Enhancing Acrylic Resin Coatings for Anti-Graffiti Applications

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anti-Graffiti Coating Technology Background and Objectives

Anti-graffiti coatings have emerged as a critical solution for protecting surfaces against vandalism, with their development tracing back to the late 1970s when urban graffiti began proliferating in major cities worldwide. Initially, these protective systems were primarily solvent-based polyurethanes offering limited durability and environmental compliance. The evolution of anti-graffiti technology has since followed broader coating industry trends toward water-based, environmentally friendly formulations with enhanced performance characteristics.

Acrylic resins represent a significant advancement in this technological progression, offering excellent weatherability, UV resistance, and optical clarity while maintaining cost-effectiveness compared to fluoropolymer alternatives. These properties have positioned acrylics as an attractive base for anti-graffiti applications, though they traditionally lack the necessary hardness and chemical resistance to withstand repeated cleaning cycles and aggressive solvents used in graffiti removal.

The current technological landscape shows a clear trend toward multi-functional coating systems that not only resist graffiti but also provide additional benefits such as anti-microbial properties, self-cleaning capabilities, and reduced environmental impact. Market leaders have developed two primary approaches: sacrificial coatings that wash away during cleaning and permanent coatings that resist multiple cleaning cycles without degradation.

Recent innovations have focused on incorporating nanomaterials and hybrid organic-inorganic components to enhance the performance of acrylic-based systems. Silica nanoparticles, fluorinated additives, and crosslinking technologies have shown promising results in laboratory settings, though commercial implementation faces challenges related to cost, scalability, and long-term performance validation.

The primary objective of enhancing acrylic resin coatings for anti-graffiti applications centers on developing formulations that maintain the inherent benefits of acrylics while significantly improving their resistance to graffiti adhesion and cleaning processes. Specifically, research aims to achieve coatings that can withstand at least 100 cleaning cycles without performance degradation, resist common graffiti media (spray paints, permanent markers, adhesives), and maintain aesthetic properties throughout their service life.

Secondary objectives include reducing volatile organic compound (VOC) content to meet increasingly stringent environmental regulations, improving application characteristics for various substrate materials, and developing cost-effective solutions accessible to public infrastructure projects with limited budgets. The ideal technology would bridge the current performance gap between affordable acrylic systems and premium fluoropolymer or polysiloxane alternatives.

The technological trajectory suggests potential breakthroughs in self-healing acrylic formulations, stimuli-responsive systems that facilitate easier cleaning, and bio-based components that reduce environmental footprint while maintaining performance standards. These advancements align with broader sustainability initiatives and increasing demand for smart coating technologies in urban environments.

Acrylic resins represent a significant advancement in this technological progression, offering excellent weatherability, UV resistance, and optical clarity while maintaining cost-effectiveness compared to fluoropolymer alternatives. These properties have positioned acrylics as an attractive base for anti-graffiti applications, though they traditionally lack the necessary hardness and chemical resistance to withstand repeated cleaning cycles and aggressive solvents used in graffiti removal.

The current technological landscape shows a clear trend toward multi-functional coating systems that not only resist graffiti but also provide additional benefits such as anti-microbial properties, self-cleaning capabilities, and reduced environmental impact. Market leaders have developed two primary approaches: sacrificial coatings that wash away during cleaning and permanent coatings that resist multiple cleaning cycles without degradation.

Recent innovations have focused on incorporating nanomaterials and hybrid organic-inorganic components to enhance the performance of acrylic-based systems. Silica nanoparticles, fluorinated additives, and crosslinking technologies have shown promising results in laboratory settings, though commercial implementation faces challenges related to cost, scalability, and long-term performance validation.

The primary objective of enhancing acrylic resin coatings for anti-graffiti applications centers on developing formulations that maintain the inherent benefits of acrylics while significantly improving their resistance to graffiti adhesion and cleaning processes. Specifically, research aims to achieve coatings that can withstand at least 100 cleaning cycles without performance degradation, resist common graffiti media (spray paints, permanent markers, adhesives), and maintain aesthetic properties throughout their service life.

Secondary objectives include reducing volatile organic compound (VOC) content to meet increasingly stringent environmental regulations, improving application characteristics for various substrate materials, and developing cost-effective solutions accessible to public infrastructure projects with limited budgets. The ideal technology would bridge the current performance gap between affordable acrylic systems and premium fluoropolymer or polysiloxane alternatives.

