Optimization Of Metamaterial Porosity For Balanced Sound Absorption

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metamaterial Acoustics Background and Objectives

Acoustic metamaterials represent a revolutionary frontier in sound engineering, emerging from the broader field of metamaterials that first gained prominence in electromagnetic applications during the late 1990s. These engineered structures manipulate sound waves in ways that natural materials cannot, offering unprecedented control over acoustic properties through their geometric arrangement rather than chemical composition. The development trajectory of acoustic metamaterials has accelerated significantly over the past decade, transitioning from theoretical concepts to practical implementations across various industries.

The optimization of metamaterial porosity for balanced sound absorption addresses a critical challenge in acoustic engineering: achieving effective sound absorption across a wide frequency spectrum while maintaining structural integrity and practical manufacturability. Traditional porous absorbers typically excel at high frequencies but perform poorly at low frequencies without substantial thickness, creating a fundamental design constraint in space-limited applications.

Current research trends indicate a shift toward multi-functional acoustic metamaterials that can simultaneously address absorption, insulation, and structural requirements. The integration of computational design methods, including topology optimization and machine learning algorithms, has enabled more sophisticated approaches to porosity design that can target specific acoustic profiles with greater precision.

The technical objectives of this research domain encompass several interconnected goals. First, to develop systematic methodologies for optimizing pore size, distribution, and interconnectivity to achieve balanced absorption across targeted frequency ranges. Second, to establish quantifiable relationships between porosity parameters and acoustic performance metrics, enabling predictive modeling capabilities. Third, to overcome the inherent trade-offs between low-frequency absorption and material thickness through innovative geometric configurations.

Additionally, researchers aim to bridge the gap between theoretical models and practical manufacturing constraints, ensuring that optimized designs can be produced using current or emerging fabrication technologies such as advanced 3D printing, selective laser sintering, and precision molding techniques. This includes addressing challenges related to material selection, structural stability, and scalability of production processes.

The ultimate goal extends beyond pure acoustic performance to encompass broader considerations including sustainability, cost-effectiveness, and integration capabilities with existing systems. As architectural acoustics, transportation noise control, and consumer electronics increasingly demand sophisticated sound management solutions, the optimization of metamaterial porosity represents a key enabling technology for next-generation acoustic environments that balance functional performance with practical implementation requirements.

The optimization of metamaterial porosity for balanced sound absorption addresses a critical challenge in acoustic engineering: achieving effective sound absorption across a wide frequency spectrum while maintaining structural integrity and practical manufacturability. Traditional porous absorbers typically excel at high frequencies but perform poorly at low frequencies without substantial thickness, creating a fundamental design constraint in space-limited applications.

Current research trends indicate a shift toward multi-functional acoustic metamaterials that can simultaneously address absorption, insulation, and structural requirements. The integration of computational design methods, including topology optimization and machine learning algorithms, has enabled more sophisticated approaches to porosity design that can target specific acoustic profiles with greater precision.

The technical objectives of this research domain encompass several interconnected goals. First, to develop systematic methodologies for optimizing pore size, distribution, and interconnectivity to achieve balanced absorption across targeted frequency ranges. Second, to establish quantifiable relationships between porosity parameters and acoustic performance metrics, enabling predictive modeling capabilities. Third, to overcome the inherent trade-offs between low-frequency absorption and material thickness through innovative geometric configurations.

Additionally, researchers aim to bridge the gap between theoretical models and practical manufacturing constraints, ensuring that optimized designs can be produced using current or emerging fabrication technologies such as advanced 3D printing, selective laser sintering, and precision molding techniques. This includes addressing challenges related to material selection, structural stability, and scalability of production processes.

The ultimate goal extends beyond pure acoustic performance to encompass broader considerations including sustainability, cost-effectiveness, and integration capabilities with existing systems. As architectural acoustics, transportation noise control, and consumer electronics increasingly demand sophisticated sound management solutions, the optimization of metamaterial porosity represents a key enabling technology for next-generation acoustic environments that balance functional performance with practical implementation requirements.

