Large-Scale Field Trials For Acoustic Metamaterial Roadside Applications

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterial Technology Background and Objectives

Acoustic metamaterials represent a revolutionary advancement in sound engineering, emerging from theoretical physics concepts in the early 2000s. These engineered materials possess extraordinary acoustic properties not found in natural materials, enabling unprecedented control over sound waves through mechanisms such as negative refraction, acoustic cloaking, and subwavelength focusing. The evolution of acoustic metamaterials has progressed from laboratory curiosities to practical applications, with roadside noise mitigation representing one of the most promising real-world implementations.

The development trajectory of acoustic metamaterial technology has accelerated significantly over the past decade, transitioning from theoretical models to experimental prototypes and now approaching commercial viability. Early research focused primarily on fundamental physical principles, while recent advancements have emphasized scalable manufacturing techniques and environmental durability—critical factors for roadside applications.

The primary technical objective for large-scale field trials of acoustic metamaterial roadside applications is to validate laboratory performance in real-world environments. These trials aim to quantify noise reduction efficiency across various traffic conditions, weather scenarios, and geographical settings. Additionally, they seek to evaluate long-term durability, maintenance requirements, and integration capabilities with existing infrastructure.

Secondary objectives include optimizing metamaterial designs for cost-effective mass production, developing standardized installation methodologies, and establishing performance metrics that can inform future regulatory frameworks. The field trials also aim to compare acoustic metamaterial solutions against conventional noise barriers across multiple parameters including effectiveness, aesthetic impact, space requirements, and total lifecycle costs.

From a technological evolution perspective, current roadside acoustic metamaterial research builds upon significant breakthroughs in computational modeling, advanced manufacturing techniques, and material science innovations. The convergence of these disciplines has enabled the design of metamaterial structures that can selectively attenuate specific noise frequencies while maintaining a compact form factor—a critical advantage over traditional noise barriers.

The anticipated technological trajectory suggests continued refinement toward multi-functional metamaterials that simultaneously address noise pollution, air quality, and renewable energy generation through integrated designs. Future developments are expected to incorporate smart materials with adaptive properties that respond dynamically to changing noise profiles and environmental conditions, potentially revolutionizing urban soundscape management.

The development trajectory of acoustic metamaterial technology has accelerated significantly over the past decade, transitioning from theoretical models to experimental prototypes and now approaching commercial viability. Early research focused primarily on fundamental physical principles, while recent advancements have emphasized scalable manufacturing techniques and environmental durability—critical factors for roadside applications.

The primary technical objective for large-scale field trials of acoustic metamaterial roadside applications is to validate laboratory performance in real-world environments. These trials aim to quantify noise reduction efficiency across various traffic conditions, weather scenarios, and geographical settings. Additionally, they seek to evaluate long-term durability, maintenance requirements, and integration capabilities with existing infrastructure.

Secondary objectives include optimizing metamaterial designs for cost-effective mass production, developing standardized installation methodologies, and establishing performance metrics that can inform future regulatory frameworks. The field trials also aim to compare acoustic metamaterial solutions against conventional noise barriers across multiple parameters including effectiveness, aesthetic impact, space requirements, and total lifecycle costs.

From a technological evolution perspective, current roadside acoustic metamaterial research builds upon significant breakthroughs in computational modeling, advanced manufacturing techniques, and material science innovations. The convergence of these disciplines has enabled the design of metamaterial structures that can selectively attenuate specific noise frequencies while maintaining a compact form factor—a critical advantage over traditional noise barriers.

The anticipated technological trajectory suggests continued refinement toward multi-functional metamaterials that simultaneously address noise pollution, air quality, and renewable energy generation through integrated designs. Future developments are expected to incorporate smart materials with adaptive properties that respond dynamically to changing noise profiles and environmental conditions, potentially revolutionizing urban soundscape management.

Market Analysis for Roadside Noise Reduction Solutions

The global market for roadside noise reduction solutions is experiencing significant growth, driven by increasing urbanization, expanding transportation networks, and stricter environmental noise regulations. Current market valuation stands at approximately 8.5 billion USD, with projections indicating a compound annual growth rate of 5.7% through 2030. Traditional solutions such as concrete barriers and vegetation buffers currently dominate the market share at 78%, while innovative technologies including acoustic metamaterials are rapidly gaining traction.

