Enhancing Acrylic Resin’s Corrosion Resistance on Metal Coatings

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Corrosion Protection Background and Objectives

Acrylic resins have emerged as a significant material in protective coatings for metal surfaces since their commercial introduction in the 1930s. Initially developed as alternatives to nitrocellulose lacquers, these versatile polymers have evolved substantially over the decades, transitioning from simple decorative applications to sophisticated protective systems for various industrial environments. The trajectory of acrylic resin development has been characterized by continuous improvements in durability, adhesion properties, and most critically, corrosion resistance capabilities.

The evolution of acrylic resin technology has been driven by increasing industrial demands for more effective metal protection solutions against aggressive environmental conditions. Early formulations offered limited protection against mild corrosive environments, but technological advancements have progressively enhanced their performance. The introduction of functional monomers, crosslinking technologies, and nano-additives represents significant milestones in this evolutionary process, each contributing to improved corrosion resistance profiles.

Current market trends indicate a growing preference for environmentally friendly coating solutions with reduced volatile organic compound (VOC) emissions, which has accelerated research into water-based acrylic systems and high-solids formulations. Simultaneously, regulatory frameworks worldwide have become increasingly stringent regarding environmental impact and human health considerations, further shaping the direction of acrylic resin development.

The primary technical objective in enhancing acrylic resin's corrosion resistance centers on developing formulations that create more effective barriers against corrosive agents while maintaining or improving other desirable properties such as adhesion, flexibility, and weatherability. This involves optimizing polymer architecture, incorporating specialized additives, and developing novel curing mechanisms that enhance crosslinking density and reduce permeability to corrosive species.

Secondary objectives include extending service life under extreme conditions, reducing application complexity, and ensuring compatibility with various metal substrates including steel, aluminum, and galvanized surfaces. The development of multi-functional acrylic systems capable of providing simultaneous protection against multiple degradation mechanisms represents another critical goal in this technological domain.

From a commercial perspective, the objective extends to creating cost-effective solutions that balance performance requirements with economic considerations, enabling broader market adoption across diverse industrial sectors including automotive, construction, marine, and aerospace applications. The ideal acrylic resin system would offer superior corrosion protection while maintaining competitive application costs and reducing maintenance requirements over the coating's service life.

Recent technological breakthroughs in polymer science, particularly in controlled polymerization techniques and hybrid material development, have opened new avenues for innovation in this field. These advances provide promising pathways toward achieving the ambitious performance targets required for next-generation metal protection systems based on acrylic resin technology.

The evolution of acrylic resin technology has been driven by increasing industrial demands for more effective metal protection solutions against aggressive environmental conditions. Early formulations offered limited protection against mild corrosive environments, but technological advancements have progressively enhanced their performance. The introduction of functional monomers, crosslinking technologies, and nano-additives represents significant milestones in this evolutionary process, each contributing to improved corrosion resistance profiles.

Current market trends indicate a growing preference for environmentally friendly coating solutions with reduced volatile organic compound (VOC) emissions, which has accelerated research into water-based acrylic systems and high-solids formulations. Simultaneously, regulatory frameworks worldwide have become increasingly stringent regarding environmental impact and human health considerations, further shaping the direction of acrylic resin development.

The primary technical objective in enhancing acrylic resin's corrosion resistance centers on developing formulations that create more effective barriers against corrosive agents while maintaining or improving other desirable properties such as adhesion, flexibility, and weatherability. This involves optimizing polymer architecture, incorporating specialized additives, and developing novel curing mechanisms that enhance crosslinking density and reduce permeability to corrosive species.

Secondary objectives include extending service life under extreme conditions, reducing application complexity, and ensuring compatibility with various metal substrates including steel, aluminum, and galvanized surfaces. The development of multi-functional acrylic systems capable of providing simultaneous protection against multiple degradation mechanisms represents another critical goal in this technological domain.

From a commercial perspective, the objective extends to creating cost-effective solutions that balance performance requirements with economic considerations, enabling broader market adoption across diverse industrial sectors including automotive, construction, marine, and aerospace applications. The ideal acrylic resin system would offer superior corrosion protection while maintaining competitive application costs and reducing maintenance requirements over the coating's service life.

