Acoustic Metamaterials For Industrial Noise Sources: Retrofit Guidelines

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterials Background and Objectives

Acoustic metamaterials represent a revolutionary advancement in noise control engineering, emerging from theoretical physics concepts in the early 2000s to practical applications in the 2010s. These engineered materials possess extraordinary acoustic properties not found in natural materials, enabling unprecedented control over sound waves through mechanisms such as negative effective density, negative bulk modulus, and local resonance phenomena. The evolution of acoustic metamaterials has progressed from simple laboratory demonstrations to increasingly sophisticated designs capable of addressing complex industrial noise challenges.

The industrial noise control landscape has traditionally relied on conventional solutions like absorptive materials, barriers, and enclosures, which often present limitations in low-frequency performance, space requirements, and durability in harsh environments. Acoustic metamaterials offer promising alternatives by providing targeted frequency attenuation, reduced material thickness, and potentially improved durability—characteristics particularly valuable in industrial settings where space constraints and environmental conditions pose significant challenges.

Recent technological breakthroughs have accelerated the development trajectory, including advances in computational modeling, additive manufacturing techniques, and multi-physics optimization algorithms. These innovations have collectively enhanced the ability to design, simulate, and fabricate increasingly complex metamaterial structures tailored to specific noise profiles. The convergence of these enabling technologies has created a fertile ground for transitioning acoustic metamaterials from academic research to practical industrial applications.

The primary objective of this technical investigation is to establish comprehensive retrofit guidelines for implementing acoustic metamaterial solutions in existing industrial environments. This includes developing systematic approaches for characterizing industrial noise sources, identifying optimal metamaterial configurations for specific noise profiles, and creating practical implementation frameworks that address installation constraints, durability requirements, and maintenance considerations in operational industrial settings.

Secondary objectives encompass quantifying the performance advantages of metamaterial solutions compared to conventional approaches, particularly focusing on low-frequency noise reduction capabilities, space efficiency, and long-term durability under industrial conditions. Additionally, the research aims to identify scalable manufacturing techniques suitable for industrial-scale production of acoustic metamaterial components, ensuring cost-effectiveness and consistency in performance.

The ultimate goal is to bridge the gap between laboratory demonstrations and practical industrial applications, providing engineers with actionable guidelines for integrating these advanced materials into existing noise control strategies. This represents a critical step in the technology transfer process, potentially revolutionizing industrial noise control practices across manufacturing, energy production, transportation, and other sectors where noise mitigation remains a persistent challenge.

The industrial noise control landscape has traditionally relied on conventional solutions like absorptive materials, barriers, and enclosures, which often present limitations in low-frequency performance, space requirements, and durability in harsh environments. Acoustic metamaterials offer promising alternatives by providing targeted frequency attenuation, reduced material thickness, and potentially improved durability—characteristics particularly valuable in industrial settings where space constraints and environmental conditions pose significant challenges.

Recent technological breakthroughs have accelerated the development trajectory, including advances in computational modeling, additive manufacturing techniques, and multi-physics optimization algorithms. These innovations have collectively enhanced the ability to design, simulate, and fabricate increasingly complex metamaterial structures tailored to specific noise profiles. The convergence of these enabling technologies has created a fertile ground for transitioning acoustic metamaterials from academic research to practical industrial applications.

The primary objective of this technical investigation is to establish comprehensive retrofit guidelines for implementing acoustic metamaterial solutions in existing industrial environments. This includes developing systematic approaches for characterizing industrial noise sources, identifying optimal metamaterial configurations for specific noise profiles, and creating practical implementation frameworks that address installation constraints, durability requirements, and maintenance considerations in operational industrial settings.

Secondary objectives encompass quantifying the performance advantages of metamaterial solutions compared to conventional approaches, particularly focusing on low-frequency noise reduction capabilities, space efficiency, and long-term durability under industrial conditions. Additionally, the research aims to identify scalable manufacturing techniques suitable for industrial-scale production of acoustic metamaterial components, ensuring cost-effectiveness and consistency in performance.

The ultimate goal is to bridge the gap between laboratory demonstrations and practical industrial applications, providing engineers with actionable guidelines for integrating these advanced materials into existing noise control strategies. This represents a critical step in the technology transfer process, potentially revolutionizing industrial noise control practices across manufacturing, energy production, transportation, and other sectors where noise mitigation remains a persistent challenge.

Industrial Noise Control Market Analysis

The global industrial noise control market is experiencing significant growth, valued at approximately $6.3 billion in 2022 and projected to reach $8.9 billion by 2027, with a compound annual growth rate (CAGR) of 7.2%. This growth is primarily driven by stringent noise regulations across industries, increasing awareness of occupational health hazards, and the rising demand for acoustic comfort in industrial environments.

Manufacturing sectors, particularly heavy machinery, automotive, and aerospace industries, represent the largest market segments for industrial noise control solutions. These industries face substantial challenges in meeting regulatory requirements while maintaining operational efficiency. The energy sector, including power generation and oil & gas, follows closely as the second-largest market segment, where noise from turbines, generators, and compressors presents significant control challenges.