Market Analysis for Porous Acoustic Metamaterials

The global market for porous acoustic metamaterials is experiencing significant growth, driven by increasing concerns about noise pollution across various sectors including construction, automotive, aerospace, and consumer electronics. Current market valuation stands at approximately $1.2 billion in 2023, with projections indicating a compound annual growth rate of 7.8% through 2030, potentially reaching $2.1 billion by the end of the forecast period.

The construction industry represents the largest market segment, accounting for nearly 38% of total demand. This is primarily due to stringent building codes and regulations regarding acoustic performance in commercial and residential structures. The automotive sector follows closely at 27% market share, where premium vehicle manufacturers are increasingly incorporating advanced acoustic solutions to enhance cabin quietness and overall driving experience.

Geographically, North America and Europe dominate the market with combined revenue exceeding 60% of global sales. However, the Asia-Pacific region is emerging as the fastest-growing market with 11.2% annual growth, particularly driven by rapid urbanization in China and India, alongside increasing adoption of acoustic solutions in Japan's precision manufacturing facilities.

Consumer preference trends indicate growing demand for multifunctional materials that combine acoustic performance with other properties such as fire resistance, thermal insulation, and sustainability. This has created a premium segment within the market where optimized metamaterials with balanced sound absorption across frequency ranges command price premiums of 15-25% over conventional solutions.

The competitive landscape features both established players and innovative startups. Traditional acoustic material manufacturers like Saint-Gobain, Owens Corning, and Knauf Insulation hold approximately 45% market share collectively. However, specialized metamaterial technology companies such as Acoustic Metamaterials Group and Metasonics are rapidly gaining traction with their patented optimized porosity solutions.

Supply chain analysis reveals increasing vertical integration among major players, with companies investing in raw material production to ensure quality control and cost management. The raw materials market for metamaterial production is experiencing price volatility due to fluctuating petroleum prices, creating opportunities for bio-based alternatives.

Customer segmentation shows distinct requirements across different industries. While the automotive sector prioritizes lightweight solutions with minimal space requirements, the construction industry values durability and aesthetic integration. Healthcare facilities emphasize hygiene and cleanability alongside acoustic performance, representing a specialized niche with premium pricing potential.

The construction industry represents the largest market segment, accounting for nearly 38% of total demand. This is primarily due to stringent building codes and regulations regarding acoustic performance in commercial and residential structures. The automotive sector follows closely at 27% market share, where premium vehicle manufacturers are increasingly incorporating advanced acoustic solutions to enhance cabin quietness and overall driving experience.

Geographically, North America and Europe dominate the market with combined revenue exceeding 60% of global sales. However, the Asia-Pacific region is emerging as the fastest-growing market with 11.2% annual growth, particularly driven by rapid urbanization in China and India, alongside increasing adoption of acoustic solutions in Japan's precision manufacturing facilities.

Consumer preference trends indicate growing demand for multifunctional materials that combine acoustic performance with other properties such as fire resistance, thermal insulation, and sustainability. This has created a premium segment within the market where optimized metamaterials with balanced sound absorption across frequency ranges command price premiums of 15-25% over conventional solutions.

The competitive landscape features both established players and innovative startups. Traditional acoustic material manufacturers like Saint-Gobain, Owens Corning, and Knauf Insulation hold approximately 45% market share collectively. However, specialized metamaterial technology companies such as Acoustic Metamaterials Group and Metasonics are rapidly gaining traction with their patented optimized porosity solutions.

Supply chain analysis reveals increasing vertical integration among major players, with companies investing in raw material production to ensure quality control and cost management. The raw materials market for metamaterial production is experiencing price volatility due to fluctuating petroleum prices, creating opportunities for bio-based alternatives.