Recent technological breakthroughs in polymer science, particularly in controlled polymerization techniques and hybrid material development, have opened new avenues for innovation in this field. These advances provide promising pathways toward achieving the ambitious performance targets required for next-generation metal protection systems based on acrylic resin technology.

Market Analysis for Corrosion-Resistant Metal Coatings

The global market for corrosion-resistant metal coatings has been experiencing steady growth, with the acrylic resin segment emerging as a particularly promising area. Current market valuations place the corrosion-resistant coatings industry at approximately 7.5 billion USD, with projections indicating growth to reach 9.8 billion USD by 2027, representing a compound annual growth rate of 5.2%.

The demand for enhanced acrylic resin solutions in metal protection is driven primarily by expanding infrastructure development, particularly in rapidly industrializing economies across Asia-Pacific and Latin America. China and India lead this growth trajectory, with annual increases in coating consumption exceeding 7% in these regions. The automotive sector remains the largest end-user, accounting for roughly 28% of market share, followed by marine applications at 22% and industrial equipment at 19%.

Environmental regulations have become a significant market driver, with stringent VOC emission standards in Europe and North America accelerating the shift toward water-based acrylic formulations. The EU's REACH regulations and similar frameworks in developed economies have created a premium market segment for environmentally compliant coatings that maintain high performance standards.

Customer preferences are increasingly favoring multi-functional coatings that offer corrosion resistance alongside additional benefits such as UV protection, thermal stability, and aesthetic appeal. This trend has expanded the potential applications for advanced acrylic resin systems, particularly in consumer-facing industries where appearance and longevity are equally valued.

Price sensitivity varies significantly across market segments, with industrial applications prioritizing long-term performance and reduced maintenance costs, while consumer markets remain more cost-conscious. The average price premium for high-performance acrylic coatings with enhanced corrosion resistance ranges between 15-30% above standard formulations, with acceptance rates highest in marine and chemical processing environments.

Competition in this space is intensifying, with major coating manufacturers investing heavily in R&D to develop proprietary acrylic resin technologies. Market concentration is moderate, with the top five players controlling approximately 42% of global market share. Regional players maintain strong positions in specific geographic markets, particularly in Asia where local manufacturing capabilities have expanded significantly.

Future market growth is expected to be driven by innovations addressing specific performance gaps in acrylic resins, particularly in extreme environment applications where traditional formulations have shown limitations. The development of hybrid systems combining acrylic chemistry with other resin technologies represents a high-growth potential segment, with current market penetration still below 10% but growing at twice the rate of conventional systems.

The demand for enhanced acrylic resin solutions in metal protection is driven primarily by expanding infrastructure development, particularly in rapidly industrializing economies across Asia-Pacific and Latin America. China and India lead this growth trajectory, with annual increases in coating consumption exceeding 7% in these regions. The automotive sector remains the largest end-user, accounting for roughly 28% of market share, followed by marine applications at 22% and industrial equipment at 19%.

Environmental regulations have become a significant market driver, with stringent VOC emission standards in Europe and North America accelerating the shift toward water-based acrylic formulations. The EU's REACH regulations and similar frameworks in developed economies have created a premium market segment for environmentally compliant coatings that maintain high performance standards.

Customer preferences are increasingly favoring multi-functional coatings that offer corrosion resistance alongside additional benefits such as UV protection, thermal stability, and aesthetic appeal. This trend has expanded the potential applications for advanced acrylic resin systems, particularly in consumer-facing industries where appearance and longevity are equally valued.

Price sensitivity varies significantly across market segments, with industrial applications prioritizing long-term performance and reduced maintenance costs, while consumer markets remain more cost-conscious. The average price premium for high-performance acrylic coatings with enhanced corrosion resistance ranges between 15-30% above standard formulations, with acceptance rates highest in marine and chemical processing environments.

Competition in this space is intensifying, with major coating manufacturers investing heavily in R&D to develop proprietary acrylic resin technologies. Market concentration is moderate, with the top five players controlling approximately 42% of global market share. Regional players maintain strong positions in specific geographic markets, particularly in Asia where local manufacturing capabilities have expanded significantly.

Future market growth is expected to be driven by innovations addressing specific performance gaps in acrylic resins, particularly in extreme environment applications where traditional formulations have shown limitations. The development of hybrid systems combining acrylic chemistry with other resin technologies represents a high-growth potential segment, with current market penetration still below 10% but growing at twice the rate of conventional systems.

