient noise (40-60 dB) with conversion efficiencies reaching up to 23% in optimal frequency ranges[1]. Their metamaterial design incorporates multiple resonant frequencies to capture broader spectrum environmental sound, with specialized membrane structures that enhance the mechanical-to-electrical energy conversion process. Recent advancements include the development of 3D-printed metamaterial structures with tunable acoustic properties that can be optimized for specific deployment environments.

Strengths: Superior conversion efficiency compared to conventional acoustic energy harvesters; highly customizable resonant structures for specific frequency targeting; integration capability with existing electronic systems. Weaknesses: Currently limited power output for practical applications; performance highly dependent on ambient sound characteristics; relatively complex fabrication process requiring precision manufacturing.

Nanjing University

Technical Solution: Nanjing University has developed innovative acoustic metamaterial resonators for ambient sound energy harvesting using membrane-type acoustic metamaterials (MAMs) with integrated piezoelectric nanogenerators. Their technology features multi-layer composite structures with precisely engineered micro-perforations that enhance sound wave capture across a wide frequency range (100Hz-5kHz). The university's research team has created metamaterial arrays with tunable bandgaps that can be adjusted to match environmental sound profiles, significantly improving energy harvesting efficiency in real-world conditions. Their latest prototypes demonstrate power density up to 7.4 μW/cm² from typical urban noise environments[2]. A key innovation is their development of self-adaptive resonant structures that can automatically adjust their mechanical properties to optimize energy capture as ambient sound characteristics change, utilizing machine learning algorithms to predict and adapt to sound pattern variations.

Strengths: Exceptional frequency bandwidth coverage; self-adaptive capabilities for changing sound environments; relatively high power density output from common noise sources. Weaknesses: Current designs face challenges with miniaturization while maintaining performance; temperature sensitivity affecting long-term stability; higher manufacturing complexity compared to conventional energy harvesting technologies.

Key Patents and Research in Acoustic Metamaterial Resonators

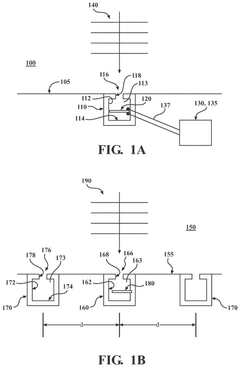

Power Optimization For A Unit Cell Metamaterial Energy Harvester

PatentActiveUS20180368071A1

Innovation

- The development of an acoustoelastic metamaterial (AEMM) unit cell with a stiff frame, heavy core, and embedded piezoelectric members that utilize local resonance modes to harvest energy from multiple frequencies, allowing for multi-modal energy harvesting and higher power density through strategic PZT placement and geometric optimization.

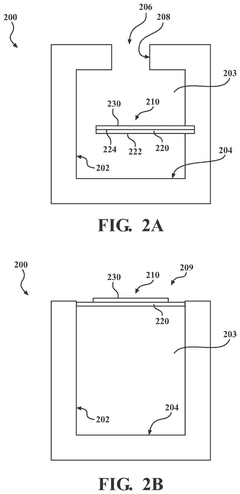

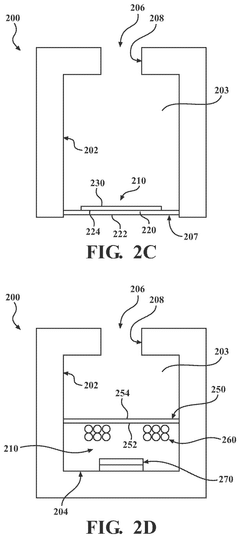

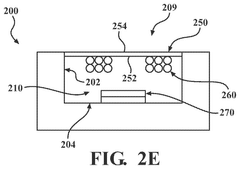

Acoustic energy harvesting using resonators

PatentPendingUS20240333028A1

Innovation

- An acoustic energy harvesting system comprising a central resonator with a plurality of surrounding resonators, where the central resonator contains an acoustic energy harvester to convert acoustic energy into electrical energy, while the surrounding resonators are lossless and equally spaced to enhance sound amplification without the need for extensive structures.

