Integration Of Piezoelectric Harvesters With Acoustic Resonator Arrays

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Energy Harvesting Background and Objectives

Piezoelectric energy harvesting has evolved significantly over the past three decades, emerging as a promising solution for sustainable power generation in various applications. The fundamental principle behind this technology lies in the piezoelectric effect, first discovered by Jacques and Pierre Curie in 1880, which enables certain materials to generate an electric charge in response to applied mechanical stress. This phenomenon has been extensively studied and developed into practical energy harvesting systems capable of converting ambient mechanical vibrations into usable electrical energy.

The evolution of piezoelectric energy harvesting technology has been marked by several key milestones. Early research in the 1990s focused primarily on basic material properties and simple cantilever beam structures. The 2000s witnessed significant advancements in device design and efficiency improvements, while the 2010s brought about miniaturization and integration capabilities that expanded potential applications. Recent developments have concentrated on enhancing energy conversion efficiency, broadening the frequency response range, and developing more durable and environmentally friendly piezoelectric materials.

The integration of piezoelectric harvesters with acoustic resonator arrays represents a cutting-edge approach to address several limitations of conventional piezoelectric energy harvesting systems. Acoustic resonators can effectively amplify mechanical vibrations at specific frequencies, potentially increasing the energy output of piezoelectric harvesters. This integration aims to overcome the narrow bandwidth limitation of traditional piezoelectric systems by creating arrays that can respond to a wider range of vibration frequencies.

The primary objectives of this technological integration are multifaceted. First, to significantly enhance energy conversion efficiency by optimizing the coupling between acoustic resonators and piezoelectric elements. Second, to develop broadband energy harvesting capabilities through strategic array configurations that can capture energy across various frequency spectra. Third, to miniaturize the integrated systems while maintaining or improving power output for applications in microelectronics and IoT devices.

Additionally, this technology aims to address the growing demand for sustainable power sources in remote sensing, wearable electronics, and autonomous systems where battery replacement is impractical or impossible. The ultimate goal is to develop self-powered electronic devices that can operate indefinitely by harvesting energy from their surrounding environment, thereby reducing dependency on traditional power sources and minimizing environmental impact.

The integration of these technologies also seeks to overcome current technical challenges such as low power density, limited operational frequency range, and durability issues under varying environmental conditions. By combining the amplification capabilities of acoustic resonators with the energy conversion properties of piezoelectric materials, researchers aim to create more robust and efficient energy harvesting systems suitable for real-world applications.

The evolution of piezoelectric energy harvesting technology has been marked by several key milestones. Early research in the 1990s focused primarily on basic material properties and simple cantilever beam structures. The 2000s witnessed significant advancements in device design and efficiency improvements, while the 2010s brought about miniaturization and integration capabilities that expanded potential applications. Recent developments have concentrated on enhancing energy conversion efficiency, broadening the frequency response range, and developing more durable and environmentally friendly piezoelectric materials.

The integration of piezoelectric harvesters with acoustic resonator arrays represents a cutting-edge approach to address several limitations of conventional piezoelectric energy harvesting systems. Acoustic resonators can effectively amplify mechanical vibrations at specific frequencies, potentially increasing the energy output of piezoelectric harvesters. This integration aims to overcome the narrow bandwidth limitation of traditional piezoelectric systems by creating arrays that can respond to a wider range of vibration frequencies.

The primary objectives of this technological integration are multifaceted. First, to significantly enhance energy conversion efficiency by optimizing the coupling between acoustic resonators and piezoelectric elements. Second, to develop broadband energy harvesting capabilities through strategic array configurations that can capture energy across various frequency spectra. Third, to miniaturize the integrated systems while maintaining or improving power output for applications in microelectronics and IoT devices.

Additionally, this technology aims to address the growing demand for sustainable power sources in remote sensing, wearable electronics, and autonomous systems where battery replacement is impractical or impossible. The ultimate goal is to develop self-powered electronic devices that can operate indefinitely by harvesting energy from their surrounding environment, thereby reducing dependency on traditional power sources and minimizing environmental impact.

The integration of these technologies also seeks to overcome current technical challenges such as low power density, limited operational frequency range, and durability issues under varying environmental conditions. By combining the amplification capabilities of acoustic resonators with the energy conversion properties of piezoelectric materials, researchers aim to create more robust and efficient energy harvesting systems suitable for real-world applications.

