Measurement Protocols For Acoustic Metamaterial Insertion Loss

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterial Measurement Background & Objectives

Acoustic metamaterials represent a revolutionary advancement in sound engineering, offering unprecedented control over acoustic wave propagation through engineered structures. The development of these materials has evolved significantly since their theoretical conception in the early 2000s, progressing from mathematical models to practical implementations across various industries. This technological evolution has been driven by the growing demand for effective noise control solutions in urban environments, transportation systems, and industrial settings where traditional acoustic treatments prove inadequate.

The measurement of insertion loss—the reduction in sound pressure level at a specific location when an acoustic treatment is introduced—serves as a critical performance metric for acoustic metamaterials. However, standardized measurement protocols specifically designed for these novel materials remain underdeveloped, creating significant challenges for consistent evaluation and comparison across research institutions and industrial applications.

Current measurement approaches often borrow methodologies from traditional acoustic material testing, which fail to capture the unique wave manipulation mechanisms of metamaterials, including negative refraction, acoustic cloaking, and subwavelength focusing. These conventional methods typically assume linear behavior and homogeneous material properties, assumptions that do not hold for the complex, often nonlinear response of acoustic metamaterials.

The primary objective of this technical research is to establish comprehensive, standardized measurement protocols specifically tailored for quantifying the insertion loss of acoustic metamaterials. These protocols must account for the frequency-dependent behavior, directional sensitivity, and potentially nonlinear responses characteristic of metamaterial structures.

Additionally, this research aims to bridge the gap between laboratory measurements and real-world performance by developing testing methodologies that can predict in-situ effectiveness from controlled laboratory experiments. This translation is particularly challenging for metamaterials, whose performance can vary significantly between idealized and practical environments.

The development of these measurement protocols will facilitate meaningful comparisons between different metamaterial designs, accelerate the validation of theoretical models, and provide industry with reliable metrics for product development and quality control. Furthermore, standardized measurement approaches will support regulatory compliance and certification processes as acoustic metamaterials transition from research curiosities to commercial products.

By establishing clear measurement standards, this research will contribute to the broader adoption of acoustic metamaterial technologies across industries, ultimately advancing noise control capabilities beyond the limitations of conventional materials and supporting the next generation of acoustic engineering solutions.

The measurement of insertion loss—the reduction in sound pressure level at a specific location when an acoustic treatment is introduced—serves as a critical performance metric for acoustic metamaterials. However, standardized measurement protocols specifically designed for these novel materials remain underdeveloped, creating significant challenges for consistent evaluation and comparison across research institutions and industrial applications.

Current measurement approaches often borrow methodologies from traditional acoustic material testing, which fail to capture the unique wave manipulation mechanisms of metamaterials, including negative refraction, acoustic cloaking, and subwavelength focusing. These conventional methods typically assume linear behavior and homogeneous material properties, assumptions that do not hold for the complex, often nonlinear response of acoustic metamaterials.

The primary objective of this technical research is to establish comprehensive, standardized measurement protocols specifically tailored for quantifying the insertion loss of acoustic metamaterials. These protocols must account for the frequency-dependent behavior, directional sensitivity, and potentially nonlinear responses characteristic of metamaterial structures.

Additionally, this research aims to bridge the gap between laboratory measurements and real-world performance by developing testing methodologies that can predict in-situ effectiveness from controlled laboratory experiments. This translation is particularly challenging for metamaterials, whose performance can vary significantly between idealized and practical environments.

The development of these measurement protocols will facilitate meaningful comparisons between different metamaterial designs, accelerate the validation of theoretical models, and provide industry with reliable metrics for product development and quality control. Furthermore, standardized measurement approaches will support regulatory compliance and certification processes as acoustic metamaterials transition from research curiosities to commercial products.

By establishing clear measurement standards, this research will contribute to the broader adoption of acoustic metamaterial technologies across industries, ultimately advancing noise control capabilities beyond the limitations of conventional materials and supporting the next generation of acoustic engineering solutions.

