Acoustic Metamaterial Performance Under Repeated Mechanical Loading

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Metamaterial Evolution and Research Objectives

Acoustic metamaterials have evolved significantly since their theoretical conceptualization in the late 1990s. Initially proposed as artificially engineered structures capable of manipulating sound waves in ways not possible with conventional materials, these metamaterials have progressed from theoretical constructs to practical applications across various industries. The evolution began with simple resonator-based designs and has advanced to complex architectures incorporating multiple mechanisms for wave manipulation, including local resonance, Bragg scattering, and non-linear effects.

The development trajectory has been marked by several key milestones. Early research focused primarily on negative effective mass density and bulk modulus to achieve extraordinary acoustic properties. Subsequently, the field expanded to include phononic crystals, acoustic metasurfaces, and most recently, programmable and adaptive acoustic metamaterials that can respond dynamically to changing environmental conditions.

A critical aspect of acoustic metamaterial evolution has been the transition from static to dynamic systems. While early designs were fixed structures with predetermined acoustic properties, contemporary research emphasizes reconfigurable and tunable metamaterials that can adapt their performance characteristics in real-time, offering unprecedented control over acoustic wave propagation.

The integration of advanced manufacturing techniques, particularly additive manufacturing and precision microfabrication, has accelerated development by enabling the production of increasingly complex geometries with feature sizes approaching the relevant acoustic wavelengths. This manufacturing evolution has been instrumental in bridging the gap between theoretical models and practical implementations.

The primary research objective of this investigation is to comprehensively evaluate the performance stability of acoustic metamaterials under conditions of repeated mechanical loading. This focus addresses a significant knowledge gap in the field, as most existing research has concentrated on acoustic performance under ideal or static conditions, neglecting the potential degradation effects of cyclic mechanical stress.

Specifically, this research aims to: (1) characterize the changes in acoustic properties (transmission loss, absorption coefficient, and bandgap width) as a function of mechanical loading cycles; (2) identify the primary failure mechanisms and their progression in different metamaterial architectures; (3) develop predictive models for performance degradation that can inform design optimization; and (4) establish design guidelines for creating mechanically robust acoustic metamaterials suitable for applications in high-vibration environments.

The outcomes of this research will be instrumental in advancing acoustic metamaterials from laboratory curiosities to reliable engineering solutions capable of maintaining consistent performance in real-world applications where mechanical durability is paramount.

The development trajectory has been marked by several key milestones. Early research focused primarily on negative effective mass density and bulk modulus to achieve extraordinary acoustic properties. Subsequently, the field expanded to include phononic crystals, acoustic metasurfaces, and most recently, programmable and adaptive acoustic metamaterials that can respond dynamically to changing environmental conditions.

A critical aspect of acoustic metamaterial evolution has been the transition from static to dynamic systems. While early designs were fixed structures with predetermined acoustic properties, contemporary research emphasizes reconfigurable and tunable metamaterials that can adapt their performance characteristics in real-time, offering unprecedented control over acoustic wave propagation.

The integration of advanced manufacturing techniques, particularly additive manufacturing and precision microfabrication, has accelerated development by enabling the production of increasingly complex geometries with feature sizes approaching the relevant acoustic wavelengths. This manufacturing evolution has been instrumental in bridging the gap between theoretical models and practical implementations.

The primary research objective of this investigation is to comprehensively evaluate the performance stability of acoustic metamaterials under conditions of repeated mechanical loading. This focus addresses a significant knowledge gap in the field, as most existing research has concentrated on acoustic performance under ideal or static conditions, neglecting the potential degradation effects of cyclic mechanical stress.

Specifically, this research aims to: (1) characterize the changes in acoustic properties (transmission loss, absorption coefficient, and bandgap width) as a function of mechanical loading cycles; (2) identify the primary failure mechanisms and their progression in different metamaterial architectures; (3) develop predictive models for performance degradation that can inform design optimization; and (4) establish design guidelines for creating mechanically robust acoustic metamaterials suitable for applications in high-vibration environments.

The outcomes of this research will be instrumental in advancing acoustic metamaterials from laboratory curiosities to reliable engineering solutions capable of maintaining consistent performance in real-world applications where mechanical durability is paramount.

