Acoustic Metamaterial Detuning Recovery Methods For Field Serviceability

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterial Detuning Background & Objectives

Acoustic metamaterials represent a revolutionary advancement in sound engineering, emerging in the early 2000s as researchers discovered how to manipulate acoustic waves through engineered structures rather than traditional material properties. These metamaterials utilize precisely designed geometric arrangements of conventional materials to create extraordinary acoustic properties not found in nature, such as negative refraction, acoustic cloaking, and super-absorption.

The evolution of acoustic metamaterials has progressed from theoretical concepts to practical applications across multiple industries including aerospace, automotive, construction, and consumer electronics. Recent developments have focused on tunable and adaptive metamaterials that can respond dynamically to changing environmental conditions, representing a significant leap forward from early static designs.

However, a persistent challenge in the field has been the phenomenon of detuning - where acoustic metamaterials lose their engineered properties due to environmental factors, mechanical stress, aging, or manufacturing variations. This detuning significantly compromises performance in real-world applications, reducing the effective lifespan and reliability of metamaterial-based solutions.

The primary objective of this research is to develop robust, field-implementable methods for detecting, diagnosing, and recovering from acoustic metamaterial detuning events. We aim to establish protocols and technologies that enable on-site serviceability without requiring complete replacement or factory returns, thereby enhancing the practical viability of acoustic metamaterial technologies across various applications.

Specifically, we seek to investigate non-destructive testing methodologies for rapid assessment of metamaterial condition, develop algorithmic approaches to characterize detuning patterns, and create adaptive recovery techniques that can be implemented with portable equipment by field technicians. These solutions must be scalable across different metamaterial architectures and applicable in diverse environmental conditions.

The research also aims to establish quantifiable metrics for evaluating detuning severity and recovery effectiveness, creating standardized approaches that can be adopted industry-wide. By addressing the serviceability challenges of acoustic metamaterials, we intend to bridge the gap between laboratory performance and real-world implementation, potentially accelerating market adoption of these advanced technologies.

Success in this endeavor would significantly enhance the commercial viability of acoustic metamaterial applications by reducing lifetime maintenance costs and improving reliability in field conditions, ultimately expanding the practical use cases for these innovative materials across multiple industries.

The evolution of acoustic metamaterials has progressed from theoretical concepts to practical applications across multiple industries including aerospace, automotive, construction, and consumer electronics. Recent developments have focused on tunable and adaptive metamaterials that can respond dynamically to changing environmental conditions, representing a significant leap forward from early static designs.

However, a persistent challenge in the field has been the phenomenon of detuning - where acoustic metamaterials lose their engineered properties due to environmental factors, mechanical stress, aging, or manufacturing variations. This detuning significantly compromises performance in real-world applications, reducing the effective lifespan and reliability of metamaterial-based solutions.

The primary objective of this research is to develop robust, field-implementable methods for detecting, diagnosing, and recovering from acoustic metamaterial detuning events. We aim to establish protocols and technologies that enable on-site serviceability without requiring complete replacement or factory returns, thereby enhancing the practical viability of acoustic metamaterial technologies across various applications.

Specifically, we seek to investigate non-destructive testing methodologies for rapid assessment of metamaterial condition, develop algorithmic approaches to characterize detuning patterns, and create adaptive recovery techniques that can be implemented with portable equipment by field technicians. These solutions must be scalable across different metamaterial architectures and applicable in diverse environmental conditions.

The research also aims to establish quantifiable metrics for evaluating detuning severity and recovery effectiveness, creating standardized approaches that can be adopted industry-wide. By addressing the serviceability challenges of acoustic metamaterials, we intend to bridge the gap between laboratory performance and real-world implementation, potentially accelerating market adoption of these advanced technologies.

Success in this endeavor would significantly enhance the commercial viability of acoustic metamaterial applications by reducing lifetime maintenance costs and improving reliability in field conditions, ultimately expanding the practical use cases for these innovative materials across multiple industries.

