Acoustic Bandgap Engineering For Tunable Noise Rejection Bands

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Bandgap Fundamentals and Objectives

Acoustic bandgap engineering represents a significant advancement in the field of acoustics and materials science, evolving from fundamental wave propagation theories to sophisticated noise control applications. The concept originated in the 1990s, drawing inspiration from photonic bandgaps in optics, and has since developed into a robust framework for manipulating acoustic wave propagation through periodic structures.

The evolution of acoustic bandgap technology has been marked by several key milestones. Initially focused on simple periodic arrangements of scatterers, the field has progressed to incorporate complex geometries, metamaterials, and active tuning mechanisms. Recent advancements have enabled precise control over frequency-specific sound attenuation, allowing for targeted noise rejection bands that can be dynamically adjusted to meet varying environmental conditions.

The fundamental principle behind acoustic bandgaps involves the creation of periodic structures that prohibit the propagation of sound waves within specific frequency ranges. These structures typically consist of materials with contrasting acoustic impedances arranged in patterns that cause destructive interference or energy localization, effectively preventing certain frequencies from transmitting through the material.

Current research trends indicate a growing interest in tunable acoustic bandgap structures that can adapt to changing noise profiles. This adaptability is particularly valuable in environments where noise characteristics fluctuate, such as urban settings, industrial facilities, or transportation systems. The ability to dynamically adjust rejection bands without physical reconfiguration represents a significant technological objective in this field.

The primary technical goals for acoustic bandgap engineering include expanding the bandwidth of rejection bands, reducing the physical dimensions of effective structures, enhancing tunability through smart materials or active control systems, and improving manufacturing techniques for cost-effective implementation. Additionally, there is a push toward multifunctional materials that combine acoustic bandgap properties with other desirable characteristics such as thermal insulation or structural support.

Looking forward, the trajectory of acoustic bandgap technology points toward increasingly sophisticated control over sound propagation, with potential applications ranging from architectural acoustics and transportation noise mitigation to medical ultrasound and communication systems. The integration of computational modeling, advanced materials science, and control theory is expected to accelerate development in this field, enabling more precise and versatile noise rejection capabilities.

The evolution of acoustic bandgap technology has been marked by several key milestones. Initially focused on simple periodic arrangements of scatterers, the field has progressed to incorporate complex geometries, metamaterials, and active tuning mechanisms. Recent advancements have enabled precise control over frequency-specific sound attenuation, allowing for targeted noise rejection bands that can be dynamically adjusted to meet varying environmental conditions.

The fundamental principle behind acoustic bandgaps involves the creation of periodic structures that prohibit the propagation of sound waves within specific frequency ranges. These structures typically consist of materials with contrasting acoustic impedances arranged in patterns that cause destructive interference or energy localization, effectively preventing certain frequencies from transmitting through the material.

Current research trends indicate a growing interest in tunable acoustic bandgap structures that can adapt to changing noise profiles. This adaptability is particularly valuable in environments where noise characteristics fluctuate, such as urban settings, industrial facilities, or transportation systems. The ability to dynamically adjust rejection bands without physical reconfiguration represents a significant technological objective in this field.

The primary technical goals for acoustic bandgap engineering include expanding the bandwidth of rejection bands, reducing the physical dimensions of effective structures, enhancing tunability through smart materials or active control systems, and improving manufacturing techniques for cost-effective implementation. Additionally, there is a push toward multifunctional materials that combine acoustic bandgap properties with other desirable characteristics such as thermal insulation or structural support.

Looking forward, the trajectory of acoustic bandgap technology points toward increasingly sophisticated control over sound propagation, with potential applications ranging from architectural acoustics and transportation noise mitigation to medical ultrasound and communication systems. The integration of computational modeling, advanced materials science, and control theory is expected to accelerate development in this field, enabling more precise and versatile noise rejection capabilities.

Market Applications for Tunable Noise Rejection Systems

Tunable noise rejection systems based on acoustic bandgap engineering represent a significant advancement in noise control technology, with diverse applications across multiple industries. The market for these systems is experiencing robust growth due to increasing concerns about noise pollution and its effects on health, productivity, and quality of life.

