Design Of Lightweight Panels For Marine Acoustic Absorption

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Acoustic Absorption Background and Objectives

Marine acoustic absorption has emerged as a critical field of study in naval engineering and marine technology over the past several decades. The underwater environment presents unique acoustic challenges due to its distinctive physical properties, with sound waves traveling approximately four times faster in water than in air. This phenomenon has significant implications for naval vessels, offshore structures, and marine research equipment, where unwanted noise can compromise operational effectiveness, environmental compliance, and crew comfort.

The evolution of marine acoustic absorption technology can be traced back to World War II, when submarine detection and stealth became strategically vital. Early solutions primarily relied on heavy rubber and metal composites, which, while effective to some degree, added substantial weight to marine structures. The subsequent decades saw incremental improvements in materials science, with the introduction of viscoelastic polymers and composite structures in the 1970s and 1980s marking significant advancements.

Recent technological trends have shifted toward multifunctional lightweight materials that can simultaneously address acoustic absorption, structural integrity, and corrosion resistance. Metamaterials and micro-perforated panels have gained particular attention for their ability to achieve broadband absorption while maintaining minimal weight profiles. Additionally, biomimetic approaches inspired by marine organisms with natural sound-dampening capabilities are emerging as promising research directions.

The global push for more environmentally friendly shipping and naval operations has further accelerated research in this field. International maritime regulations have established increasingly stringent noise emission standards, compelling the industry to develop more effective acoustic solutions. Simultaneously, the expansion of offshore energy infrastructure has created new contexts requiring specialized acoustic absorption technologies.

The primary objectives of lightweight panel design for marine acoustic absorption encompass several interconnected goals. First, achieving significant weight reduction compared to traditional solutions while maintaining or improving acoustic performance across relevant frequency ranges. Second, ensuring durability in the harsh marine environment, with resistance to saltwater corrosion, biofouling, and mechanical stress. Third, developing cost-effective manufacturing processes that can be scaled for industrial application.

Additional objectives include optimizing the thickness-to-performance ratio to maximize space utilization in confined marine environments, and creating modular designs that can be tailored to specific acoustic profiles and installation requirements. The ultimate aim is to establish a new generation of acoustic absorption solutions that balance technical performance, economic viability, and environmental sustainability in marine applications.

The evolution of marine acoustic absorption technology can be traced back to World War II, when submarine detection and stealth became strategically vital. Early solutions primarily relied on heavy rubber and metal composites, which, while effective to some degree, added substantial weight to marine structures. The subsequent decades saw incremental improvements in materials science, with the introduction of viscoelastic polymers and composite structures in the 1970s and 1980s marking significant advancements.

Recent technological trends have shifted toward multifunctional lightweight materials that can simultaneously address acoustic absorption, structural integrity, and corrosion resistance. Metamaterials and micro-perforated panels have gained particular attention for their ability to achieve broadband absorption while maintaining minimal weight profiles. Additionally, biomimetic approaches inspired by marine organisms with natural sound-dampening capabilities are emerging as promising research directions.

The global push for more environmentally friendly shipping and naval operations has further accelerated research in this field. International maritime regulations have established increasingly stringent noise emission standards, compelling the industry to develop more effective acoustic solutions. Simultaneously, the expansion of offshore energy infrastructure has created new contexts requiring specialized acoustic absorption technologies.

The primary objectives of lightweight panel design for marine acoustic absorption encompass several interconnected goals. First, achieving significant weight reduction compared to traditional solutions while maintaining or improving acoustic performance across relevant frequency ranges. Second, ensuring durability in the harsh marine environment, with resistance to saltwater corrosion, biofouling, and mechanical stress. Third, developing cost-effective manufacturing processes that can be scaled for industrial application.

Additional objectives include optimizing the thickness-to-performance ratio to maximize space utilization in confined marine environments, and creating modular designs that can be tailored to specific acoustic profiles and installation requirements. The ultimate aim is to establish a new generation of acoustic absorption solutions that balance technical performance, economic viability, and environmental sustainability in marine applications.

Market Analysis for Lightweight Marine Acoustic Panels

The global market for lightweight marine acoustic absorption panels is experiencing significant growth, driven by increasing regulations on noise pollution in marine environments and the growing demand for quieter, more efficient vessels. The market size was valued at approximately 1.2 billion USD in 2022 and is projected to reach 1.8 billion USD by 2028, representing a compound annual growth rate of 7.2% during the forecast period.