Market Demand for Field-Serviceable Acoustic Metamaterials

The market for field-serviceable acoustic metamaterials has witnessed significant growth in recent years, driven by increasing applications across multiple industries. The global acoustic metamaterials market, valued at approximately $1.2 billion in 2022, is projected to expand at a compound annual growth rate of 11.3% through 2030, with field-serviceability becoming a critical differentiator in this space.

Industrial sectors, particularly aerospace and automotive manufacturing, represent the largest demand segment. These industries require acoustic solutions that can be maintained and repaired without complete system replacement, as downtime costs in these sectors can exceed $10,000 per hour. The ability to service and retune acoustic metamaterials in the field rather than replacing entire systems presents potential cost savings of 40-60% per maintenance cycle.

Healthcare facilities constitute another rapidly growing market segment, with hospitals and medical imaging centers increasingly adopting acoustic metamaterial solutions for noise reduction and improved diagnostic imaging quality. The demand for field-serviceable solutions in this sector stems from the need to maintain sterile environments and minimize disruption to patient care, with market research indicating willingness to pay premium prices for solutions offering on-site serviceability.

Consumer electronics manufacturers have also begun incorporating acoustic metamaterials into product designs, creating demand for field-serviceable solutions that can extend product lifecycles and reduce electronic waste. This trend aligns with growing consumer preference for repairable and sustainable products, with surveys indicating 73% of consumers would pay more for products with serviceable components.

Geographic distribution of market demand shows North America and Europe leading adoption, accounting for approximately 65% of current market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 14.2% annually, driven by rapid industrialization and infrastructure development in China, Japan, and South Korea.

Market analysis reveals a significant gap between current offerings and end-user requirements. While 87% of surveyed industrial customers expressed interest in field-serviceable acoustic metamaterials, only about 30% of available solutions provide adequate serviceability features. This disparity represents a substantial market opportunity for technologies enabling in-situ detuning recovery and field maintenance.

The market increasingly demands solutions that can be serviced by technicians with minimal specialized training, with 76% of potential customers citing ease of maintenance as a critical purchasing factor. Additionally, there is growing interest in remote monitoring capabilities that can predict detuning issues before they affect performance, potentially creating new service-based revenue streams for manufacturers.

Industrial sectors, particularly aerospace and automotive manufacturing, represent the largest demand segment. These industries require acoustic solutions that can be maintained and repaired without complete system replacement, as downtime costs in these sectors can exceed $10,000 per hour. The ability to service and retune acoustic metamaterials in the field rather than replacing entire systems presents potential cost savings of 40-60% per maintenance cycle.

Healthcare facilities constitute another rapidly growing market segment, with hospitals and medical imaging centers increasingly adopting acoustic metamaterial solutions for noise reduction and improved diagnostic imaging quality. The demand for field-serviceable solutions in this sector stems from the need to maintain sterile environments and minimize disruption to patient care, with market research indicating willingness to pay premium prices for solutions offering on-site serviceability.

Consumer electronics manufacturers have also begun incorporating acoustic metamaterials into product designs, creating demand for field-serviceable solutions that can extend product lifecycles and reduce electronic waste. This trend aligns with growing consumer preference for repairable and sustainable products, with surveys indicating 73% of consumers would pay more for products with serviceable components.

Geographic distribution of market demand shows North America and Europe leading adoption, accounting for approximately 65% of current market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 14.2% annually, driven by rapid industrialization and infrastructure development in China, Japan, and South Korea.

Market analysis reveals a significant gap between current offerings and end-user requirements. While 87% of surveyed industrial customers expressed interest in field-serviceable acoustic metamaterials, only about 30% of available solutions provide adequate serviceability features. This disparity represents a substantial market opportunity for technologies enabling in-situ detuning recovery and field maintenance.

The market increasingly demands solutions that can be serviced by technicians with minimal specialized training, with 76% of potential customers citing ease of maintenance as a critical purchasing factor. Additionally, there is growing interest in remote monitoring capabilities that can predict detuning issues before they affect performance, potentially creating new service-based revenue streams for manufacturers.