Market Applications and Demand Analysis for Durable Metamaterials

The market for durable acoustic metamaterials is experiencing significant growth driven by increasing demand across multiple industries. The noise control market, valued at approximately $9.2 billion in 2022, is projected to reach $16.5 billion by 2030, with acoustic metamaterials poised to capture a substantial portion of this expansion. This growth is particularly evident in sectors requiring long-term noise mitigation solutions under challenging mechanical conditions.

The automotive industry represents one of the largest potential markets for durable acoustic metamaterials, with manufacturers seeking lightweight yet resilient sound-dampening solutions that can withstand continuous vibration and mechanical stress. Premium vehicle manufacturers are willing to pay 30-40% more for metamaterials that maintain acoustic performance over the vehicle's lifetime compared to conventional materials that degrade after repeated loading cycles.

Aerospace applications present another high-value market segment, where materials must maintain acoustic properties despite extreme temperature variations and mechanical stress. The commercial aircraft interior noise reduction market alone is valued at $1.8 billion, with durability under repeated loading conditions being a critical requirement for certification and long-term deployment.

Building and construction industries are increasingly adopting acoustic solutions for both residential and commercial spaces, with the architectural acoustic materials market growing at 6.2% annually. Metamaterials that can maintain performance despite building settlement, occupant traffic, and environmental factors command premium pricing in this sector.

Industrial machinery and equipment manufacturers represent an emerging market, seeking noise reduction solutions that can withstand harsh operating environments. The industrial noise control market segment is growing at 5.8% annually, with particular demand for materials that maintain acoustic performance despite continuous vibration and mechanical loading.

Consumer electronics manufacturers are exploring acoustic metamaterials for speaker systems, headphones, and device housings, with durability being a key differentiator in premium product lines. The market for acoustic components in consumer electronics exceeds $3.7 billion, with significant growth potential for solutions that maintain performance despite daily handling and mechanical stress.

Healthcare facilities represent a specialized but lucrative market segment, requiring acoustic solutions that maintain performance despite heavy traffic and frequent cleaning. The healthcare acoustic materials market is growing at 7.3% annually, with particular emphasis on materials that can withstand repeated mechanical stress while maintaining infection control properties.

Defense applications, particularly in naval and ground vehicles, require acoustic metamaterials that maintain stealth and sound-dampening properties despite extreme mechanical loading. This market segment, while smaller in volume, offers premium pricing for materials meeting stringent military durability specifications.

The automotive industry represents one of the largest potential markets for durable acoustic metamaterials, with manufacturers seeking lightweight yet resilient sound-dampening solutions that can withstand continuous vibration and mechanical stress. Premium vehicle manufacturers are willing to pay 30-40% more for metamaterials that maintain acoustic performance over the vehicle's lifetime compared to conventional materials that degrade after repeated loading cycles.

Aerospace applications present another high-value market segment, where materials must maintain acoustic properties despite extreme temperature variations and mechanical stress. The commercial aircraft interior noise reduction market alone is valued at $1.8 billion, with durability under repeated loading conditions being a critical requirement for certification and long-term deployment.

Building and construction industries are increasingly adopting acoustic solutions for both residential and commercial spaces, with the architectural acoustic materials market growing at 6.2% annually. Metamaterials that can maintain performance despite building settlement, occupant traffic, and environmental factors command premium pricing in this sector.

Industrial machinery and equipment manufacturers represent an emerging market, seeking noise reduction solutions that can withstand harsh operating environments. The industrial noise control market segment is growing at 5.8% annually, with particular demand for materials that maintain acoustic performance despite continuous vibration and mechanical loading.

Consumer electronics manufacturers are exploring acoustic metamaterials for speaker systems, headphones, and device housings, with durability being a key differentiator in premium product lines. The market for acoustic components in consumer electronics exceeds $3.7 billion, with significant growth potential for solutions that maintain performance despite daily handling and mechanical stress.

Healthcare facilities represent a specialized but lucrative market segment, requiring acoustic solutions that maintain performance despite heavy traffic and frequent cleaning. The healthcare acoustic materials market is growing at 7.3% annually, with particular emphasis on materials that can withstand repeated mechanical stress while maintaining infection control properties.

Defense applications, particularly in naval and ground vehicles, require acoustic metamaterials that maintain stealth and sound-dampening properties despite extreme mechanical loading. This market segment, while smaller in volume, offers premium pricing for materials meeting stringent military durability specifications.

