Acoustic Metamaterial Prototyping Workflows: From Simulation To Anechoic Tests

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterial Evolution and Research Objectives

Acoustic metamaterials represent a revolutionary advancement in sound engineering, emerging from theoretical concepts in the late 1990s to practical applications in the 2020s. These engineered materials possess extraordinary acoustic properties not found in natural materials, enabling unprecedented control over sound waves through mechanisms such as negative effective density, negative bulk modulus, or both. The evolution of acoustic metamaterials has been characterized by progressive breakthroughs in theoretical understanding, computational modeling capabilities, and fabrication techniques.

The field originated with pioneering work on electromagnetic metamaterials, which subsequently inspired acoustic counterparts. Early research focused primarily on theoretical frameworks and simple proof-of-concept designs. As computational power increased, more sophisticated simulation approaches emerged, allowing researchers to model complex acoustic interactions and predict metamaterial behaviors with greater accuracy. This computational evolution has been crucial in bridging the gap between theoretical concepts and practical implementations.

Manufacturing capabilities have similarly evolved, from basic laboratory prototypes to more sophisticated fabrication techniques including 3D printing, precision machining, and advanced composite material processing. These advancements have enabled increasingly complex geometric structures necessary for achieving desired acoustic properties. The progression from simple resonator arrays to intricate, multi-scale architectures has dramatically expanded the functional capabilities of acoustic metamaterials.

Current research objectives in acoustic metamaterial prototyping workflows center on establishing robust methodologies that seamlessly connect simulation predictions with physical performance. Key goals include developing standardized simulation protocols that accurately predict real-world acoustic behavior, creating efficient design optimization algorithms that can rapidly iterate through potential configurations, and establishing reliable fabrication techniques that faithfully reproduce designed structures at various scales.

Another critical objective is the development of comprehensive testing methodologies that can validate metamaterial performance under controlled conditions, particularly in anechoic environments where external acoustic influences are minimized. This includes establishing correlations between simulation parameters and measurable physical quantities, quantifying uncertainties in the simulation-to-fabrication-to-testing pipeline, and developing calibration procedures to reconcile theoretical predictions with experimental results.

The ultimate research aim is to create an integrated workflow that enables rapid prototyping of acoustic metamaterials with predictable performance characteristics, thereby accelerating their adoption in practical applications such as noise control, acoustic imaging, sound focusing, and architectural acoustics. This requires not only technical advancements but also the development of accessible design tools and knowledge bases that can democratize acoustic metamaterial innovation across various industries and research domains.

The field originated with pioneering work on electromagnetic metamaterials, which subsequently inspired acoustic counterparts. Early research focused primarily on theoretical frameworks and simple proof-of-concept designs. As computational power increased, more sophisticated simulation approaches emerged, allowing researchers to model complex acoustic interactions and predict metamaterial behaviors with greater accuracy. This computational evolution has been crucial in bridging the gap between theoretical concepts and practical implementations.

Manufacturing capabilities have similarly evolved, from basic laboratory prototypes to more sophisticated fabrication techniques including 3D printing, precision machining, and advanced composite material processing. These advancements have enabled increasingly complex geometric structures necessary for achieving desired acoustic properties. The progression from simple resonator arrays to intricate, multi-scale architectures has dramatically expanded the functional capabilities of acoustic metamaterials.

Current research objectives in acoustic metamaterial prototyping workflows center on establishing robust methodologies that seamlessly connect simulation predictions with physical performance. Key goals include developing standardized simulation protocols that accurately predict real-world acoustic behavior, creating efficient design optimization algorithms that can rapidly iterate through potential configurations, and establishing reliable fabrication techniques that faithfully reproduce designed structures at various scales.

Another critical objective is the development of comprehensive testing methodologies that can validate metamaterial performance under controlled conditions, particularly in anechoic environments where external acoustic influences are minimized. This includes establishing correlations between simulation parameters and measurable physical quantities, quantifying uncertainties in the simulation-to-fabrication-to-testing pipeline, and developing calibration procedures to reconcile theoretical predictions with experimental results.