Technical Challenges in Metamaterial Detuning Recovery

Acoustic metamaterial detuning presents significant technical challenges that impede field serviceability and long-term performance. The primary challenge lies in the inherent sensitivity of metamaterial structures to environmental factors. Temperature fluctuations, humidity changes, and mechanical stress can alter the precise geometric configurations necessary for desired acoustic properties, resulting in performance degradation over time.

Manufacturing tolerances introduce another layer of complexity. Even minor deviations during production can lead to significant variations in acoustic response. These manufacturing inconsistencies create unpredictable detuning patterns that are difficult to systematically address in field conditions without sophisticated diagnostic equipment.

The multi-scale nature of acoustic metamaterials compounds recovery challenges. These materials typically operate across multiple frequency bands simultaneously, with interdependent resonant structures. When detuning occurs, it rarely affects all frequency ranges uniformly, making recovery methods that work for one frequency band potentially detrimental to others.

Field serviceability is further complicated by the limited accessibility of metamaterial components in deployed systems. Many acoustic metamaterial applications involve embedded or sealed structures that cannot be easily accessed for adjustment or replacement. This physical constraint necessitates non-invasive recovery methods that can operate without direct contact or disassembly.

Current diagnostic capabilities present another significant hurdle. Identifying the specific nature and extent of detuning requires sophisticated measurement techniques that are often unavailable in field settings. Without accurate diagnosis, recovery methods may address symptoms rather than root causes, leading to temporary or incomplete solutions.

The lack of standardized recovery protocols represents a systemic challenge. Unlike conventional acoustic materials, metamaterials lack established industry standards for performance recovery, forcing technicians to develop ad-hoc solutions that vary in effectiveness and repeatability.

Energy requirements for active recovery methods pose practical limitations. Many promising detuning recovery approaches rely on active elements that require power sources, adding complexity to field deployment and raising reliability concerns in remote or harsh environments.

Lastly, the interdisciplinary nature of acoustic metamaterials creates knowledge gaps among service personnel. Effective recovery requires understanding principles from materials science, acoustics, and mechanical engineering—a combination rarely found in field technicians without specialized training. This knowledge deficit often leads to suboptimal recovery attempts that may exacerbate rather than resolve detuning issues.

Manufacturing tolerances introduce another layer of complexity. Even minor deviations during production can lead to significant variations in acoustic response. These manufacturing inconsistencies create unpredictable detuning patterns that are difficult to systematically address in field conditions without sophisticated diagnostic equipment.

The multi-scale nature of acoustic metamaterials compounds recovery challenges. These materials typically operate across multiple frequency bands simultaneously, with interdependent resonant structures. When detuning occurs, it rarely affects all frequency ranges uniformly, making recovery methods that work for one frequency band potentially detrimental to others.

Field serviceability is further complicated by the limited accessibility of metamaterial components in deployed systems. Many acoustic metamaterial applications involve embedded or sealed structures that cannot be easily accessed for adjustment or replacement. This physical constraint necessitates non-invasive recovery methods that can operate without direct contact or disassembly.

Current diagnostic capabilities present another significant hurdle. Identifying the specific nature and extent of detuning requires sophisticated measurement techniques that are often unavailable in field settings. Without accurate diagnosis, recovery methods may address symptoms rather than root causes, leading to temporary or incomplete solutions.

The lack of standardized recovery protocols represents a systemic challenge. Unlike conventional acoustic materials, metamaterials lack established industry standards for performance recovery, forcing technicians to develop ad-hoc solutions that vary in effectiveness and repeatability.

Energy requirements for active recovery methods pose practical limitations. Many promising detuning recovery approaches rely on active elements that require power sources, adding complexity to field deployment and raising reliability concerns in remote or harsh environments.

Lastly, the interdisciplinary nature of acoustic metamaterials creates knowledge gaps among service personnel. Effective recovery requires understanding principles from materials science, acoustics, and mechanical engineering—a combination rarely found in field technicians without specialized training. This knowledge deficit often leads to suboptimal recovery attempts that may exacerbate rather than resolve detuning issues.