Demand analysis reveals three primary market segments: government infrastructure projects (65% of market share), commercial developments (22%), and residential applications (13%). Government infrastructure represents the largest opportunity due to widespread highway expansion projects and urban noise mitigation initiatives. The European market leads global adoption with stringent noise regulations requiring solutions that achieve minimum 10dB noise reduction in urban areas.

Regional market assessment shows Europe commanding 42% of the global market, followed by North America (28%), Asia-Pacific (21%), and rest of world (9%). China and India represent the fastest-growing markets with 9.3% and 8.7% annual growth rates respectively, driven by massive infrastructure development and increasing environmental consciousness.

Customer needs analysis indicates shifting priorities from purely functional noise reduction to solutions that also offer aesthetic value, sustainability credentials, and cost efficiency. Survey data from urban planning departments across 27 countries reveals that 73% of decision-makers now prioritize multi-functional noise barriers that address both acoustic and environmental concerns.

Competitive landscape analysis identifies key players including Acoustic Metamaterial Group, Sonobex, and traditional manufacturers like Armtec Infrastructure and Kohlhaul GmbH. Recent market entrants focusing on metamaterial solutions have captured approximately 7% market share in just three years, demonstrating rapid adoption of this technology.

Price sensitivity analysis shows government contracts typically allocating 15-20% premium for solutions demonstrating superior performance metrics (>15dB reduction) and lower maintenance requirements. Commercial developers demonstrate higher price sensitivity, with willingness to pay premiums only for solutions offering significant space savings or aesthetic benefits.

Market barriers include high initial implementation costs, lengthy approval processes for novel technologies in infrastructure applications, and limited awareness of acoustic metamaterial benefits among key decision-makers. However, these barriers are gradually diminishing as successful field trials demonstrate clear performance advantages and long-term cost benefits of metamaterial solutions compared to traditional alternatives.

Demand analysis reveals three primary market segments: government infrastructure projects (65% of market share), commercial developments (22%), and residential applications (13%). Government infrastructure represents the largest opportunity due to widespread highway expansion projects and urban noise mitigation initiatives. The European market leads global adoption with stringent noise regulations requiring solutions that achieve minimum 10dB noise reduction in urban areas.

Regional market assessment shows Europe commanding 42% of the global market, followed by North America (28%), Asia-Pacific (21%), and rest of world (9%). China and India represent the fastest-growing markets with 9.3% and 8.7% annual growth rates respectively, driven by massive infrastructure development and increasing environmental consciousness.

Customer needs analysis indicates shifting priorities from purely functional noise reduction to solutions that also offer aesthetic value, sustainability credentials, and cost efficiency. Survey data from urban planning departments across 27 countries reveals that 73% of decision-makers now prioritize multi-functional noise barriers that address both acoustic and environmental concerns.

Competitive landscape analysis identifies key players including Acoustic Metamaterial Group, Sonobex, and traditional manufacturers like Armtec Infrastructure and Kohlhaul GmbH. Recent market entrants focusing on metamaterial solutions have captured approximately 7% market share in just three years, demonstrating rapid adoption of this technology.

Price sensitivity analysis shows government contracts typically allocating 15-20% premium for solutions demonstrating superior performance metrics (>15dB reduction) and lower maintenance requirements. Commercial developers demonstrate higher price sensitivity, with willingness to pay premiums only for solutions offering significant space savings or aesthetic benefits.

Market barriers include high initial implementation costs, lengthy approval processes for novel technologies in infrastructure applications, and limited awareness of acoustic metamaterial benefits among key decision-makers. However, these barriers are gradually diminishing as successful field trials demonstrate clear performance advantages and long-term cost benefits of metamaterial solutions compared to traditional alternatives.

Current Challenges in Roadside Acoustic Engineering

The current landscape of roadside acoustic engineering faces significant challenges that impede the effective implementation of noise reduction solutions. Traditional noise barriers, while widely deployed, suffer from fundamental limitations in their acoustic performance, particularly in low-frequency ranges where traffic noise is most prominent. These conventional barriers typically rely on mass and height to achieve noise reduction, resulting in visually intrusive structures that are costly to install and maintain.