Market Applications & Demand Analysis

The acoustic metamaterial market is experiencing significant growth driven by increasing demand for advanced noise control solutions across multiple industries. The global market for acoustic metamaterials was valued at approximately $560 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 13.5%. This growth trajectory underscores the expanding commercial interest in quantifiable insertion loss measurement protocols.

The automotive sector represents one of the largest application areas, with manufacturers seeking lightweight noise reduction solutions to meet stringent vehicle noise regulations while supporting fuel efficiency goals. Accurate insertion loss measurements are critical for automotive engineers to validate metamaterial performance in reducing cabin noise without adding significant weight.

The aerospace industry constitutes another major market segment, where acoustic metamaterials offer potential weight savings of 30-40% compared to traditional sound insulation materials. Airlines and aircraft manufacturers require standardized measurement protocols to verify insertion loss claims before implementing these materials in commercial aircraft, where weight reduction directly impacts fuel consumption and operating costs.

Building construction and architectural acoustics represent a rapidly growing application area, with the green building movement driving demand for thinner, more effective sound insulation solutions. Architects and builders increasingly specify acoustic metamaterials for walls, ceilings, and floors, but require reliable insertion loss data to justify the premium cost over conventional materials.

Consumer electronics manufacturers have begun incorporating acoustic metamaterials in product designs, particularly for speakers, headphones, and microphone isolation. The ability to accurately measure and compare insertion loss across different metamaterial configurations is essential for product development and quality control in this competitive sector.

Industrial machinery and equipment manufacturers represent an emerging market segment, seeking solutions for machinery noise reduction to comply with workplace safety regulations. Standardized measurement protocols for insertion loss would accelerate adoption in this sector by providing comparable performance metrics across different metamaterial solutions.

Healthcare facilities constitute a specialized but growing application area, where acoustic metamaterials can improve patient comfort and privacy. Hospital administrators and healthcare facility designers require validated insertion loss measurements to justify investments in these advanced acoustic solutions.

The defense sector has shown increasing interest in acoustic metamaterials for stealth applications and personnel protection, with specialized requirements for insertion loss measurements across specific frequency ranges relevant to military applications.

The automotive sector represents one of the largest application areas, with manufacturers seeking lightweight noise reduction solutions to meet stringent vehicle noise regulations while supporting fuel efficiency goals. Accurate insertion loss measurements are critical for automotive engineers to validate metamaterial performance in reducing cabin noise without adding significant weight.

The aerospace industry constitutes another major market segment, where acoustic metamaterials offer potential weight savings of 30-40% compared to traditional sound insulation materials. Airlines and aircraft manufacturers require standardized measurement protocols to verify insertion loss claims before implementing these materials in commercial aircraft, where weight reduction directly impacts fuel consumption and operating costs.

Building construction and architectural acoustics represent a rapidly growing application area, with the green building movement driving demand for thinner, more effective sound insulation solutions. Architects and builders increasingly specify acoustic metamaterials for walls, ceilings, and floors, but require reliable insertion loss data to justify the premium cost over conventional materials.

Consumer electronics manufacturers have begun incorporating acoustic metamaterials in product designs, particularly for speakers, headphones, and microphone isolation. The ability to accurately measure and compare insertion loss across different metamaterial configurations is essential for product development and quality control in this competitive sector.

Industrial machinery and equipment manufacturers represent an emerging market segment, seeking solutions for machinery noise reduction to comply with workplace safety regulations. Standardized measurement protocols for insertion loss would accelerate adoption in this sector by providing comparable performance metrics across different metamaterial solutions.

Healthcare facilities constitute a specialized but growing application area, where acoustic metamaterials can improve patient comfort and privacy. Hospital administrators and healthcare facility designers require validated insertion loss measurements to justify investments in these advanced acoustic solutions.

The defense sector has shown increasing interest in acoustic metamaterials for stealth applications and personnel protection, with specialized requirements for insertion loss measurements across specific frequency ranges relevant to military applications.

Current Challenges in Insertion Loss Measurement

Despite significant advancements in acoustic metamaterial research, the measurement of insertion loss presents several persistent challenges that impede standardization and reliable performance evaluation. The primary challenge stems from the inherent complexity of acoustic metamaterial structures, which often feature intricate geometries and resonant elements operating across multiple scales. These complexities make it difficult to establish consistent measurement protocols that accurately capture the true insertion loss performance.