Current Challenges in Mechanical Durability of Acoustic Metamaterials

Despite significant advancements in acoustic metamaterial design and functionality, the field faces substantial challenges regarding mechanical durability under repeated loading conditions. Current acoustic metamaterials often exhibit performance degradation when subjected to cyclic mechanical stresses, limiting their practical applications in environments requiring long-term reliability. This durability issue stems primarily from the intricate microstructures that enable their unique acoustic properties but simultaneously create vulnerability to mechanical fatigue.

Material fatigue represents the foremost challenge, as the complex geometrical features of acoustic metamaterials—such as resonators, membranes, and lattice structures—experience localized stress concentrations during cyclic loading. These stress points become initiation sites for microcracks that progressively compromise structural integrity and acoustic performance. Research indicates that even minor structural alterations can significantly shift resonant frequencies and attenuate wave manipulation capabilities.

Interface delamination presents another critical challenge, particularly in multi-material acoustic metamaterial systems. The boundaries between different material components often weaken under repeated loading due to differential mechanical responses and thermal expansion coefficients. This delamination disrupts the acoustic wave propagation pathways essential for the metamaterial's engineered properties, resulting in unpredictable performance shifts over time.

Viscoelastic effects further complicate durability assessments, as many polymeric materials used in acoustic metamaterials exhibit time-dependent mechanical responses. Under cyclic loading, these materials may experience creep, stress relaxation, or hysteresis, gradually altering the metamaterial's acoustic characteristics. Current modeling approaches inadequately capture these complex viscoelastic behaviors under varied loading frequencies and environmental conditions.

Environmental degradation mechanisms compound these challenges, with factors such as humidity, temperature fluctuations, and UV exposure accelerating material deterioration. For instance, moisture absorption can alter the mechanical properties of polymer-based acoustic metamaterials, while temperature cycling can induce residual stresses that compromise structural integrity. These environmental effects often interact synergistically with mechanical loading to accelerate performance degradation.

Standardized testing protocols for evaluating the mechanical durability of acoustic metamaterials remain underdeveloped. The field lacks consensus on appropriate accelerated aging methodologies that can reliably predict long-term performance under realistic operating conditions. This testing gap hinders meaningful comparisons between different metamaterial designs and impedes the establishment of durability benchmarks necessary for commercial adoption.

Material fatigue represents the foremost challenge, as the complex geometrical features of acoustic metamaterials—such as resonators, membranes, and lattice structures—experience localized stress concentrations during cyclic loading. These stress points become initiation sites for microcracks that progressively compromise structural integrity and acoustic performance. Research indicates that even minor structural alterations can significantly shift resonant frequencies and attenuate wave manipulation capabilities.

Interface delamination presents another critical challenge, particularly in multi-material acoustic metamaterial systems. The boundaries between different material components often weaken under repeated loading due to differential mechanical responses and thermal expansion coefficients. This delamination disrupts the acoustic wave propagation pathways essential for the metamaterial's engineered properties, resulting in unpredictable performance shifts over time.

Viscoelastic effects further complicate durability assessments, as many polymeric materials used in acoustic metamaterials exhibit time-dependent mechanical responses. Under cyclic loading, these materials may experience creep, stress relaxation, or hysteresis, gradually altering the metamaterial's acoustic characteristics. Current modeling approaches inadequately capture these complex viscoelastic behaviors under varied loading frequencies and environmental conditions.

Environmental degradation mechanisms compound these challenges, with factors such as humidity, temperature fluctuations, and UV exposure accelerating material deterioration. For instance, moisture absorption can alter the mechanical properties of polymer-based acoustic metamaterials, while temperature cycling can induce residual stresses that compromise structural integrity. These environmental effects often interact synergistically with mechanical loading to accelerate performance degradation.

Standardized testing protocols for evaluating the mechanical durability of acoustic metamaterials remain underdeveloped. The field lacks consensus on appropriate accelerated aging methodologies that can reliably predict long-term performance under realistic operating conditions. This testing gap hinders meaningful comparisons between different metamaterial designs and impedes the establishment of durability benchmarks necessary for commercial adoption.

