Acoustic Metamaterials For HVAC Noise Reduction: Case Studies

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterials Evolution and Noise Reduction Goals

Acoustic metamaterials represent a revolutionary advancement in noise control engineering, emerging from theoretical concepts in the early 2000s to practical applications in the 2020s. These engineered structures manipulate sound waves through their unique physical properties rather than traditional mass-based absorption, offering unprecedented control over acoustic energy. The evolution of acoustic metamaterials has been marked by significant breakthroughs in material science, computational modeling, and manufacturing techniques, enabling increasingly sophisticated designs that can target specific frequency ranges with remarkable precision.

The historical trajectory of acoustic metamaterial development began with simple resonator-based structures and has progressed to complex architectures including sonic crystals, membrane-type acoustic metamaterials, and space-coiling metamaterials. Each generation has expanded the functional capabilities, moving from narrow-band noise reduction to broadband solutions capable of addressing the complex acoustic signatures typical of HVAC systems.

In HVAC applications, noise reduction goals have become increasingly stringent as awareness of the health impacts of noise pollution has grown. Modern building standards now specify maximum allowable noise levels for different environments, with particularly strict requirements for healthcare facilities, educational institutions, and high-end residential buildings. The primary technical targets include reducing low-frequency rumble (20-200 Hz) from air handlers, mid-frequency aerodynamic noise (200-1000 Hz) from airflow, and high-frequency tonal components (1000-4000 Hz) from motors and bearings.

Current industry benchmarks aim for HVAC noise reduction of 15-25 dBA compared to untreated systems, with minimal impact on system efficiency and airflow. Advanced goals include achieving these reductions while maintaining or even improving thermal performance, minimizing spatial requirements, and ensuring long-term durability under varying temperature and humidity conditions.

The integration of acoustic metamaterials into HVAC systems represents a paradigm shift from traditional approaches that rely on bulky sound attenuators, lined ducts, and vibration isolators. The ultimate objective is to develop metamaterial solutions that can be retrofitted to existing systems or incorporated into new designs with minimal modifications to standard components, providing cost-effective noise reduction without compromising system performance.

Recent research has established specific technical parameters for metamaterial-based HVAC noise solutions, including transmission loss targets exceeding 30 dB in critical frequency bands, insertion loss consistency across varying airflow rates, and resilience to contamination from particulates in air streams. These quantifiable goals provide clear metrics for evaluating the success of metamaterial implementations in real-world HVAC applications.

The historical trajectory of acoustic metamaterial development began with simple resonator-based structures and has progressed to complex architectures including sonic crystals, membrane-type acoustic metamaterials, and space-coiling metamaterials. Each generation has expanded the functional capabilities, moving from narrow-band noise reduction to broadband solutions capable of addressing the complex acoustic signatures typical of HVAC systems.

In HVAC applications, noise reduction goals have become increasingly stringent as awareness of the health impacts of noise pollution has grown. Modern building standards now specify maximum allowable noise levels for different environments, with particularly strict requirements for healthcare facilities, educational institutions, and high-end residential buildings. The primary technical targets include reducing low-frequency rumble (20-200 Hz) from air handlers, mid-frequency aerodynamic noise (200-1000 Hz) from airflow, and high-frequency tonal components (1000-4000 Hz) from motors and bearings.

Current industry benchmarks aim for HVAC noise reduction of 15-25 dBA compared to untreated systems, with minimal impact on system efficiency and airflow. Advanced goals include achieving these reductions while maintaining or even improving thermal performance, minimizing spatial requirements, and ensuring long-term durability under varying temperature and humidity conditions.

The integration of acoustic metamaterials into HVAC systems represents a paradigm shift from traditional approaches that rely on bulky sound attenuators, lined ducts, and vibration isolators. The ultimate objective is to develop metamaterial solutions that can be retrofitted to existing systems or incorporated into new designs with minimal modifications to standard components, providing cost-effective noise reduction without compromising system performance.

Recent research has established specific technical parameters for metamaterial-based HVAC noise solutions, including transmission loss targets exceeding 30 dB in critical frequency bands, insertion loss consistency across varying airflow rates, and resilience to contamination from particulates in air streams. These quantifiable goals provide clear metrics for evaluating the success of metamaterial implementations in real-world HVAC applications.