Environmental factors significantly impact measurement accuracy, with ambient temperature, humidity, and air pressure all influencing acoustic wave propagation. These variables can introduce substantial measurement uncertainties, particularly for metamaterials designed to operate within narrow frequency bands or specific environmental conditions. The lack of controlled testing environments in many research facilities further compounds this issue.

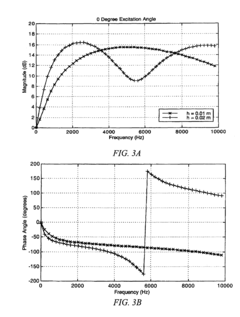

Frequency-dependent behavior represents another major challenge. Acoustic metamaterials typically exhibit non-linear responses across different frequency ranges, with insertion loss characteristics varying dramatically between low, mid, and high frequencies. Current measurement techniques often fail to adequately capture this spectral complexity, leading to incomplete performance assessments that may miss critical operational ranges.

Boundary condition effects create additional complications, as the performance of acoustic metamaterials can change significantly depending on how they interface with surrounding structures. Edge effects, mounting configurations, and sample size limitations all contribute to measurement inconsistencies that make direct comparisons between different research studies problematic.

The absence of standardized reference samples presents a fundamental obstacle to establishing reliable measurement protocols. Unlike traditional acoustic materials, metamaterials lack universally accepted reference standards against which new designs can be benchmarked, resulting in isolated measurement approaches that yield results difficult to validate across different laboratories.

Instrumentation limitations further restrict measurement capabilities, with many facilities lacking the specialized equipment needed to accurately characterize metamaterial performance across relevant frequency ranges and spatial dimensions. The high cost of precision acoustic measurement systems places additional constraints on comprehensive testing, particularly for smaller research groups.

Reproducibility issues persist throughout the field, with many published studies reporting insertion loss measurements that prove difficult to replicate independently. This challenge undermines confidence in reported performance metrics and hinders the translation of laboratory prototypes into practical applications where reliable performance predictions are essential.

Environmental factors significantly impact measurement accuracy, with ambient temperature, humidity, and air pressure all influencing acoustic wave propagation. These variables can introduce substantial measurement uncertainties, particularly for metamaterials designed to operate within narrow frequency bands or specific environmental conditions. The lack of controlled testing environments in many research facilities further compounds this issue.

Frequency-dependent behavior represents another major challenge. Acoustic metamaterials typically exhibit non-linear responses across different frequency ranges, with insertion loss characteristics varying dramatically between low, mid, and high frequencies. Current measurement techniques often fail to adequately capture this spectral complexity, leading to incomplete performance assessments that may miss critical operational ranges.

Boundary condition effects create additional complications, as the performance of acoustic metamaterials can change significantly depending on how they interface with surrounding structures. Edge effects, mounting configurations, and sample size limitations all contribute to measurement inconsistencies that make direct comparisons between different research studies problematic.

The absence of standardized reference samples presents a fundamental obstacle to establishing reliable measurement protocols. Unlike traditional acoustic materials, metamaterials lack universally accepted reference standards against which new designs can be benchmarked, resulting in isolated measurement approaches that yield results difficult to validate across different laboratories.

Instrumentation limitations further restrict measurement capabilities, with many facilities lacking the specialized equipment needed to accurately characterize metamaterial performance across relevant frequency ranges and spatial dimensions. The high cost of precision acoustic measurement systems places additional constraints on comprehensive testing, particularly for smaller research groups.

Reproducibility issues persist throughout the field, with many published studies reporting insertion loss measurements that prove difficult to replicate independently. This challenge undermines confidence in reported performance metrics and hinders the translation of laboratory prototypes into practical applications where reliable performance predictions are essential.