The commercial shipping sector currently dominates the market demand, accounting for nearly 45% of the total market share. This is primarily due to stringent International Maritime Organization (IMO) regulations regarding noise levels on commercial vessels and the impact of underwater noise on marine ecosystems. The naval defense sector follows closely, representing approximately 30% of the market, with increasing investments in stealth technology and crew comfort driving adoption.

Geographically, Europe leads the market with a 38% share, attributed to strict environmental regulations and the presence of major shipbuilding nations like Norway, Germany, and Italy. Asia-Pacific is the fastest-growing region with a projected growth rate of 9.5% annually, fueled by expanding shipbuilding activities in China, South Korea, and Japan.

Key market drivers include the growing focus on crew welfare and comfort, increasing awareness of underwater noise pollution's environmental impact, and the push for fuel efficiency through weight reduction in marine vessels. The lightweight nature of modern acoustic panels contributes to reduced fuel consumption, aligning with global sustainability goals and offering economic benefits to operators.

Customer requirements are evolving toward multi-functional materials that provide not only acoustic absorption but also thermal insulation, fire resistance, and corrosion protection. This trend is creating new market opportunities for integrated solution providers who can deliver comprehensive lightweight panel systems.

Price sensitivity varies significantly across market segments, with luxury yacht manufacturers willing to pay premium prices for high-performance, aesthetically pleasing solutions, while commercial shipping operators prioritize cost-effectiveness and durability. The average price point for marine-grade acoustic panels ranges from $50 to $200 per square meter, depending on performance specifications and material composition.

Market challenges include the high initial cost of advanced lightweight acoustic materials, technical difficulties in achieving optimal performance in harsh marine environments, and the complex certification processes required for marine applications. These factors create significant barriers to entry for new market participants but also present opportunities for established players to differentiate through innovation and technical expertise.

The commercial shipping sector currently dominates the market demand, accounting for nearly 45% of the total market share. This is primarily due to stringent International Maritime Organization (IMO) regulations regarding noise levels on commercial vessels and the impact of underwater noise on marine ecosystems. The naval defense sector follows closely, representing approximately 30% of the market, with increasing investments in stealth technology and crew comfort driving adoption.

Geographically, Europe leads the market with a 38% share, attributed to strict environmental regulations and the presence of major shipbuilding nations like Norway, Germany, and Italy. Asia-Pacific is the fastest-growing region with a projected growth rate of 9.5% annually, fueled by expanding shipbuilding activities in China, South Korea, and Japan.

Key market drivers include the growing focus on crew welfare and comfort, increasing awareness of underwater noise pollution's environmental impact, and the push for fuel efficiency through weight reduction in marine vessels. The lightweight nature of modern acoustic panels contributes to reduced fuel consumption, aligning with global sustainability goals and offering economic benefits to operators.

Customer requirements are evolving toward multi-functional materials that provide not only acoustic absorption but also thermal insulation, fire resistance, and corrosion protection. This trend is creating new market opportunities for integrated solution providers who can deliver comprehensive lightweight panel systems.

Price sensitivity varies significantly across market segments, with luxury yacht manufacturers willing to pay premium prices for high-performance, aesthetically pleasing solutions, while commercial shipping operators prioritize cost-effectiveness and durability. The average price point for marine-grade acoustic panels ranges from $50 to $200 per square meter, depending on performance specifications and material composition.

Market challenges include the high initial cost of advanced lightweight acoustic materials, technical difficulties in achieving optimal performance in harsh marine environments, and the complex certification processes required for marine applications. These factors create significant barriers to entry for new market participants but also present opportunities for established players to differentiate through innovation and technical expertise.

Current Challenges in Marine Acoustic Materials

Marine acoustic absorption materials face significant challenges in meeting the demanding requirements of modern naval applications. Traditional acoustic materials often struggle to balance performance with practical constraints such as weight, durability, and cost-effectiveness in harsh marine environments.

Weight reduction remains a primary challenge, as conventional acoustic treatments typically add substantial mass to marine structures. This additional weight impacts vessel performance, fuel efficiency, and operational capabilities. Naval architects and engineers continuously seek lightweight alternatives that can provide effective sound absorption without compromising the vessel's performance characteristics.