HVAC Noise Control Market Analysis

The global HVAC noise control market is experiencing robust growth, valued at approximately $7.3 billion in 2022 and projected to reach $10.5 billion by 2028, representing a compound annual growth rate (CAGR) of 6.2%. This growth is primarily driven by increasing awareness of noise pollution impacts on health and productivity, alongside stricter regulatory frameworks governing acceptable noise levels in residential, commercial, and industrial environments.

The market segmentation reveals distinct patterns across applications and regions. Commercial buildings constitute the largest market segment (38%), followed by industrial facilities (32%), residential buildings (22%), and transportation infrastructure (8%). Geographically, North America leads with 35% market share, followed by Europe (28%), Asia-Pacific (25%), and rest of the world (12%). The Asia-Pacific region demonstrates the highest growth potential with an anticipated CAGR of 8.7% through 2028, attributed to rapid urbanization and infrastructure development.

Customer demand analysis indicates shifting priorities, with 73% of building managers now ranking noise reduction as a "high priority" consideration when selecting HVAC systems, compared to just 47% five years ago. This shift correlates with growing evidence linking noise pollution to decreased productivity, increased stress levels, and negative health outcomes in occupational settings.

The competitive landscape features established players like Kinetics Noise Control, Vibro-Acoustics, and IAC Acoustics dominating with combined market share of 42%. However, specialized firms focusing exclusively on metamaterial-based solutions are gaining traction, with companies like Acoustic Metamaterials Group and Metasonics experiencing revenue growth exceeding 25% annually over the past three years.

Price sensitivity analysis reveals willingness to pay premiums of 15-20% for solutions demonstrating superior noise reduction capabilities, particularly in high-end commercial and healthcare applications. However, residential and small business segments remain highly price-sensitive, with acceptable premiums limited to 5-8% over conventional solutions.

Distribution channels are evolving, with direct sales to HVAC system manufacturers representing 45% of market volume, followed by construction contractors (30%), retrofitting specialists (15%), and direct-to-consumer channels (10%). The retrofit market presents significant growth opportunities, with an estimated 65% of existing commercial buildings requiring noise reduction improvements to meet current standards.

The market segmentation reveals distinct patterns across applications and regions. Commercial buildings constitute the largest market segment (38%), followed by industrial facilities (32%), residential buildings (22%), and transportation infrastructure (8%). Geographically, North America leads with 35% market share, followed by Europe (28%), Asia-Pacific (25%), and rest of the world (12%). The Asia-Pacific region demonstrates the highest growth potential with an anticipated CAGR of 8.7% through 2028, attributed to rapid urbanization and infrastructure development.

Customer demand analysis indicates shifting priorities, with 73% of building managers now ranking noise reduction as a "high priority" consideration when selecting HVAC systems, compared to just 47% five years ago. This shift correlates with growing evidence linking noise pollution to decreased productivity, increased stress levels, and negative health outcomes in occupational settings.

The competitive landscape features established players like Kinetics Noise Control, Vibro-Acoustics, and IAC Acoustics dominating with combined market share of 42%. However, specialized firms focusing exclusively on metamaterial-based solutions are gaining traction, with companies like Acoustic Metamaterials Group and Metasonics experiencing revenue growth exceeding 25% annually over the past three years.

Price sensitivity analysis reveals willingness to pay premiums of 15-20% for solutions demonstrating superior noise reduction capabilities, particularly in high-end commercial and healthcare applications. However, residential and small business segments remain highly price-sensitive, with acceptable premiums limited to 5-8% over conventional solutions.

Distribution channels are evolving, with direct sales to HVAC system manufacturers representing 45% of market volume, followed by construction contractors (30%), retrofitting specialists (15%), and direct-to-consumer channels (10%). The retrofit market presents significant growth opportunities, with an estimated 65% of existing commercial buildings requiring noise reduction improvements to meet current standards.

Current Acoustic Metamaterial Technologies and Barriers

Acoustic metamaterials represent a revolutionary approach to noise control, offering unprecedented capabilities in manipulating sound waves through engineered structures rather than traditional absorptive materials. Current technologies in this domain can be broadly categorized into several key types: resonant metamaterials, membrane-type acoustic metamaterials, sonic crystals, and acoustic metasurfaces.