In the automotive sector, tunable noise rejection systems are revolutionizing cabin acoustics by selectively filtering road, engine, and environmental noise while preserving important audio cues like emergency vehicle sirens or navigation instructions. Premium vehicle manufacturers are particularly interested in these technologies to enhance the driving experience and differentiate their offerings in a competitive market.

The aerospace industry presents another substantial market opportunity, where tunable noise rejection systems can address the persistent challenge of cabin noise in commercial aircraft. These systems can be integrated into cabin walls and seating structures to create more comfortable environments for passengers during long flights, potentially commanding premium pricing for airlines that implement such technology.

Consumer electronics manufacturers are exploring applications in headphones and earbuds, where adaptive noise cancellation that can selectively filter specific frequency bands offers significant advantages over traditional noise-cancellation technologies. This allows users to remain aware of important environmental sounds while blocking unwanted noise, addressing safety concerns associated with complete noise isolation.

In industrial settings, tunable noise rejection systems are finding applications in manufacturing facilities where they can protect workers from harmful noise frequencies while maintaining situational awareness. This technology enables compliance with occupational safety regulations without compromising communication or operational efficiency.

The healthcare sector represents an emerging market, with applications in hospital environments where selective noise filtering can improve patient recovery by reducing stress-inducing sounds while maintaining alertness to important medical alarms and communications. Studies have shown that improved acoustic environments can significantly impact patient outcomes and recovery times.

Smart building technology integrators are incorporating tunable noise rejection systems into architectural acoustics, creating spaces that can dynamically adapt to different uses and occupancy levels. This is particularly valuable in multi-purpose commercial spaces and modern open-plan offices where acoustic requirements vary throughout the day.

Military and defense applications constitute a high-value market segment, with requirements for communication systems that can operate effectively in high-noise environments while maintaining situational awareness. The ability to selectively filter battlefield noise while preserving critical communications represents a significant tactical advantage.

In the automotive sector, tunable noise rejection systems are revolutionizing cabin acoustics by selectively filtering road, engine, and environmental noise while preserving important audio cues like emergency vehicle sirens or navigation instructions. Premium vehicle manufacturers are particularly interested in these technologies to enhance the driving experience and differentiate their offerings in a competitive market.

The aerospace industry presents another substantial market opportunity, where tunable noise rejection systems can address the persistent challenge of cabin noise in commercial aircraft. These systems can be integrated into cabin walls and seating structures to create more comfortable environments for passengers during long flights, potentially commanding premium pricing for airlines that implement such technology.

Consumer electronics manufacturers are exploring applications in headphones and earbuds, where adaptive noise cancellation that can selectively filter specific frequency bands offers significant advantages over traditional noise-cancellation technologies. This allows users to remain aware of important environmental sounds while blocking unwanted noise, addressing safety concerns associated with complete noise isolation.

In industrial settings, tunable noise rejection systems are finding applications in manufacturing facilities where they can protect workers from harmful noise frequencies while maintaining situational awareness. This technology enables compliance with occupational safety regulations without compromising communication or operational efficiency.

The healthcare sector represents an emerging market, with applications in hospital environments where selective noise filtering can improve patient recovery by reducing stress-inducing sounds while maintaining alertness to important medical alarms and communications. Studies have shown that improved acoustic environments can significantly impact patient outcomes and recovery times.

Smart building technology integrators are incorporating tunable noise rejection systems into architectural acoustics, creating spaces that can dynamically adapt to different uses and occupancy levels. This is particularly valuable in multi-purpose commercial spaces and modern open-plan offices where acoustic requirements vary throughout the day.

Military and defense applications constitute a high-value market segment, with requirements for communication systems that can operate effectively in high-noise environments while maintaining situational awareness. The ability to selectively filter battlefield noise while preserving critical communications represents a significant tactical advantage.

Current Challenges in Acoustic Bandgap Engineering

Despite significant advancements in acoustic bandgap engineering, several critical challenges continue to impede the development of truly tunable noise rejection systems. The fundamental physics of acoustic wave propagation presents inherent limitations, particularly when attempting to create bandgaps that can be dynamically adjusted across wide frequency ranges. Current materials used in acoustic metamaterials often exhibit fixed mechanical properties, making real-time tunability difficult to achieve without complex actuation mechanisms.

