Acoustic Metamaterials For Wearable Hearing Protection Devices

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterials Evolution and Protection Goals

Acoustic metamaterials represent a revolutionary advancement in sound engineering, emerging from theoretical physics concepts in the early 2000s. These engineered structures manipulate sound waves through their unique geometric configurations rather than material composition, enabling unprecedented control over acoustic properties. The evolution of acoustic metamaterials has progressed from simple resonator-based designs to complex architectures capable of achieving negative acoustic parameters, sound absorption, and directional manipulation of acoustic waves.

The field has witnessed significant milestones, including the development of sonic crystals, acoustic black holes, and pentamode metamaterials. Recent innovations have focused on creating lightweight, flexible metamaterial structures specifically designed for wearable applications, moving away from rigid, bulky configurations that dominated early research. This transition marks a critical shift toward practical implementation in personal protective equipment.

For wearable hearing protection devices, the technical objectives are multifaceted and ambitious. Primary goals include achieving selective frequency attenuation that blocks harmful noise while preserving speech intelligibility and environmental awareness. This selective filtering capability represents a significant advancement over conventional hearing protection that uniformly reduces sound across all frequencies, often compromising situational awareness and communication.

Another critical objective is developing metamaterial structures that maintain effectiveness while conforming to the ergonomic requirements of wearable devices. This includes creating ultra-thin, flexible designs that can be incorporated into comfortable ear protection without adding significant bulk or weight. The ideal solution would provide customizable acoustic properties that adapt to different noise environments without requiring physical modification of the device.

Long-term technical goals extend to creating adaptive metamaterials that can dynamically respond to changing acoustic environments, potentially incorporating smart materials or micro-electromechanical systems. These would enable real-time adjustment of acoustic properties based on environmental conditions, offering personalized protection tailored to specific user needs and preferences.

The trajectory of acoustic metamaterial development for hearing protection is increasingly focused on miniaturization, integration with existing wearable technologies, and manufacturing scalability. Research efforts are directed toward overcoming challenges in bandwidth limitations, achieving omnidirectional protection, and ensuring durability under real-world conditions. As the technology matures, the ultimate goal is to develop hearing protection solutions that offer superior acoustic performance while maintaining comfort and practicality for everyday use.

The field has witnessed significant milestones, including the development of sonic crystals, acoustic black holes, and pentamode metamaterials. Recent innovations have focused on creating lightweight, flexible metamaterial structures specifically designed for wearable applications, moving away from rigid, bulky configurations that dominated early research. This transition marks a critical shift toward practical implementation in personal protective equipment.

For wearable hearing protection devices, the technical objectives are multifaceted and ambitious. Primary goals include achieving selective frequency attenuation that blocks harmful noise while preserving speech intelligibility and environmental awareness. This selective filtering capability represents a significant advancement over conventional hearing protection that uniformly reduces sound across all frequencies, often compromising situational awareness and communication.

Another critical objective is developing metamaterial structures that maintain effectiveness while conforming to the ergonomic requirements of wearable devices. This includes creating ultra-thin, flexible designs that can be incorporated into comfortable ear protection without adding significant bulk or weight. The ideal solution would provide customizable acoustic properties that adapt to different noise environments without requiring physical modification of the device.

Long-term technical goals extend to creating adaptive metamaterials that can dynamically respond to changing acoustic environments, potentially incorporating smart materials or micro-electromechanical systems. These would enable real-time adjustment of acoustic properties based on environmental conditions, offering personalized protection tailored to specific user needs and preferences.

The trajectory of acoustic metamaterial development for hearing protection is increasingly focused on miniaturization, integration with existing wearable technologies, and manufacturing scalability. Research efforts are directed toward overcoming challenges in bandwidth limitations, achieving omnidirectional protection, and ensuring durability under real-world conditions. As the technology matures, the ultimate goal is to develop hearing protection solutions that offer superior acoustic performance while maintaining comfort and practicality for everyday use.