Customer segmentation shows distinct requirements across different industries. While the automotive sector prioritizes lightweight solutions with minimal space requirements, the construction industry values durability and aesthetic integration. Healthcare facilities emphasize hygiene and cleanability alongside acoustic performance, representing a specialized niche with premium pricing potential.

Current Challenges in Metamaterial Porosity Design

Despite significant advancements in metamaterial design for acoustic applications, several critical challenges persist in optimizing metamaterial porosity for balanced sound absorption. The primary difficulty lies in the inherent trade-off between low-frequency and high-frequency absorption performance. Current metamaterial designs often excel in specific frequency ranges but struggle to maintain balanced absorption across the entire acoustic spectrum, creating a fundamental design dilemma.

Material characterization presents another significant obstacle. Precise measurement and modeling of complex porous structures remain difficult, particularly when dealing with multi-scale porosity that combines micro, meso, and macro-scale features. The lack of standardized characterization methods leads to inconsistencies in reported performance metrics across research groups, hampering comparative analysis and technological progress.

Manufacturing constraints further complicate porosity optimization. Advanced metamaterial designs with precisely controlled pore size, shape, and distribution often require sophisticated fabrication techniques that are difficult to scale for mass production. The gap between theoretical designs and practically manufacturable structures remains substantial, with many innovative concepts proving too complex or costly for industrial implementation.

Computational modeling challenges also impede progress. Current simulation tools struggle with the multi-physics nature of acoustic metamaterials, where structural mechanics, fluid dynamics, and thermal effects interact in complex ways. The computational resources required for accurate modeling of detailed porous structures across multiple scales often exceed practical limitations, forcing researchers to rely on simplified models with reduced accuracy.

Durability and environmental stability represent additional concerns. Porous metamaterials are susceptible to clogging, moisture absorption, and structural degradation over time, potentially compromising their acoustic performance. Developing materials that maintain consistent porosity characteristics under varying environmental conditions remains challenging, particularly for applications requiring long-term stability.

The interdisciplinary nature of the field creates knowledge integration barriers. Effective optimization requires expertise spanning materials science, acoustics, fluid dynamics, and manufacturing technology. The siloed nature of these disciplines often results in suboptimal solutions that fail to leverage insights from all relevant domains.

Finally, design methodology limitations hinder systematic optimization. Current approaches often rely heavily on trial-and-error experimentation or parametric studies with limited design space exploration. The lack of comprehensive design frameworks that can simultaneously address multiple performance criteria across different frequency ranges and application scenarios restricts the development of truly optimized porous metamaterials for balanced sound absorption.

Material characterization presents another significant obstacle. Precise measurement and modeling of complex porous structures remain difficult, particularly when dealing with multi-scale porosity that combines micro, meso, and macro-scale features. The lack of standardized characterization methods leads to inconsistencies in reported performance metrics across research groups, hampering comparative analysis and technological progress.

Manufacturing constraints further complicate porosity optimization. Advanced metamaterial designs with precisely controlled pore size, shape, and distribution often require sophisticated fabrication techniques that are difficult to scale for mass production. The gap between theoretical designs and practically manufacturable structures remains substantial, with many innovative concepts proving too complex or costly for industrial implementation.

Computational modeling challenges also impede progress. Current simulation tools struggle with the multi-physics nature of acoustic metamaterials, where structural mechanics, fluid dynamics, and thermal effects interact in complex ways. The computational resources required for accurate modeling of detailed porous structures across multiple scales often exceed practical limitations, forcing researchers to rely on simplified models with reduced accuracy.

Durability and environmental stability represent additional concerns. Porous metamaterials are susceptible to clogging, moisture absorption, and structural degradation over time, potentially compromising their acoustic performance. Developing materials that maintain consistent porosity characteristics under varying environmental conditions remains challenging, particularly for applications requiring long-term stability.

The interdisciplinary nature of the field creates knowledge integration barriers. Effective optimization requires expertise spanning materials science, acoustics, fluid dynamics, and manufacturing technology. The siloed nature of these disciplines often results in suboptimal solutions that fail to leverage insights from all relevant domains.