Current Limitations in Acrylic Resin Metal Protection

Despite the widespread use of acrylic resins in metal coating applications, several significant limitations hinder their effectiveness in providing comprehensive corrosion protection. The primary deficiency lies in their inherent permeability to water, oxygen, and corrosive ions. Unlike epoxy or polyurethane coatings, acrylic resins possess a relatively open polymer network structure that allows the penetration of moisture and aggressive chemical species, which eventually reach the metal substrate and initiate corrosion processes.

The adhesion properties of acrylic resins to metal substrates present another critical limitation. While initial adhesion may be satisfactory, long-term adhesion under environmental stress conditions often deteriorates. This is particularly evident in environments with fluctuating temperatures and humidity levels, where the differential thermal expansion between the coating and metal substrate creates interfacial stresses that compromise coating integrity.

Acrylic resins also demonstrate limited chemical resistance when exposed to acidic or alkaline environments. Industrial atmospheres containing sulfur dioxide, nitrogen oxides, or chloride ions can rapidly degrade acrylic coatings, reducing their protective lifespan. The ester linkages in acrylic polymers are susceptible to hydrolysis under acidic conditions, leading to coating breakdown and subsequent corrosion of the underlying metal.

UV stability represents another challenge for acrylic resin coatings. While generally considered to have good UV resistance compared to some other polymer systems, prolonged exposure to intense sunlight can still cause photodegradation, resulting in chalking, cracking, and reduced protective properties. This limitation is particularly problematic for outdoor applications in regions with high solar radiation.

The mechanical properties of acrylic coatings further constrain their protective capabilities. They typically exhibit lower hardness and abrasion resistance compared to other coating systems, making them vulnerable to physical damage that creates pathways for corrosive agents to reach the metal substrate. Their relatively low glass transition temperature also limits their application in high-temperature environments.

Current formulations also struggle with the incorporation of effective corrosion inhibitors. Many traditional inhibitors show compatibility issues with acrylic resin matrices, either reducing the coating's physical properties or failing to maintain long-term effectiveness due to leaching phenomena. This limitation significantly impacts the coating's ability to provide active corrosion protection when barrier properties are compromised.

The relatively high water absorption rate of acrylic resins compared to other coating systems leads to dimensional instability and plasticization effects, which further compromise protective performance. This water uptake can also facilitate the transport of corrosive species through the coating, accelerating the corrosion process at the metal-coating interface.

The adhesion properties of acrylic resins to metal substrates present another critical limitation. While initial adhesion may be satisfactory, long-term adhesion under environmental stress conditions often deteriorates. This is particularly evident in environments with fluctuating temperatures and humidity levels, where the differential thermal expansion between the coating and metal substrate creates interfacial stresses that compromise coating integrity.

Acrylic resins also demonstrate limited chemical resistance when exposed to acidic or alkaline environments. Industrial atmospheres containing sulfur dioxide, nitrogen oxides, or chloride ions can rapidly degrade acrylic coatings, reducing their protective lifespan. The ester linkages in acrylic polymers are susceptible to hydrolysis under acidic conditions, leading to coating breakdown and subsequent corrosion of the underlying metal.

UV stability represents another challenge for acrylic resin coatings. While generally considered to have good UV resistance compared to some other polymer systems, prolonged exposure to intense sunlight can still cause photodegradation, resulting in chalking, cracking, and reduced protective properties. This limitation is particularly problematic for outdoor applications in regions with high solar radiation.

The mechanical properties of acrylic coatings further constrain their protective capabilities. They typically exhibit lower hardness and abrasion resistance compared to other coating systems, making them vulnerable to physical damage that creates pathways for corrosive agents to reach the metal substrate. Their relatively low glass transition temperature also limits their application in high-temperature environments.

Current formulations also struggle with the incorporation of effective corrosion inhibitors. Many traditional inhibitors show compatibility issues with acrylic resin matrices, either reducing the coating's physical properties or failing to maintain long-term effectiveness due to leaching phenomena. This limitation significantly impacts the coating's ability to provide active corrosion protection when barrier properties are compromised.

The relatively high water absorption rate of acrylic resins compared to other coating systems leads to dimensional instability and plasticization effects, which further compromise protective performance. This water uptake can also facilitate the transport of corrosive species through the coating, accelerating the corrosion process at the metal-coating interface.