Environmental durability presents another major obstacle. Marine acoustic materials must withstand constant exposure to saltwater, humidity, temperature fluctuations, and biological growth. Many existing materials degrade rapidly under these conditions, leading to diminished acoustic performance over time and increased maintenance requirements. The development of materials that maintain their acoustic properties while resisting environmental degradation remains an ongoing challenge.

Broadband effectiveness across varying frequencies poses significant technical difficulties. Marine environments contain diverse noise sources operating at different frequencies, from low-frequency engine vibrations to high-frequency propeller cavitation. Creating lightweight panels that effectively absorb this wide spectrum of noise without excessive thickness or complexity continues to challenge materials scientists and acoustic engineers.

Manufacturing complexity and cost considerations further complicate the development of advanced marine acoustic materials. Sophisticated composite structures with optimized acoustic properties often require specialized production techniques, driving up costs and limiting widespread implementation. Simplifying manufacturing processes while maintaining acoustic performance represents a critical industry need.

Integration with existing vessel structures presents additional challenges. Acoustic treatments must be compatible with structural elements and other shipboard systems without compromising safety or functionality. The limited space available on marine vessels necessitates thin, efficient acoustic solutions that can be seamlessly incorporated into complex geometries.

Regulatory compliance adds another layer of complexity. Materials must meet stringent maritime safety standards regarding fire resistance, smoke generation, and toxicity. These requirements often conflict with optimal acoustic properties, forcing compromises in material selection and design. Finding materials that satisfy both acoustic performance targets and regulatory requirements remains a persistent challenge in the industry.

Weight reduction remains a primary challenge, as conventional acoustic treatments typically add substantial mass to marine structures. This additional weight impacts vessel performance, fuel efficiency, and operational capabilities. Naval architects and engineers continuously seek lightweight alternatives that can provide effective sound absorption without compromising the vessel's performance characteristics.

Environmental durability presents another major obstacle. Marine acoustic materials must withstand constant exposure to saltwater, humidity, temperature fluctuations, and biological growth. Many existing materials degrade rapidly under these conditions, leading to diminished acoustic performance over time and increased maintenance requirements. The development of materials that maintain their acoustic properties while resisting environmental degradation remains an ongoing challenge.

Broadband effectiveness across varying frequencies poses significant technical difficulties. Marine environments contain diverse noise sources operating at different frequencies, from low-frequency engine vibrations to high-frequency propeller cavitation. Creating lightweight panels that effectively absorb this wide spectrum of noise without excessive thickness or complexity continues to challenge materials scientists and acoustic engineers.

Manufacturing complexity and cost considerations further complicate the development of advanced marine acoustic materials. Sophisticated composite structures with optimized acoustic properties often require specialized production techniques, driving up costs and limiting widespread implementation. Simplifying manufacturing processes while maintaining acoustic performance represents a critical industry need.

Integration with existing vessel structures presents additional challenges. Acoustic treatments must be compatible with structural elements and other shipboard systems without compromising safety or functionality. The limited space available on marine vessels necessitates thin, efficient acoustic solutions that can be seamlessly incorporated into complex geometries.

Regulatory compliance adds another layer of complexity. Materials must meet stringent maritime safety standards regarding fire resistance, smoke generation, and toxicity. These requirements often conflict with optimal acoustic properties, forcing compromises in material selection and design. Finding materials that satisfy both acoustic performance targets and regulatory requirements remains a persistent challenge in the industry.

Current Lightweight Panel Design Solutions

01 Composite panel structures for acoustic absorption

Lightweight acoustic panels can be constructed using composite structures that combine different materials to enhance sound absorption. These panels typically feature a core material sandwiched between facing layers. The core material often consists of honeycomb structures, foam, or other lightweight materials that provide both structural integrity and sound absorption properties. The facing layers can be perforated to allow sound waves to enter the absorptive core. This composite design optimizes the balance between weight reduction and acoustic performance.- Composite panel structures for acoustic absorption: Lightweight acoustic panels can be constructed using composite structures that combine different materials to enhance sound absorption. These panels typically feature a core material sandwiched between facing layers. The core material often consists of honeycomb structures, foam, or other lightweight materials that provide both structural integrity and sound absorption properties. The facing layers can be perforated or micro-perforated to allow sound waves to enter the absorptive core. This composite design optimizes the balance between weight reduction and acoustic performance.