Finally, design methodology limitations hinder systematic optimization. Current approaches often rely heavily on trial-and-error experimentation or parametric studies with limited design space exploration. The lack of comprehensive design frameworks that can simultaneously address multiple performance criteria across different frequency ranges and application scenarios restricts the development of truly optimized porous metamaterials for balanced sound absorption.

Current Porosity Optimization Methodologies

01 Porous metamaterial structures for electromagnetic applications

Metamaterials with controlled porosity can be designed to manipulate electromagnetic waves in specific ways. These structures typically feature periodic arrangements of pores or voids that create unique electromagnetic properties not found in natural materials. The porosity can be engineered to achieve negative refractive indices, enhanced wave absorption, or selective frequency filtering. These porous metamaterials are particularly useful in antenna design, electromagnetic shielding, and communication systems where precise control of electromagnetic wave propagation is required.- Porous metamaterial structures for electromagnetic applications: Metamaterials with controlled porosity can be designed to manipulate electromagnetic waves in specific ways. These structures typically feature periodic arrangements of pores or voids that create unique electromagnetic properties not found in natural materials. The porosity can be engineered to achieve negative refractive indices, enhanced wave absorption, or selective frequency filtering. These porous metamaterials are particularly useful in antenna design, electromagnetic shielding, and communication systems.

- Acoustic metamaterials with engineered porosity: Acoustic metamaterials utilize controlled porosity to manipulate sound waves in unprecedented ways. By designing specific porous structures, these metamaterials can achieve acoustic properties such as sound absorption, noise reduction, and wave guiding. The size, shape, and distribution of pores significantly influence the acoustic behavior, allowing for the creation of materials with negative acoustic refraction, acoustic cloaking capabilities, or selective frequency filtering. These materials have applications in noise control, ultrasonic imaging, and architectural acoustics.

- Thermal management through metamaterial porosity: Porous metamaterials can be engineered to control thermal energy flow in ways not possible with conventional materials. By carefully designing the porosity patterns, these materials can direct, concentrate, or disperse heat. The pore structure affects thermal conductivity, heat capacity, and thermal expansion properties. Applications include thermal insulation systems, heat exchangers with enhanced efficiency, and thermal energy harvesting devices. These materials are particularly valuable in electronics cooling, building insulation, and energy conservation systems.

- Mechanical properties of porous metamaterials: Porous metamaterials can exhibit unique mechanical properties through carefully engineered void structures. These materials can achieve seemingly contradictory combinations of properties such as high strength with low density, or high stiffness with high energy absorption. The arrangement, size, and shape of pores determine characteristics like compressive strength, tensile behavior, and deformation response. Applications include lightweight structural components, impact-absorbing materials, and materials with programmable mechanical responses for use in aerospace, automotive, and protective equipment.

- Fabrication techniques for porous metamaterials: Various manufacturing methods have been developed to create metamaterials with precisely controlled porosity. These techniques include 3D printing, lithography, self-assembly processes, and template-based approaches. Each method offers different capabilities in terms of achievable pore sizes, geometries, and material compositions. Advanced fabrication techniques allow for multi-scale porosity, gradient structures, and complex three-dimensional architectures. The choice of fabrication method significantly impacts the final properties and performance of the porous metamaterial.

02 Acoustic metamaterials with engineered porosity

Acoustic metamaterials utilize engineered porosity to control sound waves in unprecedented ways. By carefully designing the size, shape, and distribution of pores within the material structure, these metamaterials can achieve acoustic properties such as sound absorption, noise reduction, and wave guiding. The porous structure creates resonant cavities that interact with sound waves at specific frequencies, enabling applications like acoustic cloaking, sound focusing, and vibration isolation. These materials are particularly valuable in environments where noise control is critical.Expand Specific Solutions03 Fabrication methods for porous metamaterials