The technological trajectory suggests potential breakthroughs in self-healing acrylic formulations, stimuli-responsive systems that facilitate easier cleaning, and bio-based components that reduce environmental footprint while maintaining performance standards. These advancements align with broader sustainability initiatives and increasing demand for smart coating technologies in urban environments.

Market Analysis for Anti-Graffiti Solutions

The global anti-graffiti coatings market has been experiencing steady growth, valued at approximately $72.4 billion in 2022 and projected to reach $105.6 billion by 2028, representing a compound annual growth rate (CAGR) of 6.5%. This growth is primarily driven by increasing urbanization, rising instances of vandalism in public spaces, and growing awareness about the economic impact of graffiti removal among municipal authorities and property owners.

Urban centers worldwide are allocating substantial budgets for graffiti removal and prevention. For instance, major cities like New York, London, and Sydney each spend between $15-25 million annually on graffiti management programs. These expenditures highlight the significant economic burden that unauthorized graffiti places on public resources and private property owners.

The market for anti-graffiti solutions can be segmented by application into transportation infrastructure (30% market share), public buildings (25%), commercial properties (20%), residential buildings (15%), and others (10%). Transportation infrastructure, including bridges, tunnels, and transit stations, represents the largest segment due to high visibility and accessibility to vandals.

Geographically, North America and Europe currently dominate the anti-graffiti coatings market, collectively accounting for 65% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market with a CAGR of 8.2%, driven by rapid urbanization in countries like China and India.

Customer requirements for anti-graffiti coatings have evolved significantly. End-users now demand solutions that not only prevent graffiti adhesion but also offer environmental sustainability, durability under various weather conditions, and ease of maintenance. The market increasingly favors permanent anti-graffiti systems over sacrificial coatings due to their long-term cost-effectiveness despite higher initial investment.

Recent market surveys indicate that 78% of potential customers prioritize performance longevity, while 65% consider environmental impact a critical factor in purchasing decisions. This trend aligns with stricter environmental regulations limiting volatile organic compound (VOC) content in coating products, particularly in European and North American markets.

The competitive landscape features both specialized coating manufacturers and diversified chemical companies. Key market players include PPG Industries, Sherwin-Williams, Axalta Coating Systems, and AkzoNobel, who collectively hold approximately 45% market share. These companies are increasingly investing in R&D to develop acrylic resin formulations that offer superior anti-graffiti properties while meeting environmental standards.

Urban centers worldwide are allocating substantial budgets for graffiti removal and prevention. For instance, major cities like New York, London, and Sydney each spend between $15-25 million annually on graffiti management programs. These expenditures highlight the significant economic burden that unauthorized graffiti places on public resources and private property owners.

The market for anti-graffiti solutions can be segmented by application into transportation infrastructure (30% market share), public buildings (25%), commercial properties (20%), residential buildings (15%), and others (10%). Transportation infrastructure, including bridges, tunnels, and transit stations, represents the largest segment due to high visibility and accessibility to vandals.

Geographically, North America and Europe currently dominate the anti-graffiti coatings market, collectively accounting for 65% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market with a CAGR of 8.2%, driven by rapid urbanization in countries like China and India.

Customer requirements for anti-graffiti coatings have evolved significantly. End-users now demand solutions that not only prevent graffiti adhesion but also offer environmental sustainability, durability under various weather conditions, and ease of maintenance. The market increasingly favors permanent anti-graffiti systems over sacrificial coatings due to their long-term cost-effectiveness despite higher initial investment.

Recent market surveys indicate that 78% of potential customers prioritize performance longevity, while 65% consider environmental impact a critical factor in purchasing decisions. This trend aligns with stricter environmental regulations limiting volatile organic compound (VOC) content in coating products, particularly in European and North American markets.

The competitive landscape features both specialized coating manufacturers and diversified chemical companies. Key market players include PPG Industries, Sherwin-Williams, Axalta Coating Systems, and AkzoNobel, who collectively hold approximately 45% market share. These companies are increasingly investing in R&D to develop acrylic resin formulations that offer superior anti-graffiti properties while meeting environmental standards.

Current Acrylic Resin Coating Limitations

Despite the widespread use of acrylic resin coatings in anti-graffiti applications, these materials face significant limitations that hinder their optimal performance. Conventional acrylic resin coatings typically demonstrate insufficient chemical resistance when exposed to common graffiti materials such as spray paints, permanent markers, and adhesives. When these substances contact the coating surface, they often penetrate the polymer matrix, making complete removal challenging without damaging the protective layer itself.