Geographically, North America and Europe dominate the market due to strict regulatory frameworks and high awareness levels. However, the Asia-Pacific region is witnessing the fastest growth rate at approximately 9.5% annually, driven by rapid industrialization in China, India, and Southeast Asian countries, coupled with increasing adoption of workplace safety standards.

Traditional noise control solutions such as barriers, enclosures, and absorptive materials currently hold approximately 65% of the market share. However, advanced solutions incorporating acoustic metamaterials are gaining traction, with an estimated market penetration of 8% and growing at twice the rate of conventional solutions.

The retrofit segment specifically represents about 40% of the total market, as industries seek cost-effective solutions to address noise issues in existing facilities without major infrastructure changes. This segment is expected to grow at 8.3% annually through 2027, outpacing new installations.

Key market drivers include increasingly stringent occupational noise exposure limits, with many countries adopting the 85 dBA threshold recommended by the World Health Organization. Additionally, the economic impact of noise-induced hearing loss, estimated at $242 million annually in workers' compensation claims in the United States alone, is pushing industries toward proactive noise control measures.

Customer demand is shifting toward customizable, modular solutions that offer ease of installation and minimal disruption to operations. There is also growing interest in smart noise control systems that can adapt to varying operational conditions, presenting new market opportunities for innovative acoustic metamaterial applications.

Manufacturing sectors, particularly heavy machinery, automotive, and aerospace industries, represent the largest market segments for industrial noise control solutions. These industries face substantial challenges in meeting regulatory requirements while maintaining operational efficiency. The energy sector, including power generation and oil & gas, follows closely as the second-largest market segment, where noise from turbines, generators, and compressors presents significant control challenges.

Geographically, North America and Europe dominate the market due to strict regulatory frameworks and high awareness levels. However, the Asia-Pacific region is witnessing the fastest growth rate at approximately 9.5% annually, driven by rapid industrialization in China, India, and Southeast Asian countries, coupled with increasing adoption of workplace safety standards.

Traditional noise control solutions such as barriers, enclosures, and absorptive materials currently hold approximately 65% of the market share. However, advanced solutions incorporating acoustic metamaterials are gaining traction, with an estimated market penetration of 8% and growing at twice the rate of conventional solutions.

The retrofit segment specifically represents about 40% of the total market, as industries seek cost-effective solutions to address noise issues in existing facilities without major infrastructure changes. This segment is expected to grow at 8.3% annually through 2027, outpacing new installations.

Key market drivers include increasingly stringent occupational noise exposure limits, with many countries adopting the 85 dBA threshold recommended by the World Health Organization. Additionally, the economic impact of noise-induced hearing loss, estimated at $242 million annually in workers' compensation claims in the United States alone, is pushing industries toward proactive noise control measures.

Customer demand is shifting toward customizable, modular solutions that offer ease of installation and minimal disruption to operations. There is also growing interest in smart noise control systems that can adapt to varying operational conditions, presenting new market opportunities for innovative acoustic metamaterial applications.

Current Challenges in Retrofit Noise Reduction

Despite the proven effectiveness of acoustic metamaterials in laboratory settings, implementing these solutions in existing industrial environments presents significant challenges. The retrofit application of metamaterial-based noise reduction systems must overcome spatial constraints that were not considered during the original facility design. Industrial settings typically feature complex machinery layouts with limited clearance between equipment, making it difficult to install bulky noise reduction solutions without disrupting operations or maintenance access.

Material compatibility poses another substantial challenge, as industrial environments often contain harsh conditions including extreme temperatures, chemical exposure, and high humidity. Acoustic metamaterials must maintain their performance characteristics under these conditions while meeting stringent safety requirements, including fire resistance and non-toxicity standards that vary across industries and regulatory jurisdictions.

Structural integration represents a critical hurdle, as retrofitting requires attachment to existing structures without compromising their integrity. Many industrial facilities were not designed with the additional load-bearing capacity needed for noise reduction systems, necessitating careful structural assessment before implementation. The attachment methods must also accommodate vibration without degrading the acoustic performance of the metamaterial.

Cost-effectiveness remains a primary concern for industry stakeholders. While laboratory prototypes demonstrate impressive noise reduction capabilities, scaling these solutions to industrial proportions often reveals unforeseen expenses in materials, manufacturing, and installation. The economic justification for retrofitting must account for both direct implementation costs and potential production disruptions during installation.

Performance verification in real-world conditions presents methodological challenges that laboratory testing cannot fully address. Industrial noise sources are typically complex, featuring multiple frequencies and directional characteristics that interact with the existing acoustic environment. Predicting and measuring the actual performance of metamaterial solutions in these settings requires sophisticated modeling and testing protocols that are still evolving.

Maintenance requirements introduce long-term considerations that affect adoption decisions. Industrial environments subject noise reduction systems to accelerated wear, contamination, and damage. Acoustic metamaterials must be designed for durability or easy replacement, with clear protocols for performance monitoring and maintenance that integrate with existing facility management systems.