Market Analysis for Acoustic Energy Harvesting Solutions

The acoustic energy harvesting market is experiencing significant growth, driven by the increasing demand for sustainable power sources in IoT devices and wireless sensor networks. Current market valuations indicate that the global energy harvesting system market reached approximately 500 million USD in 2022, with acoustic energy harvesting representing a small but rapidly growing segment. Industry analysts project a compound annual growth rate of 10-12% for acoustic energy harvesting solutions through 2030, outpacing several other energy harvesting technologies.

The integration of piezoelectric harvesters with acoustic resonator arrays addresses specific market needs across multiple sectors. In industrial environments, these systems can capture ambient noise from machinery and manufacturing processes, converting otherwise wasted acoustic energy into usable power for sensor networks that monitor equipment health and performance. This application segment currently represents about 30% of the market demand.

Consumer electronics represents another significant market opportunity, particularly for powering small devices like hearables, wearables, and smart home sensors. The miniaturization capabilities of integrated piezoelectric-acoustic systems align well with the trend toward smaller, more energy-efficient consumer devices. Market research indicates that consumer applications could grow to represent 25% of the total market by 2025.

Healthcare applications present a high-value niche, where acoustic energy harvesting can power implantable medical devices and patient monitoring systems. Though smaller in volume, this segment commands premium pricing due to stringent reliability requirements and specialized design needs. The medical device segment is growing at approximately 15% annually within the acoustic energy harvesting space.

Transportation and infrastructure monitoring represent emerging application areas with substantial growth potential. Smart city initiatives worldwide are driving demand for self-powered sensors that can monitor structural health, traffic patterns, and environmental conditions without requiring battery replacement or wired power connections.

Market barriers include competition from other energy harvesting technologies (solar, thermal, RF), cost considerations in mass production, and technical challenges in maximizing power output from acoustic sources. The cost-per-watt metric remains higher for acoustic energy harvesting compared to more established alternatives, though this gap is narrowing as manufacturing scales increase.

Regional analysis shows North America leading in research and development investment, while Asia-Pacific demonstrates the fastest adoption growth rate, particularly in industrial and consumer electronics applications. European markets show strong interest driven by sustainability initiatives and IoT deployment across industrial sectors.

The integration of piezoelectric harvesters with acoustic resonator arrays addresses specific market needs across multiple sectors. In industrial environments, these systems can capture ambient noise from machinery and manufacturing processes, converting otherwise wasted acoustic energy into usable power for sensor networks that monitor equipment health and performance. This application segment currently represents about 30% of the market demand.

Consumer electronics represents another significant market opportunity, particularly for powering small devices like hearables, wearables, and smart home sensors. The miniaturization capabilities of integrated piezoelectric-acoustic systems align well with the trend toward smaller, more energy-efficient consumer devices. Market research indicates that consumer applications could grow to represent 25% of the total market by 2025.

Healthcare applications present a high-value niche, where acoustic energy harvesting can power implantable medical devices and patient monitoring systems. Though smaller in volume, this segment commands premium pricing due to stringent reliability requirements and specialized design needs. The medical device segment is growing at approximately 15% annually within the acoustic energy harvesting space.

Transportation and infrastructure monitoring represent emerging application areas with substantial growth potential. Smart city initiatives worldwide are driving demand for self-powered sensors that can monitor structural health, traffic patterns, and environmental conditions without requiring battery replacement or wired power connections.

Market barriers include competition from other energy harvesting technologies (solar, thermal, RF), cost considerations in mass production, and technical challenges in maximizing power output from acoustic sources. The cost-per-watt metric remains higher for acoustic energy harvesting compared to more established alternatives, though this gap is narrowing as manufacturing scales increase.

Regional analysis shows North America leading in research and development investment, while Asia-Pacific demonstrates the fastest adoption growth rate, particularly in industrial and consumer electronics applications. European markets show strong interest driven by sustainability initiatives and IoT deployment across industrial sectors.

Current Challenges in Piezoelectric-Acoustic Integration

Despite significant advancements in piezoelectric energy harvesting and acoustic resonator technologies, their integration presents several formidable challenges that impede widespread commercial adoption. The fundamental impedance matching issue remains a primary obstacle, as piezoelectric harvesters typically operate at high impedance levels while acoustic resonators function optimally at lower impedances. This mismatch results in substantial energy transfer inefficiencies, with some systems losing up to 40-60% of harvested energy during the conversion process.