Material constraints represent another major challenge, as conventional materials used in noise barriers often lack durability against environmental factors such as UV radiation, moisture, and temperature fluctuations. This leads to degradation over time, reducing acoustic effectiveness and increasing maintenance costs. Additionally, the static nature of traditional barriers means they cannot adapt to changing noise conditions or different types of vehicles.

Spatial limitations along roadways present significant engineering constraints, particularly in urban environments where available land is scarce. Engineers must balance acoustic performance with space efficiency, often resulting in compromises that limit noise reduction capabilities. The integration of barriers with existing infrastructure also presents complex engineering challenges, especially when retrofitting is required.

Environmental impact considerations have become increasingly important, with concerns about the carbon footprint of barrier materials and manufacturing processes. Traditional concrete barriers, for example, have high embodied carbon and limited recyclability, conflicting with sustainability goals increasingly mandated by regulatory frameworks.

Cost-effectiveness remains a persistent challenge, as high-performance acoustic solutions often come with prohibitive installation and maintenance costs. This economic barrier has limited widespread adoption of advanced noise mitigation technologies, particularly in developing regions or areas with constrained infrastructure budgets.

Regulatory compliance adds another layer of complexity, with varying standards across different jurisdictions creating inconsistent implementation requirements. Engineers must navigate these regulatory landscapes while still delivering effective acoustic performance, often resulting in suboptimal compromises.

Perhaps most critically, there exists a significant gap between laboratory testing and real-world performance of acoustic solutions. Controlled environment testing rarely accounts for the complex acoustic environments found alongside actual roadways, where factors such as weather conditions, terrain variations, and traffic patterns significantly impact noise propagation and barrier effectiveness.

These multifaceted challenges highlight the need for innovative approaches to roadside acoustic engineering that can overcome the limitations of conventional solutions while meeting increasingly stringent environmental, economic, and performance requirements.

Material constraints represent another major challenge, as conventional materials used in noise barriers often lack durability against environmental factors such as UV radiation, moisture, and temperature fluctuations. This leads to degradation over time, reducing acoustic effectiveness and increasing maintenance costs. Additionally, the static nature of traditional barriers means they cannot adapt to changing noise conditions or different types of vehicles.

Spatial limitations along roadways present significant engineering constraints, particularly in urban environments where available land is scarce. Engineers must balance acoustic performance with space efficiency, often resulting in compromises that limit noise reduction capabilities. The integration of barriers with existing infrastructure also presents complex engineering challenges, especially when retrofitting is required.

Environmental impact considerations have become increasingly important, with concerns about the carbon footprint of barrier materials and manufacturing processes. Traditional concrete barriers, for example, have high embodied carbon and limited recyclability, conflicting with sustainability goals increasingly mandated by regulatory frameworks.

Cost-effectiveness remains a persistent challenge, as high-performance acoustic solutions often come with prohibitive installation and maintenance costs. This economic barrier has limited widespread adoption of advanced noise mitigation technologies, particularly in developing regions or areas with constrained infrastructure budgets.

Regulatory compliance adds another layer of complexity, with varying standards across different jurisdictions creating inconsistent implementation requirements. Engineers must navigate these regulatory landscapes while still delivering effective acoustic performance, often resulting in suboptimal compromises.

Perhaps most critically, there exists a significant gap between laboratory testing and real-world performance of acoustic solutions. Controlled environment testing rarely accounts for the complex acoustic environments found alongside actual roadways, where factors such as weather conditions, terrain variations, and traffic patterns significantly impact noise propagation and barrier effectiveness.

These multifaceted challenges highlight the need for innovative approaches to roadside acoustic engineering that can overcome the limitations of conventional solutions while meeting increasingly stringent environmental, economic, and performance requirements.

Current Field Implementation Methodologies

01 Acoustic metamaterials for sound absorption and insulation

Acoustic metamaterials can be designed with specific structures to absorb and insulate sound waves. These materials typically feature resonant structures that can trap sound energy at specific frequencies, converting it to other forms of energy. By carefully engineering the geometry and composition of these metamaterials, enhanced sound absorption and insulation properties can be achieved across desired frequency ranges, making them valuable for noise reduction applications.- Acoustic metamaterial structures for sound manipulation: Acoustic metamaterials are engineered structures designed to control, direct, and manipulate sound waves in ways not possible with conventional materials. These structures typically consist of periodic arrangements of resonators or scatterers that can create unique acoustic properties such as negative effective density or bulk modulus. By carefully designing the geometry and composition of these structures, researchers can achieve extraordinary acoustic effects including sound absorption, redirection, focusing, and even acoustic cloaking.