The durability of current acrylic resin formulations presents another critical limitation. Most commercial anti-graffiti acrylic coatings deteriorate after multiple cleaning cycles, with noticeable degradation occurring after 5-10 graffiti removal events. This deterioration manifests as reduced gloss, increased surface roughness, and compromised protective properties, necessitating frequent reapplication and increasing maintenance costs.

Weather resistance constitutes a significant challenge for existing acrylic resin systems. Extended exposure to UV radiation causes photodegradation of the polymer chains, resulting in yellowing, chalking, and reduced mechanical properties. Additionally, thermal cycling between seasons induces stress within the coating, leading to microcracking that compromises the anti-graffiti functionality and aesthetic appearance.

Adhesion issues represent another limitation of current acrylic formulations. Many acrylic resin coatings exhibit suboptimal adhesion to diverse substrate materials, particularly porous surfaces like concrete and natural stone. This inadequate adhesion leads to premature coating failure through delamination, especially when subjected to the mechanical stresses of graffiti removal processes or environmental factors.

The mechanical properties of existing acrylic resin coatings often fail to meet the demands of anti-graffiti applications. Most formulations lack the optimal balance between hardness and flexibility required to resist both abrasion during cleaning and impact damage from environmental factors. This imbalance results in either brittle coatings prone to cracking or overly soft coatings susceptible to scratching and wear.

Application limitations further constrain the effectiveness of current acrylic resin systems. Many formulations require specific environmental conditions for proper application and curing, restricting their use in variable climate conditions. Additionally, most systems necessitate multiple coating layers to achieve adequate protection, increasing both material costs and application time.

Environmental and health concerns also present significant limitations. Many current acrylic resin formulations contain volatile organic compounds (VOCs) and other potentially harmful substances that pose environmental and health risks during application and throughout the coating's lifecycle. These concerns have led to increasing regulatory restrictions on traditional formulations, necessitating the development of more environmentally friendly alternatives.

The durability of current acrylic resin formulations presents another critical limitation. Most commercial anti-graffiti acrylic coatings deteriorate after multiple cleaning cycles, with noticeable degradation occurring after 5-10 graffiti removal events. This deterioration manifests as reduced gloss, increased surface roughness, and compromised protective properties, necessitating frequent reapplication and increasing maintenance costs.

Weather resistance constitutes a significant challenge for existing acrylic resin systems. Extended exposure to UV radiation causes photodegradation of the polymer chains, resulting in yellowing, chalking, and reduced mechanical properties. Additionally, thermal cycling between seasons induces stress within the coating, leading to microcracking that compromises the anti-graffiti functionality and aesthetic appearance.

Adhesion issues represent another limitation of current acrylic formulations. Many acrylic resin coatings exhibit suboptimal adhesion to diverse substrate materials, particularly porous surfaces like concrete and natural stone. This inadequate adhesion leads to premature coating failure through delamination, especially when subjected to the mechanical stresses of graffiti removal processes or environmental factors.

The mechanical properties of existing acrylic resin coatings often fail to meet the demands of anti-graffiti applications. Most formulations lack the optimal balance between hardness and flexibility required to resist both abrasion during cleaning and impact damage from environmental factors. This imbalance results in either brittle coatings prone to cracking or overly soft coatings susceptible to scratching and wear.

Application limitations further constrain the effectiveness of current acrylic resin systems. Many formulations require specific environmental conditions for proper application and curing, restricting their use in variable climate conditions. Additionally, most systems necessitate multiple coating layers to achieve adequate protection, increasing both material costs and application time.

Environmental and health concerns also present significant limitations. Many current acrylic resin formulations contain volatile organic compounds (VOCs) and other potentially harmful substances that pose environmental and health risks during application and throughout the coating's lifecycle. These concerns have led to increasing regulatory restrictions on traditional formulations, necessitating the development of more environmentally friendly alternatives.