- Porous materials for sound absorption: Porous materials are widely used in lightweight acoustic panels due to their excellent sound absorption characteristics. These materials contain interconnected air spaces that allow sound waves to enter and dissipate energy through friction. Common porous materials include mineral wool, fiberglass, melamine foam, and recycled fibers. The acoustic performance of these materials can be enhanced by controlling their density, thickness, and airflow resistance. Porous materials are particularly effective at absorbing mid to high-frequency sounds while maintaining a lightweight structure.

- Resonant systems for low-frequency absorption: Lightweight acoustic panels can incorporate resonant systems to enhance low-frequency sound absorption, which is typically challenging for thin, lightweight structures. These systems include Helmholtz resonators, membrane absorbers, and micro-perforated panels that work by converting sound energy into mechanical vibrations. The resonant frequency can be tuned by adjusting the geometry of the system, such as the size of air cavities, the thickness of membranes, or the pattern of perforations. This approach allows lightweight panels to achieve effective low-frequency absorption without adding significant mass.

- Multi-layer acoustic panel designs: Multi-layer designs are employed in lightweight acoustic panels to achieve broadband sound absorption across different frequency ranges. These panels typically consist of several layers with varying acoustic properties, such as a combination of porous absorbers, resonant elements, and air gaps. The arrangement and thickness of each layer can be optimized to target specific frequency bands. Some designs incorporate graduated density layers, where the density increases from the face to the back of the panel, creating a progressive impedance change that enhances sound absorption while maintaining lightweight characteristics.

- Sustainable and eco-friendly acoustic materials: Sustainable and eco-friendly materials are increasingly being used in lightweight acoustic panels to reduce environmental impact. These materials include recycled textiles, natural fibers (such as hemp, jute, or coconut), recycled plastic, and agricultural waste products. These sustainable alternatives can provide comparable acoustic performance to traditional materials while being renewable, biodegradable, or recyclable. Additionally, these materials often have lower embodied energy and carbon footprint compared to conventional synthetic acoustic materials, making them suitable for green building projects that require lightweight acoustic solutions.

02 Perforated panel designs for sound absorption

Perforated panels are widely used in lightweight acoustic solutions. These panels feature precisely designed holes or slots that allow sound waves to enter the absorptive material behind them. The size, shape, and pattern of perforations can be optimized to target specific frequency ranges for absorption. Some designs incorporate micro-perforations that are particularly effective for high-frequency noise reduction while maintaining structural integrity. These panels can be made from various materials including metal, wood, and polymers, offering flexibility in both acoustic performance and aesthetic design.Expand Specific Solutions03 Lightweight materials for acoustic panels

Various lightweight materials are employed in acoustic panels to minimize weight while maximizing sound absorption. These include recycled materials, natural fibers, aerogels, and specialized foams with optimized density and cell structure. Some panels utilize lightweight polymers or composite materials that offer excellent strength-to-weight ratios. Advanced manufacturing techniques allow for the creation of materials with precisely controlled porosity and flow resistance, which are critical parameters for sound absorption. The selection of materials often involves balancing acoustic performance, weight considerations, fire resistance, and environmental impact.Expand Specific Solutions04 Multi-layer acoustic panel systems

Multi-layer acoustic panel systems combine different materials in strategic layers to enhance sound absorption across a broader frequency range. These systems typically include combinations of porous absorbers, resonant panels, and air gaps arranged in specific sequences. The layering approach allows for targeting different sound frequencies with specific materials optimized for those ranges. Some designs incorporate graduated density layers that progressively absorb sound energy as it passes through the panel. This approach enables the creation of lightweight panels that perform effectively across the full audible spectrum while maintaining minimal thickness and weight.Expand Specific Solutions05 Installation systems for lightweight acoustic panels