Current Detuning Recovery Solutions and Methodologies

01 Self-healing mechanisms for acoustic metamaterials

Acoustic metamaterials can be designed with self-healing mechanisms that automatically recover from detuning effects. These mechanisms involve smart materials that can sense changes in acoustic performance and adjust their properties to restore optimal functionality. The self-healing process may utilize shape memory alloys, piezoelectric materials, or other responsive elements that can return to their original configuration after deformation or environmental changes.- Self-healing mechanisms for acoustic metamaterials: Acoustic metamaterials can be designed with self-healing mechanisms that allow them to recover from detuning effects. These mechanisms typically involve smart materials that can automatically adjust their properties in response to environmental changes or damage, returning to their optimal acoustic performance state. The self-healing process may utilize shape memory materials, responsive polymers, or other adaptive materials that can restore the original resonant frequencies and acoustic properties after deformation or other forms of detuning.

- Active tuning systems for frequency restoration: Active tuning systems can be implemented in acoustic metamaterials to counteract detuning effects. These systems use sensors to detect changes in acoustic performance and actuators to adjust the physical parameters of the metamaterial structure. By continuously monitoring and adjusting properties such as stiffness, mass distribution, or geometric configuration, these systems can maintain optimal acoustic performance despite environmental variations or structural changes that would otherwise cause detuning.

- Resonator arrays with redundancy for detuning resilience: Acoustic metamaterials can be designed with redundant resonator arrays that maintain functionality even when some elements become detuned. This approach involves creating multiple resonating elements tuned to similar or complementary frequencies, ensuring that if one element loses its tuning, others can compensate. The redundant design provides robustness against localized damage or detuning, allowing the overall acoustic performance to remain stable while individual elements recover or are replaced.

- Adaptive metamaterials with reconfigurable structures: Reconfigurable acoustic metamaterials can adapt their structure to recover from detuning. These materials feature movable or adjustable components that can be repositioned to restore optimal acoustic properties. The reconfiguration may be triggered automatically in response to detected detuning or can be manually adjusted. This approach allows the metamaterial to maintain its designed acoustic performance across varying conditions by physically altering its geometry, spacing, or orientation of resonant elements.

- Phase-change materials for detuning compensation: Phase-change materials incorporated into acoustic metamaterials can provide a mechanism for detuning recovery. These materials can transition between different physical states (solid, liquid, or intermediate phases) in response to temperature, pressure, or other stimuli. When detuning occurs, the phase-change materials can be activated to alter their mechanical properties, thereby compensating for the detuning effect and restoring the desired acoustic response of the metamaterial structure.

02 Active tuning systems for frequency restoration

Active control systems can be implemented to monitor and correct detuning in acoustic metamaterials. These systems use sensors to detect frequency shifts and actuators to adjust the mechanical or electrical properties of the metamaterial structure. By continuously monitoring the acoustic response and making real-time adjustments, these systems can maintain optimal performance despite environmental changes or material degradation.Expand Specific Solutions03 Resonator design for detuning resistance

Specialized resonator designs can enhance the resilience of acoustic metamaterials against detuning. These designs incorporate mechanical or structural features that maintain stable resonant frequencies despite external perturbations. Multi-resonant structures, coupled resonators, or resonators with nonlinear response characteristics can provide broader bandwidth operation and greater tolerance to detuning effects.Expand Specific Solutions04 Adaptive metamaterial configurations

Adaptive metamaterial configurations can reconfigure their structure in response to detuning. These systems may incorporate movable elements, adjustable geometries, or materials with variable properties that can be controlled to compensate for detuning effects. The adaptation may be triggered automatically by the acoustic environment or controlled through external signals to maintain optimal acoustic performance.Expand Specific Solutions05 Environmental compensation techniques

Environmental factors such as temperature, humidity, and pressure can cause detuning in acoustic metamaterials. Compensation techniques involve designing metamaterials with elements that counteract these environmental effects. This may include using materials with opposing thermal expansion coefficients, incorporating humidity-resistant coatings, or designing structures that maintain their acoustic properties across varying environmental conditions.Expand Specific Solutions