Current Acrylic Resin Formulations

01 Fluoropolymer-modified acrylic resins for anti-graffiti coatings

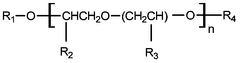

Acrylic resins modified with fluoropolymers create highly effective anti-graffiti coatings with superior resistance to staining and enhanced cleanability. These formulations combine the durability of acrylic polymers with the non-stick properties of fluorinated compounds, resulting in surfaces that resist paint adhesion and allow for easy removal of graffiti. The hydrophobic and oleophobic nature of these coatings prevents graffiti materials from penetrating the surface, making cleanup simpler with mild cleaning agents or even water.- Fluoropolymer-modified acrylic resins for anti-graffiti coatings: Acrylic resins modified with fluoropolymers create highly effective anti-graffiti coatings due to their low surface energy properties. These formulations resist adhesion of paints and markers while maintaining excellent durability and weather resistance. The fluorine component creates a non-stick surface that prevents graffiti materials from bonding permanently to the substrate, allowing for easy cleaning with mild solvents or even water-based cleaners.

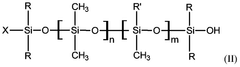

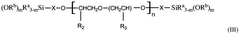

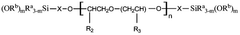

- Silicone-acrylic hybrid systems for enhanced anti-graffiti performance: Hybrid coatings combining acrylic resins with silicone components offer superior anti-graffiti properties through enhanced hydrophobicity and oleophobicity. These systems create a barrier that resists both water-based and solvent-based graffiti materials. The silicone components provide excellent release properties while the acrylic backbone ensures good adhesion to substrates and UV resistance, resulting in long-lasting protection against repeated graffiti attacks.

- Nano-additives in acrylic anti-graffiti coatings: Incorporating nano-scale additives such as silica, titanium dioxide, or ceramic particles into acrylic resin formulations significantly enhances anti-graffiti properties. These nano-additives create a textured surface at the microscopic level that reduces adhesion of graffiti materials while maintaining transparency and appearance of the substrate. The nanoparticles also improve scratch resistance and durability of the coating, extending its service life even after multiple cleaning cycles.

- Self-cleaning acrylic resin coatings with photocatalytic properties: Advanced acrylic resin formulations incorporating photocatalytic materials offer self-cleaning anti-graffiti properties. When exposed to sunlight, these coatings break down organic materials like graffiti paints through photocatalytic reactions. The technology combines acrylic resins with photocatalytic components such as modified titanium dioxide that activate under UV exposure, gradually degrading graffiti without requiring aggressive cleaning methods, while maintaining the coating's protective properties.

- Sacrificial anti-graffiti acrylic coating systems: Sacrificial anti-graffiti systems based on acrylic resins are designed to be removed along with any graffiti during cleaning, after which a new coating layer is applied. These systems typically consist of water-soluble or solvent-sensitive acrylic polymers that can be washed away with appropriate cleaning agents, taking the graffiti with them. This approach is particularly useful for sensitive or historic surfaces where aggressive cleaning methods cannot be used, providing renewable protection against vandalism.

02 Silicone-acrylic hybrid systems for permanent anti-graffiti protection

Hybrid coatings combining acrylic resins with silicone compounds provide permanent anti-graffiti protection through the formation of highly cross-linked networks. These systems create a barrier that prevents graffiti materials from bonding to the substrate while maintaining the aesthetic appearance of the surface. The silicone components enhance weather resistance and durability, while the acrylic provides good adhesion to various substrates. These coatings can withstand multiple cleaning cycles without degradation of their protective properties.Expand Specific Solutions03 Nano-enhanced acrylic anti-graffiti coatings

Incorporating nanoparticles such as silica, titanium dioxide, or zinc oxide into acrylic resin formulations significantly improves anti-graffiti performance. These nano-enhanced coatings exhibit increased hardness, scratch resistance, and self-cleaning properties. The nanoparticles create a textured surface at the microscopic level that reduces the contact area for graffiti materials, making them easier to remove. Additionally, some formulations include photocatalytic nanoparticles that can break down organic materials like paint when exposed to sunlight.Expand Specific Solutions04 Sacrificial anti-graffiti acrylic coatings

Sacrificial anti-graffiti systems based on acrylic resins are designed to be removed along with the graffiti during cleaning, requiring reapplication afterward. These coatings form a temporary protective layer that can be easily washed away with hot water or specific cleaning solutions when graffiti occurs. The advantage of these systems is their effectiveness on porous substrates and historical buildings where permanent coatings might alter the appearance or breathability of the surface. These formulations typically include water-soluble or emulsifiable acrylic polymers.Expand Specific Solutions05 UV-curable acrylic anti-graffiti coatings