The ultimate research aim is to create an integrated workflow that enables rapid prototyping of acoustic metamaterials with predictable performance characteristics, thereby accelerating their adoption in practical applications such as noise control, acoustic imaging, sound focusing, and architectural acoustics. This requires not only technical advancements but also the development of accessible design tools and knowledge bases that can democratize acoustic metamaterial innovation across various industries and research domains.

Market Applications and Industry Demand Analysis

The acoustic metamaterial market is experiencing significant growth driven by increasing demand for noise control solutions across multiple industries. The global market for acoustic materials was valued at approximately $13.5 billion in 2022 and is projected to reach $18.9 billion by 2027, with metamaterials representing an emerging high-growth segment within this broader market. This growth trajectory is supported by stringent noise regulations in industrial and urban environments, alongside consumer demand for quieter products.

The automotive industry represents one of the largest application areas, with manufacturers seeking lightweight acoustic solutions to replace traditional dampening materials. Acoustic metamaterials offer weight reduction of up to 80% compared to conventional materials while maintaining or improving sound absorption properties, directly addressing the industry's push toward vehicle lightweighting for improved fuel efficiency and extended EV range.

Aerospace applications constitute another significant market segment, where acoustic metamaterials are being integrated into aircraft cabins and engine components to reduce noise levels while minimizing weight penalties. Major aerospace manufacturers have initiated research programs specifically targeting metamaterial implementation, with potential market value estimated at $1.2 billion by 2028.

Consumer electronics manufacturers are increasingly exploring acoustic metamaterials for speaker systems, headphones, and device housings. The ability to precisely control sound directionality and create acoustic "cloaking" effects presents opportunities for innovative product differentiation in a highly competitive market.

The building and construction sector demonstrates growing interest in architectural acoustic solutions utilizing metamaterial principles. These applications range from specialized acoustic panels for concert halls and recording studios to noise-mitigating building elements for urban residential developments near transportation hubs or industrial zones.

Healthcare environments represent an emerging application area, with hospitals and medical facilities seeking solutions to create quieter healing environments. Studies have demonstrated correlations between noise reduction and improved patient outcomes, creating market pull for advanced acoustic solutions.

Defense applications, particularly in submarine and naval vessel stealth technology, constitute a specialized but high-value market segment. Military research agencies have allocated substantial funding toward acoustic metamaterial development programs focused on signature reduction capabilities.

The prototyping workflow market itself—encompassing simulation software, fabrication equipment, and testing infrastructure—is projected to grow at 14.3% CAGR through 2030, driven by research institutions and industrial R&D departments seeking to accelerate acoustic metamaterial development cycles and reduce time-to-market for innovative solutions.

The automotive industry represents one of the largest application areas, with manufacturers seeking lightweight acoustic solutions to replace traditional dampening materials. Acoustic metamaterials offer weight reduction of up to 80% compared to conventional materials while maintaining or improving sound absorption properties, directly addressing the industry's push toward vehicle lightweighting for improved fuel efficiency and extended EV range.

Aerospace applications constitute another significant market segment, where acoustic metamaterials are being integrated into aircraft cabins and engine components to reduce noise levels while minimizing weight penalties. Major aerospace manufacturers have initiated research programs specifically targeting metamaterial implementation, with potential market value estimated at $1.2 billion by 2028.

Consumer electronics manufacturers are increasingly exploring acoustic metamaterials for speaker systems, headphones, and device housings. The ability to precisely control sound directionality and create acoustic "cloaking" effects presents opportunities for innovative product differentiation in a highly competitive market.

The building and construction sector demonstrates growing interest in architectural acoustic solutions utilizing metamaterial principles. These applications range from specialized acoustic panels for concert halls and recording studios to noise-mitigating building elements for urban residential developments near transportation hubs or industrial zones.

