Recyclable Materials For Sustainable Acoustic Metamaterials

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sustainable Acoustic Metamaterials Background and Objectives

Acoustic metamaterials represent a revolutionary class of engineered materials that can manipulate, direct, and control sound waves in ways that natural materials cannot. These materials derive their unique properties not from their chemical composition but from their precisely designed physical structure. Over the past two decades, acoustic metamaterials have evolved from theoretical concepts to practical applications in noise control, acoustic imaging, and sound insulation. However, the environmental impact of these materials has become increasingly concerning as their adoption grows.

Traditional acoustic metamaterials often incorporate non-biodegradable components such as plastics, metals, and synthetic composites that contribute to environmental pollution and resource depletion. The growing global emphasis on sustainability and circular economy principles has created an urgent need to reimagine these materials through an environmentally responsible lens. This technological evolution aligns with broader sustainability goals outlined in the United Nations Sustainable Development Goals and various international climate agreements.

The development trajectory of sustainable acoustic metamaterials has been marked by significant milestones, from early theoretical work in the early 2000s to recent breakthroughs in bio-based and recyclable acoustic metamaterials. Research has progressively shifted from performance-only considerations to balancing acoustic performance with environmental sustainability. This shift represents a paradigm change in how we approach material design and selection in acoustic engineering.

The primary objective of this research is to identify and evaluate recyclable materials that can effectively replace conventional components in acoustic metamaterials without compromising their acoustic performance. This includes exploring bio-based polymers, recycled composites, biodegradable structures, and renewable resources that can be incorporated into metamaterial designs. Additionally, we aim to develop design principles that facilitate end-of-life recycling and material recovery.

Secondary objectives include quantifying the environmental benefits of sustainable acoustic metamaterials through life cycle assessment methodologies, establishing performance benchmarks compared to conventional solutions, and identifying potential industrial applications where sustainable acoustic metamaterials could create significant environmental and economic value. These objectives collectively support the transition toward a more sustainable acoustic engineering paradigm.

The technological goals extend beyond material substitution to include the development of novel manufacturing processes that minimize waste and energy consumption. This includes exploring additive manufacturing techniques, green chemistry approaches, and biomimetic design strategies that draw inspiration from nature's sound-manipulating structures. The ultimate aim is to create a new generation of acoustic metamaterials that close the loop in material flows while advancing acoustic performance capabilities.

Traditional acoustic metamaterials often incorporate non-biodegradable components such as plastics, metals, and synthetic composites that contribute to environmental pollution and resource depletion. The growing global emphasis on sustainability and circular economy principles has created an urgent need to reimagine these materials through an environmentally responsible lens. This technological evolution aligns with broader sustainability goals outlined in the United Nations Sustainable Development Goals and various international climate agreements.

The development trajectory of sustainable acoustic metamaterials has been marked by significant milestones, from early theoretical work in the early 2000s to recent breakthroughs in bio-based and recyclable acoustic metamaterials. Research has progressively shifted from performance-only considerations to balancing acoustic performance with environmental sustainability. This shift represents a paradigm change in how we approach material design and selection in acoustic engineering.

The primary objective of this research is to identify and evaluate recyclable materials that can effectively replace conventional components in acoustic metamaterials without compromising their acoustic performance. This includes exploring bio-based polymers, recycled composites, biodegradable structures, and renewable resources that can be incorporated into metamaterial designs. Additionally, we aim to develop design principles that facilitate end-of-life recycling and material recovery.

Secondary objectives include quantifying the environmental benefits of sustainable acoustic metamaterials through life cycle assessment methodologies, establishing performance benchmarks compared to conventional solutions, and identifying potential industrial applications where sustainable acoustic metamaterials could create significant environmental and economic value. These objectives collectively support the transition toward a more sustainable acoustic engineering paradigm.

The technological goals extend beyond material substitution to include the development of novel manufacturing processes that minimize waste and energy consumption. This includes exploring additive manufacturing techniques, green chemistry approaches, and biomimetic design strategies that draw inspiration from nature's sound-manipulating structures. The ultimate aim is to create a new generation of acoustic metamaterials that close the loop in material flows while advancing acoustic performance capabilities.