Scale-dependent challenges remain prominent, as most laboratory demonstrations operate at specific frequency ranges that don't easily translate across the acoustic spectrum. Designs that work effectively for ultrasonic frequencies often fail when scaled to audible ranges due to size constraints and material property limitations. This creates significant barriers when attempting to develop universal solutions for noise control applications.

Manufacturing precision represents another substantial hurdle. The performance of acoustic bandgap structures depends critically on dimensional accuracy, with even minor deviations potentially causing significant degradation in bandgap properties. Current fabrication techniques struggle to consistently produce the required precision at commercially viable scales, especially for complex 3D architectures necessary for omnidirectional bandgaps.

Energy efficiency in active tuning mechanisms remains problematic. Many current approaches to achieve tunability rely on external stimuli such as electrical, thermal, or mechanical inputs that require continuous power consumption. This limitation severely restricts practical deployment in portable devices or energy-constrained environments where power availability is limited.

Bandwidth-tunability tradeoffs continue to challenge designers. Systems capable of wide-range tunability typically sacrifice rejection band depth or sharpness, while highly effective fixed bandgap structures resist modification. Finding the optimal balance between these competing requirements remains an open research question without definitive solutions.

Integration challenges with existing acoustic systems present significant obstacles to commercial adoption. Many promising acoustic bandgap technologies require fundamental redesigns of established acoustic components rather than offering drop-in solutions. This incompatibility with legacy systems substantially increases implementation costs and slows market penetration.

Computational modeling limitations further complicate development efforts. Current simulation tools struggle to accurately predict the behavior of complex, multi-material acoustic metamaterials, particularly when incorporating active elements for tunability. This gap between theoretical models and experimental results extends development cycles and increases costs.

Scale-dependent challenges remain prominent, as most laboratory demonstrations operate at specific frequency ranges that don't easily translate across the acoustic spectrum. Designs that work effectively for ultrasonic frequencies often fail when scaled to audible ranges due to size constraints and material property limitations. This creates significant barriers when attempting to develop universal solutions for noise control applications.

Manufacturing precision represents another substantial hurdle. The performance of acoustic bandgap structures depends critically on dimensional accuracy, with even minor deviations potentially causing significant degradation in bandgap properties. Current fabrication techniques struggle to consistently produce the required precision at commercially viable scales, especially for complex 3D architectures necessary for omnidirectional bandgaps.

Energy efficiency in active tuning mechanisms remains problematic. Many current approaches to achieve tunability rely on external stimuli such as electrical, thermal, or mechanical inputs that require continuous power consumption. This limitation severely restricts practical deployment in portable devices or energy-constrained environments where power availability is limited.

Bandwidth-tunability tradeoffs continue to challenge designers. Systems capable of wide-range tunability typically sacrifice rejection band depth or sharpness, while highly effective fixed bandgap structures resist modification. Finding the optimal balance between these competing requirements remains an open research question without definitive solutions.

Integration challenges with existing acoustic systems present significant obstacles to commercial adoption. Many promising acoustic bandgap technologies require fundamental redesigns of established acoustic components rather than offering drop-in solutions. This incompatibility with legacy systems substantially increases implementation costs and slows market penetration.

Computational modeling limitations further complicate development efforts. Current simulation tools struggle to accurately predict the behavior of complex, multi-material acoustic metamaterials, particularly when incorporating active elements for tunability. This gap between theoretical models and experimental results extends development cycles and increases costs.

State-of-the-Art Tunable Noise Rejection Solutions

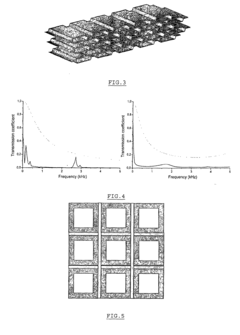

01 Phononic crystal structures for acoustic bandgap engineering

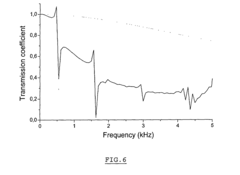

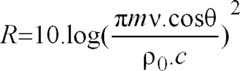

Phononic crystals are engineered structures with periodic arrangements of materials having different acoustic properties. These structures create acoustic bandgaps that prevent sound waves of specific frequencies from propagating through them. By carefully designing the geometry, spacing, and material properties of these periodic structures, engineers can create effective noise rejection bands. These structures can be implemented in various applications including noise barriers, acoustic filters, and vibration isolation systems.- Phononic crystal structures for acoustic bandgap engineering: Phononic crystals are engineered structures with periodic arrangements of materials having different acoustic properties. These structures create acoustic bandgaps that prevent sound waves of specific frequencies from propagating through them. By carefully designing the geometry, material properties, and periodicity of these structures, engineers can create effective noise rejection bands. These phononic crystals can be implemented in various applications including noise barriers, acoustic filters, and vibration isolation systems.