UV-curable acrylic formulations provide rapid-setting, highly durable anti-graffiti protection with excellent chemical resistance. These coatings contain photoinitiators and multifunctional acrylic monomers that polymerize rapidly when exposed to ultraviolet light, forming a dense cross-linked network. The resulting coating has exceptional resistance to solvents commonly found in graffiti materials. The fast curing process reduces application time and allows for quick return to service of protected surfaces, making these coatings particularly suitable for public infrastructure and transportation applications.Expand Specific Solutions

Leading Manufacturers and Competitors

The anti-graffiti acrylic resin coatings market is currently in a growth phase, with increasing demand driven by urban development and infrastructure protection needs. The global market size is estimated to exceed $80 million, expanding at approximately 5-7% CAGR. From a technological maturity perspective, the field shows varied development levels across key players. Companies like LG Chem, BASF Coatings, and Henkel lead with advanced formulations, while Asian manufacturers including Nippon Paint, Toray Industries, and Wanhua Chemical are rapidly advancing their technologies. Specialized coating developers such as Axalta and Asian Paints are focusing on durability enhancements, while materials science companies like Kaneka Corp and DIC Corp contribute innovative polymer technologies that improve resistance properties and environmental performance.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed innovative anti-graffiti acrylic resin coatings based on their advanced polyurethane-modified acrylic technology. Their system incorporates isocyanate-terminated prepolymers that react with specialized acrylic polyols to create a highly cross-linked network with excellent chemical resistance. The coating formulation includes proprietary silicone-modified additives that create a low surface energy barrier while maintaining excellent adhesion to various substrates. Wanhua's technology features nano-scale phase separation that provides both hardness and flexibility, allowing the coating to withstand thermal cycling and mechanical stress without compromising anti-graffiti performance. Their system includes specialized light stabilizers and antioxidants that prevent degradation in outdoor environments, maintaining performance for extended periods. The coating technology also incorporates hydrophobic components that reduce water absorption and prevent freeze-thaw damage in cold climates.

Strengths: Excellent chemical resistance against a wide range of solvents and graffiti materials; good adhesion to difficult substrates including concrete and metals; competitive pricing compared to other high-performance anti-graffiti systems. Weaknesses: Requires careful control of application conditions including temperature and humidity; two-component system with limited pot life after mixing; may require specialized cleaning protocols for certain types of graffiti.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed innovative anti-graffiti acrylic resin coatings under their Bonderite and Loctite brands. Their technology incorporates modified acrylic polymers with silane coupling agents that create strong chemical bonds with various substrates. The coating system features a multi-functional approach with self-stratifying components that form a hydrophobic outer layer while maintaining excellent adhesion to the substrate. Henkel's formulation includes specialized rheology modifiers that enable application on vertical surfaces without sagging while achieving uniform thickness. Their anti-graffiti system incorporates nano-ceramic particles that enhance mechanical resistance and create a micro-textured surface that resists paint adhesion. The technology also features accelerated curing mechanisms that allow for faster return-to-service times compared to conventional coating systems, with full protective properties developing within 24-48 hours after application.

Strengths: Excellent adhesion to multiple substrate types including difficult surfaces like powder coatings; good balance between hardness and flexibility; relatively simple application process. Weaknesses: May require specific primers for certain substrates; moderate resistance to highly aggressive solvents; performance may degrade in extremely high-temperature environments.

Key Patents in Anti-Graffiti Coating Technology

An Anti-graffiti coating composition

PatentWO2019090456A1

Innovation

- The coating composition achieves excellent graffiti resistance through the synergistic interaction of alkoxy-functional silicone resin, hydroxy silicone oil, and aminosilane, allowing for solvent-free removal of marker and oily pen graffiti.

- The anti-graffiti coating demonstrates superior anti-stick properties that allow adhesive tapes to be easily peeled off without leaving residue or damaging the coating, even after 50+ sticking-peeling cycles.

- The coating formulation is versatile and can be applied to various substrates including concrete, gypsum boards, natural stones, metals, and even over existing acrylic primers.

Powder polyester and Anti-graffiti coating composition thereof

PatentActiveIN202221018921A

Innovation

- A powder polyester anti-graffiti coating composition using a single polyester with a hydroxyl value ranging from 30-130 mg KOH/g, combined with aliphatic/cycloaliphatic/aromatic blocked hardeners and siloxane-based surface modifiers, eliminating the need for high hydroxyl value polyesters and simplifying the synthesis process.