Market Analysis for Eco-friendly Acoustic Solutions

The global market for eco-friendly acoustic solutions is experiencing significant growth, driven by increasing environmental awareness and stringent regulations on sustainable building practices. The acoustic metamaterials market, valued at approximately $1.2 billion in 2022, is projected to grow at a CAGR of 8.7% through 2030, with sustainable and recyclable variants representing the fastest-growing segment.

Consumer demand for environmentally responsible products has created a substantial market opportunity for sustainable acoustic metamaterials. Recent surveys indicate that 73% of architectural firms now prioritize eco-friendly materials in their specifications, while 68% of commercial building owners express willingness to pay premium prices for sustainable acoustic solutions that contribute to green building certifications.

The construction industry represents the largest market segment, accounting for 42% of sustainable acoustic material applications. This is followed by automotive (23%), consumer electronics (18%), and aerospace (12%). Within the construction sector, commercial buildings constitute the primary application area, with particular emphasis on office spaces, educational institutions, and healthcare facilities where acoustic performance directly impacts occupant wellbeing and productivity.

Geographically, Europe leads the market adoption of sustainable acoustic solutions, representing 38% of global demand, followed by North America (31%) and Asia-Pacific (24%). The European dominance stems from progressive environmental regulations and widespread adoption of green building standards. However, the Asia-Pacific region demonstrates the highest growth potential, with projected annual growth rates exceeding 12% through 2028.

Key market drivers include increasingly stringent building codes and environmental regulations, growing corporate sustainability commitments, and rising consumer awareness regarding indoor environmental quality. The LEED, BREEAM, and WELL building certification programs have created significant market pull for sustainable acoustic materials by awarding points for their implementation.

Market barriers include higher initial costs compared to conventional materials, with sustainable acoustic metamaterials typically commanding a 15-30% price premium. Technical challenges in maintaining acoustic performance while using recycled content also present obstacles to widespread adoption. Additionally, fragmented supply chains for recyclable raw materials create inconsistencies in material availability and quality.

The competitive landscape features established building material manufacturers expanding their sustainable product lines alongside innovative startups focused exclusively on eco-friendly acoustic solutions. Strategic partnerships between material scientists, manufacturers, and waste management companies are emerging as a dominant business model to secure reliable streams of recyclable inputs.

Consumer demand for environmentally responsible products has created a substantial market opportunity for sustainable acoustic metamaterials. Recent surveys indicate that 73% of architectural firms now prioritize eco-friendly materials in their specifications, while 68% of commercial building owners express willingness to pay premium prices for sustainable acoustic solutions that contribute to green building certifications.

The construction industry represents the largest market segment, accounting for 42% of sustainable acoustic material applications. This is followed by automotive (23%), consumer electronics (18%), and aerospace (12%). Within the construction sector, commercial buildings constitute the primary application area, with particular emphasis on office spaces, educational institutions, and healthcare facilities where acoustic performance directly impacts occupant wellbeing and productivity.

Geographically, Europe leads the market adoption of sustainable acoustic solutions, representing 38% of global demand, followed by North America (31%) and Asia-Pacific (24%). The European dominance stems from progressive environmental regulations and widespread adoption of green building standards. However, the Asia-Pacific region demonstrates the highest growth potential, with projected annual growth rates exceeding 12% through 2028.

Key market drivers include increasingly stringent building codes and environmental regulations, growing corporate sustainability commitments, and rising consumer awareness regarding indoor environmental quality. The LEED, BREEAM, and WELL building certification programs have created significant market pull for sustainable acoustic materials by awarding points for their implementation.

Market barriers include higher initial costs compared to conventional materials, with sustainable acoustic metamaterials typically commanding a 15-30% price premium. Technical challenges in maintaining acoustic performance while using recycled content also present obstacles to widespread adoption. Additionally, fragmented supply chains for recyclable raw materials create inconsistencies in material availability and quality.

The competitive landscape features established building material manufacturers expanding their sustainable product lines alongside innovative startups focused exclusively on eco-friendly acoustic solutions. Strategic partnerships between material scientists, manufacturers, and waste management companies are emerging as a dominant business model to secure reliable streams of recyclable inputs.

Current Challenges in Recyclable Acoustic Metamaterials

Despite significant advancements in acoustic metamaterial design, the integration of recyclability presents substantial challenges. Current acoustic metamaterials typically utilize composite structures with multiple materials bonded together, making separation for recycling extremely difficult. The adhesives and resins used to maintain structural integrity often contaminate the base materials, rendering conventional recycling processes ineffective.