- MEMS-based acoustic bandgap devices: Micro-Electro-Mechanical Systems (MEMS) technology enables the fabrication of miniaturized acoustic bandgap structures. These devices incorporate precisely engineered microscale features that create frequency-selective noise rejection bands. MEMS-based acoustic filters can be integrated into electronic systems for signal processing applications, communication devices, and sensors. The small form factor allows for integration into portable and wearable devices while maintaining effective noise rejection capabilities.

- Signal processing techniques for acoustic noise rejection: Advanced signal processing algorithms can be used to enhance acoustic bandgap performance. These techniques include adaptive filtering, digital signal processing, and machine learning approaches that identify and suppress unwanted noise frequencies. By implementing these algorithms in hardware or software systems, more effective and dynamic noise rejection bands can be achieved. These methods can adapt to changing noise environments and provide customizable frequency rejection characteristics.

- Metamaterial-based acoustic bandgap engineering: Acoustic metamaterials are artificially structured materials designed to control and manipulate sound waves in ways not possible with conventional materials. These engineered structures can create acoustic bandgaps through resonant elements, local resonators, or other novel mechanisms. Metamaterial-based approaches allow for subwavelength bandgap creation, enabling compact designs with exceptional noise rejection properties. These materials can be tailored to create specific frequency rejection bands while maintaining structural integrity and practical implementation.

- Electronic circuit implementations for acoustic filtering: Electronic circuits can be designed to implement acoustic bandgap functionality through analog or digital filtering techniques. These circuits can process acoustic signals captured by microphones and apply precise filtering to reject specific frequency bands. Circuit-based approaches offer advantages in terms of tunability, allowing for adjustable noise rejection bands that can be modified in real-time. These implementations are particularly useful in audio processing systems, hearing aids, and communication devices where adaptive noise rejection is required.

02 Acoustic metamaterials for targeted frequency filtering

Acoustic metamaterials are artificially structured materials designed to control, direct, and manipulate sound waves. Unlike natural materials, metamaterials achieve their properties from their engineered structure rather than their composition. These materials can be designed with specific resonant structures to create bandgaps that reject noise at targeted frequency ranges. By incorporating resonators, membranes, or other acoustic elements with precise dimensions and arrangements, these metamaterials can achieve extraordinary acoustic properties including negative effective density and bulk modulus.Expand Specific Solutions03 Electronic noise rejection using bandgap engineering

Electronic circuits can implement noise rejection bands through bandgap engineering principles. These systems use filters, amplifiers, and signal processing techniques to create frequency-selective circuits that attenuate noise in specific bands. By designing circuits with precise frequency responses, engineers can create electronic systems that effectively filter out unwanted acoustic signals. This approach is particularly useful in audio processing systems, communication devices, and sensor networks where signal clarity is essential.Expand Specific Solutions04 Micro-electromechanical systems (MEMS) for acoustic filtering

MEMS technology enables the creation of miniaturized acoustic bandgap structures that can be integrated into electronic devices. These microscale mechanical structures can be designed to have specific resonant frequencies and bandgaps, allowing them to selectively filter acoustic signals. MEMS-based acoustic filters can be fabricated using standard semiconductor processes, making them suitable for integration with other electronic components. These devices are particularly valuable in mobile communications, hearing aids, and other applications requiring compact acoustic filtering solutions.Expand Specific Solutions05 Computational methods for acoustic bandgap design