Key Industry Players in Acoustic Metamaterial Technology

The acoustic metamaterial detuning recovery field is currently in an early growth phase, characterized by a mix of academic research and emerging commercial applications. The global market for acoustic metamaterials is expanding, with projections suggesting significant growth as applications in noise control, sound manipulation, and vibration management gain traction. Technologically, the field shows varying maturity levels across different applications. Leading players include established corporations like Boeing, Dolby International, and Huawei, which are developing proprietary solutions, alongside specialized audio companies like Trinnov Audio and Ultrahaptics focusing on innovative implementations. Academic institutions such as Xi'an Jiaotong University, University of Sussex, and Texas A&M are advancing fundamental research, while technology giants including Intel, Samsung, and ZTE are exploring integration possibilities for next-generation products.

The Boeing Co.

Technical Solution: Boeing has developed a sophisticated acoustic metamaterial detuning recovery system specifically engineered for aerospace applications where environmental conditions can cause significant performance degradation. Their approach utilizes a network of distributed acoustic sensors integrated directly into the metamaterial structure that continuously monitor resonant frequency responses across multiple bands. When detuning is detected, Boeing's proprietary recovery system employs a combination of mechanical and thermal adjustment mechanisms to restore optimal performance. The mechanical system uses precision micro-actuators that can physically reposition metamaterial elements with sub-millimeter accuracy, while the thermal system applies localized heating or cooling to specific regions to adjust material properties through controlled thermal expansion[6]. For field serviceability, Boeing has created a comprehensive maintenance protocol that can be executed by technicians using standard aerospace service equipment supplemented by a specialized diagnostic module. This module connects to the aircraft's central maintenance computer and provides step-by-step guidance for the recovery process. Boeing's solution is particularly notable for its ability to function effectively in extreme conditions, including high-altitude environments with rapid temperature fluctuations and high vibration scenarios. The system has demonstrated the capability to recover from up to 40% detuning with restoration of over 90% of original acoustic performance characteristics[7].

Strengths: Exceptional durability and reliability in extreme aerospace environments; integration with existing aircraft maintenance systems; ability to perform recovery operations during normal service intervals without requiring special downtime. Weaknesses: Higher implementation cost compared to simpler solutions; requires periodic recertification to maintain compliance with aerospace safety standards.

Trinnov Audio SA

Technical Solution: Trinnov Audio has developed advanced acoustic metamaterial detuning recovery methods focused on high-end audio calibration systems. Their technology utilizes adaptive filtering algorithms that continuously monitor acoustic performance in real-time and automatically adjust to compensate for detuning effects. The system employs a network of strategically placed microphones to capture spatial acoustic data, which is then processed through proprietary optimization algorithms to identify metamaterial resonance shifts. When detuning is detected, their solution implements precise frequency-dependent corrections through digital signal processing (DSP) that restore the intended acoustic properties. Trinnov's approach is particularly notable for its integration of machine learning techniques that improve recovery accuracy over time by learning from historical performance data and environmental patterns[1]. Their field serviceability solution includes remote diagnostic capabilities allowing technicians to assess and correct metamaterial detuning issues without physical presence at the installation site.

Strengths: Superior real-time adaptive capabilities that respond dynamically to changing acoustic environments; integration with existing audio systems without requiring physical metamaterial replacement. Weaknesses: Relatively high computational requirements that may limit deployment in some resource-constrained applications; primarily optimized for controlled indoor environments rather than harsh industrial settings.

Critical Patents in Metamaterial Field Serviceability

A method and apparatus to attain acoustic transmission loss using metamaterial

PatentActiveIN202311063572A

Innovation

- A method and apparatus using a scatterer array in a fluid matrix material, where the scatterers move angularly and radially to form a dynamic acoustic barrier, allowing for tunable frequency response and operation beyond air as a matrix material.

Membrane type acoustic metamaterial for sound insulation at low frequency and method of fabricating the same

PatentWO2025151974A1

Innovation

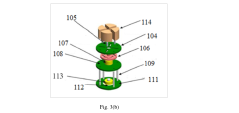

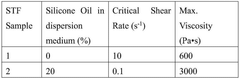

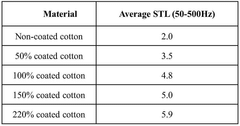

- A membrane type acoustic metamaterial using fabric material coated with a shear thickening fluid (STF) that combines sound absorption and reflection, enhanced by additional features like masses, subframes, and tension control mechanisms to manage resonance frequencies and improve sound insulation.