Market Analysis for Advanced Hearing Protection Solutions

The global market for advanced hearing protection solutions is experiencing significant growth, driven by increasing awareness of noise-induced hearing loss and stricter workplace safety regulations. The current market size for hearing protection devices is estimated at $2.5 billion, with projections indicating growth to reach $3.8 billion by 2027, representing a compound annual growth rate of approximately 6.8%. This growth trajectory is particularly pronounced in industrialized nations where occupational safety standards continue to evolve and become more stringent.

Consumer demand patterns reveal a notable shift toward more sophisticated hearing protection solutions that offer both comfort and effectiveness. Traditional passive earplugs and earmuffs, while still commanding a substantial market share of around 65%, are gradually losing ground to advanced electronic and smart hearing protection devices. These newer technologies, incorporating features such as selective noise cancellation and communication capabilities, are growing at nearly twice the rate of conventional solutions.

Industry segmentation shows distinct market categories with varying growth potentials. The industrial sector remains the largest consumer of hearing protection devices, accounting for approximately 40% of the market, followed by military applications at 25%, construction at 20%, and consumer applications at 15%. However, the consumer segment is demonstrating the fastest growth rate, indicating increasing public awareness about hearing health beyond occupational contexts.

Geographic distribution of market demand reveals North America as the dominant region, holding approximately 35% of the global market share, followed by Europe at 30%, Asia-Pacific at 25%, and the rest of the world at 10%. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate due to rapid industrialization and increasing implementation of workplace safety standards.

Key market drivers include the rising prevalence of noise-induced hearing loss, estimated to affect over 466 million people worldwide according to the World Health Organization. Additionally, evolving regulatory frameworks, such as the EU's Noise at Work Regulations and OSHA standards in the United States, are compelling employers to invest in more effective hearing protection solutions for their workforce.

Emerging trends indicate growing consumer preference for customizable, comfortable, and aesthetically appealing hearing protection devices that can be worn for extended periods. There is also increasing demand for smart hearing protection solutions that can integrate with other personal protective equipment and communication systems, particularly in high-risk industrial and military environments.

Consumer demand patterns reveal a notable shift toward more sophisticated hearing protection solutions that offer both comfort and effectiveness. Traditional passive earplugs and earmuffs, while still commanding a substantial market share of around 65%, are gradually losing ground to advanced electronic and smart hearing protection devices. These newer technologies, incorporating features such as selective noise cancellation and communication capabilities, are growing at nearly twice the rate of conventional solutions.

Industry segmentation shows distinct market categories with varying growth potentials. The industrial sector remains the largest consumer of hearing protection devices, accounting for approximately 40% of the market, followed by military applications at 25%, construction at 20%, and consumer applications at 15%. However, the consumer segment is demonstrating the fastest growth rate, indicating increasing public awareness about hearing health beyond occupational contexts.

Geographic distribution of market demand reveals North America as the dominant region, holding approximately 35% of the global market share, followed by Europe at 30%, Asia-Pacific at 25%, and the rest of the world at 10%. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate due to rapid industrialization and increasing implementation of workplace safety standards.

Key market drivers include the rising prevalence of noise-induced hearing loss, estimated to affect over 466 million people worldwide according to the World Health Organization. Additionally, evolving regulatory frameworks, such as the EU's Noise at Work Regulations and OSHA standards in the United States, are compelling employers to invest in more effective hearing protection solutions for their workforce.

Emerging trends indicate growing consumer preference for customizable, comfortable, and aesthetically appealing hearing protection devices that can be worn for extended periods. There is also increasing demand for smart hearing protection solutions that can integrate with other personal protective equipment and communication systems, particularly in high-risk industrial and military environments.

Current Challenges in Wearable Acoustic Protection Technology

Despite significant advancements in hearing protection technology, wearable acoustic protection devices continue to face substantial challenges that limit their effectiveness and adoption. Traditional passive hearing protection solutions, such as earplugs and earmuffs, suffer from fundamental limitations including poor frequency selectivity, uncomfortable wear experience, and communication interference. These devices typically provide uniform attenuation across all frequencies, which can impair situational awareness and verbal communication while offering protection.