Healthcare environments represent an emerging application area, with hospitals and medical facilities seeking solutions to create quieter healing environments. Studies have demonstrated correlations between noise reduction and improved patient outcomes, creating market pull for advanced acoustic solutions.

Defense applications, particularly in submarine and naval vessel stealth technology, constitute a specialized but high-value market segment. Military research agencies have allocated substantial funding toward acoustic metamaterial development programs focused on signature reduction capabilities.

The prototyping workflow market itself—encompassing simulation software, fabrication equipment, and testing infrastructure—is projected to grow at 14.3% CAGR through 2030, driven by research institutions and industrial R&D departments seeking to accelerate acoustic metamaterial development cycles and reduce time-to-market for innovative solutions.

Current Challenges in Acoustic Metamaterial Development

Despite significant advancements in acoustic metamaterial research, the development pipeline from conceptualization to practical implementation faces several critical challenges. The transition from simulation to physical prototyping remains particularly problematic due to the multidisciplinary nature of acoustic metamaterial design, which requires expertise in acoustics, materials science, and mechanical engineering.

Computational limitations present a significant hurdle in the simulation phase. Current simulation tools often struggle with the complex multi-physics interactions inherent in acoustic metamaterials, especially when modeling nonlinear behaviors or time-domain responses. The computational resources required for high-fidelity simulations of large-scale or complex metamaterial structures frequently exceed what is practically available to many research teams.

Material selection and fabrication precision constitute another major challenge. The performance of acoustic metamaterials is highly sensitive to geometric precision and material properties. Even minor deviations from design specifications can significantly alter acoustic performance. Advanced manufacturing techniques such as 3D printing have improved fabrication capabilities, but achieving the necessary precision at smaller scales remains difficult, particularly for metamaterials operating at higher frequencies.

The characterization and testing phase presents its own set of challenges. Standard acoustic measurement protocols are often insufficient for accurately capturing the unique properties of metamaterials. Anechoic chamber testing, while essential, introduces complexities in isolating the metamaterial's performance from environmental factors and measurement artifacts. Additionally, there is a lack of standardized testing methodologies specifically designed for acoustic metamaterials.

Scaling from laboratory prototypes to practical applications introduces further complications. Many promising designs demonstrate excellent performance in controlled laboratory conditions but fail to maintain effectiveness when scaled up or integrated into real-world environments. The gap between theoretical performance and practical implementation remains substantial.

Cost and time constraints also impede development. The iterative process of simulation, prototyping, and testing is resource-intensive and time-consuming. Each design iteration may require weeks or months to complete, significantly slowing the overall development cycle and increasing costs.

Finally, there exists a knowledge transfer gap between academic research and industrial application. Many innovative acoustic metamaterial concepts remain confined to research laboratories due to challenges in translating theoretical designs into commercially viable products. This disconnect hinders the broader adoption of acoustic metamaterial technologies across industries.

Computational limitations present a significant hurdle in the simulation phase. Current simulation tools often struggle with the complex multi-physics interactions inherent in acoustic metamaterials, especially when modeling nonlinear behaviors or time-domain responses. The computational resources required for high-fidelity simulations of large-scale or complex metamaterial structures frequently exceed what is practically available to many research teams.

Material selection and fabrication precision constitute another major challenge. The performance of acoustic metamaterials is highly sensitive to geometric precision and material properties. Even minor deviations from design specifications can significantly alter acoustic performance. Advanced manufacturing techniques such as 3D printing have improved fabrication capabilities, but achieving the necessary precision at smaller scales remains difficult, particularly for metamaterials operating at higher frequencies.

The characterization and testing phase presents its own set of challenges. Standard acoustic measurement protocols are often insufficient for accurately capturing the unique properties of metamaterials. Anechoic chamber testing, while essential, introduces complexities in isolating the metamaterial's performance from environmental factors and measurement artifacts. Additionally, there is a lack of standardized testing methodologies specifically designed for acoustic metamaterials.