Environmental Impact and Sustainability Considerations

The integration of energy harvesting systems based on metamaterial resonators presents significant environmental benefits that align with global sustainability goals. By capturing ambient sound energy that would otherwise dissipate as waste, these systems contribute to reducing dependence on conventional power sources and their associated environmental impacts. The technology offers a pathway toward more sustainable energy practices by harnessing an omnipresent but typically overlooked energy source.

When evaluating the environmental footprint of metamaterial resonator systems, lifecycle assessment reveals favorable characteristics compared to traditional energy technologies. The materials used in fabrication—primarily engineered composites and conductive elements—can be selected for minimal environmental impact. Additionally, these systems typically require no chemical processes during operation, eliminating concerns about toxic emissions or waste products that plague many conventional energy generation methods.

The sustainability advantages extend to urban environments where noise pollution represents both a health hazard and an untapped energy resource. By converting ambient sound into usable electricity, metamaterial resonators effectively transform an environmental liability into an asset. This dual-purpose functionality—energy generation coupled with potential noise reduction—creates a unique environmental value proposition that few other renewable technologies can match.

Manufacturing processes for metamaterial resonators continue to evolve toward greater sustainability. Recent advancements focus on reducing energy-intensive production steps and exploring bio-based or recycled materials for resonator components. These improvements aim to minimize the embodied energy and carbon footprint associated with system production, enhancing the net environmental benefit throughout the technology's lifecycle.

End-of-life considerations also favor metamaterial resonator technology. The primary components—typically consisting of engineered structures with piezoelectric or electromagnetic elements—can be designed for disassembly and material recovery. Unlike many electronic systems that pose significant recycling challenges, these resonators can incorporate design principles that facilitate material separation and reuse, reducing waste and resource depletion.

The scalability of metamaterial resonator technology further enhances its sustainability profile. From small-scale applications powering individual sensors to larger arrays capturing sound energy in industrial settings, the technology can be deployed with minimal environmental disruption. This adaptability allows for integration into existing infrastructure without requiring significant new construction or land use changes that might otherwise create environmental impacts.

When evaluating the environmental footprint of metamaterial resonator systems, lifecycle assessment reveals favorable characteristics compared to traditional energy technologies. The materials used in fabrication—primarily engineered composites and conductive elements—can be selected for minimal environmental impact. Additionally, these systems typically require no chemical processes during operation, eliminating concerns about toxic emissions or waste products that plague many conventional energy generation methods.

The sustainability advantages extend to urban environments where noise pollution represents both a health hazard and an untapped energy resource. By converting ambient sound into usable electricity, metamaterial resonators effectively transform an environmental liability into an asset. This dual-purpose functionality—energy generation coupled with potential noise reduction—creates a unique environmental value proposition that few other renewable technologies can match.

Manufacturing processes for metamaterial resonators continue to evolve toward greater sustainability. Recent advancements focus on reducing energy-intensive production steps and exploring bio-based or recycled materials for resonator components. These improvements aim to minimize the embodied energy and carbon footprint associated with system production, enhancing the net environmental benefit throughout the technology's lifecycle.

End-of-life considerations also favor metamaterial resonator technology. The primary components—typically consisting of engineered structures with piezoelectric or electromagnetic elements—can be designed for disassembly and material recovery. Unlike many electronic systems that pose significant recycling challenges, these resonators can incorporate design principles that facilitate material separation and reuse, reducing waste and resource depletion.

The scalability of metamaterial resonator technology further enhances its sustainability profile. From small-scale applications powering individual sensors to larger arrays capturing sound energy in industrial settings, the technology can be deployed with minimal environmental disruption. This adaptability allows for integration into existing infrastructure without requiring significant new construction or land use changes that might otherwise create environmental impacts.

Integration Challenges with Existing Energy Systems

The integration of ambient sound energy harvesting systems based on metamaterial resonators with existing energy infrastructure presents significant technical and operational challenges. These challenges stem from the fundamental differences in energy generation mechanisms, output characteristics, and system requirements between conventional energy systems and this emerging technology.