Active noise cancellation (ANC) technologies have emerged as an alternative, but they present their own set of challenges. Current ANC systems require substantial power consumption, limiting their practicality for extended wearable applications. They also struggle with unpredictable or impulse noises, which are common in industrial and military environments where hearing protection is most critical.

Miniaturization remains a significant hurdle for advanced acoustic protection technologies. The integration of sophisticated acoustic metamaterials into compact, lightweight devices suitable for everyday wear presents complex engineering challenges related to material properties, manufacturing processes, and structural design. The need to balance acoustic performance with comfort and aesthetics further complicates the development process.

Customization and fit issues persist across the industry. Human ear anatomy varies significantly between individuals, yet most commercial solutions offer limited sizing options. Poor fit not only reduces comfort but also compromises acoustic seal integrity, dramatically reducing protection effectiveness. This challenge is particularly pronounced for dynamic activities where movement can disrupt positioning.

Battery life and power management represent ongoing concerns for active protection systems. The energy requirements for continuous signal processing and active noise control create dependencies on frequent recharging or battery replacement, limiting practical deployment scenarios.

Regulatory compliance adds another layer of complexity. Hearing protection devices must meet stringent safety standards across different regions while delivering measurable noise reduction performance. The testing and certification processes for novel acoustic metamaterial-based solutions often lack standardized protocols, creating market entry barriers.

Cost factors continue to impede widespread adoption of advanced hearing protection technologies. Current manufacturing processes for acoustic metamaterials remain expensive compared to conventional materials, driving up end-user prices and limiting accessibility, particularly in developing markets where noise exposure risks are often highest.

Active noise cancellation (ANC) technologies have emerged as an alternative, but they present their own set of challenges. Current ANC systems require substantial power consumption, limiting their practicality for extended wearable applications. They also struggle with unpredictable or impulse noises, which are common in industrial and military environments where hearing protection is most critical.

Miniaturization remains a significant hurdle for advanced acoustic protection technologies. The integration of sophisticated acoustic metamaterials into compact, lightweight devices suitable for everyday wear presents complex engineering challenges related to material properties, manufacturing processes, and structural design. The need to balance acoustic performance with comfort and aesthetics further complicates the development process.

Customization and fit issues persist across the industry. Human ear anatomy varies significantly between individuals, yet most commercial solutions offer limited sizing options. Poor fit not only reduces comfort but also compromises acoustic seal integrity, dramatically reducing protection effectiveness. This challenge is particularly pronounced for dynamic activities where movement can disrupt positioning.

Battery life and power management represent ongoing concerns for active protection systems. The energy requirements for continuous signal processing and active noise control create dependencies on frequent recharging or battery replacement, limiting practical deployment scenarios.

Regulatory compliance adds another layer of complexity. Hearing protection devices must meet stringent safety standards across different regions while delivering measurable noise reduction performance. The testing and certification processes for novel acoustic metamaterial-based solutions often lack standardized protocols, creating market entry barriers.

Cost factors continue to impede widespread adoption of advanced hearing protection technologies. Current manufacturing processes for acoustic metamaterials remain expensive compared to conventional materials, driving up end-user prices and limiting accessibility, particularly in developing markets where noise exposure risks are often highest.

Current Acoustic Metamaterial Solutions for Hearing Protection

01 Metamaterial-based hearing protection devices

Acoustic metamaterials can be engineered to create effective hearing protection devices that selectively block harmful noise while allowing important sounds to pass through. These devices utilize the unique properties of metamaterials to manipulate sound waves, creating frequency-specific barriers that can protect the wearer from damaging noise levels while maintaining situational awareness. The structures can be designed to fit various ear protection formats including earplugs and earmuffs.- Metamaterial-based hearing protection devices: Acoustic metamaterials can be engineered to create effective hearing protection devices that selectively block harmful noise while allowing important sounds to pass through. These metamaterials typically consist of periodic structures with specific resonant properties that can attenuate sound waves at targeted frequencies. By incorporating these metamaterials into earplugs, earmuffs, or other hearing protection devices, they can provide superior noise reduction compared to conventional materials while maintaining speech intelligibility.