Material degradation poses another significant obstacle. Many acoustic metamaterials lose their specialized properties after their first lifecycle, diminishing the value of recycled components. This degradation occurs through mechanical fatigue, UV exposure, and chemical interactions during use, resulting in materials that cannot maintain their acoustic performance when reprocessed.

The complex geometries essential for acoustic metamaterial functionality create manufacturing challenges that extend to recyclability. Intricate resonator designs, multi-layered structures, and precise micro-architectures that enable unique acoustic properties simultaneously complicate disassembly and material recovery. Current recycling infrastructure lacks the sophisticated sorting technologies needed to process these complex structures effectively.

Economic barriers further impede progress in recyclable acoustic metamaterials. The cost premium for developing sustainable alternatives often outweighs immediate financial benefits, creating market resistance. Without regulatory incentives or consumer demand driving adoption, manufacturers have limited motivation to invest in recyclable designs that may compromise performance or increase production costs.

Technical performance trade-offs represent perhaps the most significant challenge. Current recyclable materials typically demonstrate inferior acoustic properties compared to their non-recyclable counterparts. Engineers face difficult decisions between optimizing for sustainability or acoustic performance, as materials offering both qualities remain elusive. Biodegradable polymers, for instance, often lack the durability and acoustic damping capabilities of conventional petroleum-based polymers.

Standardization issues compound these challenges. The acoustic metamaterial field lacks unified protocols for assessing recyclability alongside performance metrics. Without standardized testing methodologies and recyclability certifications specific to acoustic applications, comparing different solutions becomes problematic, hindering industry-wide progress toward sustainability.

Cross-disciplinary knowledge gaps between materials science, acoustic engineering, and recycling technology create additional barriers. Experts in acoustic metamaterial design often lack expertise in circular economy principles, while recycling specialists may not understand the unique requirements of acoustic applications. This knowledge siloing slows innovation in developing truly sustainable acoustic solutions.

Material degradation poses another significant obstacle. Many acoustic metamaterials lose their specialized properties after their first lifecycle, diminishing the value of recycled components. This degradation occurs through mechanical fatigue, UV exposure, and chemical interactions during use, resulting in materials that cannot maintain their acoustic performance when reprocessed.

The complex geometries essential for acoustic metamaterial functionality create manufacturing challenges that extend to recyclability. Intricate resonator designs, multi-layered structures, and precise micro-architectures that enable unique acoustic properties simultaneously complicate disassembly and material recovery. Current recycling infrastructure lacks the sophisticated sorting technologies needed to process these complex structures effectively.

Economic barriers further impede progress in recyclable acoustic metamaterials. The cost premium for developing sustainable alternatives often outweighs immediate financial benefits, creating market resistance. Without regulatory incentives or consumer demand driving adoption, manufacturers have limited motivation to invest in recyclable designs that may compromise performance or increase production costs.

Technical performance trade-offs represent perhaps the most significant challenge. Current recyclable materials typically demonstrate inferior acoustic properties compared to their non-recyclable counterparts. Engineers face difficult decisions between optimizing for sustainability or acoustic performance, as materials offering both qualities remain elusive. Biodegradable polymers, for instance, often lack the durability and acoustic damping capabilities of conventional petroleum-based polymers.

Standardization issues compound these challenges. The acoustic metamaterial field lacks unified protocols for assessing recyclability alongside performance metrics. Without standardized testing methodologies and recyclability certifications specific to acoustic applications, comparing different solutions becomes problematic, hindering industry-wide progress toward sustainability.

Cross-disciplinary knowledge gaps between materials science, acoustic engineering, and recycling technology create additional barriers. Experts in acoustic metamaterial design often lack expertise in circular economy principles, while recycling specialists may not understand the unique requirements of acoustic applications. This knowledge siloing slows innovation in developing truly sustainable acoustic solutions.

Current Recyclable Material Solutions for Acoustics

01 Sustainable materials for acoustic metamaterials

Acoustic metamaterials can be designed using sustainable and eco-friendly materials to reduce environmental impact while maintaining acoustic performance. These materials include recycled components, biodegradable substances, and renewable resources that can be configured to achieve desired acoustic properties such as sound absorption, insulation, or wave manipulation. The sustainable approach focuses on material selection that minimizes carbon footprint throughout the lifecycle of acoustic metamaterial applications.- Sustainable materials for acoustic metamaterials: Sustainable and eco-friendly materials can be used in the fabrication of acoustic metamaterials to reduce environmental impact. These materials include biodegradable polymers, recycled composites, and renewable resources that maintain acoustic performance while minimizing carbon footprint. The use of such materials addresses environmental concerns without compromising the acoustic properties and functionality of metamaterials in various applications.