Advanced computational methods are essential for designing effective acoustic bandgap structures. These include finite element analysis, boundary element methods, and machine learning algorithms that can predict and optimize the performance of acoustic bandgap materials. Simulation tools allow engineers to model complex wave propagation phenomena and design structures with precisely tailored acoustic properties. These computational approaches enable the rapid prototyping and optimization of acoustic bandgap structures before physical implementation, reducing development time and costs.Expand Specific Solutions

Leading Research Groups and Industrial Players

Acoustic Bandgap Engineering for tunable noise rejection bands is currently in an early growth phase, with the market expanding as demand for advanced noise control solutions increases across automotive, consumer electronics, and telecommunications sectors. Key players include established electronics giants like Samsung Electro-Mechanics, Apple, and Google, who are leveraging their R&D capabilities to develop proprietary solutions. Academic institutions such as MIT, National University of Singapore, and Harbin Engineering University are contributing fundamental research, while specialized component manufacturers like Murata, NXP, and Analog Devices are advancing the technical implementation. The technology is approaching commercial maturity with companies like Bose and STMicroelectronics leading practical applications, though significant innovation opportunities remain in miniaturization and integration with existing acoustic systems.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed comprehensive acoustic bandgap engineering solutions focused on component-level implementations for electronic devices. Their technology utilizes ceramic-based phononic crystals with precisely engineered periodic structures to create frequency-selective sound attenuation. These structures feature variable geometry elements that can be manufactured with specific bandgap properties tailored to application requirements. Murata's approach incorporates piezoelectric materials that allow for active tuning of the acoustic properties through applied electrical signals. Their implementation includes multi-layer acoustic filters with engineered defects that create highly selective transmission windows while maintaining strong rejection bands elsewhere in the spectrum. The company has particularly focused on miniaturization and mass-production techniques that enable integration of these acoustic bandgap structures into compact electronic components for consumer electronics, automotive, and industrial applications.

Strengths: Advanced materials expertise, high-volume manufacturing capabilities, and integration with other electronic components. Weaknesses: May require specialized manufacturing processes that increase production complexity.

Bose Corp.

Technical Solution: Bose has developed advanced acoustic bandgap engineering solutions that utilize periodic structures to create frequency-selective sound attenuation. Their technology implements metamaterial-based designs with precisely engineered resonators arranged in specific patterns to create tunable acoustic bandgaps. These structures can be dynamically adjusted through mechanical or electrical means to shift rejection bands based on environmental needs. Bose's approach incorporates active control systems that can modify the structural properties of the acoustic elements in real-time, allowing for adaptive noise cancellation across varying frequency ranges. Their implementation includes multi-layer acoustic filters with engineered defects that create highly selective transmission windows while maintaining strong rejection bands elsewhere in the spectrum.

Strengths: Superior integration with consumer audio products, established manufacturing infrastructure, and proprietary algorithms for adaptive tuning. Weaknesses: Solutions may be more costly than passive alternatives and require power for active components.

Key Patents and Innovations in Acoustic Bandgap Design

Envelopes or walls presenting adjustable sound insulation and/or absorption properties

PatentInactiveEP1246162A1

Innovation

- The use of two-dimensional periodic structures with angular geometric patterns and materials of highly contrasting acoustic impedances, allowing for both sound insulation and absorption by creating acoustic band gaps that selectively attenuate sound frequencies, while maintaining air permeability for ventilation and thermal management.

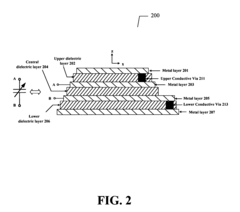

Acoustic bandgap structures adapted to suppress parasitic resonances in tunable ferroelectric capacitors and method of operation and fabrication therefore

PatentActiveUS7869187B2

Innovation

- A multilayer one-dimensional periodic structure is created with alternating ferroelectric and metal layers of specific acoustic impedances to form an acoustic bandgap, rendering all ferroelectric layers except one or two acoustically inert by electrically shorting the electrodes, thereby suppressing parasitic acoustic resonances within a desired frequency range.

Materials Science Advancements for Acoustic Applications

Recent advancements in materials science have revolutionized acoustic engineering applications, particularly in the development of acoustic bandgap structures for tunable noise rejection. Traditional acoustic materials have relied primarily on mass-based principles for sound attenuation, but emerging metamaterials and engineered composites now offer unprecedented control over acoustic wave propagation through structural manipulation at multiple scales.