Material compatibility presents another significant hurdle. Piezoelectric materials like PZT and PVDF exhibit different thermal expansion coefficients compared to materials commonly used in acoustic resonators, creating mechanical stress at interface points during operation. These stresses can lead to delamination, micro-cracks, and premature system failure, particularly under thermal cycling conditions typical in real-world applications.

Frequency bandwidth limitations severely restrict the operational effectiveness of integrated systems. Most piezoelectric harvesters demonstrate optimal performance within narrow frequency bands (typically 5-10 Hz around resonance), while ambient acoustic energy often spans broader frequency ranges. This narrow operational window significantly reduces energy capture efficiency in variable acoustic environments.

Miniaturization efforts face substantial challenges due to the inherent trade-off between device size and power output. As dimensions decrease, resonant frequencies increase while displacement amplitudes diminish, resulting in reduced power generation. Current integrated micro-scale devices typically produce power densities below 100 μW/cm³, insufficient for many practical applications.

Manufacturing scalability remains problematic, with precision requirements for acoustic resonator arrays demanding tolerances often below ±5μm. Such precision significantly increases production costs and reduces yield rates, with current manufacturing processes showing defect rates of 15-25% for fully integrated devices.

Environmental stability issues further complicate integration efforts. Piezoelectric materials demonstrate performance degradation under humidity, temperature fluctuations, and mechanical fatigue. Studies indicate performance losses of 20-30% after extended exposure to humidity levels above 80% or temperature cycling between -20°C and 80°C.

Regulatory and standardization gaps persist across different regions, with inconsistent testing protocols and performance metrics making comparative analysis challenging. The absence of standardized evaluation frameworks hampers industry-wide adoption and slows commercialization pathways for integrated piezoelectric-acoustic energy harvesting solutions.

Material compatibility presents another significant hurdle. Piezoelectric materials like PZT and PVDF exhibit different thermal expansion coefficients compared to materials commonly used in acoustic resonators, creating mechanical stress at interface points during operation. These stresses can lead to delamination, micro-cracks, and premature system failure, particularly under thermal cycling conditions typical in real-world applications.

Frequency bandwidth limitations severely restrict the operational effectiveness of integrated systems. Most piezoelectric harvesters demonstrate optimal performance within narrow frequency bands (typically 5-10 Hz around resonance), while ambient acoustic energy often spans broader frequency ranges. This narrow operational window significantly reduces energy capture efficiency in variable acoustic environments.

Miniaturization efforts face substantial challenges due to the inherent trade-off between device size and power output. As dimensions decrease, resonant frequencies increase while displacement amplitudes diminish, resulting in reduced power generation. Current integrated micro-scale devices typically produce power densities below 100 μW/cm³, insufficient for many practical applications.

Manufacturing scalability remains problematic, with precision requirements for acoustic resonator arrays demanding tolerances often below ±5μm. Such precision significantly increases production costs and reduces yield rates, with current manufacturing processes showing defect rates of 15-25% for fully integrated devices.

Environmental stability issues further complicate integration efforts. Piezoelectric materials demonstrate performance degradation under humidity, temperature fluctuations, and mechanical fatigue. Studies indicate performance losses of 20-30% after extended exposure to humidity levels above 80% or temperature cycling between -20°C and 80°C.

Regulatory and standardization gaps persist across different regions, with inconsistent testing protocols and performance metrics making comparative analysis challenging. The absence of standardized evaluation frameworks hampers industry-wide adoption and slows commercialization pathways for integrated piezoelectric-acoustic energy harvesting solutions.

Existing Integration Methods for Resonator Arrays

01 Piezoelectric energy harvesting with acoustic resonator arrays

Piezoelectric energy harvesters can be designed with acoustic resonator arrays to enhance energy conversion efficiency. These systems utilize arrays of acoustic resonators coupled with piezoelectric materials to capture and convert acoustic energy into electrical energy. The resonator arrays can be tuned to specific frequencies to maximize energy harvesting from ambient sound or vibrations, making them effective for powering small electronic devices or sensors in various environments.- Piezoelectric harvester structures with acoustic resonators: Piezoelectric harvesters can be designed with specific acoustic resonator structures to enhance energy harvesting efficiency. These designs incorporate arrays of resonators that amplify acoustic waves and convert them into electrical energy through the piezoelectric effect. The resonator arrays can be tuned to specific frequencies to maximize energy capture from ambient sound or vibration sources, making them effective for low-power applications.