Compatibility issues arise when attempting to connect metamaterial-based acoustic energy harvesters to established power management systems. The inherently low-voltage, variable output of sound energy harvesters requires specialized power conditioning circuits that can efficiently handle intermittent and unpredictable energy flows. Standard power management systems designed for consistent energy sources like solar or grid power often perform poorly with the highly variable micro-energy harvested from ambient sound.

Scale disparities create another layer of integration complexity. While conventional energy systems typically operate at watt to kilowatt scales, acoustic metamaterial harvesters currently generate power in the microwatt to milliwatt range. This significant difference necessitates either massive scaling of harvester arrays or the development of hybrid systems where sound energy harvesting serves as a supplementary power source rather than a primary one.

Temporal inconsistency of ambient sound energy further complicates integration efforts. Unlike solar or wind energy, which follow somewhat predictable patterns, ambient sound varies dramatically across different environments and timeframes. This unpredictability requires sophisticated energy storage solutions and intelligent power management systems capable of optimizing energy capture during sound-rich periods while maintaining system functionality during quiet intervals.

Physical integration challenges also exist at the hardware level. Metamaterial resonators often require specific spatial configurations and acoustic environments to function optimally. Retrofitting these devices into existing infrastructure without compromising their performance demands careful engineering considerations regarding placement, orientation, and acoustic isolation from damaging vibrations or interference.

Regulatory and standardization gaps present additional hurdles. Current energy system standards rarely account for acoustic energy harvesting technologies, creating uncertainty regarding safety requirements, performance metrics, and interoperability specifications. The absence of established standards slows adoption and complicates integration with certified energy systems in commercial and industrial applications.

Cost-effectiveness remains perhaps the most significant barrier to widespread integration. The specialized materials and precise manufacturing requirements for acoustic metamaterial resonators currently result in high production costs relative to their energy output. Until economies of scale and manufacturing innovations reduce these costs, integration with existing energy systems will likely be limited to specialized applications where conventional power sources are impractical or unavailable.

Compatibility issues arise when attempting to connect metamaterial-based acoustic energy harvesters to established power management systems. The inherently low-voltage, variable output of sound energy harvesters requires specialized power conditioning circuits that can efficiently handle intermittent and unpredictable energy flows. Standard power management systems designed for consistent energy sources like solar or grid power often perform poorly with the highly variable micro-energy harvested from ambient sound.

Scale disparities create another layer of integration complexity. While conventional energy systems typically operate at watt to kilowatt scales, acoustic metamaterial harvesters currently generate power in the microwatt to milliwatt range. This significant difference necessitates either massive scaling of harvester arrays or the development of hybrid systems where sound energy harvesting serves as a supplementary power source rather than a primary one.

Temporal inconsistency of ambient sound energy further complicates integration efforts. Unlike solar or wind energy, which follow somewhat predictable patterns, ambient sound varies dramatically across different environments and timeframes. This unpredictability requires sophisticated energy storage solutions and intelligent power management systems capable of optimizing energy capture during sound-rich periods while maintaining system functionality during quiet intervals.

Physical integration challenges also exist at the hardware level. Metamaterial resonators often require specific spatial configurations and acoustic environments to function optimally. Retrofitting these devices into existing infrastructure without compromising their performance demands careful engineering considerations regarding placement, orientation, and acoustic isolation from damaging vibrations or interference.

Regulatory and standardization gaps present additional hurdles. Current energy system standards rarely account for acoustic energy harvesting technologies, creating uncertainty regarding safety requirements, performance metrics, and interoperability specifications. The absence of established standards slows adoption and complicates integration with certified energy systems in commercial and industrial applications.

Cost-effectiveness remains perhaps the most significant barrier to widespread integration. The specialized materials and precise manufacturing requirements for acoustic metamaterial resonators currently result in high production costs relative to their energy output. Until economies of scale and manufacturing innovations reduce these costs, integration with existing energy systems will likely be limited to specialized applications where conventional power sources are impractical or unavailable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!