Various manufacturing techniques have been developed to create metamaterials with precise porosity control. These methods include 3D printing, lithography, self-assembly processes, and template-based approaches. Each technique offers different advantages in terms of achievable feature sizes, material compatibility, scalability, and cost-effectiveness. Advanced fabrication methods allow for multi-scale porosity, where pores of different sizes are incorporated into the same structure to achieve hierarchical functionality. The manufacturing approach significantly influences the final properties and performance of the porous metamaterial.Expand Specific Solutions04 Mechanical properties of porous metamaterials

Porous metamaterials can be engineered to exhibit unusual mechanical properties through their structural design. By controlling the porosity pattern, these materials can achieve properties like negative Poisson's ratio, programmable stiffness, enhanced energy absorption, and controlled deformation behavior. The relationship between porosity parameters (pore size, distribution, interconnectivity) and resulting mechanical performance allows for creating lightweight yet strong materials. These mechanically-optimized porous metamaterials find applications in impact protection, structural components, and biomedical implants.Expand Specific Solutions05 Thermal management using porous metamaterials

Porous metamaterials offer innovative solutions for thermal management challenges. The controlled porosity can be designed to direct heat flow along specific pathways, enhance or suppress thermal conductivity, and create thermal insulation with minimal material usage. These materials can incorporate phase change materials within their porous structure to absorb or release thermal energy as needed. The ability to engineer thermal properties through porosity design enables applications in electronics cooling, building insulation, and thermal energy storage systems.Expand Specific Solutions

Leading Research Groups and Manufacturers Analysis

The metamaterial porosity optimization for balanced sound absorption market is in a growth phase, characterized by increasing research activity and commercial applications. The market size is expanding as industries seek advanced acoustic solutions for noise control in various sectors including automotive, construction, and consumer electronics. Technologically, this field is maturing rapidly with academic institutions like Xi'an Jiaotong University, Nanjing University, and CNRS leading fundamental research, while companies such as Acoustic Metamaterials Group Ltd. and JNC Corp. are commercializing applications. The competitive landscape shows a blend of specialized acoustic material manufacturers, large industrial conglomerates, and research-focused organizations developing innovative solutions that balance absorption performance with material efficiency across frequency ranges.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed innovative approaches to metamaterial porosity optimization through their State Key Laboratory for Mechanical Behavior of Materials. Their research focuses on multi-physics modeling of acoustic metamaterials with controlled porosity distributions to achieve balanced sound absorption across wide frequency ranges. The university has pioneered the use of machine learning algorithms to predict and optimize acoustic performance based on complex porosity parameters, enabling rapid design iteration and discovery of non-intuitive porosity configurations. Their approach incorporates micro-CT imaging and advanced characterization techniques to establish precise structure-property relationships between metamaterial porosity and acoustic absorption. Xi'an Jiaotong researchers have developed novel manufacturing methods combining 3D printing with post-processing techniques to create hierarchical porous structures with precisely controlled pore size distributions from nano to macro scales. Their work includes the development of functionally graded metamaterials with spatially varying porosity designed to provide optimal sound absorption for specific acoustic environments while maintaining structural integrity.

Strengths: Strong integration of materials science fundamentals with acoustic engineering; extensive characterization capabilities for structure-property relationships; innovative manufacturing approaches for complex porous structures. Weaknesses: May face challenges in scaling laboratory techniques to industrial production; research might prioritize fundamental understanding over immediate practical implementation.

UNIVERSITE DU MANS

Technical Solution: UNIVERSITE DU MANS has developed a comprehensive approach to metamaterial porosity optimization through their LAUM (Laboratoire d'Acoustique de l'Université du Mans) research center. Their methodology combines theoretical acoustic modeling with experimental validation to create metamaterials with precisely engineered porosity for balanced sound absorption. The university's research team has pioneered the use of inverse design methods that start with desired acoustic performance targets and work backward to determine optimal porosity distributions. Their approach incorporates multi-scale modeling that accounts for viscous and thermal effects at different structural levels within the metamaterial. The university has developed novel characterization techniques that allow for precise measurement of acoustic properties as a function of porosity parameters, enabling iterative optimization of metamaterial structures. Their research includes the development of bio-inspired metamaterial designs that mimic natural sound-absorbing structures found in organisms, incorporating principles of hierarchical porosity to achieve broadband absorption with minimal material usage.