- Active noise control systems with metamaterials: Active noise control systems can be enhanced by incorporating acoustic metamaterials to improve their effectiveness. These systems combine electronic components with metamaterial structures to detect, process, and counteract unwanted noise. The metamaterials can be designed to work synergistically with active control algorithms, creating adaptive hearing protection that responds to changing noise environments. This approach allows for dynamic protection that can adjust to different sound conditions while maintaining comfort for the user.

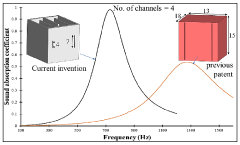

- Resonator-based acoustic metamaterials: Acoustic metamaterials featuring resonator structures can be particularly effective for hearing protection applications. These designs typically incorporate Helmholtz resonators, membrane-type resonators, or other resonant elements arranged in specific patterns to create frequency bandgaps where sound transmission is blocked. The resonators can be tuned to target specific harmful frequency ranges while allowing other frequencies to pass through, enabling selective hearing protection that blocks dangerous noise levels while preserving situational awareness.

- Customizable and adaptive hearing protection: Acoustic metamaterials enable the development of customizable and adaptive hearing protection solutions that can be tailored to individual needs or specific environments. These materials can be designed with tunable properties that adjust their acoustic response based on external conditions or user preferences. Some designs incorporate shape-memory materials or other responsive elements that can change their configuration to provide optimal protection across different noise scenarios, offering personalized hearing protection that balances safety with comfort and functionality.

- Integration with communication systems: Acoustic metamaterials can be integrated with communication systems to create advanced hearing protection devices that not only protect against harmful noise but also enhance communication capabilities. These integrated systems use metamaterial structures to selectively filter noise while allowing communication signals to pass through clearly. Some designs incorporate directional acoustic properties to improve signal-to-noise ratios or feature embedded transducers that work in conjunction with the metamaterial structure to provide clear audio transmission even in high-noise environments.

02 Active noise control systems with metamaterials

Active noise control systems incorporating acoustic metamaterials combine traditional electronic noise cancellation with the physical sound-blocking properties of metamaterials. These systems use sensors to detect incoming noise, process the signal, and generate anti-noise through actuators embedded in metamaterial structures. This hybrid approach provides superior noise reduction across a wider frequency range while maintaining a compact form factor, making it ideal for hearing protection in dynamic noise environments.Expand Specific Solutions03 Frequency-selective acoustic filtering

Acoustic metamaterials can be designed to create frequency-selective filters that block specific harmful frequency ranges while allowing other sounds to pass through. This selective filtering capability is achieved through precisely engineered resonant structures that create acoustic bandgaps. By targeting the exact frequencies that pose hearing damage risks while preserving speech intelligibility and environmental awareness, these metamaterial filters provide more functional hearing protection than traditional solutions.Expand Specific Solutions04 Adaptive and tunable hearing protection

Adaptive hearing protection systems utilize tunable acoustic metamaterials that can adjust their sound-blocking properties in response to changing noise environments. These systems incorporate materials with adjustable mechanical properties or geometries that can be controlled electronically or mechanically to modify their acoustic response. This adaptability allows for dynamic protection that can increase attenuation during high-noise events and decrease it when communication is necessary, providing optimal protection without isolation.Expand Specific Solutions05 Miniaturized metamaterial hearing protection

Miniaturized acoustic metamaterials enable the development of compact, lightweight hearing protection devices that offer performance comparable to or better than larger conventional options. These designs leverage sub-wavelength resonant structures to achieve significant noise reduction despite their small size. The miniaturization makes it possible to create comfortable, discreet hearing protection that can be worn for extended periods without discomfort, increasing user compliance and overall hearing safety.Expand Specific Solutions