Specialized mounting and installation systems are designed specifically for lightweight acoustic panels to maintain their performance while ensuring secure attachment. These systems include various clips, rails, suspension systems, and adhesive methods that minimize additional weight while providing reliable support. Some mounting solutions incorporate vibration isolation features to prevent sound transmission through the mounting structure itself. Modular installation systems allow for easy replacement or reconfiguration of panels as needed. The installation approach often considers accessibility requirements for maintenance while preserving the acoustic integrity of the overall system.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The marine acoustic absorption lightweight panel market is in a growth phase, characterized by increasing demand for noise reduction solutions in naval applications. The market is expanding due to stricter noise regulations and growing emphasis on crew comfort and stealth capabilities. Technologically, the field shows moderate maturity with ongoing innovation from aerospace leaders like Airbus Operations and Safran Aircraft Engines, who are transferring aviation acoustic expertise to marine applications. Research institutions including CNRS, Fraunhofer-Gesellschaft, and universities like HKUST and Harbin Engineering University are advancing fundamental research. Defense contractors such as Leonardo SpA and IHI Corp. are developing specialized military applications, while acoustic specialists like Armstrong Ceiling Solutions and USG Interiors are adapting commercial technologies for marine environments. The competitive landscape features cross-industry collaboration between aerospace, defense, and acoustic material specialists.

Airbus Operations SAS

Technical Solution: Airbus Operations SAS has transferred aerospace acoustic technology to marine applications, developing lightweight composite sandwich panels with micro-perforated facings and honeycomb cores specifically engineered for marine environments. Their design incorporates multiple resonant chambers within a single panel structure to target different frequency ranges simultaneously. The panels utilize advanced composite materials including carbon fiber, fiberglass, and specialized polymer matrices with controlled porosity. Airbus's marine acoustic panels feature proprietary damping treatments that are integrated directly into the composite layup during manufacturing, eliminating additional weight from separate damping layers. Testing has demonstrated these panels achieve 15-20 dB noise reduction while weighing approximately 4-5 kg/m², representing a 40% weight reduction compared to traditional marine acoustic treatments.

Strengths: Exceptional structural integrity while maintaining acoustic performance; leverages aerospace engineering expertise for weight optimization; excellent resistance to marine environmental factors. Weaknesses: Manufacturing complexity leads to higher production costs; requires specialized installation techniques; limited flexibility for retrofitting to complex hull geometries.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced microporous composite materials for marine acoustic absorption panels that combine lightweight polymer matrices with specialized acoustic absorbing fillers. Their technology utilizes proprietary microstructure control to create panels with graduated porosity and density profiles, optimizing sound absorption across multiple frequency ranges. The panels incorporate viscoelastic materials that convert sound energy into heat through molecular friction. 3M's marine acoustic panels feature a multi-layer design with a perforated protective facing, a microporous sound-absorbing middle layer, and a dense backing layer that prevents sound transmission. These panels achieve high noise reduction coefficients (NRC > 0.85) while maintaining low weight (typically 30-50% lighter than conventional solutions).

Strengths: Exceptional weight-to-performance ratio; proprietary material science expertise; established manufacturing infrastructure for consistent quality. Weaknesses: Higher initial cost compared to traditional materials; potential durability concerns in harsh marine environments with prolonged exposure to saltwater and humidity.

Key Patents and Technical Innovations

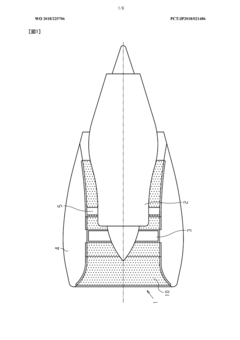

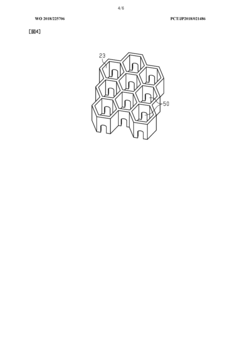

Sound-absorbing panel and manufacturing method for same

PatentWO2018225706A1

Innovation

- A lightweight sound-absorbing panel made of resin with a core layer and two skin layers, featuring a honeycomb structure and through holes that function as a Helmholtz resonator, providing excellent scratch resistance and noise absorption while allowing condensation water to be discharged.

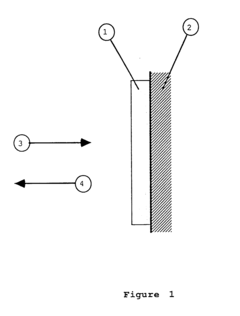

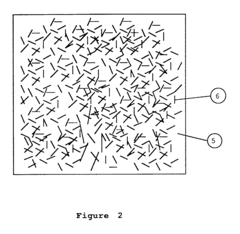

Composition absorbing acoustic waves, particularly for submarine environment

PatentInactiveEP0740287A1

Innovation

- A viscoelastic matrix material with randomly or periodically distributed metal rods, which converts longitudinal sound waves into attenuated transverse waves, maintaining acoustic performance independent of hydrostatic pressure and reducing static compressibility.