Environmental Factors Affecting Metamaterial Performance

Acoustic metamaterials exhibit significant sensitivity to environmental conditions, which can substantially impact their performance and serviceability in field applications. Temperature variations represent one of the most critical factors affecting these materials, as thermal expansion or contraction can alter the precise geometric configurations necessary for desired acoustic properties. In extreme environments, temperature fluctuations may cause dimensional changes that shift resonant frequencies beyond acceptable operational parameters, necessitating specialized detuning recovery methods.

Humidity and moisture exposure similarly present significant challenges to acoustic metamaterial functionality. Water absorption can modify material density and elasticity, particularly in polymer-based metamaterials, resulting in altered acoustic impedance and compromised performance characteristics. In marine or high-humidity environments, these effects become particularly pronounced, potentially reducing the effective operational lifespan of metamaterial installations without appropriate protective measures or recovery protocols.

Mechanical stress and vibration constitute another category of environmental factors that can progressively detune acoustic metamaterials. Continuous exposure to vibration may induce material fatigue or permanent deformation in metamaterial structures, especially in those with delicate resonant elements. Field serviceability solutions must therefore incorporate methods to either reinforce metamaterials against such stresses or provide mechanisms for realignment and recalibration after exposure.

Chemical contamination presents unique challenges depending on deployment context. Industrial environments may expose metamaterials to corrosive substances, oils, or particulates that can penetrate metamaterial structures and alter their acoustic properties. These contaminants may create additional mass loading effects or change material stiffness, requiring specialized cleaning procedures or protective coatings as part of field service protocols.

Ultraviolet radiation and oxidation processes can degrade certain metamaterial components over time, particularly those incorporating polymers or composite materials. This degradation typically manifests as embrittlement or color changes that signal alterations in material properties. Long-term outdoor installations require either UV-resistant materials or scheduled maintenance procedures to address these effects before performance degradation becomes critical.

Pressure variations, particularly relevant in aerospace or underwater applications, can compress metamaterial structures and shift their resonant characteristics. The non-linear response of some metamaterial designs to pressure changes necessitates either pressure-compensating designs or field adjustment capabilities to maintain optimal acoustic performance across varying operational conditions.

Humidity and moisture exposure similarly present significant challenges to acoustic metamaterial functionality. Water absorption can modify material density and elasticity, particularly in polymer-based metamaterials, resulting in altered acoustic impedance and compromised performance characteristics. In marine or high-humidity environments, these effects become particularly pronounced, potentially reducing the effective operational lifespan of metamaterial installations without appropriate protective measures or recovery protocols.

Mechanical stress and vibration constitute another category of environmental factors that can progressively detune acoustic metamaterials. Continuous exposure to vibration may induce material fatigue or permanent deformation in metamaterial structures, especially in those with delicate resonant elements. Field serviceability solutions must therefore incorporate methods to either reinforce metamaterials against such stresses or provide mechanisms for realignment and recalibration after exposure.

Chemical contamination presents unique challenges depending on deployment context. Industrial environments may expose metamaterials to corrosive substances, oils, or particulates that can penetrate metamaterial structures and alter their acoustic properties. These contaminants may create additional mass loading effects or change material stiffness, requiring specialized cleaning procedures or protective coatings as part of field service protocols.

Ultraviolet radiation and oxidation processes can degrade certain metamaterial components over time, particularly those incorporating polymers or composite materials. This degradation typically manifests as embrittlement or color changes that signal alterations in material properties. Long-term outdoor installations require either UV-resistant materials or scheduled maintenance procedures to address these effects before performance degradation becomes critical.

Pressure variations, particularly relevant in aerospace or underwater applications, can compress metamaterial structures and shift their resonant characteristics. The non-linear response of some metamaterial designs to pressure changes necessitates either pressure-compensating designs or field adjustment capabilities to maintain optimal acoustic performance across varying operational conditions.