Leading Companies in Acoustic Metamaterials Research

The acoustic metamaterials market for wearable hearing protection is in its early growth phase, characterized by increasing research activity and emerging commercial applications. The market is projected to expand significantly due to rising demand for advanced hearing protection in industrial, military, and consumer sectors. Technologically, the field is transitioning from research to application, with varying maturity levels among key players. Leading research institutions like MIT, Tsinghua University, and CNRS are advancing fundamental science, while companies including 3M Innovative Properties, Boeing, and Nissan are developing practical applications. Defense organizations such as National University of Defense Technology are exploring military applications. The ecosystem shows a healthy mix of academic innovation and industrial implementation, with cross-sector collaborations accelerating technology transfer from laboratory to commercial products.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed sophisticated acoustic metamaterial solutions for hearing protection based on locally resonant sonic materials (LRSMs) that create acoustic bandgaps to block specific frequency ranges. Their research has yielded metamaterial structures incorporating multiple resonance mechanisms, including Helmholtz resonators and membrane-type acoustic metamaterials arranged in optimized lattice configurations. CNRS scientists have pioneered the use of auxetic metamaterials with negative Poisson's ratio that expand laterally when stretched, creating adaptive seals for improved comfort in hearing protection devices. Their technology incorporates gradient-index metamaterials that can guide acoustic waves away from the ear canal while maintaining ventilation and pressure equalization. Recent innovations include biomimetic designs inspired by the intricate structure of mammalian ears, with multi-scale hierarchical architectures that provide broadband attenuation while preserving situational awareness through selective frequency filtering, achieving noise reduction coefficients exceeding 30 dB in critical frequency bands.

Strengths: World-class fundamental research capabilities in wave physics and materials science; strong collaboration network with European industrial partners; significant public funding support. Weaknesses: Potential challenges in technology transfer from research to commercial applications; complex designs may face manufacturing scalability issues; European focus may limit global market penetration.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered research in acoustic metamaterials for hearing protection through their development of subwavelength acoustic resonators that can block sound while allowing air flow. Their technology utilizes coiled space architectures that create acoustic pathways much longer than the physical dimensions of the device, enabling exceptional low-frequency noise attenuation in compact form factors. MIT researchers have demonstrated metamaterial-based hearing protection that can selectively filter harmful noise while preserving speech intelligibility through precisely engineered acoustic impedance matching networks. Their approach incorporates helical resonators arranged in optimized patterns to create acoustic bandgaps that block specific frequency ranges without the bulk of traditional hearing protection. Recent innovations include 3D-printed metamaterial structures with tunable properties that can be customized to different acoustic environments and user preferences, potentially enabling personalized hearing protection solutions that adapt to changing noise conditions while maintaining comfort for extended wear periods.

Strengths: Cutting-edge research capabilities and access to advanced fabrication facilities; interdisciplinary approach combining acoustics, materials science, and computational modeling; strong intellectual property portfolio. Weaknesses: Technologies still primarily in research phase rather than commercial products; potential manufacturing complexity may increase costs; academic focus may prioritize innovation over practical implementation concerns.

Key Patents in Wearable Acoustic Metamaterial Applications

Systems, apparatus, and methods for hearing protection

PatentWO2017011064A1

Innovation

- The development of sound pressure level-sensitive passive hearing protection devices using acoustic metamaterials that selectively filter sound pressure waves, featuring a mesh element and liquid membrane within a cavity to amplify or dampen sound based on resonance frequency and sound pressure levels, allowing for adjustable attenuation without the need for additional power.

Symmetrical labyrinthine acoustic metamaterial with unequal slit entries for improved low- frequency sound absorption

PatentActiveIN202311030173A

Innovation

- A symmetrical labyrinthine acoustic metamaterial with unequal slit entries, designed with a labyrinthine section and outer panel section featuring micro-slits of unequal lengths, optimized for low-frequency sound absorption, allowing for broader absorption peaks and reduced thickness.