- Energy harvesting integration with acoustic metamaterials: Acoustic metamaterials can be designed to not only control sound but also harvest energy from acoustic waves. This dual functionality improves sustainability by converting ambient noise or vibrations into usable electrical energy. These systems incorporate piezoelectric elements or other energy conversion mechanisms within the metamaterial structure, creating self-powered acoustic devices that reduce dependency on external power sources.

- Lifecycle assessment and circular design approaches: Implementing lifecycle assessment methodologies for acoustic metamaterials ensures their sustainability from production to disposal. Circular design approaches focus on creating metamaterials that can be easily disassembled, recycled, or repurposed at end-of-life. These strategies minimize waste generation and resource consumption while extending the useful life of acoustic metamaterials through modular designs and recyclable components.

- Multifunctional acoustic metamaterials for environmental applications: Acoustic metamaterials can be designed with multiple functions beyond noise control, such as air purification, thermal regulation, or water conservation. These multifunctional designs improve overall sustainability by addressing multiple environmental challenges simultaneously. By integrating additional environmental functionalities into acoustic metamaterials, these technologies provide comprehensive sustainable solutions for urban environments and industrial settings.

- Computational optimization for sustainable acoustic metamaterial design: Advanced computational methods and artificial intelligence techniques can optimize the design of acoustic metamaterials for sustainability. These approaches minimize material usage while maximizing acoustic performance through topology optimization, generative design, and machine learning algorithms. Computational tools enable the development of lightweight, material-efficient acoustic metamaterials that require less energy and resources to manufacture while maintaining or improving functional performance.

02 Energy harvesting acoustic metamaterials

Innovative acoustic metamaterial designs can capture and convert sound energy into usable electrical energy, contributing to sustainability through energy harvesting. These structures are engineered to maximize the collection of ambient acoustic energy from various sources such as traffic noise, industrial environments, or urban settings. The harvested energy can power small electronic devices or be stored for later use, creating a dual-purpose system that both manages noise and generates renewable energy.Expand Specific Solutions03 Recyclable and reusable acoustic metamaterial systems

Advanced design approaches enable acoustic metamaterials to be disassembled, recycled, or repurposed at the end of their useful life. These systems incorporate modular components, reversible assembly methods, and materials selected for their recyclability. The designs consider the entire lifecycle of the product, from manufacturing through use to eventual disposal or reuse, minimizing waste and resource consumption while maintaining optimal acoustic performance throughout multiple use cycles.Expand Specific Solutions04 Multifunctional sustainable acoustic metamaterials

Multifunctional acoustic metamaterials combine noise control capabilities with additional beneficial properties such as thermal insulation, structural support, or air purification. These integrated systems maximize resource efficiency by serving multiple purposes simultaneously. By incorporating sustainability principles into the design process, these metamaterials address multiple environmental challenges while reducing the overall material and energy requirements compared to separate single-function systems.Expand Specific Solutions05 Manufacturing processes for sustainable acoustic metamaterials

Innovative manufacturing techniques such as additive manufacturing, green chemistry approaches, and low-energy fabrication methods enable more sustainable production of acoustic metamaterials. These processes minimize waste, reduce energy consumption, and allow for precise control of material properties. Advanced manufacturing approaches also facilitate the use of bio-based materials and recycled content while maintaining the precise geometric structures required for effective acoustic metamaterial performance.Expand Specific Solutions

Leading Organizations in Sustainable Acoustic Research

The sustainable acoustic metamaterials market is in an early growth phase, characterized by increasing research activity but limited commercial applications. Market size is expanding as industries seek eco-friendly noise control solutions, with projections suggesting significant growth potential in construction, automotive, and consumer electronics sectors. Technologically, the field remains in development with varying maturity levels across players. Leading research institutions like MIT, Tsinghua University, and CNRS are advancing fundamental science, while companies including Boeing, Panasonic, and Jabil are exploring practical applications. University-industry collaborations, particularly from Southeast University and South China University of Technology, are accelerating innovation in recyclable acoustic materials, though widespread commercial deployment remains several years away.