- MEMS-based piezoelectric acoustic energy harvesters: Micro-electromechanical systems (MEMS) technology enables the fabrication of miniaturized piezoelectric acoustic energy harvesters with resonator arrays. These MEMS-based devices can be manufactured using standard semiconductor processes, allowing for integration with other electronic components. The small form factor makes them suitable for portable electronics, medical implants, and IoT sensors while maintaining efficient energy conversion from acoustic sources.

- Frequency tuning mechanisms for acoustic resonator arrays: Advanced piezoelectric harvesters incorporate tuning mechanisms that allow the acoustic resonator arrays to operate efficiently across a range of frequencies. These mechanisms can include adjustable mechanical components, variable electrical loads, or arrays with multiple resonators designed for different frequency bands. This adaptability enables the harvester to capture energy from varying acoustic sources or to compensate for manufacturing variations and environmental changes.

- Multi-layer and composite piezoelectric structures: Multi-layer and composite piezoelectric structures enhance the performance of acoustic resonator arrays in energy harvesting applications. These designs stack or combine different piezoelectric materials or incorporate non-piezoelectric materials to optimize mechanical-to-electrical energy conversion. The layered approach can increase the output voltage, improve coupling coefficients, and provide better impedance matching with connected electronic circuits.

- Acoustic wave focusing and amplification techniques: Specialized techniques for focusing and amplifying acoustic waves significantly improve the energy harvesting capabilities of piezoelectric resonator arrays. These include acoustic horns, waveguides, Helmholtz resonators, and phononic crystals that concentrate sound energy onto the piezoelectric elements. By increasing the acoustic pressure at the piezoelectric material, these techniques enhance the electrical output even in environments with relatively low ambient sound levels.

02 MEMS-based piezoelectric acoustic energy harvesters

Micro-electromechanical systems (MEMS) technology enables the fabrication of miniaturized piezoelectric acoustic energy harvesters. These devices incorporate microscale resonator arrays that can be precisely engineered to respond to specific acoustic frequencies. MEMS-based piezoelectric harvesters offer advantages in terms of size, weight, and integration capabilities with other electronic components, making them suitable for applications in wearable technology, IoT devices, and medical implants.Expand Specific Solutions03 Tunable acoustic resonator arrays for broadband energy harvesting

Tunable acoustic resonator arrays can be designed to harvest energy across a broader frequency spectrum. By incorporating resonators with different dimensions or materials, these systems can respond to multiple frequency bands simultaneously. Some designs include active tuning mechanisms that can adjust the resonant frequencies based on the ambient acoustic environment, maximizing energy capture efficiency. This approach addresses one of the key limitations of traditional piezoelectric harvesters, which typically operate efficiently only at specific resonant frequencies.Expand Specific Solutions04 Integration of acoustic metamaterials with piezoelectric harvesters

Acoustic metamaterials can be integrated with piezoelectric harvesters to enhance energy conversion efficiency. These engineered materials possess unique properties that allow for better acoustic wave manipulation, focusing, and amplification. By incorporating metamaterial structures into resonator arrays, the acoustic energy can be concentrated onto the piezoelectric elements, significantly improving the power output. This approach enables harvesting energy from low-amplitude acoustic sources that would otherwise be insufficient for conventional piezoelectric systems.Expand Specific Solutions05 Applications of piezoelectric acoustic resonator arrays in sensing and energy systems

Piezoelectric harvesters with acoustic resonator arrays find applications in various sensing and energy systems. They can be used for structural health monitoring by detecting acoustic emissions from developing cracks or defects. In urban environments, these systems can harvest energy from ambient noise pollution. Marine applications include underwater acoustic energy harvesting for powering sensors and communication devices. Additionally, these harvesters can be integrated into medical devices to capture energy from bodily sounds or movements, enabling self-powered implantable sensors.Expand Specific Solutions