Resonant metamaterials utilize local resonance phenomena to create bandgaps that block specific frequency ranges. These typically consist of arrays of Helmholtz resonators or mass-spring systems that can be tuned to target the dominant frequencies in HVAC noise (typically 250-1000 Hz). Recent implementations have achieved noise reduction coefficients of 0.7-0.9 within these targeted bands, significantly outperforming traditional acoustic treatments of similar thickness.

Membrane-type acoustic metamaterials employ thin membranes with attached masses to create low-frequency sound attenuation. These are particularly valuable for HVAC applications where low-frequency noise (below 500 Hz) has traditionally been difficult to address without substantial material thickness. Current designs have demonstrated transmission loss of 20-40 dB at frequencies as low as 100 Hz with material thicknesses under 5 cm.

Despite these promising developments, significant barriers remain in the widespread adoption of acoustic metamaterials for HVAC noise control. Manufacturing complexity presents a major challenge, as many metamaterial designs require precise micro-structural features that are difficult to produce at scale using conventional manufacturing methods. This complexity translates to higher production costs, currently estimated at 3-5 times that of traditional acoustic treatments.

Another substantial barrier is the narrow-band performance of many metamaterial solutions. While they excel at attenuating specific frequency ranges, HVAC systems generate broadband noise that requires multiple metamaterial solutions working in concert, complicating system design and integration. Current research is focused on developing multi-band or broadband metamaterials, but these remain in early development stages.

Durability and maintenance concerns also limit adoption in HVAC environments, where materials must withstand temperature fluctuations, humidity, and potential contamination. Many current metamaterial designs utilize delicate structures or materials that may degrade under these conditions, with limited field testing in actual HVAC installations beyond laboratory environments.

Regulatory and standardization gaps further impede implementation, as existing acoustic standards were not developed with metamaterials in mind. The unique performance characteristics of these materials often cannot be adequately described using traditional metrics like absorption coefficients or transmission loss values, creating uncertainty in specification and compliance verification.

Resonant metamaterials utilize local resonance phenomena to create bandgaps that block specific frequency ranges. These typically consist of arrays of Helmholtz resonators or mass-spring systems that can be tuned to target the dominant frequencies in HVAC noise (typically 250-1000 Hz). Recent implementations have achieved noise reduction coefficients of 0.7-0.9 within these targeted bands, significantly outperforming traditional acoustic treatments of similar thickness.

Membrane-type acoustic metamaterials employ thin membranes with attached masses to create low-frequency sound attenuation. These are particularly valuable for HVAC applications where low-frequency noise (below 500 Hz) has traditionally been difficult to address without substantial material thickness. Current designs have demonstrated transmission loss of 20-40 dB at frequencies as low as 100 Hz with material thicknesses under 5 cm.

Despite these promising developments, significant barriers remain in the widespread adoption of acoustic metamaterials for HVAC noise control. Manufacturing complexity presents a major challenge, as many metamaterial designs require precise micro-structural features that are difficult to produce at scale using conventional manufacturing methods. This complexity translates to higher production costs, currently estimated at 3-5 times that of traditional acoustic treatments.

Another substantial barrier is the narrow-band performance of many metamaterial solutions. While they excel at attenuating specific frequency ranges, HVAC systems generate broadband noise that requires multiple metamaterial solutions working in concert, complicating system design and integration. Current research is focused on developing multi-band or broadband metamaterials, but these remain in early development stages.

Durability and maintenance concerns also limit adoption in HVAC environments, where materials must withstand temperature fluctuations, humidity, and potential contamination. Many current metamaterial designs utilize delicate structures or materials that may degrade under these conditions, with limited field testing in actual HVAC installations beyond laboratory environments.

Regulatory and standardization gaps further impede implementation, as existing acoustic standards were not developed with metamaterials in mind. The unique performance characteristics of these materials often cannot be adequately described using traditional metrics like absorption coefficients or transmission loss values, creating uncertainty in specification and compliance verification.