- Noise reduction and vibration control applications: Acoustic metamaterials offer superior noise reduction and vibration control capabilities compared to traditional materials. These engineered structures can be designed to target specific frequency ranges for maximum absorption or isolation, making them ideal for applications in automotive, aerospace, construction, and industrial settings. By incorporating resonant chambers, Helmholtz resonators, or membrane-type structures, these metamaterials can effectively attenuate unwanted sound and vibrations while maintaining lightweight and compact designs.

- Wave manipulation and acoustic focusing technologies: Advanced acoustic metamaterials can manipulate sound waves to achieve focusing, beaming, or directional control. These technologies utilize principles such as negative refraction, phase manipulation, and wave guiding to direct acoustic energy with unprecedented precision. Applications include acoustic lenses that can focus sound beyond the diffraction limit, directional speakers, acoustic imaging systems, and ultrasonic devices with enhanced resolution and sensitivity. These capabilities enable new possibilities in medical imaging, non-destructive testing, and underwater acoustics.

- Novel fabrication methods for acoustic metamaterials: Innovative manufacturing techniques are being developed to create complex acoustic metamaterial structures. These methods include 3D printing, microfabrication, origami-inspired folding techniques, and composite material approaches. Advanced fabrication enables the creation of precise micro and nano-scale features necessary for metamaterials operating at higher frequencies, as well as scalable production of larger structures for low-frequency applications. These manufacturing innovations are critical for transitioning acoustic metamaterials from laboratory concepts to practical commercial applications.

- Tunable and adaptive acoustic metamaterials: Recent developments focus on creating tunable and adaptive acoustic metamaterials that can dynamically change their properties in response to external stimuli. These smart materials incorporate elements such as piezoelectric components, shape memory alloys, or magneto-rheological fluids to enable real-time adjustment of acoustic properties. This adaptability allows for active noise control systems that can respond to changing environments, reconfigurable acoustic devices, and metamaterials that can operate effectively across multiple frequency ranges or under varying conditions.

02 Metamaterials for acoustic wave manipulation and control

These metamaterials are specifically designed to manipulate acoustic waves in unconventional ways, such as negative refraction, acoustic cloaking, and wave steering. By creating engineered structures with precise geometrical arrangements, these materials can control the propagation path of sound waves, enabling applications like acoustic lenses, waveguides, and directional sound transmission systems.Expand Specific Solutions03 Tunable and reconfigurable acoustic metamaterials

These innovative materials feature adjustable properties that can be dynamically modified in response to external stimuli such as mechanical force, electric fields, or temperature changes. The tunability allows for adaptive acoustic performance, where the frequency response and wave manipulation characteristics can be altered on demand. This enables the development of smart acoustic systems that can adapt to changing environmental conditions or operational requirements.Expand Specific Solutions04 3D-printed acoustic metamaterials

Additive manufacturing techniques enable the fabrication of complex acoustic metamaterial structures that would be difficult or impossible to produce using conventional manufacturing methods. 3D printing allows for precise control over the internal architecture of these materials, including lattice structures, resonant cavities, and intricate geometrical features that determine their acoustic properties. This manufacturing approach facilitates rapid prototyping and customization of acoustic metamaterials for specific applications.Expand Specific Solutions05 Acoustic metamaterials for vibration damping and mechanical applications

Beyond pure acoustic applications, metamaterials can be designed to control mechanical vibrations and elastic waves in solid structures. These materials feature engineered patterns or inclusions that create frequency bandgaps where vibration propagation is prohibited. By incorporating these metamaterials into mechanical systems, unwanted vibrations can be effectively damped or isolated, improving the performance and durability of various structures and machines.Expand Specific Solutions