Regulatory compliance adds another layer of complexity, as noise reduction solutions must meet workplace safety standards while adhering to building codes and environmental regulations. The certification process for novel materials can be lengthy and varies significantly across regions, creating barriers to widespread implementation.

Material compatibility poses another substantial challenge, as industrial environments often contain harsh conditions including extreme temperatures, chemical exposure, and high humidity. Acoustic metamaterials must maintain their performance characteristics under these conditions while meeting stringent safety requirements, including fire resistance and non-toxicity standards that vary across industries and regulatory jurisdictions.

Structural integration represents a critical hurdle, as retrofitting requires attachment to existing structures without compromising their integrity. Many industrial facilities were not designed with the additional load-bearing capacity needed for noise reduction systems, necessitating careful structural assessment before implementation. The attachment methods must also accommodate vibration without degrading the acoustic performance of the metamaterial.

Cost-effectiveness remains a primary concern for industry stakeholders. While laboratory prototypes demonstrate impressive noise reduction capabilities, scaling these solutions to industrial proportions often reveals unforeseen expenses in materials, manufacturing, and installation. The economic justification for retrofitting must account for both direct implementation costs and potential production disruptions during installation.

Performance verification in real-world conditions presents methodological challenges that laboratory testing cannot fully address. Industrial noise sources are typically complex, featuring multiple frequencies and directional characteristics that interact with the existing acoustic environment. Predicting and measuring the actual performance of metamaterial solutions in these settings requires sophisticated modeling and testing protocols that are still evolving.

Maintenance requirements introduce long-term considerations that affect adoption decisions. Industrial environments subject noise reduction systems to accelerated wear, contamination, and damage. Acoustic metamaterials must be designed for durability or easy replacement, with clear protocols for performance monitoring and maintenance that integrate with existing facility management systems.

Regulatory compliance adds another layer of complexity, as noise reduction solutions must meet workplace safety standards while adhering to building codes and environmental regulations. The certification process for novel materials can be lengthy and varies significantly across regions, creating barriers to widespread implementation.