Standard Measurement Methodologies & Setups

01 Metamaterial structures for enhanced acoustic insertion loss

Acoustic metamaterials with specific structural designs can significantly enhance insertion loss across targeted frequency ranges. These structures typically incorporate resonant elements, periodic arrangements, or layered compositions that manipulate sound wave propagation through reflection, absorption, or dissipation mechanisms. The engineered structures can achieve insertion loss performance exceeding conventional materials of similar mass and thickness, making them valuable for noise control applications where space and weight constraints exist.- Metamaterial structures for enhanced acoustic insertion loss: Acoustic metamaterials with specific structural designs can significantly enhance insertion loss across targeted frequency ranges. These structures typically incorporate resonant elements, periodic arrangements, or layered configurations that manipulate acoustic wave propagation. By engineering the geometry and material properties of these metamaterials, sound waves can be effectively attenuated through mechanisms such as destructive interference, energy dissipation, and wave redirection, resulting in superior insertion loss performance compared to conventional materials.

- Frequency-selective acoustic metamaterial barriers: Specialized acoustic metamaterials can be designed to provide selective frequency filtering, allowing for targeted insertion loss at specific problematic frequencies while maintaining acoustic transparency at others. These frequency-selective barriers incorporate resonant cavities, Helmholtz resonators, or membrane-type structures that are tuned to respond to particular frequency bands. This selective approach enables noise control solutions that address specific environmental or industrial noise issues without completely blocking all sound transmission.

- Adaptive and tunable acoustic metamaterials: Adaptive acoustic metamaterials incorporate mechanisms for real-time adjustment of their acoustic properties, allowing for dynamic control of insertion loss. These systems may utilize smart materials, mechanical actuators, or electronic control systems to modify structural parameters in response to changing noise conditions. By actively tuning resonant frequencies or damping characteristics, these metamaterials can maintain optimal insertion loss performance across varying operational conditions or adapt to different noise profiles.

- Lightweight and compact metamaterial solutions: Advanced acoustic metamaterial designs achieve high insertion loss while maintaining minimal thickness and weight, addressing space and mass constraints in applications such as aerospace, automotive, and portable equipment. These solutions leverage subwavelength structures, local resonance phenomena, and novel material combinations to create efficient sound barriers that outperform traditional materials of equivalent mass. The reduced profile and weight make these metamaterials particularly valuable for applications where space and weight efficiency are critical considerations.

- Multifunctional acoustic metamaterials: Multifunctional acoustic metamaterials combine insertion loss capabilities with additional beneficial properties such as thermal insulation, vibration damping, or structural support. These integrated solutions address multiple engineering challenges simultaneously through careful material selection and structural design. By incorporating features that serve multiple purposes, these metamaterials offer space-efficient and cost-effective alternatives to multiple separate systems, while maintaining high acoustic insertion loss performance across targeted frequency ranges.

02 Frequency-selective acoustic metamaterials

Specialized acoustic metamaterials can be designed to provide selective insertion loss at specific frequency bands while allowing other frequencies to pass through. These frequency-selective structures utilize resonant cavities, Helmholtz resonators, or membrane-type elements that target particular sound frequencies. This selective approach enables the development of acoustic filters that can block problematic noise frequencies while maintaining acoustic transparency at desired frequencies, offering advantages in applications requiring communication or monitoring while providing noise reduction.Expand Specific Solutions03 Tunable and adaptive acoustic metamaterials

Tunable acoustic metamaterials incorporate mechanisms that allow adjustment of their insertion loss characteristics in response to changing requirements. These adaptive systems may utilize mechanical deformation, electrical control, magnetic actuation, or fluid-filled components to modify their acoustic properties. The ability to tune insertion loss performance enables dynamic noise control solutions that can respond to varying environmental conditions or operational states, providing optimal acoustic performance across different scenarios.Expand Specific Solutions04 Lightweight acoustic metamaterials for high insertion loss

Advanced lightweight acoustic metamaterials achieve high insertion loss while maintaining minimal mass and thickness. These designs often incorporate micro-perforated panels, porous materials with engineered pore structures, or composite arrangements that maximize acoustic performance per unit weight. The lightweight nature of these metamaterials makes them particularly valuable for transportation applications, portable equipment, and aerospace systems where weight reduction is critical while maintaining effective noise control performance.Expand Specific Solutions05 Broadband acoustic metamaterials for insertion loss