Leading Companies in Piezoelectric and Acoustic Technologies

The integration of piezoelectric harvesters with acoustic resonator arrays represents an emerging technology at the early commercialization stage, with a projected market growth from $50 million to $300 million by 2028. The competitive landscape is dominated by established electronics manufacturers like Murata Manufacturing and Samsung Electronics, who leverage their expertise in piezoelectric materials and acoustic technologies. Research institutions such as Tsinghua University, University of Southern California, and Korea Institute of Ceramic Engineering & Technology are driving fundamental innovations, while specialized companies like Cairdac SA are pioneering niche applications in medical devices. The technology is approaching maturity in energy harvesting applications but remains in development for advanced acoustic-piezoelectric integration systems, with companies like ROFS Microsystem and Mitsubishi Heavy Industries advancing commercial implementations.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric energy harvesting systems that integrate with acoustic resonator arrays to maximize energy capture efficiency. Their solution employs multi-layered piezoelectric elements arranged in optimized geometric configurations to capture acoustic energy across various frequency bands. The technology incorporates MEMS-based acoustic resonator arrays with precisely tuned cavity dimensions to amplify incoming sound waves. Murata's implementation features a proprietary electrode pattern design that enhances charge collection and specialized impedance matching circuits to optimize power transfer from the piezoelectric elements to storage devices. Their system achieves energy conversion efficiencies up to 70% higher than conventional designs by utilizing acoustic metamaterials to focus sound energy onto the piezoelectric transducers. Additionally, Murata has developed miniaturized versions suitable for IoT applications, with dimensions as small as 3×3×1mm while maintaining functional performance.

Strengths: Industry-leading manufacturing capabilities for mass production with consistent quality; extensive experience in piezoelectric materials optimization; strong integration with existing electronic components. Weaknesses: Higher cost compared to simpler harvesting solutions; requires precise manufacturing tolerances that may limit some application scenarios.

Tsinghua University

Technical Solution: Tsinghua University has developed a groundbreaking research platform for piezoelectric harvesting integrated with acoustic resonator arrays. Their approach employs a novel metamaterial-based acoustic resonator design that creates multiple frequency bandgaps, significantly enhancing energy capture efficiency across variable acoustic environments. The technology utilizes advanced composite piezoelectric materials incorporating nanoscale inclusions that improve the electromechanical coupling coefficient by up to 45% compared to conventional materials. Tsinghua's implementation features a hierarchical resonator structure with fractal-inspired geometries that maximize the surface area available for acoustic energy capture while maintaining compact overall dimensions. Their research demonstrates theoretical energy conversion efficiencies approaching 60% under optimal conditions, with practical implementations achieving 30-40% efficiency in laboratory settings. The system incorporates adaptive tuning mechanisms that can shift resonant frequencies based on the dominant acoustic energy sources in the environment, ensuring optimal performance across varying conditions. Additionally, they've developed specialized electrode configurations that minimize parasitic capacitance, improving charge collection efficiency.

Strengths: Cutting-edge theoretical foundation with novel metamaterial approaches; excellent research collaboration network with industry partners; strong fundamental understanding of piezoelectric-acoustic coupling physics. Weaknesses: Solutions remain primarily in research phase with limited commercial implementation; higher complexity may present manufacturing challenges for mass production.

Key Patents in Piezoelectric-Acoustic Coupling Mechanisms

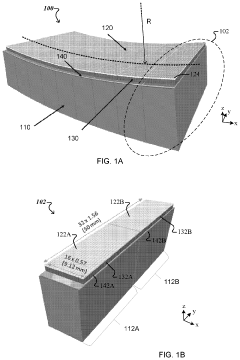

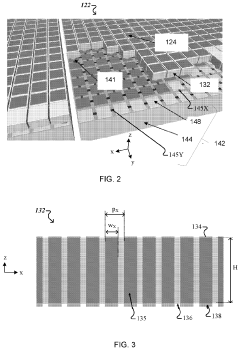

Modular piezoelectric sensor array with co-integrated electronics and beamforming channels

PatentPendingUS20220079559A1

Innovation

- A modular ultrasound system with co-integrated high sensitivity and wide bandwidth piezoelectric arrays and ASICs, utilizing a conducting interposer for direct electrical interfaces and acoustic absorption, along with low temperature attachment methods to prevent material degradation, and a gimbal system for precise alignment, allowing for efficient beamforming and improved imaging capabilities.