Existing Retrofit Solutions Using Metamaterials

01 Metamaterial structures for noise cancellation

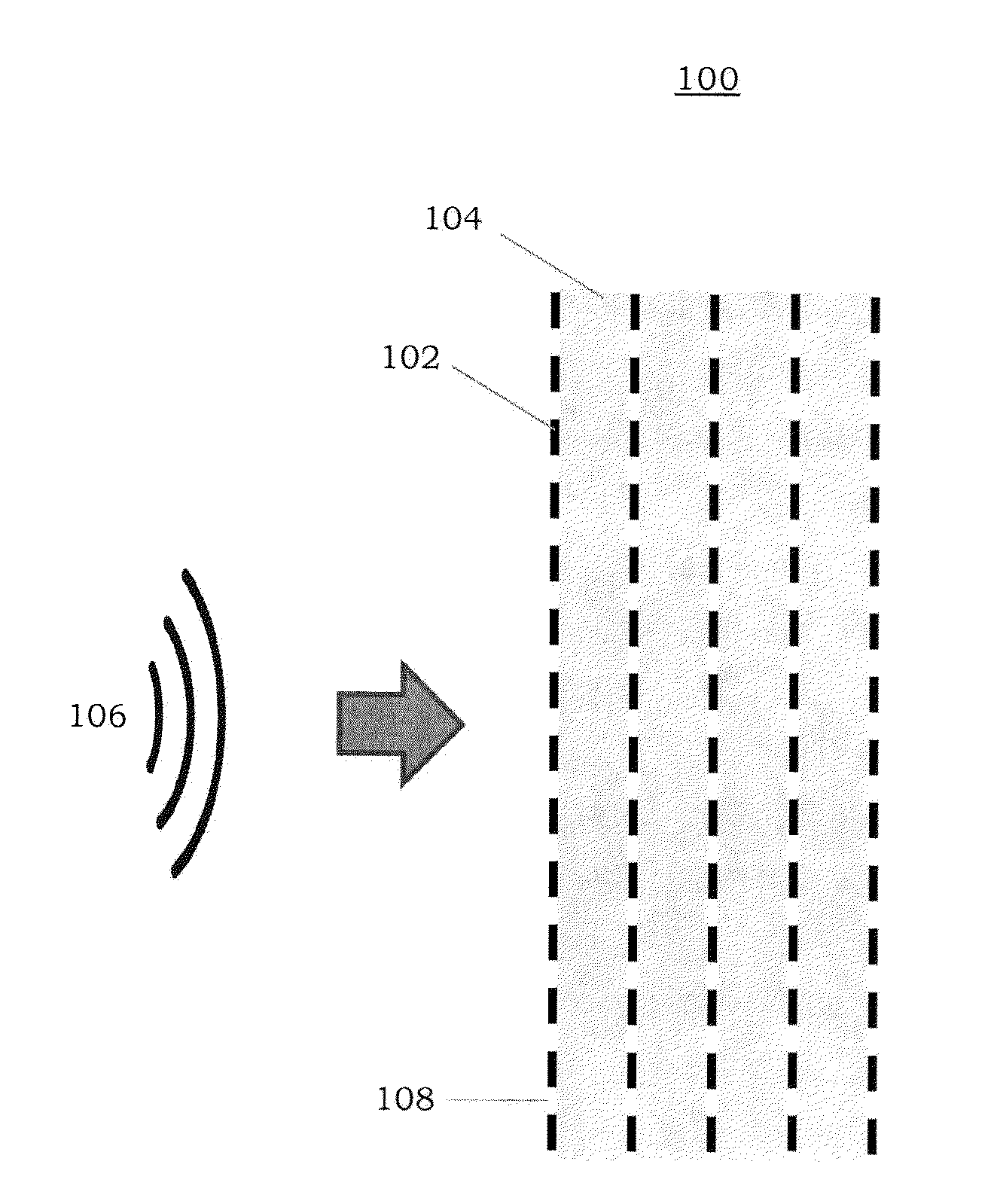

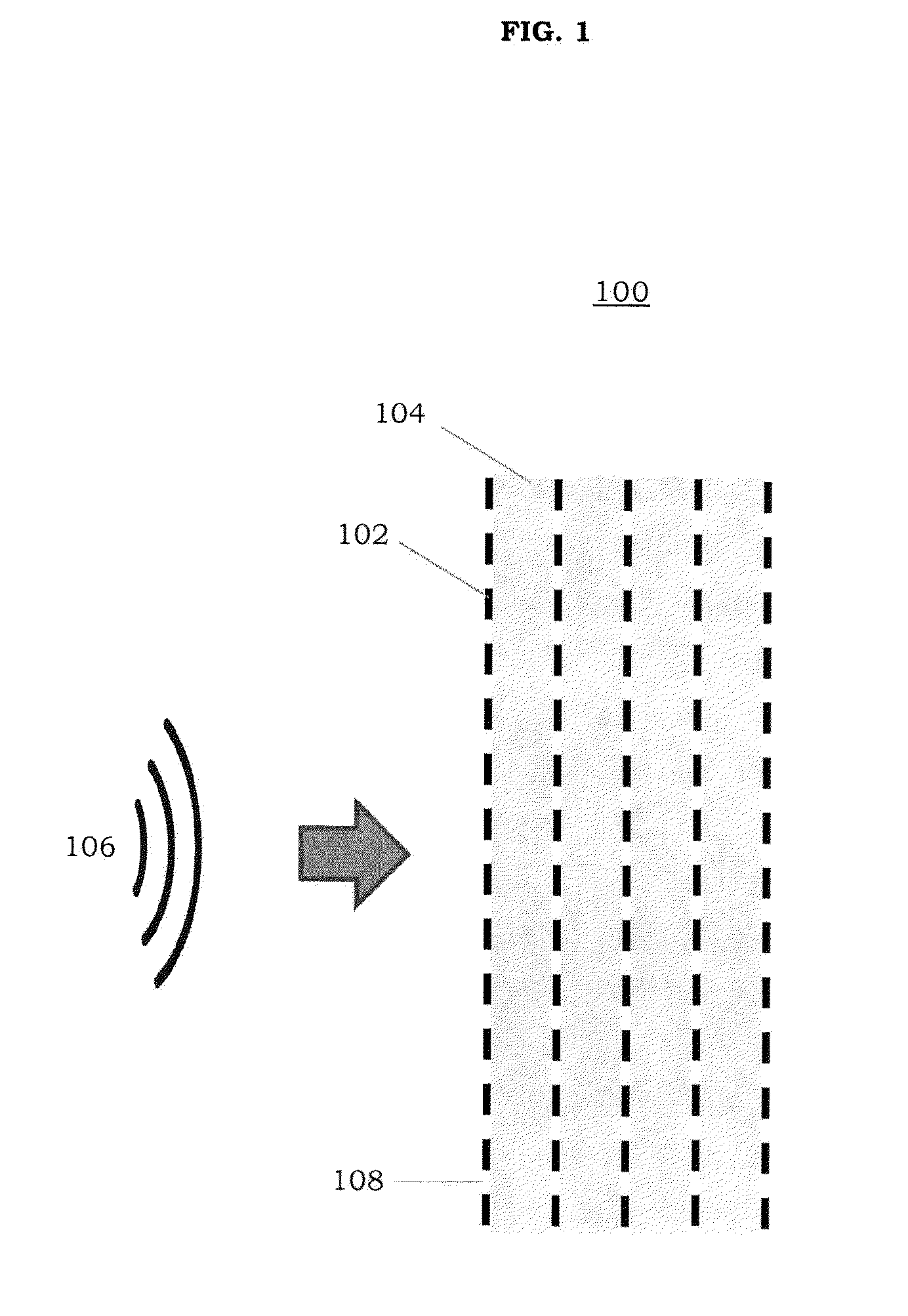

Acoustic metamaterials with engineered structures can effectively cancel or reduce noise by manipulating sound waves. These structures often include resonant cavities, periodic arrangements, or layered designs that can absorb, redirect, or destructively interfere with sound waves at specific frequencies. The metamaterial design allows for noise reduction in targeted frequency ranges, making them particularly effective for environmental noise control applications.- Metamaterial structures for noise reduction: Acoustic metamaterials with engineered structures can effectively reduce noise by manipulating sound waves. These structures often include resonant cavities, periodic arrangements, or layered compositions that can block, absorb, or redirect sound waves at specific frequencies. The unique geometric configurations of these metamaterials enable them to achieve noise reduction performance beyond what conventional materials can offer, particularly in challenging low-frequency ranges.