Broadband acoustic metamaterials are designed to provide effective insertion loss across wide frequency ranges rather than just narrow bands. These structures typically combine multiple resonant mechanisms, gradient properties, or hierarchical arrangements to address different wavelengths simultaneously. By achieving insertion loss across broader spectra, these metamaterials offer more comprehensive noise control solutions for complex acoustic environments containing varied noise sources and frequency components.Expand Specific Solutions

Leading Research Institutions & Industry Players

The acoustic metamaterial insertion loss measurement protocols market is in its growth phase, characterized by increasing research activities and emerging commercial applications. The market size is expanding as industries recognize the potential of acoustic metamaterials for noise control solutions, with projections showing significant growth in the next five years. Technologically, the field is advancing rapidly but remains in mid-maturity, with academic institutions leading development. Key players include research powerhouses like CNRS, MIT, and Zhejiang University establishing fundamental protocols, while companies such as Murata Manufacturing, W.L. Gore, and Nissan are developing practical applications. Government entities including the US Government and industrial players like Chevron and Schlumberger are investing in standardization efforts, indicating growing commercial interest in this specialized acoustic technology field.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed comprehensive measurement protocols for acoustic metamaterial insertion loss that combine both impedance tube and reverberation chamber methodologies. Their approach utilizes a modified four-microphone transfer matrix method to characterize metamaterial performance across various frequency ranges. The protocol incorporates both normal and oblique incidence measurements to provide a complete acoustic profile. CNRS researchers have established standardized procedures that account for sample mounting conditions, edge effects, and background noise—critical factors that can significantly impact measurement accuracy. Their methodology includes precise calibration techniques and uncertainty analysis frameworks that have been validated through round-robin testing across multiple laboratories, ensuring reproducibility of results across different measurement setups.

Strengths: Highly standardized and reproducible methodology with robust validation across multiple laboratories. Comprehensive approach addressing both normal and oblique incidence measurements. Weaknesses: Equipment-intensive protocols requiring specialized facilities and expertise, potentially limiting accessibility for smaller research groups or companies.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced measurement protocols for acoustic metamaterial insertion loss that integrate computational modeling with experimental validation. Their approach employs a hybrid methodology combining near-field acoustic holography with 3D laser vibrometry to map the complete acoustic field interaction with metamaterials. MIT's protocol uniquely addresses the challenges of characterizing non-linear and active acoustic metamaterials through time-domain measurements that capture transient responses. Their system incorporates automated robotic positioning systems for precise and repeatable microphone placement, eliminating human error in measurement positioning. The protocol includes specialized algorithms for separating direct and reflected sound fields, allowing for accurate insertion loss measurements even in non-anechoic environments. MIT researchers have also developed calibration procedures specifically designed for the unique phase relationships in metamaterial structures, ensuring accurate characterization of these complex acoustic systems.

Strengths: Exceptional precision in characterizing complex metamaterial behaviors including non-linear and active systems. Integration of computational modeling with experimental validation provides comprehensive understanding. Weaknesses: Extremely sophisticated equipment requirements and complex data processing needs create high barriers to entry and implementation costs.

Key Technical Innovations in Measurement Accuracy

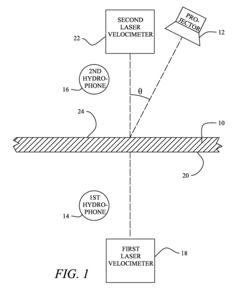

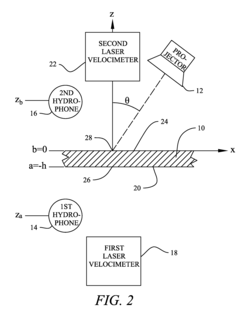

Inverse method to calculate material properties using an insertion loss test

PatentInactiveUS7584060B2

Innovation

- An inverse method is developed that combines normal wall movement measurements from insertion loss tests to calculate material properties such as Young's modulus, shear modulus, and Poisson's ratio, using a linear inverse method and requiring multiple samples of varying thickness to derive closed-form solutions from test data.