Current Formulation Approaches for Enhanced Corrosion Resistance

01 Acrylic resin compositions with enhanced corrosion resistance

Specific acrylic resin compositions can be formulated to provide enhanced corrosion resistance properties. These compositions typically include modified acrylic polymers with functional groups that improve adhesion to metal substrates and create a protective barrier against corrosive elements. The formulations may incorporate cross-linking agents to form a dense polymer network that prevents penetration of corrosive substances, resulting in improved durability and protection for metal surfaces.- Acrylic resin compositions with enhanced corrosion resistance: Specific acrylic resin compositions can be formulated to provide enhanced corrosion resistance properties. These compositions typically include modified acrylic polymers with functional groups that improve adhesion to metal substrates and create a protective barrier against corrosive elements. The formulations may incorporate cross-linking agents to form a dense polymer network that prevents penetration of corrosive substances, resulting in improved durability and protection for metal surfaces.

- Acrylic resin coatings with corrosion inhibitors: Acrylic resin coatings can be enhanced with specific corrosion inhibitors to improve their protective properties. These inhibitors work by various mechanisms including forming passive films on metal surfaces, scavenging oxygen, or neutralizing corrosive agents. The incorporation of these inhibitors into acrylic resin systems creates synergistic effects that significantly improve the coating's ability to prevent corrosion, particularly in aggressive environments such as marine or industrial settings.

- Modified acrylic resins with improved chemical resistance: Acrylic resins can be chemically modified to enhance their resistance to various corrosive chemicals. These modifications often involve copolymerization with other monomers or the introduction of specific functional groups that improve chemical stability. The resulting modified acrylic resins demonstrate superior resistance to acids, alkalis, solvents, and other aggressive chemicals, making them suitable for protective coatings in chemical processing equipment, storage tanks, and other applications exposed to harsh chemical environments.

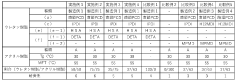

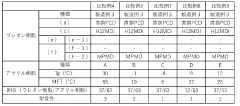

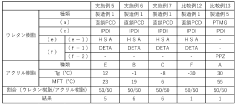

- Acrylic resin blends for enhanced durability: Blending acrylic resins with other polymer types can create composite materials with superior corrosion resistance properties. These blends often combine the weatherability and UV resistance of acrylics with the chemical resistance of other polymers such as polyurethanes, epoxies, or fluoropolymers. The resulting hybrid materials offer enhanced durability and protection against multiple degradation mechanisms, providing longer-lasting corrosion protection in outdoor and industrial environments.

- Nano-enhanced acrylic resin systems: Incorporating nanomaterials into acrylic resin formulations can significantly improve corrosion resistance properties. Nanoparticles such as silica, zinc oxide, graphene, or clay can create a tortuous path for corrosive agents, effectively blocking their penetration through the coating. These nano-enhanced acrylic systems also demonstrate improved mechanical properties, adhesion, and barrier effects. The nanomaterials can be functionalized to improve their dispersion within the acrylic matrix, resulting in uniform protection and extended service life of the coating.

02 Acrylic resin coatings with corrosion inhibitors

Acrylic resin coatings can be enhanced with specific corrosion inhibitors to improve their protective properties. These inhibitors work by various mechanisms including forming passive films on metal surfaces, scavenging corrosive species, or creating a barrier effect. Common corrosion inhibitors used with acrylic resins include zinc compounds, phosphates, silicates, and organic inhibitors. The combination of acrylic resin with these inhibitors provides synergistic protection against various corrosive environments.Expand Specific Solutions03 Modified acrylic resins with improved chemical resistance

Chemical modification of acrylic resins can significantly improve their resistance to corrosive chemicals. These modifications include copolymerization with other monomers, grafting of functional groups, or blending with compatible polymers. The resulting modified acrylic resins exhibit enhanced resistance to acids, alkalis, solvents, and other aggressive chemicals. These materials are particularly useful in applications where exposure to harsh chemical environments is expected.Expand Specific Solutions04 Acrylic resin systems for marine and industrial environments