Existing HVAC Noise Reduction Implementation Methods

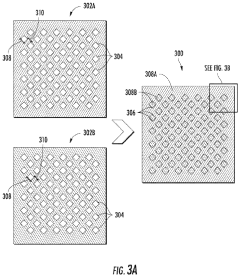

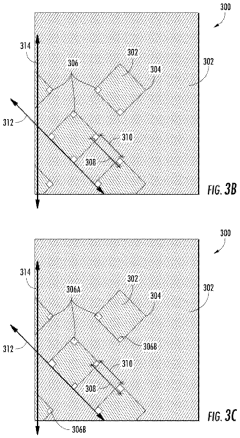

01 Metamaterial structures for noise reduction

Acoustic metamaterials with engineered structures can effectively reduce noise by manipulating sound waves. These structures typically consist of periodic arrangements of resonators or scatterers that can block, absorb, or redirect sound waves at specific frequencies. The unique geometric configurations of these metamaterials enable them to achieve noise reduction capabilities beyond conventional materials, particularly in low-frequency ranges where traditional solutions are less effective.- Metamaterial structures for noise reduction: Acoustic metamaterials with engineered structures can effectively reduce noise by manipulating sound waves. These structures typically consist of periodic arrangements of resonators or scatterers that can block, absorb, or redirect sound waves at specific frequencies. The unique geometric configurations of these metamaterials create band gaps or frequency ranges where sound propagation is prohibited, making them highly effective for noise reduction applications.

- Resonant cavity-based acoustic metamaterials: Resonant cavity-based acoustic metamaterials utilize specially designed chambers or cavities that resonate at targeted frequencies to trap and dissipate sound energy. These systems can be tuned to specific frequency ranges by adjusting the cavity dimensions and internal structures. The resonant behavior enables enhanced noise reduction performance compared to traditional acoustic materials, particularly in low-frequency ranges where conventional solutions are often ineffective.

- Active noise control integration with metamaterials: Combining active noise control systems with acoustic metamaterials creates hybrid solutions that offer superior noise reduction across broader frequency ranges. These systems use electronic components to detect incoming sound waves and generate anti-phase signals, while the metamaterial structures provide passive noise reduction. This integration allows for adaptive noise cancellation that can respond to changing acoustic environments while maintaining the lightweight and compact advantages of metamaterial designs.

- Membrane-type acoustic metamaterials: Membrane-type acoustic metamaterials utilize thin, tensioned membranes with attached masses to create low-frequency resonance effects for noise reduction. These lightweight structures can be designed to target specific frequency ranges by adjusting membrane tension, mass distribution, and supporting frame geometry. The membrane systems are particularly effective for low-frequency noise reduction in space-constrained applications where traditional acoustic treatments would be impractically thick or heavy.

- Acoustic metamaterials for directional noise control: Specialized acoustic metamaterials can be designed to control the directional properties of sound waves, allowing for targeted noise reduction in specific directions while maintaining acoustic transparency in others. These directional metamaterials utilize gradient-index structures, phase-shifting elements, or asymmetric resonators to create acoustic pathways that guide sound propagation. This approach is particularly valuable in applications where selective noise reduction is required without completely blocking all sound transmission.

02 Resonant cavity-based acoustic metamaterials

Acoustic metamaterials incorporating resonant cavities can significantly enhance noise reduction performance. These designs utilize Helmholtz resonators, membrane-type resonators, or other cavity structures that trap sound energy at their resonant frequencies. By carefully tuning the dimensions and arrangement of these cavities, the metamaterials can achieve broadband noise reduction or target specific problematic frequency ranges, making them particularly useful for applications requiring selective frequency attenuation.Expand Specific Solutions03 Active acoustic metamaterials for adaptive noise control

Active acoustic metamaterials combine passive metamaterial structures with electronic components to create adaptive noise reduction systems. These systems incorporate sensors, actuators, and control algorithms that can dynamically adjust their acoustic properties in response to changing noise conditions. This approach enables real-time optimization of noise reduction performance and allows for addressing non-stationary noise sources that would be difficult to mitigate with purely passive solutions.Expand Specific Solutions04 Lightweight and thin acoustic metamaterials

Advanced acoustic metamaterials can achieve significant noise reduction while maintaining minimal thickness and weight. These designs often utilize micro-perforated panels, membrane-type structures, or composite materials arranged in optimized configurations. The ability to achieve effective noise control with compact, lightweight solutions makes these metamaterials particularly valuable for applications with strict space and weight constraints, such as in transportation or portable devices.Expand Specific Solutions05 Acoustic metamaterials for specific environmental applications