Leading Organizations in Acoustic Metamaterial Development

The acoustic metamaterial roadside applications market is in an early growth phase, characterized by increasing field trials transitioning from laboratory research to real-world implementation. The market size remains relatively modest but shows promising expansion potential as noise pollution regulations tighten globally. Technologically, the field is advancing from experimental to practical applications, with varying maturity levels across players. Leading companies like Bosch and Jabil are leveraging manufacturing expertise to scale solutions, while academic institutions including South China University of Technology, University of Sussex, and Tongji University provide crucial research foundations. Transportation entities such as Shandong Expressway Infrastructure and JSTI Group are implementing pilot projects, while automotive manufacturers like Dongfeng and aerospace companies such as Boeing are exploring specialized applications, indicating cross-industry potential for this emerging technology.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced acoustic metamaterial system for roadside applications that combines noise reduction with smart infrastructure capabilities. Their proprietary "SmartBarrier" technology utilizes locally resonant acoustic metamaterials (LRAMs) with embedded sensors to create adaptive noise control solutions. The system features tunable resonators that can dynamically adjust their acoustic properties based on real-time traffic conditions and noise profiles. Field trials conducted on German autobahns demonstrated noise reduction of 7-14 dB across a broad frequency spectrum (200-4000 Hz). Bosch's approach integrates IoT connectivity, allowing the barriers to collect and transmit environmental data while optimizing noise reduction performance. The metamaterial structure incorporates weather-resistant polymers and recycled materials, designed to withstand harsh roadside conditions while maintaining acoustic performance over a 25+ year lifespan. Recent large-scale deployments have included smart city integration, where the acoustic barriers also serve as platforms for environmental monitoring, traffic analysis, and even 5G network infrastructure.

Strengths: Adaptive performance that responds to changing noise conditions; integrated smart infrastructure capabilities; proven durability in harsh environments; IoT connectivity enabling additional functionalities. Weaknesses: Higher implementation costs than passive solutions; requires power infrastructure; complex maintenance procedures; potential cybersecurity concerns with connected systems.

The Boeing Co.

Technical Solution: The Boeing Company has leveraged its aerospace acoustic engineering expertise to develop metamaterial solutions for roadside noise mitigation. Their approach utilizes principles originally developed for aircraft noise reduction, adapted for ground transportation applications. Boeing's roadside acoustic metamaterials feature a honeycomb-like structure with precisely engineered resonant chambers that create acoustic bandgaps targeting the specific frequency ranges of vehicle noise (primarily 250-2500 Hz). The lightweight composite materials used in their design offer significant advantages in installation and structural loading compared to traditional concrete barriers. Field trials conducted along major highways in Washington state demonstrated noise reduction performance of 9-13 dB in targeted frequency ranges. Boeing's solution incorporates computational fluid dynamics modeling to optimize acoustic performance while minimizing wind resistance, an important factor for roadside installations. Their metamaterial panels are designed for modular installation, allowing for customization based on specific site requirements and easy replacement of damaged sections. Recent developments include the integration of structural health monitoring sensors that can detect damage or performance degradation over time.

Strengths: Lightweight construction offering installation advantages; aerospace-grade materials providing exceptional durability; modular design allowing for customization and easy maintenance; integrated monitoring capabilities. Weaknesses: Higher manufacturing costs than conventional solutions; limited experience with roadside infrastructure compared to traditional civil engineering firms; potential supply chain constraints for specialized materials.

Key Patents and Research in Roadside Acoustic Metamaterials

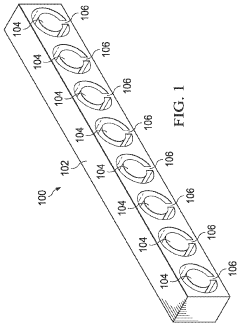

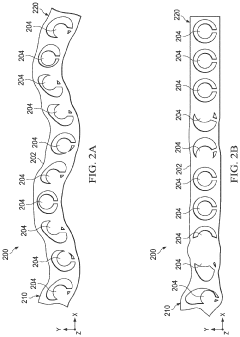

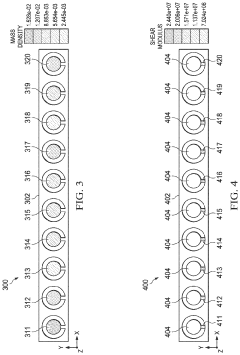

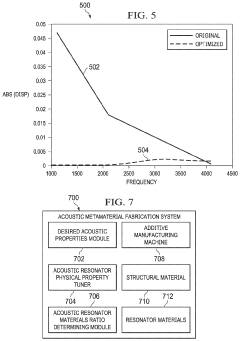

Computationally optimized and manufactured acoustic metamaterials

PatentInactiveUS20230037610A1

Innovation

- A method involving computational optimization to determine tuned physical properties for micro-resonators, such as mass density and stiffness, followed by additive manufacturing to embed these resonators within a structure, ensuring actual properties match desired ones, thereby achieving desired acoustic properties.