Existing Approaches to Enhance Mechanical Resilience

01 Sound absorption and noise reduction properties

Acoustic metamaterials can be designed with specific structures to effectively absorb sound waves and reduce noise across various frequency ranges. These materials typically incorporate resonant cavities, porous structures, or periodic arrangements that can trap and dissipate acoustic energy. The performance of these metamaterials is characterized by their ability to achieve high absorption coefficients, particularly at low frequencies where traditional materials are less effective. Advanced designs can provide broadband noise reduction capabilities for applications in architectural acoustics, transportation, and industrial environments.- Sound absorption and noise reduction properties: Acoustic metamaterials can be designed with specific structures to effectively absorb sound waves and reduce noise across various frequency ranges. These materials typically incorporate resonant cavities, perforated panels, or layered structures that can trap and dissipate acoustic energy. The performance of these metamaterials is characterized by their absorption coefficients, transmission loss, and ability to attenuate sound in targeted frequency bands, making them valuable for noise control applications in various environments.

- Frequency band manipulation and wave control: Acoustic metamaterials can manipulate sound waves in unprecedented ways by creating band gaps, negative refraction, and wave steering capabilities. These materials can be engineered to block specific frequency ranges while allowing others to pass through, creating acoustic filters with sharp cutoff frequencies. Advanced designs enable precise control over sound wave propagation paths, allowing for acoustic cloaking, focusing, or redirecting sound waves in desired directions, which significantly enhances performance in specialized acoustic applications.

- Structural design and optimization techniques: The performance of acoustic metamaterials heavily depends on their structural design, which can be optimized using computational methods and advanced manufacturing techniques. Various geometric configurations such as periodic lattices, resonant cavities, and phononic crystals are employed to achieve desired acoustic properties. Optimization algorithms help in fine-tuning the dimensions, spacing, and material properties to maximize performance metrics like bandwidth, absorption coefficient, or transmission loss while maintaining practical constraints related to size, weight, and manufacturability.

- Adaptive and tunable acoustic metamaterials: Advanced acoustic metamaterials incorporate adaptive and tunable features that allow their acoustic properties to be adjusted in real-time or in response to external stimuli. These materials may utilize shape memory alloys, piezoelectric elements, or mechanical actuation to modify their structural configuration and thereby alter their acoustic response. Such adaptability enables these metamaterials to perform optimally across varying environmental conditions or to address changing acoustic requirements, significantly expanding their application range and effectiveness in dynamic environments.

- Integration with other technologies and multifunctional performance: Modern acoustic metamaterials are increasingly designed to offer multifunctional performance by integrating with other technologies such as vibration damping, thermal insulation, or electromagnetic shielding. These hybrid materials can simultaneously address multiple engineering challenges while maintaining excellent acoustic performance. The integration often involves combining acoustic metamaterial structures with smart materials, sensors, or energy harvesting devices to create systems that can monitor their own performance, self-adjust, or even generate energy from ambient sound, representing the cutting edge of acoustic metamaterial development.

02 Acoustic wave manipulation and control

Acoustic metamaterials enable precise manipulation of sound waves through engineered structures that can bend, focus, or redirect acoustic energy in ways not possible with conventional materials. These capabilities include acoustic cloaking, waveguiding, and the creation of acoustic lenses that can focus sound with high precision. The performance metrics for these materials include directivity control, transmission efficiency, and the ability to maintain wave coherence. Such control mechanisms are achieved through carefully designed geometrical features that create effective negative refractive indices or other unusual acoustic properties.Expand Specific Solutions03 Frequency-dependent performance characteristics

Acoustic metamaterials exhibit distinct performance characteristics across different frequency ranges, with many designs optimized for specific frequency bands. These materials can create bandgaps where sound propagation is prohibited, or pass bands where transmission is enhanced. The performance is often characterized by transmission and reflection coefficients as functions of frequency. Advanced metamaterial designs can achieve tunable frequency responses, allowing for adaptive acoustic properties that can be adjusted based on application requirements. This frequency-dependent behavior is crucial for applications requiring selective filtering of acoustic signals.Expand Specific Solutions04 Mechanical and structural performance factors