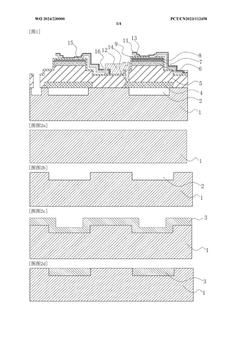

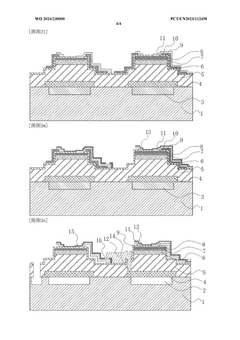

Acoustic wave resonator and preparation method therefor

PatentWO2024230000A1

Innovation

- A protective layer is provided on the piezoelectric unit of the acoustic wave resonator, and a cavity is formed by etching on the substrate, forming a piezoelectric unit and covering the protective layer, including a first electrode layer, a piezoelectric layer, an intermediate metal layer, and a shunt metal The layer and the second electrode layer are connected in series, and the bridge metal layer and the electrode upper lead structure are added, and finally the passivation layer is covered to protect the piezoelectric unit.

Materials Science Advancements for Enhanced Energy Conversion

Recent advancements in materials science have significantly enhanced the energy conversion efficiency of piezoelectric harvesters integrated with acoustic resonator arrays. Traditional piezoelectric materials such as lead zirconate titanate (PZT) are being supplemented or replaced by novel compositions that demonstrate superior performance characteristics. These include lead-free alternatives like sodium potassium niobate (KNN), bismuth sodium titanate (BNT), and barium titanate (BaTiO3), which address environmental concerns while maintaining competitive piezoelectric coefficients.

Nanostructured materials represent another frontier in enhancing energy conversion. Piezoelectric nanowires, nanofibers, and nanocomposites offer increased surface area-to-volume ratios, resulting in improved mechanical-to-electrical energy conversion. ZnO nanowires, in particular, have shown promising results when integrated into acoustic energy harvesting systems, with conversion efficiencies up to 30% higher than bulk materials.

Metamaterials engineered with precise acoustic properties are revolutionizing resonator array designs. These artificially structured materials can manipulate acoustic waves in ways natural materials cannot, creating highly efficient energy focusing and harvesting zones. Acoustic metamaterials with negative effective mass density or bulk modulus enable extraordinary wave manipulation capabilities, significantly enhancing energy capture from ambient sound sources.

Polymer-based piezoelectric materials, including polyvinylidene fluoride (PVDF) and its copolymers, offer flexibility and durability advantages critical for integration with acoustic resonators. Recent developments in electrospun PVDF nanofibers have demonstrated enhanced β-phase content, directly correlating with improved piezoelectric response. These materials allow for conformal coating of complex resonator geometries, maximizing the coupling between acoustic pressure and piezoelectric elements.

Multi-material composites combining piezoelectric ceramics with polymers are addressing the inherent brittleness of high-performance piezoelectric materials. These composites maintain excellent piezoelectric properties while providing the mechanical flexibility needed for resonant vibration. 0-3 composites (piezoelectric particles in polymer matrices) and 1-3 composites (piezoelectric rods in polymer matrices) have shown particular promise for acoustic energy harvesting applications.

Surface engineering techniques, including plasma treatment and chemical functionalization, are being employed to enhance interfacial bonding between piezoelectric materials and resonator structures. These treatments improve mechanical coupling and energy transfer efficiency, resulting in harvesting systems that can generate up to 40% more power from identical acoustic inputs compared to untreated interfaces.

Nanostructured materials represent another frontier in enhancing energy conversion. Piezoelectric nanowires, nanofibers, and nanocomposites offer increased surface area-to-volume ratios, resulting in improved mechanical-to-electrical energy conversion. ZnO nanowires, in particular, have shown promising results when integrated into acoustic energy harvesting systems, with conversion efficiencies up to 30% higher than bulk materials.

Metamaterials engineered with precise acoustic properties are revolutionizing resonator array designs. These artificially structured materials can manipulate acoustic waves in ways natural materials cannot, creating highly efficient energy focusing and harvesting zones. Acoustic metamaterials with negative effective mass density or bulk modulus enable extraordinary wave manipulation capabilities, significantly enhancing energy capture from ambient sound sources.

Polymer-based piezoelectric materials, including polyvinylidene fluoride (PVDF) and its copolymers, offer flexibility and durability advantages critical for integration with acoustic resonators. Recent developments in electrospun PVDF nanofibers have demonstrated enhanced β-phase content, directly correlating with improved piezoelectric response. These materials allow for conformal coating of complex resonator geometries, maximizing the coupling between acoustic pressure and piezoelectric elements.

Multi-material composites combining piezoelectric ceramics with polymers are addressing the inherent brittleness of high-performance piezoelectric materials. These composites maintain excellent piezoelectric properties while providing the mechanical flexibility needed for resonant vibration. 0-3 composites (piezoelectric particles in polymer matrices) and 1-3 composites (piezoelectric rods in polymer matrices) have shown particular promise for acoustic energy harvesting applications.