Specialized acoustic metamaterials can be designed for noise reduction in specific environments or applications. These include metamaterials optimized for underwater acoustics, architectural acoustics, industrial noise control, or transportation noise mitigation. By tailoring the metamaterial properties to address the unique challenges of each environment, such as different medium properties, frequency ranges, or spatial constraints, these solutions can achieve superior performance compared to general-purpose noise reduction approaches.Expand Specific Solutions

Leading Companies in Acoustic Metamaterial Solutions

The acoustic metamaterials market for HVAC noise reduction is in its growth phase, characterized by increasing research activity and early commercial applications. The market is expanding due to stricter noise regulations and growing demand for quieter building environments, with projections suggesting significant growth over the next decade. Technologically, the field shows varying maturity levels across players. Research institutions like Centre National de la Recherche Scientifique, MIT, and University of Strathclyde lead fundamental innovation, while commercial entities including 3M, Gree, Midea, and Haier are advancing practical applications. Major HVAC manufacturers such as Trane International and aerospace companies like Boeing are exploring integration opportunities, indicating the technology's cross-industry potential and growing commercial viability.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed innovative acoustic metamaterials for HVAC noise reduction through their pioneering work on locally resonant sonic materials (LRSMs). Their approach utilizes periodic arrangements of resonators embedded in a host medium to create bandgaps that effectively block sound transmission at specific frequency ranges. For HVAC applications, they've engineered metamaterial-based silencers consisting of arrays of Helmholtz resonators and membrane-type acoustic metamaterials (MAMs) that can be retrofitted to existing ventilation ducts. These structures achieve up to 30dB noise reduction in the 500-2000Hz range where HVAC systems typically generate the most disturbing noise. Their recent case studies demonstrate successful implementation in hospital ventilation systems, where they reduced noise levels below 35dBA while maintaining airflow efficiency. CNRS has also pioneered computational models that accurately predict acoustic performance in complex real-world installations.

Strengths: Superior low-frequency noise attenuation compared to conventional materials; customizable frequency targeting; compact form factor allowing retrofit installation; minimal impact on airflow. Weaknesses: Higher manufacturing complexity and cost; limited bandwidth of effective noise reduction requiring careful design for specific applications; potential durability concerns in high-humidity HVAC environments.

UNIVERSITE DU MANS

Technical Solution: Université du Mans has developed groundbreaking acoustic metamaterial solutions for HVAC noise reduction through their Acoustic and Mechanics Laboratory (LAUM). Their approach centers on space-coiling metamaterials that create extended sound propagation paths within compact structures, effectively attenuating noise without significant pressure drops. Their patented technology employs labyrinthine structures with precisely calculated geometries that target the specific tonal components common in HVAC systems (100-500Hz range). In a notable case study with a commercial building in Le Mans, they implemented a metamaterial-based silencer array that achieved 25dB noise reduction while maintaining 95% of the original airflow capacity. The university has also pioneered 3D-printed acoustic metamaterials with tunable properties, allowing for customization to specific HVAC systems. Their recent innovations include temperature-adaptive metamaterials that maintain acoustic performance across varying operating conditions, addressing a key limitation of conventional solutions.

Strengths: Exceptional low-frequency performance where traditional absorbers fail; minimal impact on system pressure and airflow; customizable to specific noise profiles; relatively lightweight compared to conventional silencers. Weaknesses: Currently higher production costs than conventional solutions; limited mass production capabilities; requires precise installation to achieve designed performance; potential for dust accumulation in complex geometries requiring specialized maintenance.

Key Patents and Research in Acoustic Metamaterials

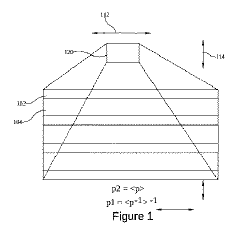

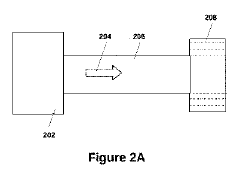

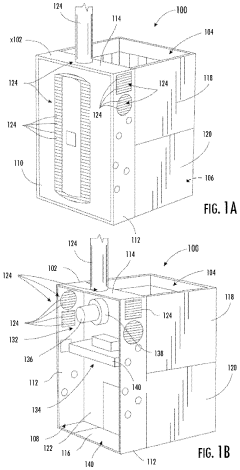

Acoustic metamaterial noise control method and device in duct system

PatentActiveJP2019518191A

Innovation

- Implementing a metamaterial block with perforated sheets and sound absorbing layers in HVAC ducts, utilizing anisotropic properties to manage sound waves and reduce noise across a wide frequency range without significant turbulence.