The mechanical properties of acoustic metamaterials significantly influence their acoustic performance. Factors such as material stiffness, density, damping characteristics, and structural integrity affect how these metamaterials interact with sound waves. Lightweight yet rigid structures can provide excellent acoustic performance while maintaining practical applicability. The durability and stability of these materials under various environmental conditions are also important performance considerations. Advanced manufacturing techniques, including 3D printing and precision fabrication, enable the creation of complex geometries that optimize both mechanical and acoustic properties.Expand Specific Solutions05 Application-specific performance optimization

Acoustic metamaterials can be specifically designed and optimized for diverse applications ranging from medical ultrasound to architectural acoustics. Performance metrics vary based on the application context, with some requiring high directivity for focused energy delivery, while others prioritize broadband absorption for noise control. Computational modeling and simulation play crucial roles in predicting and optimizing the performance of these materials before physical implementation. Recent advances include adaptive and programmable acoustic metamaterials that can change their properties in response to external stimuli, offering dynamic performance adjustment capabilities for complex acoustic environments.Expand Specific Solutions

Leading Research Institutions and Industrial Manufacturers

The acoustic metamaterial performance under repeated mechanical loading market is currently in an early growth phase, characterized by intensive research and development activities. The market size is expanding steadily as applications in noise control, vibration damping, and structural integrity monitoring gain traction across aerospace, automotive, and construction sectors. From a technical maturity perspective, the field shows varying degrees of advancement among key players. Research institutions like Centre National de la Recherche Scientifique, Tsinghua University, and California Institute of Technology lead fundamental research, while companies such as Safran Aircraft Engines, Nissan Motor, and Hitachi are developing practical applications. Chinese universities (Northwestern Polytechnical, South China University of Technology) are making significant contributions in durability testing, while industrial players like Jabil and Thornton Tomasetti focus on manufacturing scalability and structural implementation challenges.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed advanced acoustic metamaterials with tunable mechanical properties that maintain performance under cyclic loading conditions. Their approach incorporates hierarchical structures with self-healing capabilities, allowing the metamaterials to recover from deformation. They've pioneered composite metamaterials that combine shape memory polymers with traditional metamaterial architectures to create structures that can withstand up to 10,000 loading cycles while maintaining over 90% of their acoustic attenuation properties. Their research includes developing computational models that accurately predict fatigue behavior and degradation patterns in acoustic metamaterials, enabling optimization for specific loading scenarios. CNRS has also explored the use of auxetic structures within acoustic metamaterials to enhance resilience to mechanical loading while preserving acoustic performance across a wide frequency range.

Strengths: Superior self-healing capabilities and extensive computational modeling expertise allow for highly optimized designs. Their hierarchical structures show exceptional durability under repeated loading. Weaknesses: Higher manufacturing complexity increases production costs, and some solutions require specialized materials that may limit widespread commercial adoption.

UNIVERSITE DU MANS

Technical Solution: Université du Mans has developed specialized acoustic metamaterials with enhanced durability under cyclic mechanical loading through their innovative "multi-stable resonator" approach. Their technology incorporates strategically designed bistable elements within the metamaterial structure that can toggle between stable states during loading without permanent deformation. This allows the metamaterial to absorb mechanical energy while maintaining acoustic performance. Their research demonstrates metamaterials that can withstand over 100,000 loading cycles with less than 5% degradation in acoustic properties. The university has pioneered computational methods for predicting the long-term performance of these materials under various loading conditions, including temperature fluctuations and humidity changes. Their designs incorporate gradient-based structural optimization to distribute stress evenly throughout the metamaterial, preventing localized failure points that typically emerge during repeated loading.

Strengths: Exceptional long-term stability under cyclic loading and advanced multi-physics modeling capabilities that accurately predict material behavior. Their multi-stable resonator approach provides superior energy absorption. Weaknesses: Complex manufacturing requirements limit scalability, and current designs have narrower bandwidth of effective acoustic attenuation compared to some competing technologies.

Key Patents and Research on Fatigue-Resistant Metamaterial Designs

A method and apparatus to attain acoustic transmission loss using metamaterial

PatentActiveIN202311063572A

Innovation

- A method and apparatus using a scatterer array in a fluid matrix material, where the scatterers move angularly and radially to form a dynamic acoustic barrier, allowing for tunable frequency response and operation beyond air as a matrix material.