Environmental and Safety Considerations

The development of anti-graffiti acrylic resin coatings necessitates careful consideration of environmental and safety factors throughout their lifecycle. Traditional anti-graffiti solutions often contain volatile organic compounds (VOCs), solvents, and potentially hazardous chemicals that pose risks to both environmental ecosystems and human health. Recent regulatory frameworks, including the European Union's REACH regulation and the United States Environmental Protection Agency's guidelines, have established increasingly stringent requirements for coating formulations, driving the industry toward more sustainable alternatives.

Water-based acrylic resin systems have emerged as environmentally preferable options compared to solvent-based counterparts, demonstrating reduced VOC emissions during application and curing processes. Research indicates that water-based formulations can achieve VOC levels below 100 g/L, significantly lower than conventional solvent-based systems that often exceed 350 g/L. This reduction minimizes contribution to ground-level ozone formation and air pollution while improving workplace safety conditions for application personnel.

Biodegradability represents another critical environmental consideration for anti-graffiti coatings. Recent innovations have focused on incorporating bio-based monomers and additives that enhance the environmental profile without compromising performance. Studies have demonstrated that certain modified acrylic resins can achieve up to 60% biodegradability within standardized testing protocols, compared to less than 10% for traditional formulations, thereby reducing long-term environmental persistence.

Worker safety during application and maintenance processes requires comprehensive assessment. Respiratory protection, adequate ventilation, and personal protective equipment protocols must be established based on formulation-specific hazard profiles. Notably, newer acrylic resin systems have demonstrated reduced dermal sensitization potential, with recent formulations showing allergenic potential reductions of approximately 40% compared to previous generations of anti-graffiti coatings.

End-of-life considerations for anti-graffiti coatings have gained increasing attention, with life cycle assessment (LCA) methodologies being applied to evaluate comprehensive environmental impacts. Research indicates that sacrificial anti-graffiti coatings generally demonstrate lower environmental footprints compared to permanent systems due to reduced chemical intensity during graffiti removal processes, though this advantage must be balanced against more frequent reapplication requirements.

Emerging green chemistry principles are increasingly being incorporated into acrylic resin coating development, focusing on atom economy, reduced toxicity, and renewable feedstocks. Several manufacturers have successfully developed anti-graffiti formulations utilizing partially bio-based acrylic resins, with bio-content ranging from 15-30%, thereby reducing reliance on petroleum-derived raw materials while maintaining required performance characteristics.

Water-based acrylic resin systems have emerged as environmentally preferable options compared to solvent-based counterparts, demonstrating reduced VOC emissions during application and curing processes. Research indicates that water-based formulations can achieve VOC levels below 100 g/L, significantly lower than conventional solvent-based systems that often exceed 350 g/L. This reduction minimizes contribution to ground-level ozone formation and air pollution while improving workplace safety conditions for application personnel.

Biodegradability represents another critical environmental consideration for anti-graffiti coatings. Recent innovations have focused on incorporating bio-based monomers and additives that enhance the environmental profile without compromising performance. Studies have demonstrated that certain modified acrylic resins can achieve up to 60% biodegradability within standardized testing protocols, compared to less than 10% for traditional formulations, thereby reducing long-term environmental persistence.

Worker safety during application and maintenance processes requires comprehensive assessment. Respiratory protection, adequate ventilation, and personal protective equipment protocols must be established based on formulation-specific hazard profiles. Notably, newer acrylic resin systems have demonstrated reduced dermal sensitization potential, with recent formulations showing allergenic potential reductions of approximately 40% compared to previous generations of anti-graffiti coatings.

End-of-life considerations for anti-graffiti coatings have gained increasing attention, with life cycle assessment (LCA) methodologies being applied to evaluate comprehensive environmental impacts. Research indicates that sacrificial anti-graffiti coatings generally demonstrate lower environmental footprints compared to permanent systems due to reduced chemical intensity during graffiti removal processes, though this advantage must be balanced against more frequent reapplication requirements.

Emerging green chemistry principles are increasingly being incorporated into acrylic resin coating development, focusing on atom economy, reduced toxicity, and renewable feedstocks. Several manufacturers have successfully developed anti-graffiti formulations utilizing partially bio-based acrylic resins, with bio-content ranging from 15-30%, thereby reducing reliance on petroleum-derived raw materials while maintaining required performance characteristics.