- Active noise control systems with metamaterials: Combining active noise control technologies with acoustic metamaterials creates advanced noise reduction solutions. These systems use electronic components to detect incoming sound waves and generate anti-phase signals, while metamaterial structures enhance the overall performance. The integration allows for adaptive noise cancellation across broader frequency ranges and can be particularly effective in dynamic noise environments where passive solutions alone would be insufficient.

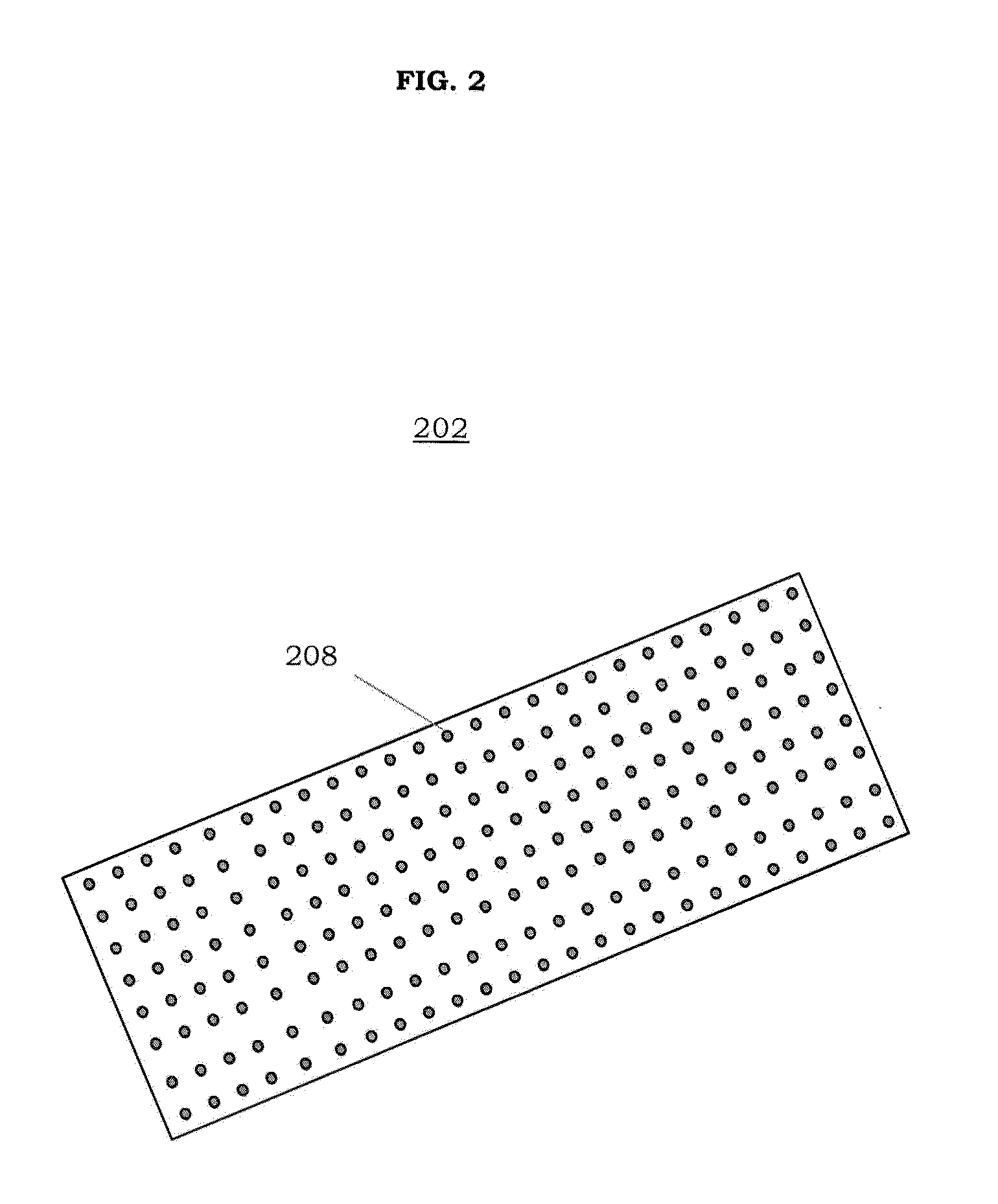

- Resonant cavity-based metamaterial absorbers: Acoustic metamaterials featuring resonant cavities or chambers can be designed to target specific noise frequencies. These absorbers work by converting sound energy into heat through viscous and thermal losses within the cavities. The dimensions and shapes of these resonant structures can be precisely engineered to address particular noise problems, making them ideal for applications requiring selective frequency attenuation without adding significant mass or volume.