Specialized acrylic resin systems have been developed for marine and industrial environments where corrosion resistance is critical. These systems are formulated to withstand salt spray, humidity, UV radiation, and industrial pollutants. They often incorporate hydrophobic components, UV stabilizers, and specific fillers to enhance their protective properties. The formulations are designed to provide long-term protection for structures and equipment exposed to these challenging environments.Expand Specific Solutions05 Nanocomposite acrylic resins for superior corrosion protection

Incorporating nanomaterials into acrylic resin systems can provide superior corrosion protection. Nanoparticles such as silica, clay, graphene, or metal oxides can be dispersed within the acrylic matrix to create nanocomposite materials with enhanced barrier properties. These nanocomposites exhibit improved mechanical strength, reduced permeability to corrosive agents, and better adhesion to substrates. The nanoscale reinforcement creates multiple protective mechanisms that significantly extend the service life of coated surfaces.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acrylic resin corrosion resistance market for metal coatings is currently in a growth phase, with increasing demand driven by automotive, construction, and industrial applications. The global market size is estimated to exceed $5 billion, expanding at approximately 5-7% CAGR. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include Nippon Paint and Kansai Paint from Japan, who have established strong positions through specialized marine and industrial coatings. Akzo Nobel and Henkel bring European expertise with advanced polymer technologies, while BASF Coatings and Mitsui Chemicals contribute significant R&D capabilities in resin formulation. Emerging competitors like Jiangsu Champion and Dongjin Semichem are rapidly advancing with cost-effective solutions, particularly in automotive applications, creating a competitive landscape balanced between established leaders and innovative challengers.

Nippon Paint Co., Ltd. /Shinagawa-ku/

Technical Solution: Nippon Paint has developed a revolutionary acrylic resin system called "AQUA MARINE" specifically designed for enhanced corrosion protection on metal substrates. Their technology utilizes hydrophobic modified acrylic polymers with siloxane side chains that create a water-repellent barrier while maintaining excellent adhesion to metal surfaces. The company's research has led to the development of self-assembling acrylic nanocomposites that form a highly ordered structure during curing, significantly reducing ion permeability through the coating. Their formulations incorporate proprietary corrosion inhibitors that form complexes with metal ions, preventing the cathodic reaction necessary for corrosion progression. Testing has shown these coatings provide protection for over 3,000 hours in salt spray conditions without significant deterioration. Nippon Paint has also pioneered the use of core-shell acrylic particles where the core contains hydrophobic components while the shell provides compatibility with various additives and pigments, creating an optimal balance of properties.

Strengths: Exceptional water resistance and hydrophobicity; excellent adhesion even in high-humidity environments; superior salt spray resistance compared to conventional acrylics. Weaknesses: Higher production costs due to complex polymer architecture; requires specific application conditions for optimal performance; limited compatibility with some pigment systems.

Kansai Paint Co., Ltd.

Technical Solution: Kansai Paint has developed an innovative acrylic resin technology called "ZINCTECT-AC" specifically engineered for superior metal corrosion protection. This system incorporates zinc-rich primers with specially modified acrylic resins containing hydroxyl functional groups that enhance adhesion to metal substrates. Their technology employs a dual protection mechanism: galvanic protection from zinc particles and barrier protection from the dense acrylic polymer network. The company's research has led to the development of self-stratifying acrylic formulations that automatically form optimal layer structures during curing, with corrosion inhibitors concentrating near the metal interface. Their advanced weathering tests demonstrate that these coatings maintain gloss retention above 80% after 5,000 hours of accelerated weathering, while providing corrosion protection in salt spray environments for over 2,000 hours. Kansai has also pioneered the incorporation of cerium-based corrosion inhibitors into acrylic matrices as an environmentally friendly alternative to chromate treatments.

Strengths: Excellent adhesion to various metal substrates; superior weatherability and UV resistance; environmentally friendly formulations with reduced heavy metals. Weaknesses: Requires specific application parameters for optimal performance; higher cost compared to conventional systems; some formulations have limited chemical resistance to strong solvents.

Key Patents and Innovations in Acrylic Protective Coatings

Metal surface treatment composition containing acrylic resin, method for treatment, and treated metal materials

PatentWO1998017735A1

Innovation

- An acrylic resin-containing metal surface treatment composition that is water-soluble or emulsion-type, featuring amino or ammonium groups, hydroxyl groups, and hydrophobic groups, which forms interconnected inorganic films with heavy metals or their salts, enhancing corrosion resistance and coating adhesion while reducing friction resistance.