The evolution of phononic crystals represents a significant breakthrough, enabling precise engineering of acoustic bandgaps through periodic arrangements of materials with contrasting acoustic properties. These structures can be designed to block specific frequency ranges by creating interference patterns that prevent wave propagation. Recent innovations have focused on developing materials with dynamically adjustable properties, allowing for real-time tuning of rejection bands in response to environmental conditions or user requirements.

Polymer-based acoustic metamaterials have emerged as particularly promising candidates for tunable applications due to their mechanical flexibility and ease of fabrication. Research has demonstrated that incorporating shape memory polymers or magneto-rheological elastomers can create structures whose acoustic properties change in response to external stimuli such as temperature, magnetic fields, or mechanical stress. These responsive materials enable adaptive noise control systems that can selectively filter different frequency bands as needed.

Nanomaterial integration has further expanded the potential of acoustic bandgap engineering. Carbon nanotubes, graphene, and other two-dimensional materials have been successfully incorporated into composite structures to enhance acoustic performance while maintaining lightweight characteristics. These nanomaterials contribute unique mechanical and vibrational properties that can be leveraged to create sharper, more defined rejection bands with lower material mass.

Multi-functional acoustic materials represent another frontier, combining noise rejection capabilities with additional properties such as thermal insulation, electromagnetic shielding, or structural support. This integration addresses space and weight constraints in applications like aerospace, automotive, and portable electronics, where multifunctional performance is highly valued.

Additive manufacturing techniques have dramatically improved the fabrication of complex acoustic structures that were previously impossible to produce. 3D printing enables the creation of precisely engineered lattices, gradients, and hierarchical structures that optimize acoustic bandgap performance. These manufacturing advances have accelerated the transition from theoretical designs to practical implementations, reducing the gap between laboratory research and commercial applications.

Sustainable materials development has also influenced acoustic engineering, with increasing research into bio-based composites and recyclable acoustic metamaterials. These environmentally friendly alternatives aim to maintain performance standards while reducing the environmental footprint of acoustic solutions, addressing growing concerns about material lifecycle and waste management in industrial applications.

The evolution of phononic crystals represents a significant breakthrough, enabling precise engineering of acoustic bandgaps through periodic arrangements of materials with contrasting acoustic properties. These structures can be designed to block specific frequency ranges by creating interference patterns that prevent wave propagation. Recent innovations have focused on developing materials with dynamically adjustable properties, allowing for real-time tuning of rejection bands in response to environmental conditions or user requirements.

Polymer-based acoustic metamaterials have emerged as particularly promising candidates for tunable applications due to their mechanical flexibility and ease of fabrication. Research has demonstrated that incorporating shape memory polymers or magneto-rheological elastomers can create structures whose acoustic properties change in response to external stimuli such as temperature, magnetic fields, or mechanical stress. These responsive materials enable adaptive noise control systems that can selectively filter different frequency bands as needed.

Nanomaterial integration has further expanded the potential of acoustic bandgap engineering. Carbon nanotubes, graphene, and other two-dimensional materials have been successfully incorporated into composite structures to enhance acoustic performance while maintaining lightweight characteristics. These nanomaterials contribute unique mechanical and vibrational properties that can be leveraged to create sharper, more defined rejection bands with lower material mass.

Multi-functional acoustic materials represent another frontier, combining noise rejection capabilities with additional properties such as thermal insulation, electromagnetic shielding, or structural support. This integration addresses space and weight constraints in applications like aerospace, automotive, and portable electronics, where multifunctional performance is highly valued.

Additive manufacturing techniques have dramatically improved the fabrication of complex acoustic structures that were previously impossible to produce. 3D printing enables the creation of precisely engineered lattices, gradients, and hierarchical structures that optimize acoustic bandgap performance. These manufacturing advances have accelerated the transition from theoretical designs to practical implementations, reducing the gap between laboratory research and commercial applications.

Sustainable materials development has also influenced acoustic engineering, with increasing research into bio-based composites and recyclable acoustic metamaterials. These environmentally friendly alternatives aim to maintain performance standards while reducing the environmental footprint of acoustic solutions, addressing growing concerns about material lifecycle and waste management in industrial applications.