- Membrane-type acoustic metamaterials: Membrane-based acoustic metamaterials utilize thin, tensioned membranes with attached masses to create effective noise barriers. These lightweight structures can achieve exceptional low-frequency noise reduction, which is typically challenging for conventional materials of similar thickness. The membranes vibrate in response to sound waves, dissipating acoustic energy through damping mechanisms. Their lightweight nature makes them particularly valuable for applications where adding minimal mass is critical.

- Phononic crystal structures for sound insulation: Phononic crystals are a type of acoustic metamaterial that uses periodic arrangements of materials with different acoustic properties to create bandgaps where sound propagation is prohibited. These structures can be designed to block specific frequency ranges by causing destructive interference or wave localization. The periodic arrangement can be optimized for different noise profiles, making phononic crystals adaptable to various environmental noise challenges while maintaining structural integrity.

02 Active noise control systems with metamaterials

Integration of active noise control systems with acoustic metamaterials enhances noise reduction capabilities. These systems combine traditional active noise cancellation technology with the passive noise reduction properties of metamaterials. Sensors detect incoming sound waves, and controllers generate anti-phase signals that are amplified by the metamaterial structures, resulting in more effective noise cancellation across broader frequency ranges than either technology alone.Expand Specific Solutions03 Resonant cavity metamaterials for targeted frequency absorption

Acoustic metamaterials designed with resonant cavities can be tuned to absorb specific frequency ranges. These structures typically consist of arrays of Helmholtz resonators or other cavity designs that capture sound energy at their resonant frequencies. By carefully engineering the dimensions and arrangement of these cavities, the metamaterials can provide exceptional noise reduction at problematic frequencies while maintaining a relatively thin and lightweight profile compared to traditional acoustic treatments.Expand Specific Solutions04 Membrane-based acoustic metamaterials

Membrane-based acoustic metamaterials utilize thin, tensioned membranes combined with air cavities to achieve noise reduction. These designs often incorporate multiple membrane layers with different tensions and masses to target various frequency ranges. The membranes vibrate in response to sound waves, converting acoustic energy into mechanical energy that is then dissipated. This approach is particularly effective for low-frequency noise reduction, which is traditionally difficult to address with conventional materials.Expand Specific Solutions05 Adaptive and tunable acoustic metamaterials

Adaptive acoustic metamaterials can be tuned or reconfigured to address changing noise conditions. These advanced designs incorporate elements that can be adjusted mechanically, electrically, or through other means to modify their acoustic properties. Some implementations use smart materials that respond to external stimuli, allowing the metamaterial to automatically adapt to different noise profiles. This adaptability makes these metamaterials particularly valuable in environments with variable noise characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acoustic metamaterials market for industrial noise control is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market size is expanding as industries seek cost-effective noise reduction solutions that comply with stricter environmental regulations. Technologically, the field shows varying maturity levels across players. Research institutions like MIT, Chinese Academy of Sciences, and CNRS are advancing fundamental science, while companies including 3M, Boeing, and Toshiba are developing practical applications. Industrial players such as BYD, Hyundai, and Kia are exploring automotive implementations. Specialized firms like Pixie Dust Technologies and Ultrahaptics are creating innovative niche solutions. The retrofit market specifically remains underdeveloped but presents significant growth potential as implementation guidelines mature.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed advanced acoustic metamaterials featuring engineered resonant structures that can effectively attenuate industrial noise across specific frequency ranges. Their technology utilizes periodic arrangements of locally resonant elements with carefully designed geometries to create acoustic bandgaps. These metamaterials incorporate both membrane-type and Helmholtz resonator configurations optimized for different industrial noise profiles. CNRS researchers have pioneered multi-physics modeling approaches that account for thermal and viscous effects in acoustic metamaterials, significantly improving prediction accuracy for real-world applications. Their retrofit solutions include modular panels that can be attached to existing machinery housings without requiring extensive modifications to the original equipment. Recent developments include adaptive metamaterials with tunable properties that can respond to changing noise characteristics, providing more versatile noise control across variable industrial operating conditions.

Strengths: Superior low-frequency noise attenuation compared to conventional materials; highly customizable for specific industrial noise profiles; non-invasive retrofit capability for existing equipment. Weaknesses: Higher manufacturing complexity and cost compared to traditional solutions; potential durability concerns in harsh industrial environments; limited effectiveness at very high temperatures.