Emulsion composition

PatentWO2023190888A1

Innovation

- An emulsion composition comprising a polyurethane resin with a specific skeletal structure, including a polycarbonate polyol, acidic group-containing polyol, polyisocyanate compound, and a chain extender with multiple amino or imino groups, combined with an acrylic resin having a glass transition temperature between -10°C and 75°C, and a coalescent agent like β-alkoxypropionamide, to enhance adhesion and corrosion resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of acrylic resin coatings for metal corrosion protection represents a critical consideration in modern industrial applications. Traditional corrosion-resistant coatings often contain heavy metals and volatile organic compounds (VOCs) that pose significant environmental hazards throughout their lifecycle. Acrylic resin systems, particularly water-based formulations, offer substantial environmental advantages with VOC emissions typically 50-70% lower than conventional solvent-based alternatives.

Recent advancements in acrylic resin technology have focused on developing bio-based monomers derived from renewable resources such as plant oils and agricultural waste. These sustainable raw materials can reduce the carbon footprint of coating production by up to 35% compared to petroleum-based counterparts, according to lifecycle assessment studies conducted across the coating industry.

The durability enhancement of acrylic resins directly contributes to sustainability by extending service intervals and reducing maintenance requirements. Longer-lasting coatings minimize waste generation and resource consumption associated with frequent reapplication. Research indicates that high-performance acrylic coatings can extend maintenance cycles by 2-3 times compared to conventional systems, significantly reducing the cumulative environmental impact over the asset's lifetime.

End-of-life considerations present both challenges and opportunities for acrylic coating systems. While traditional coating removal processes often involve chemical strippers with environmental concerns, newer mechanical methods and biodegradable removal agents show promise for reducing environmental impact. Additionally, research into designing acrylic resins with improved recyclability and biodegradability is gaining momentum, with several promising approaches under development.

Regulatory frameworks worldwide increasingly emphasize environmental performance alongside technical requirements. The European Union's REACH regulations, California's stringent VOC limits, and similar global initiatives are driving innovation toward greener acrylic formulations. Companies demonstrating environmental leadership through sustainable coating technologies gain competitive advantages in markets where environmental credentials influence purchasing decisions.

Water consumption represents another important environmental dimension, with water-based acrylic systems requiring careful assessment of water usage during manufacturing and application. Advanced water recycling systems in production facilities can reduce freshwater consumption by up to 80%, addressing this concern while maintaining the environmental benefits of water-based formulations over solvent alternatives.

Recent advancements in acrylic resin technology have focused on developing bio-based monomers derived from renewable resources such as plant oils and agricultural waste. These sustainable raw materials can reduce the carbon footprint of coating production by up to 35% compared to petroleum-based counterparts, according to lifecycle assessment studies conducted across the coating industry.

The durability enhancement of acrylic resins directly contributes to sustainability by extending service intervals and reducing maintenance requirements. Longer-lasting coatings minimize waste generation and resource consumption associated with frequent reapplication. Research indicates that high-performance acrylic coatings can extend maintenance cycles by 2-3 times compared to conventional systems, significantly reducing the cumulative environmental impact over the asset's lifetime.

End-of-life considerations present both challenges and opportunities for acrylic coating systems. While traditional coating removal processes often involve chemical strippers with environmental concerns, newer mechanical methods and biodegradable removal agents show promise for reducing environmental impact. Additionally, research into designing acrylic resins with improved recyclability and biodegradability is gaining momentum, with several promising approaches under development.

Regulatory frameworks worldwide increasingly emphasize environmental performance alongside technical requirements. The European Union's REACH regulations, California's stringent VOC limits, and similar global initiatives are driving innovation toward greener acrylic formulations. Companies demonstrating environmental leadership through sustainable coating technologies gain competitive advantages in markets where environmental credentials influence purchasing decisions.

Water consumption represents another important environmental dimension, with water-based acrylic systems requiring careful assessment of water usage during manufacturing and application. Advanced water recycling systems in production facilities can reduce freshwater consumption by up to 80%, addressing this concern while maintaining the environmental benefits of water-based formulations over solvent alternatives.