Surface engineering techniques, including plasma treatment and chemical functionalization, are being employed to enhance interfacial bonding between piezoelectric materials and resonator structures. These treatments improve mechanical coupling and energy transfer efficiency, resulting in harvesting systems that can generate up to 40% more power from identical acoustic inputs compared to untreated interfaces.

Sustainability Impact of Ambient Energy Harvesting Technologies

The integration of piezoelectric harvesting technologies with acoustic resonator arrays represents a significant advancement in sustainable energy solutions. These systems capture ambient sound vibrations and convert them into usable electrical energy, offering a promising pathway toward reducing dependence on conventional power sources and their associated environmental impacts.

From a sustainability perspective, these integrated systems provide substantial benefits through their minimal ecological footprint. Unlike traditional energy generation methods that rely on fossil fuels or resource-intensive manufacturing processes, piezoelectric acoustic harvesting systems utilize existing ambient noise pollution—effectively transforming an environmental nuisance into a valuable resource. This represents a paradigm shift in how we conceptualize energy generation within urban environments.

The carbon reduction potential of widespread implementation is noteworthy. Preliminary studies indicate that large-scale deployment of acoustic resonator arrays with piezoelectric harvesters could potentially offset carbon emissions by reducing reliance on grid electricity for low-power applications. In dense urban environments where ambient noise levels consistently exceed 70dB, these systems could generate sufficient energy to power sensor networks, IoT devices, and small-scale public infrastructure components.

Material sustainability considerations also favor these technologies. Modern piezoelectric materials are increasingly being developed with environmental considerations in mind, moving away from lead-based compounds toward more eco-friendly alternatives such as zinc oxide and aluminum nitride. The longevity of these systems—with estimated operational lifespans exceeding 15 years with minimal maintenance—further enhances their sustainability profile through reduced replacement and disposal requirements.

Water conservation represents another indirect benefit. By enabling self-powered monitoring systems for water infrastructure, these technologies can contribute to more efficient water management through real-time leak detection and usage optimization. This application demonstrates how energy harvesting technologies can create cascading sustainability benefits beyond their immediate energy generation function.

From a circular economy perspective, the integration of piezoelectric harvesters with acoustic resonators aligns with principles of resource efficiency and waste minimization. The systems can be designed for disassembly, with components that are recyclable or reusable at end-of-life. This approach contrasts sharply with disposable battery technologies that contribute significantly to electronic waste streams and associated environmental contamination.

From a sustainability perspective, these integrated systems provide substantial benefits through their minimal ecological footprint. Unlike traditional energy generation methods that rely on fossil fuels or resource-intensive manufacturing processes, piezoelectric acoustic harvesting systems utilize existing ambient noise pollution—effectively transforming an environmental nuisance into a valuable resource. This represents a paradigm shift in how we conceptualize energy generation within urban environments.

The carbon reduction potential of widespread implementation is noteworthy. Preliminary studies indicate that large-scale deployment of acoustic resonator arrays with piezoelectric harvesters could potentially offset carbon emissions by reducing reliance on grid electricity for low-power applications. In dense urban environments where ambient noise levels consistently exceed 70dB, these systems could generate sufficient energy to power sensor networks, IoT devices, and small-scale public infrastructure components.

Material sustainability considerations also favor these technologies. Modern piezoelectric materials are increasingly being developed with environmental considerations in mind, moving away from lead-based compounds toward more eco-friendly alternatives such as zinc oxide and aluminum nitride. The longevity of these systems—with estimated operational lifespans exceeding 15 years with minimal maintenance—further enhances their sustainability profile through reduced replacement and disposal requirements.

Water conservation represents another indirect benefit. By enabling self-powered monitoring systems for water infrastructure, these technologies can contribute to more efficient water management through real-time leak detection and usage optimization. This application demonstrates how energy harvesting technologies can create cascading sustainability benefits beyond their immediate energy generation function.

From a circular economy perspective, the integration of piezoelectric harvesters with acoustic resonators aligns with principles of resource efficiency and waste minimization. The systems can be designed for disassembly, with components that are recyclable or reusable at end-of-life. This approach contrasts sharply with disposable battery technologies that contribute significantly to electronic waste streams and associated environmental contamination.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!