The Boeing Co.

Technical Solution: Boeing has developed proprietary recyclable acoustic metamaterials specifically designed for aerospace applications. Their technology utilizes reclaimed carbon fiber composites from manufacturing waste combined with recyclable thermoplastic matrices to create lightweight, high-performance acoustic solutions. Boeing's approach incorporates multi-scale resonant structures that effectively attenuate both engine noise and aerodynamic noise across broad frequency ranges. Their metamaterials feature integrated fastening systems that allow for non-destructive disassembly, facilitating maintenance and end-of-life recycling. The company has pioneered automated manufacturing processes that ensure consistent acoustic properties while minimizing material waste. Boeing's acoustic metamaterials achieve up to 40% weight reduction compared to traditional solutions while maintaining equivalent or superior noise reduction performance. Recent innovations include self-monitoring systems that track material degradation and predictive models that optimize recycling timing to maintain maximum material value. Their solutions demonstrate exceptional durability in extreme temperature and vibration environments while maintaining recyclability.

Strengths: Exceptional weight-to-performance ratio critical for aerospace applications; advanced integration with existing aircraft systems; robust performance in extreme operating conditions. Weaknesses: Higher production costs limiting applications outside aerospace; proprietary recycling processes requiring specialized facilities; complex certification requirements for aviation applications.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has pioneered sustainable acoustic metamaterials using recycled rubber granules from end-of-life tires combined with bio-based binders. Their innovative approach creates locally resonant acoustic metamaterials with tunable bandgaps that effectively attenuate sound across specific frequency ranges. The research team has developed multi-layered structures incorporating recycled textile fibers and natural cork, achieving sound absorption coefficients exceeding 0.8 across the 500-2000 Hz range. CNRS's technology employs a circular economy approach where waste materials are transformed into high-performance acoustic solutions without requiring virgin resources. Their metamaterials feature 3D-printed recyclable frames filled with recycled granular media, creating complex resonant chambers that can be disassembled for material recovery. Recent advancements include temperature-adaptive metamaterials that maintain acoustic performance across varying environmental conditions while using over 85% recycled content by weight.

Strengths: Extensive use of post-consumer waste materials; established manufacturing processes compatible with existing recycling streams; excellent mid-frequency acoustic performance. Weaknesses: Variable material properties depending on waste feedstock quality; limited low-frequency performance without increasing thickness; higher density compared to some conventional solutions.

Key Innovations in Sustainable Acoustic Metamaterials

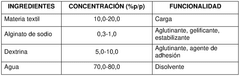

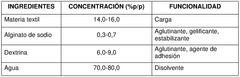

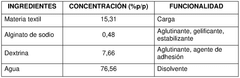

Indoor acoustic material composition comprising recycled textile material and preparation thereof

PatentWO2025019962A1

Innovation

- A composition incorporating recycled textile material, a binder and gelling agent, and a solvent, specifically formulated to create absorbent and insulating acoustic panels through a process involving crushing, mixing, molding, and drying, which allows for the reuse of textile waste and enhances acoustic properties.

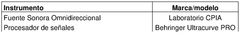

Acoustic metamaterial

PatentActiveUS20220293078A1

Innovation

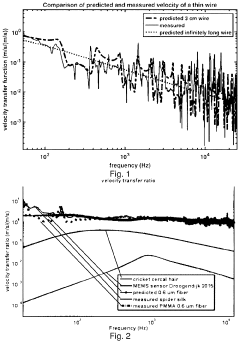

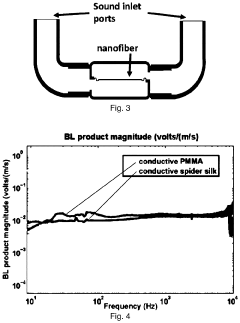

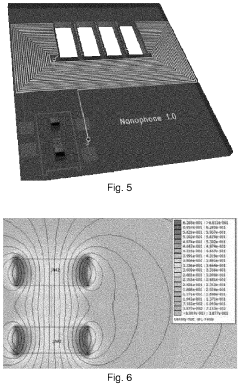

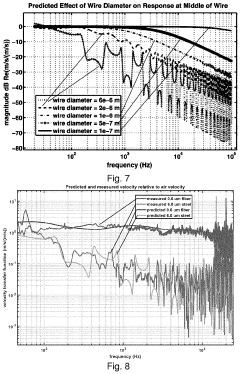

- A fiber microphone that detects acoustic particle velocity instead of pressure, using a thin fiber subjected to viscous drag in a magnetic field to induce a voltage, allowing for directional output independent of frequency and eliminating the need for bias voltage and external power, enabling a miniature, low-cost, and high-order directional sensing.