Scaling from laboratory prototypes to practical applications introduces further complications. Many promising designs demonstrate excellent performance in controlled laboratory conditions but fail to maintain effectiveness when scaled up or integrated into real-world environments. The gap between theoretical performance and practical implementation remains substantial.

Cost and time constraints also impede development. The iterative process of simulation, prototyping, and testing is resource-intensive and time-consuming. Each design iteration may require weeks or months to complete, significantly slowing the overall development cycle and increasing costs.

Finally, there exists a knowledge transfer gap between academic research and industrial application. Many innovative acoustic metamaterial concepts remain confined to research laboratories due to challenges in translating theoretical designs into commercially viable products. This disconnect hinders the broader adoption of acoustic metamaterial technologies across industries.

Simulation-to-Fabrication Methodologies

01 3D Printing and Additive Manufacturing Techniques

Acoustic metamaterials can be prototyped using various 3D printing and additive manufacturing techniques. These methods allow for precise fabrication of complex geometric structures with specific acoustic properties. The workflow typically involves designing the metamaterial structure using CAD software, selecting appropriate materials with desired acoustic properties, and fabricating the structure using techniques such as fused deposition modeling, stereolithography, or selective laser sintering. These manufacturing approaches enable rapid prototyping and iteration of acoustic metamaterial designs.- 3D Printing and Additive Manufacturing Techniques: Acoustic metamaterials can be prototyped using various 3D printing and additive manufacturing techniques. These methods allow for precise fabrication of complex geometric structures with specific acoustic properties. The workflow typically involves digital design, material selection, printing parameter optimization, and post-processing treatments to achieve the desired acoustic performance. These techniques enable rapid prototyping and iteration of metamaterial designs with controlled internal structures.

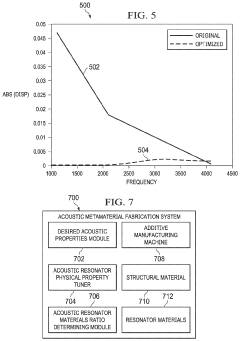

- Computational Design and Simulation Methods: Computational methods play a crucial role in acoustic metamaterial prototyping workflows. This includes finite element analysis, boundary element methods, and machine learning approaches to predict and optimize acoustic properties before physical fabrication. These simulation tools help designers understand wave propagation, resonance phenomena, and acoustic absorption characteristics. The workflow integrates parametric design with performance simulation to achieve targeted acoustic responses such as sound absorption, redirection, or isolation.

- Multi-material and Composite Fabrication Approaches: Prototyping workflows for acoustic metamaterials often involve multi-material and composite fabrication approaches. These methods combine different materials with varying acoustic properties to create structures with enhanced performance. The workflow includes material selection based on acoustic impedance, density, and elasticity, followed by specialized fabrication techniques such as co-extrusion, multi-material printing, or manual assembly. This approach enables the creation of metamaterials with gradient properties or locally resonant structures.

- Testing and Characterization Protocols: Specialized testing and characterization protocols are essential components of acoustic metamaterial prototyping workflows. These include impedance tube measurements, acoustic transmission loss testing, modal analysis, and in-situ performance evaluation. The workflow incorporates iterative testing to validate simulation results and refine designs. Advanced characterization techniques such as laser vibrometry and acoustic holography help visualize and quantify the metamaterial's response to sound waves across different frequencies and incidence angles.

- Scalable Manufacturing and Industrial Implementation: Workflows for transitioning acoustic metamaterial prototypes to scalable manufacturing and industrial implementation involve several key steps. These include design optimization for mass production, material substitution for cost-effectiveness, manufacturing process adaptation, and quality control procedures. The workflow addresses challenges in scaling from laboratory prototypes to commercial products while maintaining acoustic performance. Considerations include production efficiency, repeatability, durability testing, and integration with existing acoustic systems or structures.