Environmental Impact and Sustainability Considerations

The environmental impact of marine acoustic absorption panels has become increasingly significant as maritime industries face stricter regulations and growing sustainability concerns. Traditional acoustic materials often contain synthetic compounds, adhesives, and treatments that can leach harmful substances into marine environments. These materials typically have high embodied carbon footprints due to energy-intensive manufacturing processes and petroleum-based raw materials. When designing lightweight panels for marine acoustic absorption, lifecycle assessment becomes essential to evaluate environmental impacts from raw material extraction through disposal.

Recent innovations have focused on developing bio-based alternatives to conventional synthetic absorbers. Materials derived from agricultural waste, recycled textiles, and sustainable forestry products show promising acoustic performance while significantly reducing environmental impact. For instance, panels incorporating processed cellulose fibers from paper industry byproducts have demonstrated absorption coefficients comparable to traditional materials while reducing carbon footprint by up to 40%.

Water pollution concerns are particularly relevant for marine applications. Next-generation acoustic panels must minimize leaching of microplastics, biocides, and other potentially harmful compounds. Research indicates that natural fiber composites treated with non-toxic, biodegradable waterproofing agents can maintain performance integrity while dramatically reducing marine ecosystem impacts compared to conventional solutions.

End-of-life considerations represent another critical environmental dimension. Designing for disassembly and material recovery enables more effective recycling and reduces waste. Some innovative manufacturers have implemented take-back programs where panels are collected after service life for material recovery or refurbishment, creating circular economy opportunities within the marine acoustics sector.

Energy efficiency during operation also merits consideration. Lightweight acoustic panels that contribute to vessel weight reduction can decrease fuel consumption and associated emissions throughout operational life. Studies suggest that for every 10% reduction in vessel weight, fuel efficiency improves by approximately 6-8%, representing significant lifetime carbon savings for commercial vessels.

Certification standards are evolving to address these environmental concerns. Programs like Blue Angel, Cradle to Cradle, and various marine-specific environmental certifications now include criteria for acoustic materials. Forward-thinking manufacturers are pursuing these certifications to demonstrate environmental commitment and gain competitive advantage in increasingly eco-conscious markets.

Recent innovations have focused on developing bio-based alternatives to conventional synthetic absorbers. Materials derived from agricultural waste, recycled textiles, and sustainable forestry products show promising acoustic performance while significantly reducing environmental impact. For instance, panels incorporating processed cellulose fibers from paper industry byproducts have demonstrated absorption coefficients comparable to traditional materials while reducing carbon footprint by up to 40%.

Water pollution concerns are particularly relevant for marine applications. Next-generation acoustic panels must minimize leaching of microplastics, biocides, and other potentially harmful compounds. Research indicates that natural fiber composites treated with non-toxic, biodegradable waterproofing agents can maintain performance integrity while dramatically reducing marine ecosystem impacts compared to conventional solutions.

End-of-life considerations represent another critical environmental dimension. Designing for disassembly and material recovery enables more effective recycling and reduces waste. Some innovative manufacturers have implemented take-back programs where panels are collected after service life for material recovery or refurbishment, creating circular economy opportunities within the marine acoustics sector.

Energy efficiency during operation also merits consideration. Lightweight acoustic panels that contribute to vessel weight reduction can decrease fuel consumption and associated emissions throughout operational life. Studies suggest that for every 10% reduction in vessel weight, fuel efficiency improves by approximately 6-8%, representing significant lifetime carbon savings for commercial vessels.

Certification standards are evolving to address these environmental concerns. Programs like Blue Angel, Cradle to Cradle, and various marine-specific environmental certifications now include criteria for acoustic materials. Forward-thinking manufacturers are pursuing these certifications to demonstrate environmental commitment and gain competitive advantage in increasingly eco-conscious markets.