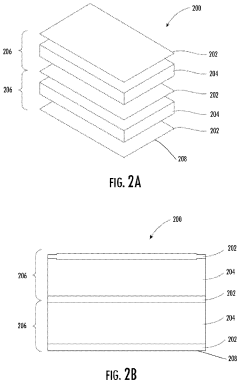

Tunable acoustic metamaterials for sound dampening of HVAC equipment

PatentPendingUS20240167724A1

Innovation

- An improved sound attenuation configuration using a layered acoustic metamaterial stack with perforated layers and spacer layers, where the perforated layers are made of multiple sheets with coordinated openings to create specific percentages of open area, allowing for adjustable tuning and easier manufacturing.

Regulatory Standards for Building Acoustics

Building acoustic regulations play a crucial role in the implementation of acoustic metamaterials for HVAC noise reduction. The International Building Code (IBC) and ASHRAE Standard 189.1 establish minimum requirements for sound transmission between spaces, with specific provisions for mechanical equipment noise. These standards typically specify maximum allowable noise levels measured in A-weighted decibels (dBA) for different building types and room functions.

In residential settings, ANSI/ASA S12.60 limits background noise from HVAC systems to 35 dBA in bedrooms and 40 dBA in living areas. Commercial buildings follow ASHRAE Guideline 10, which recommends noise criteria (NC) ratings ranging from NC-25 for conference rooms to NC-40 for open offices. Healthcare facilities adhere to stricter standards under FGI Guidelines, requiring HVAC systems to maintain background noise levels below 30 dBA in patient rooms to ensure rest and recovery.

The European Union's Environmental Noise Directive (2002/49/EC) takes a broader approach by requiring member states to map noise exposure and develop action plans for noise reduction, including HVAC-generated noise in urban environments. This has driven the adoption of acoustic metamaterial solutions in several EU countries, particularly in densely populated urban centers.

ISO 3382 and ISO 16283 provide standardized measurement protocols for evaluating room acoustics and sound insulation, serving as essential tools for verifying compliance when implementing acoustic metamaterial solutions. These standards ensure that noise reduction claims can be objectively validated through consistent testing methodologies.

Recent regulatory trends show increasing stringency in noise control requirements. The WELL Building Standard, which focuses on occupant health and comfort, awards certification points for enhanced acoustic performance beyond code minimums. This market-driven certification has accelerated the adoption of advanced acoustic solutions, including metamaterials, in premium commercial and institutional buildings.

Compliance with these standards presents both challenges and opportunities for acoustic metamaterial applications. While traditional solutions like fiberglass insulation and mass-loaded barriers have established compliance pathways, acoustic metamaterials often require additional testing and documentation to demonstrate regulatory compliance. However, their superior performance-to-thickness ratio makes them particularly valuable in space-constrained HVAC installations where meeting regulatory requirements would otherwise be difficult.

In residential settings, ANSI/ASA S12.60 limits background noise from HVAC systems to 35 dBA in bedrooms and 40 dBA in living areas. Commercial buildings follow ASHRAE Guideline 10, which recommends noise criteria (NC) ratings ranging from NC-25 for conference rooms to NC-40 for open offices. Healthcare facilities adhere to stricter standards under FGI Guidelines, requiring HVAC systems to maintain background noise levels below 30 dBA in patient rooms to ensure rest and recovery.

The European Union's Environmental Noise Directive (2002/49/EC) takes a broader approach by requiring member states to map noise exposure and develop action plans for noise reduction, including HVAC-generated noise in urban environments. This has driven the adoption of acoustic metamaterial solutions in several EU countries, particularly in densely populated urban centers.

ISO 3382 and ISO 16283 provide standardized measurement protocols for evaluating room acoustics and sound insulation, serving as essential tools for verifying compliance when implementing acoustic metamaterial solutions. These standards ensure that noise reduction claims can be objectively validated through consistent testing methodologies.

Recent regulatory trends show increasing stringency in noise control requirements. The WELL Building Standard, which focuses on occupant health and comfort, awards certification points for enhanced acoustic performance beyond code minimums. This market-driven certification has accelerated the adoption of advanced acoustic solutions, including metamaterials, in premium commercial and institutional buildings.