02 Computational Design and Simulation Methods

Computational methods play a crucial role in the prototyping workflow of acoustic metamaterials. This includes finite element analysis, boundary element methods, and other numerical simulation techniques to predict and optimize the acoustic performance of metamaterial structures before physical fabrication. The workflow involves modeling the acoustic wave propagation through the metamaterial, analyzing frequency responses, and iteratively refining the design to achieve desired acoustic properties such as sound absorption, reflection, or directional control.Expand Specific Solutions03 Multi-material and Composite Metamaterial Fabrication

Prototyping workflows for acoustic metamaterials often involve the use of multiple materials or composites to achieve specific acoustic properties. This approach combines materials with different acoustic impedances, densities, and elastic properties to create structures with enhanced sound manipulation capabilities. The workflow includes material selection based on acoustic requirements, designing heterogeneous structures, and developing fabrication methods that can precisely integrate different materials into a unified metamaterial structure.Expand Specific Solutions04 Micro and Nanoscale Fabrication Techniques

Advanced micro and nanoscale fabrication techniques are employed in acoustic metamaterial prototyping workflows to create structures with features at scales comparable to the wavelength of sound. These techniques include lithography, etching, deposition, and micromachining processes adapted from semiconductor manufacturing. The workflow involves designing microscale resonators, cavities, and channels, followed by precision fabrication using cleanroom facilities and specialized equipment to achieve the required dimensional accuracy for effective acoustic wave manipulation.Expand Specific Solutions05 Testing and Characterization Methodologies

Comprehensive testing and characterization form an essential part of acoustic metamaterial prototyping workflows. This includes experimental setups for measuring acoustic transmission, reflection, absorption, and directivity properties of the fabricated metamaterials. The workflow involves using impedance tubes, anechoic chambers, laser vibrometry, and acoustic holography to validate the performance of prototypes against simulation predictions. Iterative testing and refinement processes help optimize the metamaterial design to meet specific acoustic performance targets.Expand Specific Solutions

Leading Research Institutions and Industrial Manufacturers

Acoustic metamaterial prototyping workflows are currently in a transitional phase from research to commercial applications, with the market showing promising growth potential. The technology maturity varies significantly across key players, with aerospace giants like Boeing and Safran Aircraft Engines leading industrial implementation, while research institutions such as CNRS and Guangdong University of Technology drive fundamental innovation. Oil industry players including Saudi Aramco and Schlumberger are exploring applications for noise control in harsh environments. Technology companies like Panasonic, IBM, and Yamaha are developing consumer and professional audio applications, indicating cross-sector interest. The competitive landscape shows a balanced distribution between academic research, industrial R&D, and commercial product development, suggesting a maturing but not yet fully commercialized technology ecosystem.

The Boeing Co.

Technical Solution: Boeing has established an end-to-end acoustic metamaterial prototyping workflow that spans from conceptual design to full-scale aircraft implementation. Their approach begins with multi-scale modeling that combines analytical methods for rapid design space exploration with detailed finite element analysis for final performance prediction. Boeing utilizes proprietary simulation tools that integrate acoustic performance with structural mechanics and thermal considerations, essential for aerospace applications. Their manufacturing process leverages advanced composite fabrication techniques including automated fiber placement and resin transfer molding, allowing precise control of material properties at multiple scales. Boeing has developed specialized metamaterial configurations that target the specific frequency ranges of aircraft noise (particularly 1-5kHz for cabin noise and 50-500Hz for community noise). Their testing protocol includes progressive validation from material coupons to full-scale sections in Boeing's anechoic wind tunnel facility, which can simulate flight conditions up to Mach 0.3 while measuring acoustic performance. Boeing's workflow incorporates digital twin technology that maintains a virtual representation of each prototype throughout development, enabling rapid iteration based on test results. Their implementation has achieved noise reduction of up to 4dB in cabin environments while adding less than 1% to the structural weight.