A method and apparatus to attain acoustic transmission loss using metamaterial

PatentActiveIN202311063572A

Innovation

- A method and apparatus using a scatterer array in a fluid matrix material, where the scatterers move angularly and radially to form a dynamic acoustic barrier, allowing for tunable frequency response and operation beyond air as a matrix material.

Standardization & Certification Requirements

The standardization and certification landscape for acoustic metamaterial insertion loss measurement remains in a developmental phase, with significant gaps in established protocols. Currently, ISO 10140 and ASTM E90 standards, which govern sound insulation measurements for building elements, serve as reference points but lack specific provisions for metamaterial characterization. This absence creates challenges for industry-wide adoption and comparative analysis of acoustic metamaterial performance.

Regulatory bodies including ISO, ASTM International, and the International Electrotechnical Commission (IEC) have begun preliminary discussions on developing dedicated standards. The European Committee for Standardization (CEN) has established a technical committee exploring measurement methodologies specifically for novel acoustic materials, with anticipated draft standards expected within the next 24-36 months.

Certification requirements present additional complexity due to the multi-physics nature of acoustic metamaterials. Current certification processes typically require validation across multiple parameters including frequency-dependent insertion loss, durability under environmental conditions, and consistency in manufacturing. The absence of standardized test methods necessitates case-by-case evaluation approaches, significantly increasing certification costs and timelines.

Industry stakeholders have formed the Acoustic Metamaterial Consortium (AMC) to accelerate standardization efforts. Their proposed framework includes three-tiered testing protocols: laboratory characterization, semi-anechoic chamber validation, and in-situ performance verification. This approach aims to establish minimum performance thresholds across different application domains including architectural acoustics, transportation noise mitigation, and industrial sound control.

Regulatory compliance presents another dimension of complexity. In the European Union, acoustic metamaterials intended for building applications must conform to Construction Products Regulation (CPR) requirements, while those for transportation applications face separate regulatory frameworks under automotive and aerospace directives. The U.S. market presents different challenges with state-level variations in acoustic performance requirements.

For market entry, manufacturers currently navigate a fragmented landscape of third-party testing laboratories offering customized validation services. Organizations including Underwriters Laboratories (UL), TÜV, and national metrology institutes have begun developing specialized testing capabilities, though methodological consistency remains problematic without unified standards.

The path toward comprehensive standardization will likely require collaborative efforts between academic research institutions, industry players, and regulatory bodies to establish consensus on measurement protocols that accurately capture the unique performance characteristics of acoustic metamaterials across their intended application environments.

Regulatory bodies including ISO, ASTM International, and the International Electrotechnical Commission (IEC) have begun preliminary discussions on developing dedicated standards. The European Committee for Standardization (CEN) has established a technical committee exploring measurement methodologies specifically for novel acoustic materials, with anticipated draft standards expected within the next 24-36 months.

Certification requirements present additional complexity due to the multi-physics nature of acoustic metamaterials. Current certification processes typically require validation across multiple parameters including frequency-dependent insertion loss, durability under environmental conditions, and consistency in manufacturing. The absence of standardized test methods necessitates case-by-case evaluation approaches, significantly increasing certification costs and timelines.

Industry stakeholders have formed the Acoustic Metamaterial Consortium (AMC) to accelerate standardization efforts. Their proposed framework includes three-tiered testing protocols: laboratory characterization, semi-anechoic chamber validation, and in-situ performance verification. This approach aims to establish minimum performance thresholds across different application domains including architectural acoustics, transportation noise mitigation, and industrial sound control.

Regulatory compliance presents another dimension of complexity. In the European Union, acoustic metamaterials intended for building applications must conform to Construction Products Regulation (CPR) requirements, while those for transportation applications face separate regulatory frameworks under automotive and aerospace directives. The U.S. market presents different challenges with state-level variations in acoustic performance requirements.

For market entry, manufacturers currently navigate a fragmented landscape of third-party testing laboratories offering customized validation services. Organizations including Underwriters Laboratories (UL), TÜV, and national metrology institutes have begun developing specialized testing capabilities, though methodological consistency remains problematic without unified standards.