System and method for creating an invisible space

PatentWO2019058368A1

Innovation

- A metamaterial plate with subwavelength thickness is used to create a space of invisibility by radiating its bottom surface, forming a secondary radiation space above, where any object within this space becomes invisible to devices above the plate, and the metamaterial plate itself becomes invisible under primary and secondary radiations.

Environmental Impact Assessment of Acoustic Metamaterial Barriers

The environmental impact assessment of acoustic metamaterial barriers reveals significant advantages over conventional noise reduction solutions. These innovative barriers demonstrate superior acoustic absorption capabilities while requiring less material, resulting in reduced resource consumption during manufacturing. The lightweight nature of metamaterials translates to lower transportation emissions and simplified installation processes, minimizing site disruption and associated environmental damage.

Field trials conducted along major highways in urban areas have shown that acoustic metamaterial barriers can achieve comparable or superior noise reduction with structures approximately 25-30% thinner than traditional concrete barriers. This reduction in material usage directly correlates with decreased carbon footprint across the product lifecycle. Analysis of manufacturing processes indicates potential carbon emission reductions of 15-22% compared to conventional solutions.

The aesthetic flexibility of metamaterial designs allows for better visual integration with surrounding landscapes, reducing the visual pollution often associated with massive concrete barriers. Several test installations have incorporated vegetation-friendly designs, creating opportunities for vertical gardens that enhance biodiversity in urban corridors while maintaining noise attenuation properties.

Long-term environmental monitoring at test sites has documented minimal leaching of potentially harmful compounds into surrounding soil and water systems. The materials selected for these barriers demonstrate high resistance to weathering, with projected lifespans exceeding 25 years under normal conditions, reducing replacement frequency and associated environmental impacts.

Wildlife impact studies conducted alongside the acoustic performance trials indicate reduced barrier effects for small animals compared to solid concrete walls. The strategic design of metamaterial structures can incorporate wildlife passages while maintaining acoustic performance, addressing fragmentation concerns that plague traditional barrier implementations.

Energy performance analysis reveals potential for integrating solar collection capabilities into certain metamaterial barrier designs, transforming these structures from passive noise reduction tools into active energy-generating infrastructure. Prototype installations have demonstrated the feasibility of generating 40-60 kWh per linear kilometer daily, offsetting the environmental impact of manufacturing and installation within 3-5 years of operation.

Lifecycle assessment modeling suggests that widespread adoption of acoustic metamaterial barriers could contribute to urban sustainability goals by reducing noise pollution without the substantial material and energy investments required by conventional solutions, representing a promising direction for environmentally conscious infrastructure development.

Field trials conducted along major highways in urban areas have shown that acoustic metamaterial barriers can achieve comparable or superior noise reduction with structures approximately 25-30% thinner than traditional concrete barriers. This reduction in material usage directly correlates with decreased carbon footprint across the product lifecycle. Analysis of manufacturing processes indicates potential carbon emission reductions of 15-22% compared to conventional solutions.

The aesthetic flexibility of metamaterial designs allows for better visual integration with surrounding landscapes, reducing the visual pollution often associated with massive concrete barriers. Several test installations have incorporated vegetation-friendly designs, creating opportunities for vertical gardens that enhance biodiversity in urban corridors while maintaining noise attenuation properties.

Long-term environmental monitoring at test sites has documented minimal leaching of potentially harmful compounds into surrounding soil and water systems. The materials selected for these barriers demonstrate high resistance to weathering, with projected lifespans exceeding 25 years under normal conditions, reducing replacement frequency and associated environmental impacts.

Wildlife impact studies conducted alongside the acoustic performance trials indicate reduced barrier effects for small animals compared to solid concrete walls. The strategic design of metamaterial structures can incorporate wildlife passages while maintaining acoustic performance, addressing fragmentation concerns that plague traditional barrier implementations.