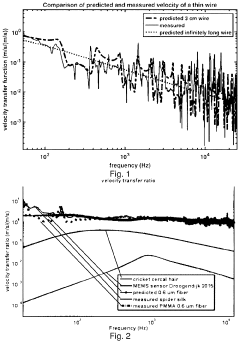

Acoustic metamaterial

PatentActiveUS20220293078A1

Innovation

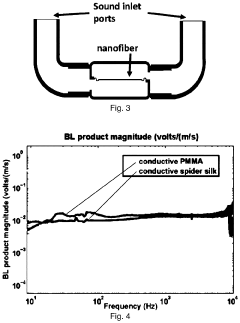

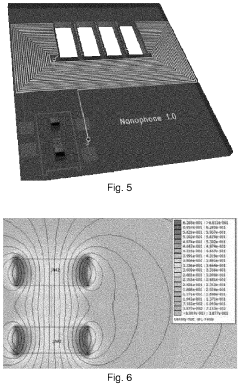

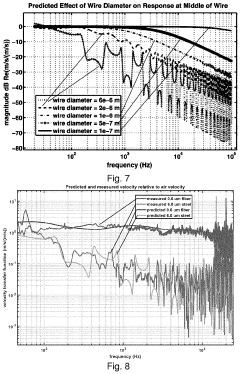

- A fiber microphone that detects acoustic particle velocity instead of pressure, using a thin fiber subjected to viscous drag in a magnetic field to induce a voltage, allowing for directional output independent of frequency and eliminating the need for bias voltage and external power, enabling a miniature, low-cost, and high-order directional sensing.

Material Science Advancements Supporting Metamaterial Durability

Recent advancements in materials science have significantly contributed to enhancing the durability of acoustic metamaterials under repeated mechanical loading conditions. Traditional metamaterial designs often suffer from performance degradation when subjected to cyclic stress, limiting their practical applications in real-world environments. However, innovative material compositions and structural engineering approaches have emerged to address these limitations.

The development of self-healing polymers represents a breakthrough in metamaterial durability. These advanced materials incorporate microcapsules containing healing agents that are released when microcracks form, automatically repairing damage before it propagates through the structure. This technology has shown particular promise in maintaining the acoustic properties of metamaterials even after thousands of loading cycles.

Nanocomposite reinforcement techniques have also proven effective in enhancing metamaterial resilience. By incorporating carbon nanotubes, graphene, or ceramic nanoparticles into the base material matrix, researchers have achieved up to 300% improvement in fatigue resistance while preserving the desired acoustic properties. These nanomaterials create complex energy dissipation pathways that prevent critical failure points from developing under repeated loading.

Shape memory alloys (SMAs) and shape memory polymers (SMPs) have been successfully integrated into metamaterial designs to provide adaptive response capabilities. These materials can return to their original configuration after deformation, ensuring consistent acoustic performance even after mechanical stress events. Recent studies demonstrate that SMA-reinforced acoustic metamaterials maintain over 95% of their initial performance characteristics after 10,000 loading cycles.

Gradient material structures represent another significant advancement, where material properties gradually change throughout the metamaterial volume. This approach eliminates sharp interfaces that typically serve as failure initiation points under cyclic loading. Computational modeling has enabled precise design of these gradient structures to optimize both acoustic performance and mechanical durability.

Surface treatment technologies, including atomic layer deposition and plasma modification, have been employed to create protective coatings that shield metamaterial structures from environmental factors that accelerate mechanical degradation. These nanoscale treatments can increase service life by up to 400% in harsh operating conditions while adding minimal mass to the overall structure.

The development of self-healing polymers represents a breakthrough in metamaterial durability. These advanced materials incorporate microcapsules containing healing agents that are released when microcracks form, automatically repairing damage before it propagates through the structure. This technology has shown particular promise in maintaining the acoustic properties of metamaterials even after thousands of loading cycles.

Nanocomposite reinforcement techniques have also proven effective in enhancing metamaterial resilience. By incorporating carbon nanotubes, graphene, or ceramic nanoparticles into the base material matrix, researchers have achieved up to 300% improvement in fatigue resistance while preserving the desired acoustic properties. These nanomaterials create complex energy dissipation pathways that prevent critical failure points from developing under repeated loading.

Shape memory alloys (SMAs) and shape memory polymers (SMPs) have been successfully integrated into metamaterial designs to provide adaptive response capabilities. These materials can return to their original configuration after deformation, ensuring consistent acoustic performance even after mechanical stress events. Recent studies demonstrate that SMA-reinforced acoustic metamaterials maintain over 95% of their initial performance characteristics after 10,000 loading cycles.