Strengths: Strong theoretical foundation combined with experimental validation capabilities; academic approach allows for fundamental innovation beyond immediate commercial constraints; collaboration with multiple industry partners. Weaknesses: May face challenges in scaling laboratory solutions to industrial production; academic focus might prioritize theoretical advances over practical implementation considerations.

Key Patents in Balanced Sound Absorption Technologies

Sound absorption material

PatentActiveJP2023006757A

Innovation

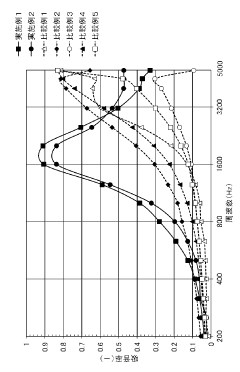

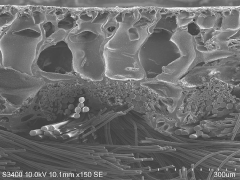

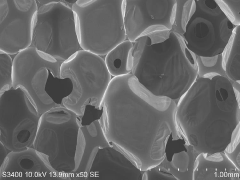

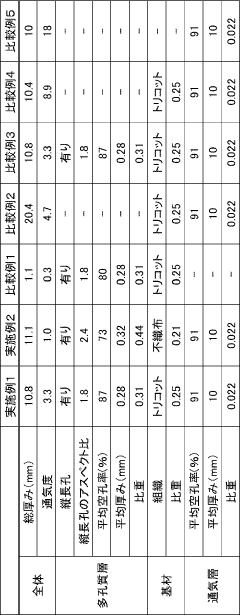

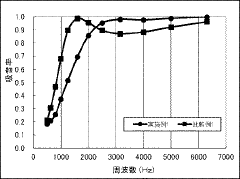

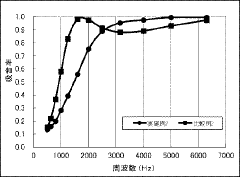

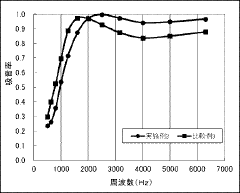

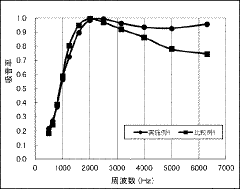

- A sound absorbing material comprising a base material with a porous layer having longitudinally elongated holes and a ventilation layer, where the porous layer faces the sound source side, featuring a specific gravity and porosity configuration to enhance sound absorption across a wide frequency range from low to high frequencies.

Sound absorption material

PatentInactiveJP2020106625A

Innovation

- A laminated sound absorbing material structure comprising first, second, third, and fourth porous layers, where the airflow resistance and air permeability of the first and third layers are specifically configured to enhance sound absorption in high frequency bands, with the first and third layers having lower airflow resistance and higher air permeability than the second and fourth layers.

Computational Modeling Approaches for Acoustic Metamaterials

Computational modeling has become an indispensable tool in the design and optimization of acoustic metamaterials with controlled porosity for sound absorption applications. These modeling approaches can be broadly categorized into analytical methods, numerical simulations, and machine learning techniques, each offering unique advantages for different aspects of metamaterial design.

Analytical models, such as the Johnson-Champoux-Allard (JCA) model and Biot theory, provide fundamental frameworks for understanding the relationship between metamaterial porosity and acoustic performance. These models establish mathematical relationships between microstructural parameters (pore size, tortuosity, porosity) and macroscopic acoustic properties (absorption coefficient, transmission loss). While computationally efficient, analytical approaches often require simplifying assumptions that may limit their accuracy for complex geometries.