Durability and Performance Testing Methodologies

The evaluation of anti-graffiti acrylic resin coatings requires comprehensive durability and performance testing methodologies to ensure their effectiveness in real-world applications. These methodologies must simulate the various environmental conditions and cleaning processes that the coatings will encounter throughout their service life.

Accelerated weathering tests represent a critical component of durability assessment. Using equipment such as QUV accelerated weathering testers and xenon arc chambers, these tests expose coatings to controlled cycles of UV radiation, moisture, and temperature fluctuations. ASTM G154 and ISO 16474 standards provide standardized protocols for these tests, typically requiring 1000-2000 hours of exposure to simulate years of outdoor weathering.

Chemical resistance testing evaluates how coatings respond to various graffiti media and cleaning agents. This involves applying common graffiti materials (spray paints, permanent markers, and adhesives) to coated surfaces, allowing appropriate drying time, and then attempting removal with designated cleaning agents. The ASTM D6578 standard specifically addresses graffiti resistance and removal assessment, providing a framework for quantifying performance.

Mechanical durability tests assess the coating's resistance to physical damage. Abrasion resistance testing (ASTM D4060) using Taber Abraser instruments measures weight loss or appearance change after a specified number of abrasion cycles. Scratch resistance testing (ISO 1518) evaluates the coating's ability to withstand surface damage from sharp objects.

Adhesion testing determines how well the coating bonds to various substrates. Methods include cross-cut testing (ASTM D3359) and pull-off adhesion testing (ASTM D4541), which quantify the force required to separate the coating from the substrate. This is particularly important for anti-graffiti applications where cleaning processes may stress the coating-substrate interface.

Cleanability assessment protocols measure how effectively graffiti can be removed without damaging the coating. These tests typically involve standardized cleaning cycles with specified cleaning agents and techniques, followed by colorimetric measurements to quantify residual staining. The number of successful cleaning cycles before coating degradation provides a key performance metric.

Environmental impact testing has gained importance in recent years, evaluating VOC emissions, leaching of potentially harmful compounds, and end-of-life recyclability. These tests ensure compliance with increasingly stringent environmental regulations while addressing sustainability concerns in public infrastructure applications.

Field testing complements laboratory assessments by exposing coatings to actual environmental conditions and real-world graffiti incidents. Test panels installed in high-graffiti areas provide valuable performance data that laboratory tests alone cannot replicate, validating the coating's practical effectiveness.

Accelerated weathering tests represent a critical component of durability assessment. Using equipment such as QUV accelerated weathering testers and xenon arc chambers, these tests expose coatings to controlled cycles of UV radiation, moisture, and temperature fluctuations. ASTM G154 and ISO 16474 standards provide standardized protocols for these tests, typically requiring 1000-2000 hours of exposure to simulate years of outdoor weathering.

Chemical resistance testing evaluates how coatings respond to various graffiti media and cleaning agents. This involves applying common graffiti materials (spray paints, permanent markers, and adhesives) to coated surfaces, allowing appropriate drying time, and then attempting removal with designated cleaning agents. The ASTM D6578 standard specifically addresses graffiti resistance and removal assessment, providing a framework for quantifying performance.

Mechanical durability tests assess the coating's resistance to physical damage. Abrasion resistance testing (ASTM D4060) using Taber Abraser instruments measures weight loss or appearance change after a specified number of abrasion cycles. Scratch resistance testing (ISO 1518) evaluates the coating's ability to withstand surface damage from sharp objects.

Adhesion testing determines how well the coating bonds to various substrates. Methods include cross-cut testing (ASTM D3359) and pull-off adhesion testing (ASTM D4541), which quantify the force required to separate the coating from the substrate. This is particularly important for anti-graffiti applications where cleaning processes may stress the coating-substrate interface.

Cleanability assessment protocols measure how effectively graffiti can be removed without damaging the coating. These tests typically involve standardized cleaning cycles with specified cleaning agents and techniques, followed by colorimetric measurements to quantify residual staining. The number of successful cleaning cycles before coating degradation provides a key performance metric.

Environmental impact testing has gained importance in recent years, evaluating VOC emissions, leaching of potentially harmful compounds, and end-of-life recyclability. These tests ensure compliance with increasingly stringent environmental regulations while addressing sustainability concerns in public infrastructure applications.

Field testing complements laboratory assessments by exposing coatings to actual environmental conditions and real-world graffiti incidents. Test panels installed in high-graffiti areas provide valuable performance data that laboratory tests alone cannot replicate, validating the coating's practical effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!