The path toward comprehensive standardization will likely require collaborative efforts between academic research institutions, industry players, and regulatory bodies to establish consensus on measurement protocols that accurately capture the unique performance characteristics of acoustic metamaterials across their intended application environments.

Uncertainty Analysis & Error Mitigation Strategies

Measurement uncertainty represents a critical challenge in acoustic metamaterial insertion loss evaluation, necessitating rigorous analysis methodologies. Primary uncertainty sources include environmental factors (ambient noise, temperature fluctuations, humidity variations), instrumentation limitations (microphone sensitivity drift, analyzer frequency resolution, calibration accuracy), and experimental setup inconsistencies (specimen mounting variations, edge diffraction effects, sample-to-sample variability). These factors can significantly impact measurement reliability, with combined uncertainties potentially reaching 3-5 dB in critical frequency bands.

Statistical approaches for quantifying measurement uncertainty involve repeated measurements under controlled conditions to establish confidence intervals. The Guide to the Expression of Uncertainty in Measurement (GUM) framework provides standardized procedures for calculating combined standard uncertainties through sensitivity coefficients and probability distributions. Monte Carlo simulations offer complementary approaches for complex measurement scenarios where analytical solutions prove challenging.

Error mitigation strategies encompass both procedural and analytical techniques. Environmental control measures include anechoic or semi-anechoic testing environments with temperature and humidity regulation. Regular calibration protocols with traceable reference standards help minimize instrumentation-related uncertainties. Standardized mounting fixtures and boundary condition management reduce setup variability, while differential measurement techniques can compensate for systematic errors.

Advanced signal processing techniques further enhance measurement accuracy. Time-gating methods effectively eliminate unwanted reflections, while coherence-based analysis identifies and mitigates noise contamination. Frequency-domain averaging reduces random error components, and transfer function approaches help isolate the metamaterial's acoustic properties from measurement system characteristics.

Documentation practices represent a crucial component of uncertainty management. Comprehensive measurement reports should include detailed uncertainty budgets, traceability information, and validation against reference materials. Interlaboratory comparison studies provide external validation of measurement protocols, establishing reproducibility limits across different testing facilities and equipment configurations.

Future developments in uncertainty reduction will likely leverage machine learning algorithms for automated error detection and compensation. Real-time uncertainty estimation techniques promise to provide immediate feedback during measurements, allowing for adaptive testing protocols that minimize uncertainty in critical frequency ranges where metamaterial performance is most significant.

Statistical approaches for quantifying measurement uncertainty involve repeated measurements under controlled conditions to establish confidence intervals. The Guide to the Expression of Uncertainty in Measurement (GUM) framework provides standardized procedures for calculating combined standard uncertainties through sensitivity coefficients and probability distributions. Monte Carlo simulations offer complementary approaches for complex measurement scenarios where analytical solutions prove challenging.

Error mitigation strategies encompass both procedural and analytical techniques. Environmental control measures include anechoic or semi-anechoic testing environments with temperature and humidity regulation. Regular calibration protocols with traceable reference standards help minimize instrumentation-related uncertainties. Standardized mounting fixtures and boundary condition management reduce setup variability, while differential measurement techniques can compensate for systematic errors.

Advanced signal processing techniques further enhance measurement accuracy. Time-gating methods effectively eliminate unwanted reflections, while coherence-based analysis identifies and mitigates noise contamination. Frequency-domain averaging reduces random error components, and transfer function approaches help isolate the metamaterial's acoustic properties from measurement system characteristics.

Documentation practices represent a crucial component of uncertainty management. Comprehensive measurement reports should include detailed uncertainty budgets, traceability information, and validation against reference materials. Interlaboratory comparison studies provide external validation of measurement protocols, establishing reproducibility limits across different testing facilities and equipment configurations.

Future developments in uncertainty reduction will likely leverage machine learning algorithms for automated error detection and compensation. Real-time uncertainty estimation techniques promise to provide immediate feedback during measurements, allowing for adaptive testing protocols that minimize uncertainty in critical frequency ranges where metamaterial performance is most significant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!