Durability Testing Methods and Industry Standards

Durability testing methods for acrylic resin coatings on metal substrates follow established protocols that evaluate performance under various environmental stressors. The American Society for Testing and Materials (ASTM) provides several key standards, including ASTM B117 for salt spray testing, which exposes coated samples to a continuous salt fog environment for periods ranging from 500 to 3000 hours. This test simulates coastal or marine environments and remains the industry benchmark for corrosion resistance evaluation.

The International Organization for Standardization (ISO) contributes complementary standards such as ISO 12944, which categorizes environments by corrosivity levels from C1 (very low) to C5 (very high) and prescribes appropriate testing regimes. For acrylic resin coatings specifically, ISO 16474 series standards address weathering resistance through accelerated exposure tests.

Electrochemical Impedance Spectroscopy (EIS) has emerged as a sophisticated analytical method that measures coating degradation without physical destruction. This technique provides quantitative data on barrier properties and can detect early signs of coating failure before visible corrosion appears, making it invaluable for long-term performance prediction of acrylic resin systems.

Cyclic corrosion testing represents an advancement over traditional salt spray methods by incorporating wet/dry cycles and temperature variations that more accurately reflect real-world conditions. ASTM D5894 combines ultraviolet exposure with condensation and salt fog cycles, providing comprehensive assessment of acrylic coating durability under multiple stressors simultaneously.

Adhesion testing per ASTM D3359 (tape test) and ASTM D4541 (pull-off test) evaluates the coating's ability to maintain attachment to metal substrates after exposure to corrosive environments. These tests are critical as coating delamination often precedes corrosion failure in acrylic systems.

Chemical resistance testing involves immersion in various solvents, acids, and alkalis according to ASTM D1308 protocols. For acrylic resins intended for industrial applications, resistance to specific chemicals relevant to the target environment must be verified through customized testing regimens.

Accelerated weathering chambers utilizing xenon arc (ASTM G155) or QUV fluorescent UV exposure (ASTM G154) simulate solar radiation effects on coating degradation. These tests are particularly relevant for exterior applications where UV degradation can compromise the corrosion resistance of acrylic resin coatings over time.

Industry acceptance criteria typically require acrylic coatings to maintain performance after 1000+ hours of salt spray exposure with minimal scribe creepage (<3mm) and no blistering or delamination. However, specifications vary by sector, with automotive standards generally requiring 1000-1500 hours, while marine and offshore applications may demand 3000+ hours of corrosion resistance.

The International Organization for Standardization (ISO) contributes complementary standards such as ISO 12944, which categorizes environments by corrosivity levels from C1 (very low) to C5 (very high) and prescribes appropriate testing regimes. For acrylic resin coatings specifically, ISO 16474 series standards address weathering resistance through accelerated exposure tests.

Electrochemical Impedance Spectroscopy (EIS) has emerged as a sophisticated analytical method that measures coating degradation without physical destruction. This technique provides quantitative data on barrier properties and can detect early signs of coating failure before visible corrosion appears, making it invaluable for long-term performance prediction of acrylic resin systems.

Cyclic corrosion testing represents an advancement over traditional salt spray methods by incorporating wet/dry cycles and temperature variations that more accurately reflect real-world conditions. ASTM D5894 combines ultraviolet exposure with condensation and salt fog cycles, providing comprehensive assessment of acrylic coating durability under multiple stressors simultaneously.

Adhesion testing per ASTM D3359 (tape test) and ASTM D4541 (pull-off test) evaluates the coating's ability to maintain attachment to metal substrates after exposure to corrosive environments. These tests are critical as coating delamination often precedes corrosion failure in acrylic systems.

Chemical resistance testing involves immersion in various solvents, acids, and alkalis according to ASTM D1308 protocols. For acrylic resins intended for industrial applications, resistance to specific chemicals relevant to the target environment must be verified through customized testing regimens.

Accelerated weathering chambers utilizing xenon arc (ASTM G155) or QUV fluorescent UV exposure (ASTM G154) simulate solar radiation effects on coating degradation. These tests are particularly relevant for exterior applications where UV degradation can compromise the corrosion resistance of acrylic resin coatings over time.

Industry acceptance criteria typically require acrylic coatings to maintain performance after 1000+ hours of salt spray exposure with minimal scribe creepage (<3mm) and no blistering or delamination. However, specifications vary by sector, with automotive standards generally requiring 1000-1500 hours, while marine and offshore applications may demand 3000+ hours of corrosion resistance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!