UNIVERSITE DU MANS

Technical Solution: Université du Mans has developed innovative acoustic metamaterial solutions specifically designed for industrial retrofit applications. Their technology features multi-layered metamaterial panels incorporating micro-perforated plates combined with resonant cavities that achieve broadband noise reduction. These metamaterials are engineered to target the specific frequency signatures of industrial machinery while maintaining a compact form factor suitable for retrofit applications. The university's research team has created computational models that optimize metamaterial geometries for specific noise sources, allowing customized solutions for different industrial environments. Their retrofit guidelines emphasize non-invasive installation methods using modular components that can be attached to existing machinery without compromising operational access. The technology incorporates passive acoustic metamaterials that require no power input, ensuring reliability in industrial settings. Recent advancements include the development of 3D-printed metamaterial structures that can be rapidly customized and manufactured for specific industrial applications, significantly reducing implementation time.

Strengths: Exceptional performance in mid-frequency ranges typical of many industrial processes; modular design allows for easy installation and maintenance; passive operation eliminates power requirements and potential failure points. Weaknesses: Less effective for very low-frequency noise without significant thickness; may require periodic cleaning in dusty industrial environments; higher initial cost compared to conventional acoustic treatments.

Key Patents and Innovations in Industrial Applications

Acoustic metamaterial architectured composite layers, methods of manufacturing the same, and methods for noise control using the same

PatentActiveUS20150279345A1

Innovation

- The use of acoustic metamaterials, specifically designed composite layers comprising micro-perforated plates and absorptive materials, optimized using Transformation Acoustics principles to achieve broadband acoustic transmission loss and absorption, minimizing weight and enhancing sound insulation across a wide frequency range.

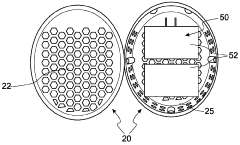

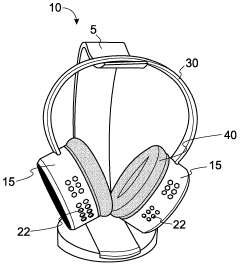

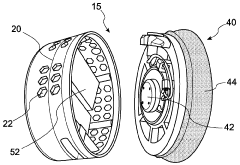

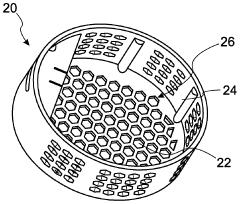

Acoustic metamaterials

PatentWO2023131787A1

Innovation

- The use of acoustic metamaterials, specifically arrays of unit cells like Helmholtz resonators and membranes, integrated into consumer devices like headphones, which are designed to attenuate sound in the frequency range of 300 to 3000 Hz by dissipating sound waves through strategically placed openings in the device housing, enhancing sound absorption and reducing reflection.

Implementation Cost-Benefit Analysis

The implementation of acoustic metamaterials for industrial noise control requires careful cost-benefit analysis to justify investment decisions. Initial implementation costs typically include design engineering (15-20% of total cost), material procurement (30-40%), fabrication (25-30%), and installation (15-25%). These percentages vary based on complexity, scale, and customization requirements of the retrofit solution.

When comparing with traditional noise control methods, acoustic metamaterials demonstrate compelling long-term economic advantages despite higher upfront costs. Traditional solutions like acoustic panels or enclosures generally cost 30-50% less initially but require replacement every 3-5 years and offer limited performance in low-frequency ranges. Metamaterial solutions, while commanding a premium of 40-70% in initial investment, typically maintain effectiveness for 8-12 years with minimal maintenance requirements.

Return on investment (ROI) calculations reveal that metamaterial implementations reach break-even points within 2.5-4 years in high-noise industrial environments. This favorable ROI stems from multiple benefit streams: reduced workplace noise-related health claims (estimated 15-25% reduction), improved worker productivity in noise-sensitive operations (7-12% improvement), decreased equipment maintenance costs due to vibration reduction (10-18% savings), and enhanced regulatory compliance with reduced risk of penalties.

Energy efficiency gains represent another significant benefit, particularly in HVAC systems where metamaterial treatments can reduce operational energy consumption by 5-8% through improved acoustic performance without airflow restriction. This translates to substantial operational savings over the installation lifetime.

Case studies across various industries demonstrate consistent financial benefits. A power generation facility reported a 32% reduction in maintenance costs and 18% improvement in equipment lifespan following metamaterial implementation at critical noise sources. Similarly, a manufacturing plant documented a 21% decrease in noise-related workplace incidents and associated compensation claims within the first year of implementation.

Scalability considerations reveal that per-unit costs decrease significantly with implementation scale, with cost reductions of 15-25% achievable when treating multiple similar noise sources simultaneously. This economy of scale makes facility-wide implementation more financially attractive than isolated applications, particularly when coordinated with scheduled maintenance or facility upgrades.

When comparing with traditional noise control methods, acoustic metamaterials demonstrate compelling long-term economic advantages despite higher upfront costs. Traditional solutions like acoustic panels or enclosures generally cost 30-50% less initially but require replacement every 3-5 years and offer limited performance in low-frequency ranges. Metamaterial solutions, while commanding a premium of 40-70% in initial investment, typically maintain effectiveness for 8-12 years with minimal maintenance requirements.