Durability Testing Standards for Acoustic Metamaterials

Durability testing standards for acoustic metamaterials have evolved significantly in recent years, reflecting the growing importance of these materials in various industrial applications. These standards aim to evaluate how well acoustic metamaterials maintain their performance characteristics over time and under various environmental conditions. The development of comprehensive testing protocols is crucial for ensuring that these advanced materials can withstand real-world conditions while maintaining their unique acoustic properties.

Current industry standards typically include accelerated aging tests that simulate years of environmental exposure within a compressed timeframe. These tests subject acoustic metamaterials to cycles of temperature extremes, humidity variations, UV radiation, and mechanical stress to evaluate degradation patterns. The ASTM E1050 and ISO 10534 standards, while primarily focused on acoustic performance measurement, have been adapted to incorporate durability components specifically for metamaterials.

The automotive and aerospace industries have pioneered specialized durability standards for acoustic metamaterials, given their critical applications in these sectors. These standards typically require materials to maintain at least 85% of their original acoustic performance after 1,000 hours of environmental cycling. Testing protocols often include vibration resistance assessments, as metamaterial structures with resonant components are particularly susceptible to mechanical fatigue.

Chemical resistance testing forms another critical component of durability standards, particularly for metamaterials deployed in industrial environments. These tests evaluate resistance to oils, fuels, cleaning agents, and other chemicals that might compromise structural integrity or acoustic performance. The standardized testing typically involves immersion cycles followed by acoustic performance evaluation using impedance tube measurements.

Field simulation testing represents the most comprehensive approach to durability assessment. These protocols combine multiple stressors simultaneously—such as vibration with temperature cycling and humidity exposure—to more accurately replicate real-world conditions. The emerging ISO 23351 framework specifically addresses the unique requirements of metamaterials with resonant structures, establishing minimum performance retention thresholds after exposure to combined environmental factors.

Standardized reporting formats have also been established to ensure consistency across the industry. These formats require documentation of initial acoustic properties, testing conditions, and post-exposure performance metrics. The inclusion of microscopic structural analysis has become increasingly common, as it helps identify the specific failure mechanisms in metamaterial structures, whether they be delamination, resonator damage, or matrix degradation.

Current industry standards typically include accelerated aging tests that simulate years of environmental exposure within a compressed timeframe. These tests subject acoustic metamaterials to cycles of temperature extremes, humidity variations, UV radiation, and mechanical stress to evaluate degradation patterns. The ASTM E1050 and ISO 10534 standards, while primarily focused on acoustic performance measurement, have been adapted to incorporate durability components specifically for metamaterials.

The automotive and aerospace industries have pioneered specialized durability standards for acoustic metamaterials, given their critical applications in these sectors. These standards typically require materials to maintain at least 85% of their original acoustic performance after 1,000 hours of environmental cycling. Testing protocols often include vibration resistance assessments, as metamaterial structures with resonant components are particularly susceptible to mechanical fatigue.

Chemical resistance testing forms another critical component of durability standards, particularly for metamaterials deployed in industrial environments. These tests evaluate resistance to oils, fuels, cleaning agents, and other chemicals that might compromise structural integrity or acoustic performance. The standardized testing typically involves immersion cycles followed by acoustic performance evaluation using impedance tube measurements.

Field simulation testing represents the most comprehensive approach to durability assessment. These protocols combine multiple stressors simultaneously—such as vibration with temperature cycling and humidity exposure—to more accurately replicate real-world conditions. The emerging ISO 23351 framework specifically addresses the unique requirements of metamaterials with resonant structures, establishing minimum performance retention thresholds after exposure to combined environmental factors.

Standardized reporting formats have also been established to ensure consistency across the industry. These formats require documentation of initial acoustic properties, testing conditions, and post-exposure performance metrics. The inclusion of microscopic structural analysis has become increasingly common, as it helps identify the specific failure mechanisms in metamaterial structures, whether they be delamination, resonator damage, or matrix degradation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!