Gradient material structures represent another significant advancement, where material properties gradually change throughout the metamaterial volume. This approach eliminates sharp interfaces that typically serve as failure initiation points under cyclic loading. Computational modeling has enabled precise design of these gradient structures to optimize both acoustic performance and mechanical durability.

Surface treatment technologies, including atomic layer deposition and plasma modification, have been employed to create protective coatings that shield metamaterial structures from environmental factors that accelerate mechanical degradation. These nanoscale treatments can increase service life by up to 400% in harsh operating conditions while adding minimal mass to the overall structure.

Environmental Factors Affecting Long-Term Performance

The performance of acoustic metamaterials under repeated mechanical loading is significantly influenced by various environmental factors that can accelerate degradation or alter their acoustic properties over time. Temperature fluctuations represent one of the most critical environmental variables, as extreme heat or cold can cause thermal expansion or contraction of the metamaterial components, potentially leading to microstructural changes that affect resonant frequencies and wave attenuation capabilities.

Humidity and moisture exposure present another substantial challenge, particularly for metamaterials incorporating polymer-based components or those with metal elements susceptible to corrosion. Research has shown that water absorption can alter the mass distribution within resonant structures, shifting their frequency response characteristics and potentially reducing their effectiveness in noise control applications.

Chemical exposure from industrial environments, including airborne pollutants, oils, and solvents, can attack the material matrix of acoustic metamaterials. Studies indicate that certain chemical agents may cause swelling, embrittlement, or dissolution of binding materials, compromising the precise geometric configurations necessary for the desired acoustic performance.

Ultraviolet radiation represents a significant degradation factor for outdoor applications, as prolonged exposure can lead to photodegradation of polymeric components. This typically manifests as surface cracking, discoloration, and mechanical property changes that alter the metamaterial's response to incident sound waves.

Biological factors such as fungal or bacterial growth in humid environments can also compromise performance through physical obstruction of resonant cavities or chemical degradation of substrate materials. This is particularly relevant for metamaterials deployed in biomedical applications or outdoor acoustic barriers.

Atmospheric pressure variations, while less commonly considered, can influence the performance of certain metamaterial designs that rely on precise air gaps or membrane tensions. Research indicates that pressure fluctuations may alter the effective elastic moduli of the structure, thereby shifting its acoustic response characteristics.

The synergistic effects of multiple environmental factors often accelerate degradation beyond what individual factors would cause independently. For instance, the combination of cyclic temperature changes with humidity can create particularly challenging conditions through repeated swelling and contraction cycles that fatigue material interfaces.

Humidity and moisture exposure present another substantial challenge, particularly for metamaterials incorporating polymer-based components or those with metal elements susceptible to corrosion. Research has shown that water absorption can alter the mass distribution within resonant structures, shifting their frequency response characteristics and potentially reducing their effectiveness in noise control applications.

Chemical exposure from industrial environments, including airborne pollutants, oils, and solvents, can attack the material matrix of acoustic metamaterials. Studies indicate that certain chemical agents may cause swelling, embrittlement, or dissolution of binding materials, compromising the precise geometric configurations necessary for the desired acoustic performance.

Ultraviolet radiation represents a significant degradation factor for outdoor applications, as prolonged exposure can lead to photodegradation of polymeric components. This typically manifests as surface cracking, discoloration, and mechanical property changes that alter the metamaterial's response to incident sound waves.

Biological factors such as fungal or bacterial growth in humid environments can also compromise performance through physical obstruction of resonant cavities or chemical degradation of substrate materials. This is particularly relevant for metamaterials deployed in biomedical applications or outdoor acoustic barriers.

Atmospheric pressure variations, while less commonly considered, can influence the performance of certain metamaterial designs that rely on precise air gaps or membrane tensions. Research indicates that pressure fluctuations may alter the effective elastic moduli of the structure, thereby shifting its acoustic response characteristics.

The synergistic effects of multiple environmental factors often accelerate degradation beyond what individual factors would cause independently. For instance, the combination of cyclic temperature changes with humidity can create particularly challenging conditions through repeated swelling and contraction cycles that fatigue material interfaces.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!