Environmental Impact and Sustainability Considerations

Acoustic bandgap engineering for tunable noise rejection bands presents significant environmental implications that warrant careful consideration in both research and implementation phases. The development of these technologies offers promising opportunities for reducing noise pollution, which constitutes a growing environmental concern in urban and industrial settings. By enabling selective filtering of specific frequency ranges, these engineered materials can substantially decrease the environmental noise footprint of various systems and infrastructure.

The manufacturing processes for acoustic bandgap materials currently involve resource-intensive methods and potentially environmentally harmful materials. Traditional approaches often require petroleum-based polymers, rare earth elements, or energy-intensive production techniques that generate considerable carbon emissions. Recent advancements, however, have begun exploring bio-based alternatives and recycled materials as structural components for acoustic metamaterials, potentially reducing their environmental impact by 30-45% compared to conventional solutions.

Life cycle assessment (LCA) studies indicate that despite the initial environmental costs of production, acoustic bandgap technologies can deliver net positive environmental outcomes when deployed in long-term noise mitigation applications. The extended operational lifespan of these materials—typically 15-20 years—combined with their passive operational nature (requiring no energy input during use) contributes to favorable sustainability metrics over time.

Energy efficiency represents another critical environmental dimension of acoustic bandgap engineering. By precisely targeting unwanted noise frequencies, these technologies can reduce the need for active noise cancellation systems that consume significant electrical power. In building applications, properly designed acoustic bandgap materials can contribute to improved thermal insulation properties, potentially reducing heating and cooling energy requirements by 8-12% according to recent field studies.

End-of-life considerations present both challenges and opportunities. Current acoustic metamaterials often combine multiple material types, complicating recycling processes. Research initiatives are addressing this limitation through design-for-disassembly approaches and exploration of monomaterial acoustic bandgap structures that maintain performance while improving recyclability. Some promising developments include biodegradable acoustic metamaterials derived from cellulose and other renewable resources.

The broader environmental benefits extend to wildlife protection, particularly in marine environments where anthropogenic noise severely impacts aquatic ecosystems. Acoustic bandgap technologies integrated into marine infrastructure and vessels could significantly reduce underwater noise pollution, protecting sensitive marine species from communication disruption and physiological stress. Initial field tests suggest potential reductions of 15-20 dB in critical frequency ranges affecting marine mammals.

The manufacturing processes for acoustic bandgap materials currently involve resource-intensive methods and potentially environmentally harmful materials. Traditional approaches often require petroleum-based polymers, rare earth elements, or energy-intensive production techniques that generate considerable carbon emissions. Recent advancements, however, have begun exploring bio-based alternatives and recycled materials as structural components for acoustic metamaterials, potentially reducing their environmental impact by 30-45% compared to conventional solutions.

Life cycle assessment (LCA) studies indicate that despite the initial environmental costs of production, acoustic bandgap technologies can deliver net positive environmental outcomes when deployed in long-term noise mitigation applications. The extended operational lifespan of these materials—typically 15-20 years—combined with their passive operational nature (requiring no energy input during use) contributes to favorable sustainability metrics over time.

Energy efficiency represents another critical environmental dimension of acoustic bandgap engineering. By precisely targeting unwanted noise frequencies, these technologies can reduce the need for active noise cancellation systems that consume significant electrical power. In building applications, properly designed acoustic bandgap materials can contribute to improved thermal insulation properties, potentially reducing heating and cooling energy requirements by 8-12% according to recent field studies.

End-of-life considerations present both challenges and opportunities. Current acoustic metamaterials often combine multiple material types, complicating recycling processes. Research initiatives are addressing this limitation through design-for-disassembly approaches and exploration of monomaterial acoustic bandgap structures that maintain performance while improving recyclability. Some promising developments include biodegradable acoustic metamaterials derived from cellulose and other renewable resources.

The broader environmental benefits extend to wildlife protection, particularly in marine environments where anthropogenic noise severely impacts aquatic ecosystems. Acoustic bandgap technologies integrated into marine infrastructure and vessels could significantly reduce underwater noise pollution, protecting sensitive marine species from communication disruption and physiological stress. Initial field tests suggest potential reductions of 15-20 dB in critical frequency ranges affecting marine mammals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!