Finite Element Method (FEM) and Boundary Element Method (BEM) represent the cornerstone of numerical simulation approaches for acoustic metamaterials. These methods enable detailed modeling of wave propagation through complex porous structures by discretizing the computational domain into smaller elements. FEM particularly excels at handling heterogeneous materials with varying porosity distributions, allowing researchers to simulate frequency-dependent absorption characteristics across the audible spectrum.

Computational Fluid Dynamics (CFD) simulations complement structural models by capturing viscous and thermal effects within porous networks. The combination of structural mechanics and fluid dynamics in multi-physics simulations provides comprehensive insights into the mechanisms of sound absorption, including viscous losses, thermal dissipation, and resonant phenomena within the metamaterial architecture.

Recent advances in machine learning have introduced data-driven approaches to metamaterial design. Techniques such as genetic algorithms, neural networks, and topology optimization enable efficient exploration of vast design spaces to identify optimal porosity distributions for targeted acoustic responses. These methods can significantly reduce computational costs compared to traditional parametric studies while discovering non-intuitive design solutions that balance competing performance metrics.

Multi-scale modeling frameworks bridge the gap between microscopic structure and macroscopic performance by integrating simulations across different length scales. This approach is particularly valuable for metamaterials with hierarchical porosity structures, where acoustic behavior emerges from interactions across multiple spatial scales.

The computational cost remains a significant challenge, particularly for high-fidelity simulations of broadband acoustic performance. Reduced-order modeling techniques and surrogate models offer promising solutions by creating computationally efficient representations of complex acoustic systems while maintaining acceptable accuracy for design optimization purposes.

Analytical models, such as the Johnson-Champoux-Allard (JCA) model and Biot theory, provide fundamental frameworks for understanding the relationship between metamaterial porosity and acoustic performance. These models establish mathematical relationships between microstructural parameters (pore size, tortuosity, porosity) and macroscopic acoustic properties (absorption coefficient, transmission loss). While computationally efficient, analytical approaches often require simplifying assumptions that may limit their accuracy for complex geometries.

Finite Element Method (FEM) and Boundary Element Method (BEM) represent the cornerstone of numerical simulation approaches for acoustic metamaterials. These methods enable detailed modeling of wave propagation through complex porous structures by discretizing the computational domain into smaller elements. FEM particularly excels at handling heterogeneous materials with varying porosity distributions, allowing researchers to simulate frequency-dependent absorption characteristics across the audible spectrum.

Computational Fluid Dynamics (CFD) simulations complement structural models by capturing viscous and thermal effects within porous networks. The combination of structural mechanics and fluid dynamics in multi-physics simulations provides comprehensive insights into the mechanisms of sound absorption, including viscous losses, thermal dissipation, and resonant phenomena within the metamaterial architecture.

Recent advances in machine learning have introduced data-driven approaches to metamaterial design. Techniques such as genetic algorithms, neural networks, and topology optimization enable efficient exploration of vast design spaces to identify optimal porosity distributions for targeted acoustic responses. These methods can significantly reduce computational costs compared to traditional parametric studies while discovering non-intuitive design solutions that balance competing performance metrics.

Multi-scale modeling frameworks bridge the gap between microscopic structure and macroscopic performance by integrating simulations across different length scales. This approach is particularly valuable for metamaterials with hierarchical porosity structures, where acoustic behavior emerges from interactions across multiple spatial scales.

The computational cost remains a significant challenge, particularly for high-fidelity simulations of broadband acoustic performance. Reduced-order modeling techniques and surrogate models offer promising solutions by creating computationally efficient representations of complex acoustic systems while maintaining acceptable accuracy for design optimization purposes.