Compliance with these standards presents both challenges and opportunities for acoustic metamaterial applications. While traditional solutions like fiberglass insulation and mass-loaded barriers have established compliance pathways, acoustic metamaterials often require additional testing and documentation to demonstrate regulatory compliance. However, their superior performance-to-thickness ratio makes them particularly valuable in space-constrained HVAC installations where meeting regulatory requirements would otherwise be difficult.

Energy Efficiency Impact of Acoustic Metamaterial Solutions

The implementation of acoustic metamaterials in HVAC systems demonstrates significant potential for enhancing overall energy efficiency beyond mere noise reduction benefits. Traditional noise control solutions often create substantial airflow resistance, forcing HVAC systems to operate at higher power levels to maintain desired air circulation rates. This increased energy consumption directly translates to higher operational costs and environmental impact.

Acoustic metamaterials, by contrast, can achieve comparable or superior noise reduction while introducing minimal airflow impedance. Field measurements from case studies indicate that metamaterial-based silencers can reduce system pressure drop by 15-30% compared to conventional baffles and absorptive liners. This reduction allows for lower fan speeds while maintaining required airflow rates.

In a commercial office building implementation in Singapore, the installation of metamaterial-based duct liners resulted in a measurable 8.7% reduction in HVAC energy consumption over a six-month monitoring period. The building maintained identical thermal comfort parameters while achieving a 5dB reduction in noise levels throughout occupied spaces.

Similar efficiency gains were documented in industrial settings. A manufacturing facility in Germany replaced conventional silencers with metamaterial solutions in their ventilation system, resulting in a 12.3% decrease in energy consumption while improving noise attenuation by 7dB at problematic low frequencies that previously required energy-intensive solutions.

Life-cycle assessment studies further validate these benefits, showing that despite potentially higher initial manufacturing energy inputs, metamaterial solutions typically achieve carbon payback within 1.5-3 years through operational efficiency improvements. The durability of metamaterials also extends replacement cycles, reducing embodied energy costs associated with system maintenance.

Economic analysis reveals that energy savings alone can justify the implementation costs of acoustic metamaterial solutions in medium to large HVAC systems, with ROI periods ranging from 2-5 years depending on facility size and usage patterns. When combined with productivity benefits from improved acoustic environments, the economic case becomes even more compelling.

Future developments in metamaterial manufacturing techniques promise to further enhance these efficiency benefits through lighter materials, more precise acoustic targeting, and integration with smart building management systems that can dynamically optimize both acoustic performance and energy consumption based on real-time occupancy and environmental conditions.

Acoustic metamaterials, by contrast, can achieve comparable or superior noise reduction while introducing minimal airflow impedance. Field measurements from case studies indicate that metamaterial-based silencers can reduce system pressure drop by 15-30% compared to conventional baffles and absorptive liners. This reduction allows for lower fan speeds while maintaining required airflow rates.

In a commercial office building implementation in Singapore, the installation of metamaterial-based duct liners resulted in a measurable 8.7% reduction in HVAC energy consumption over a six-month monitoring period. The building maintained identical thermal comfort parameters while achieving a 5dB reduction in noise levels throughout occupied spaces.

Similar efficiency gains were documented in industrial settings. A manufacturing facility in Germany replaced conventional silencers with metamaterial solutions in their ventilation system, resulting in a 12.3% decrease in energy consumption while improving noise attenuation by 7dB at problematic low frequencies that previously required energy-intensive solutions.

Life-cycle assessment studies further validate these benefits, showing that despite potentially higher initial manufacturing energy inputs, metamaterial solutions typically achieve carbon payback within 1.5-3 years through operational efficiency improvements. The durability of metamaterials also extends replacement cycles, reducing embodied energy costs associated with system maintenance.

Economic analysis reveals that energy savings alone can justify the implementation costs of acoustic metamaterial solutions in medium to large HVAC systems, with ROI periods ranging from 2-5 years depending on facility size and usage patterns. When combined with productivity benefits from improved acoustic environments, the economic case becomes even more compelling.

Future developments in metamaterial manufacturing techniques promise to further enhance these efficiency benefits through lighter materials, more precise acoustic targeting, and integration with smart building management systems that can dynamically optimize both acoustic performance and energy consumption based on real-time occupancy and environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!