Strengths: Comprehensive integration with aircraft design processes; advanced manufacturing capabilities at industrial scale; extensive testing facilities including full-scale anechoic wind tunnels; proven implementation in commercial aircraft. Weaknesses: Highly proprietary workflow with limited academic collaboration; significant development costs; long certification cycles for new acoustic technologies in aerospace applications.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed comprehensive acoustic metamaterial prototyping workflows that integrate multi-physics simulation platforms with advanced manufacturing techniques. Their approach begins with theoretical modeling using finite element methods (FEM) and boundary element methods (BEM) to predict acoustic behavior. They've pioneered time-domain simulations that accurately capture nonlinear effects in metamaterials. CNRS utilizes additive manufacturing techniques including selective laser sintering and stereolithography to create complex geometrical structures with precise acoustic properties. Their workflow incorporates in-situ monitoring during fabrication to ensure dimensional accuracy within 50 microns tolerance. For validation, they employ anechoic chamber testing with multi-microphone arrays capable of capturing 3D acoustic fields with frequency responses from 50Hz to 20kHz. CNRS has also developed proprietary algorithms for inverse characterization that can extract effective material parameters from measured acoustic responses, creating a feedback loop to refine simulation models.

Strengths: Exceptional integration between theoretical modeling and experimental validation; advanced manufacturing capabilities for complex geometries; comprehensive testing facilities including state-of-the-art anechoic chambers. Weaknesses: High computational requirements for time-domain simulations; limited scalability for mass production; relatively long development cycles compared to industry standards.

Critical Patents and Research Breakthroughs

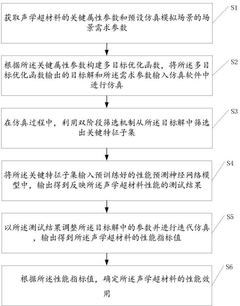

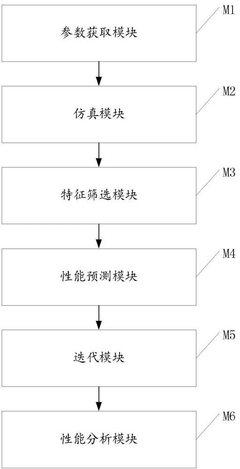

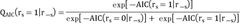

Acoustic metamaterial performance test method, system, equipment and medium

PatentActiveCN120183584A

Innovation

- By constructing multi-objective optimization function and neural network model, processing acoustic material performance data, filtering key feature subsets using a two-stage screening mechanism, and iterative simulation is performed to improve test accuracy and efficiency.

Computationally optimized and manufactured acoustic metamaterials

PatentInactiveUS20230037610A1

Innovation

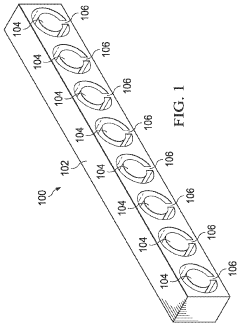

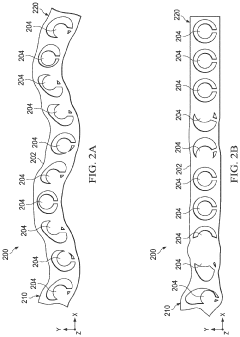

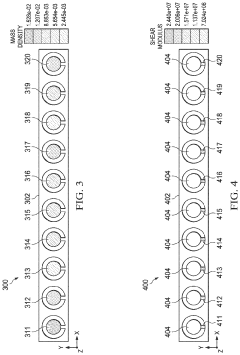

- A method involving computational optimization to determine tuned physical properties for micro-resonators, such as mass density and stiffness, followed by additive manufacturing to embed these resonators within a structure, ensuring actual properties match desired ones, thereby achieving desired acoustic properties.

Anechoic Testing Standards and Protocols

Anechoic testing represents a critical phase in acoustic metamaterial development, requiring adherence to established standards and protocols to ensure reliable, reproducible results. The International Organization for Standardization (ISO) provides several key standards, including ISO 3745 for precision measurements in anechoic chambers and ISO 26101 for qualification of free-field environments. These standards define chamber specifications, microphone placement, and measurement procedures essential for acoustic metamaterial characterization.