Performance Testing Standards and Certification Requirements

The performance testing of lightweight acoustic absorption panels for marine applications must adhere to rigorous international standards to ensure reliability in harsh maritime environments. Key testing protocols include ISO 10534 for acoustic impedance tube measurements, which quantifies absorption coefficients across frequency ranges relevant to marine noise (typically 50Hz-10kHz). Additionally, ASTM E1050 provides standardized methods for determining normal incidence sound absorption coefficients and acoustic impedance using impedance tubes.

Marine-specific standards such as ISO 16283-3 focus on field measurements of sound insulation in marine vessels, while ISO 17025 accreditation is essential for testing laboratories to demonstrate technical competence. For environmental durability, panels must undergo salt spray testing (ASTM B117) to verify corrosion resistance, and water absorption testing (ASTM D570) to ensure performance integrity in high-humidity conditions.

Mechanical performance standards include ASTM E84 for surface burning characteristics, IMO FTP Code Part 5 for flame spread properties, and ASTM D7264 for flexural properties. These tests are critical as marine acoustic panels must maintain structural integrity while meeting strict weight requirements. Vibration resistance testing according to MIL-STD-810G Method 514.7 ensures panels can withstand continuous shipboard vibrations without degradation of acoustic properties.

Certification requirements vary by jurisdiction and vessel classification. Major classification societies including DNV GL, Lloyd's Register, and American Bureau of Shipping (ABS) have established specific requirements for acoustic materials used in marine environments. These certifications typically require comprehensive documentation of fire safety compliance (SOLAS Chapter II-2), low smoke and toxicity characteristics (IMO MSC.307(88)), and weight verification.

The International Maritime Organization (IMO) Resolution MSC.337(91) establishes noise level limits on board ships, indirectly influencing the performance requirements for acoustic absorption panels. For commercial vessels, compliance with MARPOL Annex VI regulations regarding noise pollution may also apply, particularly in environmentally sensitive areas.

Emerging standards are beginning to address the lifecycle environmental impact of marine acoustic materials, with ISO 14040 series providing frameworks for life cycle assessment. This reflects growing industry concern about the environmental footprint of marine components, including potential microplastic shedding from polymer-based acoustic materials.

Testing certification must be renewed periodically, typically every 3-5 years, with random sampling inspections to ensure continued compliance with performance standards throughout production cycles. This comprehensive testing and certification framework ensures that lightweight acoustic panels can deliver reliable performance in the demanding marine environment while meeting increasingly stringent regulatory requirements.

Marine-specific standards such as ISO 16283-3 focus on field measurements of sound insulation in marine vessels, while ISO 17025 accreditation is essential for testing laboratories to demonstrate technical competence. For environmental durability, panels must undergo salt spray testing (ASTM B117) to verify corrosion resistance, and water absorption testing (ASTM D570) to ensure performance integrity in high-humidity conditions.

Mechanical performance standards include ASTM E84 for surface burning characteristics, IMO FTP Code Part 5 for flame spread properties, and ASTM D7264 for flexural properties. These tests are critical as marine acoustic panels must maintain structural integrity while meeting strict weight requirements. Vibration resistance testing according to MIL-STD-810G Method 514.7 ensures panels can withstand continuous shipboard vibrations without degradation of acoustic properties.

Certification requirements vary by jurisdiction and vessel classification. Major classification societies including DNV GL, Lloyd's Register, and American Bureau of Shipping (ABS) have established specific requirements for acoustic materials used in marine environments. These certifications typically require comprehensive documentation of fire safety compliance (SOLAS Chapter II-2), low smoke and toxicity characteristics (IMO MSC.307(88)), and weight verification.

The International Maritime Organization (IMO) Resolution MSC.337(91) establishes noise level limits on board ships, indirectly influencing the performance requirements for acoustic absorption panels. For commercial vessels, compliance with MARPOL Annex VI regulations regarding noise pollution may also apply, particularly in environmentally sensitive areas.

Emerging standards are beginning to address the lifecycle environmental impact of marine acoustic materials, with ISO 14040 series providing frameworks for life cycle assessment. This reflects growing industry concern about the environmental footprint of marine components, including potential microplastic shedding from polymer-based acoustic materials.

Testing certification must be renewed periodically, typically every 3-5 years, with random sampling inspections to ensure continued compliance with performance standards throughout production cycles. This comprehensive testing and certification framework ensures that lightweight acoustic panels can deliver reliable performance in the demanding marine environment while meeting increasingly stringent regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!