Ergonomic Design Considerations for Wearable Protection

The integration of acoustic metamaterials into wearable hearing protection devices necessitates careful consideration of ergonomic design principles to ensure user comfort, compliance, and effectiveness. Wearable protection devices must balance acoustic performance with physical comfort, as users may need to wear these devices for extended periods in various environments.

Weight distribution represents a critical ergonomic factor in the design of metamaterial-based hearing protection. Unlike conventional hearing protection that often relies on bulky foam or dense materials, acoustic metamaterials can potentially achieve similar or superior acoustic attenuation with reduced mass. This advantage allows designers to create lighter devices that minimize neck and head strain during prolonged use, particularly important for industrial workers, military personnel, and others who require continuous protection.

Material selection for the components in contact with the user's skin demands special attention. Hypoallergenic materials that prevent skin irritation while maintaining acoustic properties are essential. Additionally, these materials must accommodate temperature regulation to prevent discomfort from heat buildup during extended wear periods. Recent advances in breathable metamaterial structures show promise in addressing this challenge by allowing air circulation while maintaining acoustic isolation.

Anthropometric variations across user populations present another significant design consideration. Acoustic metamaterial-based protection must accommodate different ear canal shapes and sizes to ensure proper sealing and effective noise attenuation. Customizable or adjustable designs that can adapt to individual anatomical differences without compromising acoustic performance represent an important research direction. 3D scanning and printing technologies offer potential solutions for mass customization of these devices.

User mobility requirements significantly influence the design approach. Protection devices for active users, such as construction workers or military personnel, must remain secure during movement while maintaining acoustic performance. Metamaterial structures that can flex without compromising their acoustic properties are being investigated to address this challenge. Recent research has demonstrated promising results with origami-inspired metamaterial designs that maintain structural integrity and acoustic performance during deformation.

Interface design with other personal protective equipment (PPE) presents additional complexity. Many users who require hearing protection also use safety glasses, helmets, or respiratory protection. The metamaterial-based hearing protection must be designed to integrate seamlessly with these other items without creating pressure points or compromising the effectiveness of either protection system. Modular design approaches that allow for customization based on specific PPE combinations show particular promise in this area.

Weight distribution represents a critical ergonomic factor in the design of metamaterial-based hearing protection. Unlike conventional hearing protection that often relies on bulky foam or dense materials, acoustic metamaterials can potentially achieve similar or superior acoustic attenuation with reduced mass. This advantage allows designers to create lighter devices that minimize neck and head strain during prolonged use, particularly important for industrial workers, military personnel, and others who require continuous protection.

Material selection for the components in contact with the user's skin demands special attention. Hypoallergenic materials that prevent skin irritation while maintaining acoustic properties are essential. Additionally, these materials must accommodate temperature regulation to prevent discomfort from heat buildup during extended wear periods. Recent advances in breathable metamaterial structures show promise in addressing this challenge by allowing air circulation while maintaining acoustic isolation.

Anthropometric variations across user populations present another significant design consideration. Acoustic metamaterial-based protection must accommodate different ear canal shapes and sizes to ensure proper sealing and effective noise attenuation. Customizable or adjustable designs that can adapt to individual anatomical differences without compromising acoustic performance represent an important research direction. 3D scanning and printing technologies offer potential solutions for mass customization of these devices.

User mobility requirements significantly influence the design approach. Protection devices for active users, such as construction workers or military personnel, must remain secure during movement while maintaining acoustic performance. Metamaterial structures that can flex without compromising their acoustic properties are being investigated to address this challenge. Recent research has demonstrated promising results with origami-inspired metamaterial designs that maintain structural integrity and acoustic performance during deformation.

Interface design with other personal protective equipment (PPE) presents additional complexity. Many users who require hearing protection also use safety glasses, helmets, or respiratory protection. The metamaterial-based hearing protection must be designed to integrate seamlessly with these other items without creating pressure points or compromising the effectiveness of either protection system. Modular design approaches that allow for customization based on specific PPE combinations show particular promise in this area.