ASTM International complements these with standards such as ASTM E1050 for impedance tube measurements and ASTM C423 for sound absorption coefficients, both frequently applied when evaluating metamaterial performance. Additionally, IEC 60268-16 offers guidelines for speech intelligibility measurements, particularly relevant for metamaterials designed for speech clarity applications.

The testing protocol typically begins with pre-test calibration of all measurement equipment, including microphones, amplifiers, and signal generators. This calibration must be performed under controlled temperature and humidity conditions (typically 20°C ± 2°C and 50% ± 10% relative humidity) to minimize environmental variables. Background noise measurements establish the chamber's noise floor, which should ideally be at least 10 dB below the lowest expected measurement level.

For acoustic metamaterial testing specifically, standardized source positioning at distances of 1m, 2m, and 4m from the specimen allows for comprehensive near-field and far-field performance evaluation. Frequency sweeps typically range from 50 Hz to 20 kHz, with higher resolution measurements (1/12 octave or finer) in frequency bands of particular interest for the metamaterial's intended application.

Data acquisition protocols mandate minimum sampling rates of 48 kHz with 24-bit resolution, with measurements averaged over at least three independent test runs to ensure statistical validity. Time-domain measurements must account for the chamber's reverberation time, typically requiring measurement windows of at least 1 second for low-frequency analysis.

Documentation requirements include detailed reporting of test specimen dimensions, mounting conditions, and orientation relative to sound sources. Uncertainty analysis must quantify measurement precision, with typical acceptable uncertainty levels below ±1 dB for frequency ranges between 200 Hz and 10 kHz, and ±2 dB for frequencies outside this range.

Recent advancements in anechoic testing protocols have introduced specialized procedures for metamaterials with non-linear acoustic responses, including incremental amplitude testing to characterize amplitude-dependent behaviors and multi-angle incidence testing to evaluate directional acoustic properties.

ASTM International complements these with standards such as ASTM E1050 for impedance tube measurements and ASTM C423 for sound absorption coefficients, both frequently applied when evaluating metamaterial performance. Additionally, IEC 60268-16 offers guidelines for speech intelligibility measurements, particularly relevant for metamaterials designed for speech clarity applications.

The testing protocol typically begins with pre-test calibration of all measurement equipment, including microphones, amplifiers, and signal generators. This calibration must be performed under controlled temperature and humidity conditions (typically 20°C ± 2°C and 50% ± 10% relative humidity) to minimize environmental variables. Background noise measurements establish the chamber's noise floor, which should ideally be at least 10 dB below the lowest expected measurement level.

For acoustic metamaterial testing specifically, standardized source positioning at distances of 1m, 2m, and 4m from the specimen allows for comprehensive near-field and far-field performance evaluation. Frequency sweeps typically range from 50 Hz to 20 kHz, with higher resolution measurements (1/12 octave or finer) in frequency bands of particular interest for the metamaterial's intended application.

Data acquisition protocols mandate minimum sampling rates of 48 kHz with 24-bit resolution, with measurements averaged over at least three independent test runs to ensure statistical validity. Time-domain measurements must account for the chamber's reverberation time, typically requiring measurement windows of at least 1 second for low-frequency analysis.

Documentation requirements include detailed reporting of test specimen dimensions, mounting conditions, and orientation relative to sound sources. Uncertainty analysis must quantify measurement precision, with typical acceptable uncertainty levels below ±1 dB for frequency ranges between 200 Hz and 10 kHz, and ±2 dB for frequencies outside this range.

Recent advancements in anechoic testing protocols have introduced specialized procedures for metamaterials with non-linear acoustic responses, including incremental amplitude testing to characterize amplitude-dependent behaviors and multi-angle incidence testing to evaluate directional acoustic properties.

Materials Science Innovations for Acoustic Applications

Recent advancements in materials science have revolutionized acoustic applications, particularly in the development of acoustic metamaterials. These engineered materials possess extraordinary properties not found in nature, enabling unprecedented control over sound waves. The innovation trajectory in this field has accelerated dramatically over the past decade, with significant breakthroughs in noise cancellation, sound focusing, and acoustic cloaking technologies.