Environmental Impact and Sustainability Considerations

The optimization of metamaterial porosity for sound absorption must be evaluated not only for its acoustic performance but also for its environmental footprint. Traditional acoustic materials often contain synthetic components that pose significant environmental challenges throughout their lifecycle, from production to disposal. Metamaterials with optimized porosity offer a promising alternative that can potentially reduce these environmental impacts.

Manufacturing processes for metamaterials can be designed to consume less energy and produce fewer emissions compared to conventional acoustic materials. By carefully engineering the porosity structure, manufacturers can minimize material usage while maintaining or even enhancing acoustic performance. This resource efficiency translates directly to reduced raw material extraction and processing, which are often energy-intensive and environmentally damaging activities.

The selection of base materials for porous metamaterials presents another opportunity for environmental improvement. Bio-based and recycled materials can be incorporated into metamaterial designs, reducing dependence on petroleum-based products. Recent research has demonstrated successful sound absorption using metamaterials constructed from sustainable sources such as cellulose fibers, recycled plastics, and agricultural byproducts.

Longevity and durability of acoustic solutions significantly impact their sustainability profile. Optimized metamaterial designs can offer extended service life compared to traditional materials that may degrade or compress over time. This durability reduces replacement frequency and associated environmental costs, making metamaterials a more sustainable long-term solution for noise control applications.

End-of-life considerations must also factor into metamaterial development. Ideally, these materials should be designed for disassembly, allowing components to be separated for recycling or biodegradation. Some innovative metamaterial designs incorporate mono-material approaches that eliminate the need for composite structures that are difficult to recycle.

Carbon footprint analysis of metamaterial production and use reveals potential advantages over conventional solutions. When accounting for embodied carbon in materials, manufacturing energy, transportation, and disposal impacts, properly designed metamaterial absorbers can demonstrate lower lifecycle emissions. This is particularly true when metamaterials achieve equivalent acoustic performance with significantly less material mass.

Water usage and pollution concerns must also be addressed in metamaterial production. Water-based manufacturing processes with closed-loop systems can minimize both consumption and contamination risks. Additionally, metamaterials that avoid the use of harmful chemical treatments common in traditional acoustic materials reduce the potential for environmental contamination during use and disposal phases.

Manufacturing processes for metamaterials can be designed to consume less energy and produce fewer emissions compared to conventional acoustic materials. By carefully engineering the porosity structure, manufacturers can minimize material usage while maintaining or even enhancing acoustic performance. This resource efficiency translates directly to reduced raw material extraction and processing, which are often energy-intensive and environmentally damaging activities.

The selection of base materials for porous metamaterials presents another opportunity for environmental improvement. Bio-based and recycled materials can be incorporated into metamaterial designs, reducing dependence on petroleum-based products. Recent research has demonstrated successful sound absorption using metamaterials constructed from sustainable sources such as cellulose fibers, recycled plastics, and agricultural byproducts.

Longevity and durability of acoustic solutions significantly impact their sustainability profile. Optimized metamaterial designs can offer extended service life compared to traditional materials that may degrade or compress over time. This durability reduces replacement frequency and associated environmental costs, making metamaterials a more sustainable long-term solution for noise control applications.

End-of-life considerations must also factor into metamaterial development. Ideally, these materials should be designed for disassembly, allowing components to be separated for recycling or biodegradation. Some innovative metamaterial designs incorporate mono-material approaches that eliminate the need for composite structures that are difficult to recycle.

Carbon footprint analysis of metamaterial production and use reveals potential advantages over conventional solutions. When accounting for embodied carbon in materials, manufacturing energy, transportation, and disposal impacts, properly designed metamaterial absorbers can demonstrate lower lifecycle emissions. This is particularly true when metamaterials achieve equivalent acoustic performance with significantly less material mass.

Water usage and pollution concerns must also be addressed in metamaterial production. Water-based manufacturing processes with closed-loop systems can minimize both consumption and contamination risks. Additionally, metamaterials that avoid the use of harmful chemical treatments common in traditional acoustic materials reduce the potential for environmental contamination during use and disposal phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!