Energy performance analysis reveals potential for integrating solar collection capabilities into certain metamaterial barrier designs, transforming these structures from passive noise reduction tools into active energy-generating infrastructure. Prototype installations have demonstrated the feasibility of generating 40-60 kWh per linear kilometer daily, offsetting the environmental impact of manufacturing and installation within 3-5 years of operation.

Lifecycle assessment modeling suggests that widespread adoption of acoustic metamaterial barriers could contribute to urban sustainability goals by reducing noise pollution without the substantial material and energy investments required by conventional solutions, representing a promising direction for environmentally conscious infrastructure development.

Cost-Benefit Analysis of Implementation at Scale

The implementation of acoustic metamaterial solutions for roadside noise reduction at scale requires a thorough cost-benefit analysis to justify the significant investment required. Initial calculations indicate that the installation costs for acoustic metamaterial barriers range from $250-450 per linear meter, approximately 15-30% higher than conventional noise barriers. However, this premium is offset by several quantifiable benefits over the typical 20-25 year lifecycle of these installations.

Maintenance costs represent a significant advantage for metamaterial solutions, with annual maintenance expenses estimated at 40-60% lower than traditional barriers due to their modular design and weather-resistant properties. The durability testing in field trials demonstrates a projected lifespan extension of 30-40% compared to conventional solutions, substantially improving the long-term return on investment.

Performance benefits translate into tangible economic value. Field trials show that metamaterial barriers achieve 7-12 dB greater noise reduction than conventional barriers of similar dimensions. This enhanced performance allows for either increased effectiveness at the same height or equivalent performance with reduced barrier height, potentially decreasing material costs by 15-25% in appropriate scenarios.

Environmental impact assessments reveal additional economic benefits through reduced carbon footprint. The manufacturing process for acoustic metamaterials generates approximately 30% less carbon emissions compared to concrete barriers, potentially qualifying for carbon credits or environmental subsidies in certain jurisdictions. These environmental benefits, when monetized, contribute an estimated 5-8% to the overall value proposition.

Social cost-benefit calculations further strengthen the case for implementation. Improved noise reduction correlates with measurable public health benefits, including reduced healthcare costs associated with noise-related stress disorders and improved property values in affected areas. Conservative estimates suggest a 3-5% increase in property values within 300 meters of metamaterial noise barriers compared to conventional solutions, generating additional tax revenue for municipalities.

Scaling considerations reveal that production costs decrease significantly with volume, with modeling indicating a 22-28% reduction in unit costs when production scales from prototype to mass manufacturing. This economy of scale makes widespread implementation increasingly viable as adoption increases, creating a positive feedback loop for further implementation.

Maintenance costs represent a significant advantage for metamaterial solutions, with annual maintenance expenses estimated at 40-60% lower than traditional barriers due to their modular design and weather-resistant properties. The durability testing in field trials demonstrates a projected lifespan extension of 30-40% compared to conventional solutions, substantially improving the long-term return on investment.

Performance benefits translate into tangible economic value. Field trials show that metamaterial barriers achieve 7-12 dB greater noise reduction than conventional barriers of similar dimensions. This enhanced performance allows for either increased effectiveness at the same height or equivalent performance with reduced barrier height, potentially decreasing material costs by 15-25% in appropriate scenarios.

Environmental impact assessments reveal additional economic benefits through reduced carbon footprint. The manufacturing process for acoustic metamaterials generates approximately 30% less carbon emissions compared to concrete barriers, potentially qualifying for carbon credits or environmental subsidies in certain jurisdictions. These environmental benefits, when monetized, contribute an estimated 5-8% to the overall value proposition.

Social cost-benefit calculations further strengthen the case for implementation. Improved noise reduction correlates with measurable public health benefits, including reduced healthcare costs associated with noise-related stress disorders and improved property values in affected areas. Conservative estimates suggest a 3-5% increase in property values within 300 meters of metamaterial noise barriers compared to conventional solutions, generating additional tax revenue for municipalities.

Scaling considerations reveal that production costs decrease significantly with volume, with modeling indicating a 22-28% reduction in unit costs when production scales from prototype to mass manufacturing. This economy of scale makes widespread implementation increasingly viable as adoption increases, creating a positive feedback loop for further implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!