Materials science innovations have introduced novel composite structures that can manipulate acoustic waves through precisely designed geometrical arrangements. Phononic crystals and resonant metamaterials represent two major categories that have emerged, each offering unique capabilities for sound manipulation. These materials can be engineered to exhibit negative effective density, negative bulk modulus, or both simultaneously, creating conditions for extraordinary acoustic phenomena.

Polymer-based acoustic metamaterials have gained particular attention due to their versatility, cost-effectiveness, and ease of fabrication. Advanced manufacturing techniques, including 3D printing and precision molding, have enabled the creation of complex microstructures with tailored acoustic responses. Additionally, the integration of responsive materials that can change their properties under external stimuli has opened pathways to tunable and adaptive acoustic devices.

Nanomaterials have also made significant contributions to acoustic applications. Materials such as aerogels, carbon nanotubes, and graphene-based composites offer exceptional sound absorption capabilities due to their high surface area and unique structural properties. These materials can be engineered to target specific frequency ranges, making them valuable for specialized acoustic applications in industries ranging from automotive to aerospace.

Biomimetic approaches have inspired another wave of innovation, with researchers studying natural sound-manipulating structures found in organisms. For instance, the fibrous structure of certain insect wings and mammalian ears has informed the development of ultra-lightweight acoustic absorbers with remarkable efficiency across broad frequency spectra.

Computational materials science has accelerated discovery in this field, enabling researchers to predict acoustic properties before physical prototyping. Machine learning algorithms have been employed to optimize material compositions and structural designs, significantly reducing development time and expanding the range of achievable acoustic properties.

The integration of these materials science innovations into practical acoustic metamaterial prototyping workflows represents a critical advancement, bridging the gap between theoretical simulation and practical implementation. This integration enables more efficient development cycles, from initial concept to anechoic chamber testing, ultimately accelerating the deployment of these revolutionary materials in real-world applications.

Materials science innovations have introduced novel composite structures that can manipulate acoustic waves through precisely designed geometrical arrangements. Phononic crystals and resonant metamaterials represent two major categories that have emerged, each offering unique capabilities for sound manipulation. These materials can be engineered to exhibit negative effective density, negative bulk modulus, or both simultaneously, creating conditions for extraordinary acoustic phenomena.

Polymer-based acoustic metamaterials have gained particular attention due to their versatility, cost-effectiveness, and ease of fabrication. Advanced manufacturing techniques, including 3D printing and precision molding, have enabled the creation of complex microstructures with tailored acoustic responses. Additionally, the integration of responsive materials that can change their properties under external stimuli has opened pathways to tunable and adaptive acoustic devices.

Nanomaterials have also made significant contributions to acoustic applications. Materials such as aerogels, carbon nanotubes, and graphene-based composites offer exceptional sound absorption capabilities due to their high surface area and unique structural properties. These materials can be engineered to target specific frequency ranges, making them valuable for specialized acoustic applications in industries ranging from automotive to aerospace.

Biomimetic approaches have inspired another wave of innovation, with researchers studying natural sound-manipulating structures found in organisms. For instance, the fibrous structure of certain insect wings and mammalian ears has informed the development of ultra-lightweight acoustic absorbers with remarkable efficiency across broad frequency spectra.

Computational materials science has accelerated discovery in this field, enabling researchers to predict acoustic properties before physical prototyping. Machine learning algorithms have been employed to optimize material compositions and structural designs, significantly reducing development time and expanding the range of achievable acoustic properties.

The integration of these materials science innovations into practical acoustic metamaterial prototyping workflows represents a critical advancement, bridging the gap between theoretical simulation and practical implementation. This integration enables more efficient development cycles, from initial concept to anechoic chamber testing, ultimately accelerating the deployment of these revolutionary materials in real-world applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!