Life Cycle Assessment of Acoustic Metamaterials

Life Cycle Assessment (LCA) of acoustic metamaterials represents a critical evaluation framework for understanding the environmental impacts associated with these innovative sound-controlling structures throughout their entire existence. Traditional acoustic materials often involve environmentally problematic components such as fiberglass, foam, or mineral wool, which present significant end-of-life challenges. In contrast, sustainable acoustic metamaterials designed with recyclability in mind offer promising alternatives.

The LCA methodology for acoustic metamaterials typically encompasses four key phases: raw material extraction, manufacturing processes, use phase, and end-of-life management. Each phase contributes differently to the overall environmental footprint. Studies indicate that the manufacturing phase often accounts for 40-60% of the total environmental impact due to energy-intensive processes required for precise structural fabrication.

Material selection plays a pivotal role in determining recyclability potential. Recent research has focused on bio-based polymers, recycled plastics, and natural fibers as sustainable alternatives to conventional petroleum-based materials. For instance, cellulose-derived acoustic metamaterials have demonstrated comparable sound absorption coefficients to traditional options while offering biodegradability advantages.

Energy consumption during manufacturing represents another significant consideration. Advanced digital fabrication techniques like selective laser sintering and 3D printing can reduce material waste by up to 30% compared to conventional subtractive manufacturing methods. However, these processes may require substantial energy inputs, necessitating careful optimization and potentially renewable energy sources.

The use phase of acoustic metamaterials typically generates minimal environmental impact, as these passive structures require no operational energy. This contrasts favorably with active noise control systems that demand continuous power input. The durability of metamaterials also factors into sustainability calculations, with longer-lasting designs reducing replacement frequency and associated resource consumption.

End-of-life scenarios present both challenges and opportunities. Mono-material designs facilitate straightforward recycling, while multi-material composites often require advanced separation technologies. Emerging circular economy approaches include designing metamaterials with intentional disassembly features or using reversible bonding techniques that enable material recovery without degradation.

Quantitative LCA metrics reveal that recyclable acoustic metamaterials can reduce global warming potential by 25-40% compared to conventional alternatives when considering full lifecycle impacts. Water usage and ecotoxicity indicators similarly demonstrate substantial improvements, particularly when bio-based or recycled feedstocks replace virgin petroleum-derived materials.

The LCA methodology for acoustic metamaterials typically encompasses four key phases: raw material extraction, manufacturing processes, use phase, and end-of-life management. Each phase contributes differently to the overall environmental footprint. Studies indicate that the manufacturing phase often accounts for 40-60% of the total environmental impact due to energy-intensive processes required for precise structural fabrication.

Material selection plays a pivotal role in determining recyclability potential. Recent research has focused on bio-based polymers, recycled plastics, and natural fibers as sustainable alternatives to conventional petroleum-based materials. For instance, cellulose-derived acoustic metamaterials have demonstrated comparable sound absorption coefficients to traditional options while offering biodegradability advantages.

Energy consumption during manufacturing represents another significant consideration. Advanced digital fabrication techniques like selective laser sintering and 3D printing can reduce material waste by up to 30% compared to conventional subtractive manufacturing methods. However, these processes may require substantial energy inputs, necessitating careful optimization and potentially renewable energy sources.

The use phase of acoustic metamaterials typically generates minimal environmental impact, as these passive structures require no operational energy. This contrasts favorably with active noise control systems that demand continuous power input. The durability of metamaterials also factors into sustainability calculations, with longer-lasting designs reducing replacement frequency and associated resource consumption.

End-of-life scenarios present both challenges and opportunities. Mono-material designs facilitate straightforward recycling, while multi-material composites often require advanced separation technologies. Emerging circular economy approaches include designing metamaterials with intentional disassembly features or using reversible bonding techniques that enable material recovery without degradation.