Occupational Safety Standards and Compliance Requirements

Occupational safety standards and compliance requirements form a critical framework for the implementation of acoustic metamaterial-based hearing protection devices in workplace environments. The Occupational Safety and Health Administration (OSHA) in the United States mandates that employers must implement hearing conservation programs when worker noise exposure equals or exceeds 85 decibels averaged over an 8-hour workday. Similar regulations exist globally, with the European Union's Noise Directive 2003/10/EC establishing exposure limit values and requiring employers to provide appropriate hearing protection when engineering controls are insufficient.

These regulatory frameworks create both constraints and opportunities for acoustic metamaterial technology in hearing protection. Compliance with these standards requires that any wearable device must achieve specific noise reduction ratings (NRR), typically ranging from 15 to 33 decibels depending on the workplace environment. The American National Standards Institute (ANSI) S3.19-1974 and more recent ISO 4869 standards outline the testing methodologies for determining these ratings, which any new metamaterial-based solution must satisfy.

Beyond basic attenuation requirements, occupational safety standards increasingly emphasize the importance of speech intelligibility and situational awareness. Traditional hearing protection often creates communication challenges, potentially introducing new safety hazards. This presents a significant opportunity for acoustic metamaterials, which can be engineered for frequency-selective attenuation—blocking harmful noise while preserving speech frequencies and warning signals.

Compliance certification processes represent a substantial barrier to market entry for novel hearing protection technologies. New devices incorporating acoustic metamaterials must undergo rigorous laboratory testing and field validation before receiving approval from regulatory bodies. This process typically requires demonstration of durability, consistency in performance, and compatibility with other personal protective equipment (PPE).

Recent regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, potentially creating more favorable conditions for innovative technologies like acoustic metamaterials. The International Labour Organization (ILO) and World Health Organization (WHO) have also established global guidelines that recognize the growing problem of occupational noise-induced hearing loss, estimating that 16% of disabling hearing loss worldwide is attributable to occupational noise exposure.

For manufacturers developing metamaterial-based hearing protection, understanding these regulatory landscapes across different regions is essential for product development and market access strategies. Compliance requirements should be integrated early in the design process rather than addressed as an afterthought, ensuring that innovative technical capabilities translate to commercially viable and legally compliant products.

These regulatory frameworks create both constraints and opportunities for acoustic metamaterial technology in hearing protection. Compliance with these standards requires that any wearable device must achieve specific noise reduction ratings (NRR), typically ranging from 15 to 33 decibels depending on the workplace environment. The American National Standards Institute (ANSI) S3.19-1974 and more recent ISO 4869 standards outline the testing methodologies for determining these ratings, which any new metamaterial-based solution must satisfy.

Beyond basic attenuation requirements, occupational safety standards increasingly emphasize the importance of speech intelligibility and situational awareness. Traditional hearing protection often creates communication challenges, potentially introducing new safety hazards. This presents a significant opportunity for acoustic metamaterials, which can be engineered for frequency-selective attenuation—blocking harmful noise while preserving speech frequencies and warning signals.

Compliance certification processes represent a substantial barrier to market entry for novel hearing protection technologies. New devices incorporating acoustic metamaterials must undergo rigorous laboratory testing and field validation before receiving approval from regulatory bodies. This process typically requires demonstration of durability, consistency in performance, and compatibility with other personal protective equipment (PPE).

Recent regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, potentially creating more favorable conditions for innovative technologies like acoustic metamaterials. The International Labour Organization (ILO) and World Health Organization (WHO) have also established global guidelines that recognize the growing problem of occupational noise-induced hearing loss, estimating that 16% of disabling hearing loss worldwide is attributable to occupational noise exposure.

For manufacturers developing metamaterial-based hearing protection, understanding these regulatory landscapes across different regions is essential for product development and market access strategies. Compliance requirements should be integrated early in the design process rather than addressed as an afterthought, ensuring that innovative technical capabilities translate to commercially viable and legally compliant products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!