Return on investment (ROI) calculations reveal that metamaterial implementations reach break-even points within 2.5-4 years in high-noise industrial environments. This favorable ROI stems from multiple benefit streams: reduced workplace noise-related health claims (estimated 15-25% reduction), improved worker productivity in noise-sensitive operations (7-12% improvement), decreased equipment maintenance costs due to vibration reduction (10-18% savings), and enhanced regulatory compliance with reduced risk of penalties.

Energy efficiency gains represent another significant benefit, particularly in HVAC systems where metamaterial treatments can reduce operational energy consumption by 5-8% through improved acoustic performance without airflow restriction. This translates to substantial operational savings over the installation lifetime.

Case studies across various industries demonstrate consistent financial benefits. A power generation facility reported a 32% reduction in maintenance costs and 18% improvement in equipment lifespan following metamaterial implementation at critical noise sources. Similarly, a manufacturing plant documented a 21% decrease in noise-related workplace incidents and associated compensation claims within the first year of implementation.

Scalability considerations reveal that per-unit costs decrease significantly with implementation scale, with cost reductions of 15-25% achievable when treating multiple similar noise sources simultaneously. This economy of scale makes facility-wide implementation more financially attractive than isolated applications, particularly when coordinated with scheduled maintenance or facility upgrades.

Regulatory Compliance and Safety Standards

Regulatory frameworks governing industrial noise emissions have become increasingly stringent worldwide, necessitating comprehensive compliance strategies for industries implementing acoustic metamaterial solutions. The Occupational Safety and Health Administration (OSHA) in the United States mandates exposure limits of 85 dBA over an 8-hour time-weighted average, with required hearing conservation programs when levels exceed 85 dBA and mandatory hearing protection at 90 dBA. Similarly, the European Union's Noise Directive 2003/10/EC establishes lower and upper exposure action values at 80 dBA and 85 dBA respectively, with a limit value of 87 dBA.

When retrofitting industrial equipment with acoustic metamaterials, compliance with ISO 11690 (Acoustics - Recommended practice for the design of low-noise workplaces containing machinery) becomes essential. This standard provides guidelines for noise control strategies that can be effectively complemented by metamaterial implementations. Additionally, ISO 15667 specifically addresses acoustic enclosures and cabins, providing critical parameters that must be considered when designing metamaterial-based retrofit solutions.

The International Electrotechnical Commission (IEC) standards, particularly IEC 61672 for sound level meters, are crucial for accurate measurement and verification of noise reduction achieved through metamaterial applications. These measurements must be conducted according to standardized protocols to ensure legal compliance and demonstrate the effectiveness of implemented solutions.

Safety considerations extend beyond noise levels to include material properties of acoustic metamaterials. Fire safety standards such as ASTM E84 and EN 13501 classify building materials based on flame spread and smoke development characteristics. Acoustic metamaterial retrofits must meet these standards, particularly in high-risk industrial environments. Many jurisdictions require materials to achieve specific fire ratings depending on their application and proximity to critical equipment.

Environmental regulations, including the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, impose additional constraints on material selection for acoustic metamaterials. These regulations restrict the use of certain hazardous substances in manufacturing, necessitating careful material selection during the design phase of metamaterial solutions.

Local building codes and industry-specific regulations may impose additional requirements for noise control solutions. For instance, facilities in densely populated areas often face stricter environmental noise limits at property boundaries, requiring comprehensive noise management strategies that extend beyond worker protection to community impact mitigation.

When retrofitting industrial equipment with acoustic metamaterials, compliance with ISO 11690 (Acoustics - Recommended practice for the design of low-noise workplaces containing machinery) becomes essential. This standard provides guidelines for noise control strategies that can be effectively complemented by metamaterial implementations. Additionally, ISO 15667 specifically addresses acoustic enclosures and cabins, providing critical parameters that must be considered when designing metamaterial-based retrofit solutions.

The International Electrotechnical Commission (IEC) standards, particularly IEC 61672 for sound level meters, are crucial for accurate measurement and verification of noise reduction achieved through metamaterial applications. These measurements must be conducted according to standardized protocols to ensure legal compliance and demonstrate the effectiveness of implemented solutions.

Safety considerations extend beyond noise levels to include material properties of acoustic metamaterials. Fire safety standards such as ASTM E84 and EN 13501 classify building materials based on flame spread and smoke development characteristics. Acoustic metamaterial retrofits must meet these standards, particularly in high-risk industrial environments. Many jurisdictions require materials to achieve specific fire ratings depending on their application and proximity to critical equipment.

Environmental regulations, including the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, impose additional constraints on material selection for acoustic metamaterials. These regulations restrict the use of certain hazardous substances in manufacturing, necessitating careful material selection during the design phase of metamaterial solutions.

Local building codes and industry-specific regulations may impose additional requirements for noise control solutions. For instance, facilities in densely populated areas often face stricter environmental noise limits at property boundaries, requiring comprehensive noise management strategies that extend beyond worker protection to community impact mitigation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!