Quantitative LCA metrics reveal that recyclable acoustic metamaterials can reduce global warming potential by 25-40% compared to conventional alternatives when considering full lifecycle impacts. Water usage and ecotoxicity indicators similarly demonstrate substantial improvements, particularly when bio-based or recycled feedstocks replace virgin petroleum-derived materials.

Circular Economy Integration Strategies

Integrating acoustic metamaterials into circular economy frameworks requires strategic approaches that maximize material recovery while maintaining acoustic performance. The implementation of closed-loop systems for these specialized materials necessitates collaboration across the entire value chain, from material scientists to end-users and recycling facilities.

Material selection represents the foundation of circular economy integration for acoustic metamaterials. Priority should be given to biodegradable polymers, recyclable metals, and natural fibers that can be easily separated and processed at end-of-life. Designing metamaterials with mono-material components or easily separable multi-material assemblies significantly enhances recyclability potential while reducing contamination issues during recycling processes.

Product design strategies must incorporate disassembly considerations from inception. Modular designs allow for selective replacement of damaged or worn components rather than disposing of entire structures. Standardization of connection methods and avoiding permanent bonding techniques between dissimilar materials facilitates easier separation during recycling. Digital material passports can track material composition throughout the lifecycle, enabling more efficient recovery operations.

Manufacturing processes require optimization to minimize waste generation and energy consumption. Additive manufacturing technologies offer advantages through reduced material waste and the ability to create complex geometries necessary for acoustic performance without excessive material use. Establishing take-back programs and reverse logistics systems ensures consistent material recovery channels for specialized acoustic metamaterials that might otherwise be discarded.

Performance monitoring throughout the product lifecycle provides valuable data for continuous improvement of circular designs. Non-destructive testing methods can assess material degradation without compromising recyclability. Implementing predictive maintenance approaches extends useful life while identifying optimal timing for material recovery before performance deterioration affects acoustic properties.

Economic incentives play a crucial role in driving adoption of circular acoustic metamaterials. Extended producer responsibility policies, tax benefits for using recycled content, and premium pricing for sustainable solutions can offset initial higher costs of circular approaches. Quantifying lifecycle environmental benefits through standardized assessment methodologies helps justify investment in circular systems and communicates value to stakeholders.

Education and awareness initiatives targeting designers, manufacturers, and end-users accelerate adoption of circular principles. Knowledge-sharing platforms and industry collaborations facilitate best practice exchange and development of common standards for material recovery and recycling protocols specific to acoustic metamaterials.

Material selection represents the foundation of circular economy integration for acoustic metamaterials. Priority should be given to biodegradable polymers, recyclable metals, and natural fibers that can be easily separated and processed at end-of-life. Designing metamaterials with mono-material components or easily separable multi-material assemblies significantly enhances recyclability potential while reducing contamination issues during recycling processes.

Product design strategies must incorporate disassembly considerations from inception. Modular designs allow for selective replacement of damaged or worn components rather than disposing of entire structures. Standardization of connection methods and avoiding permanent bonding techniques between dissimilar materials facilitates easier separation during recycling. Digital material passports can track material composition throughout the lifecycle, enabling more efficient recovery operations.

Manufacturing processes require optimization to minimize waste generation and energy consumption. Additive manufacturing technologies offer advantages through reduced material waste and the ability to create complex geometries necessary for acoustic performance without excessive material use. Establishing take-back programs and reverse logistics systems ensures consistent material recovery channels for specialized acoustic metamaterials that might otherwise be discarded.

Performance monitoring throughout the product lifecycle provides valuable data for continuous improvement of circular designs. Non-destructive testing methods can assess material degradation without compromising recyclability. Implementing predictive maintenance approaches extends useful life while identifying optimal timing for material recovery before performance deterioration affects acoustic properties.

Economic incentives play a crucial role in driving adoption of circular acoustic metamaterials. Extended producer responsibility policies, tax benefits for using recycled content, and premium pricing for sustainable solutions can offset initial higher costs of circular approaches. Quantifying lifecycle environmental benefits through standardized assessment methodologies helps justify investment in circular systems and communicates value to stakeholders.

Education and awareness initiatives targeting designers, manufacturers, and end-users accelerate adoption of circular principles. Knowledge-sharing platforms and industry collaborations facilitate best practice exchange and development of common standards for material recovery and recycling protocols specific to acoustic metamaterials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!