Enhancing Environmental Solutions with Cellulose Acetate

Cellulose Acetate Background and Objectives

Cellulose acetate, a versatile biopolymer derived from cellulose, has a rich history dating back to its discovery in the late 19th century. Initially developed as a substitute for celluloid in photographic films, its applications have since expanded significantly across various industries. The evolution of cellulose acetate technology has been driven by the increasing demand for sustainable and biodegradable materials in response to growing environmental concerns.

The development of cellulose acetate has been marked by continuous improvements in production processes and material properties. From its early days as a film base, it has found applications in textiles, packaging, and more recently, in environmental solutions. The journey of cellulose acetate showcases the potential of bio-based materials to address contemporary challenges in sustainability and waste management.

In recent years, there has been a renewed focus on cellulose acetate as a promising material for enhancing environmental solutions. This resurgence is primarily due to its biodegradability, which offers a potential answer to the global plastic pollution crisis. As governments and industries worldwide seek alternatives to conventional plastics, cellulose acetate has emerged as a candidate for various applications, from single-use items to more durable products.

The current technological landscape surrounding cellulose acetate is characterized by efforts to optimize its properties for specific environmental applications. Research is ongoing to improve its degradation rates in different environments, enhance its mechanical properties, and expand its functionality through modifications and composites. These advancements aim to position cellulose acetate as a viable, eco-friendly alternative in sectors where plastic pollution is particularly problematic.

The primary objectives in the field of cellulose acetate for environmental solutions are multifaceted. Firstly, there is a push to develop more efficient and cost-effective production methods to make cellulose acetate competitive with traditional plastics. Secondly, researchers are working on tailoring the material's properties to meet the performance requirements of various applications while maintaining its biodegradability. Additionally, there is a focus on understanding and improving the end-of-life scenarios for cellulose acetate products, ensuring they break down safely and efficiently in natural environments.

As we look to the future, the potential of cellulose acetate in environmental solutions appears promising. The technology is poised to play a significant role in the transition towards a more sustainable and circular economy. However, realizing this potential will require continued innovation, cross-sector collaboration, and supportive policy frameworks to drive adoption and scale-up of cellulose acetate-based solutions.

Market Demand for Eco-friendly Materials

The market demand for eco-friendly materials has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations. Cellulose acetate, a biodegradable and renewable material derived from wood pulp or cotton fibers, has emerged as a promising solution in this context. The global cellulose acetate market is projected to expand steadily, with applications spanning various industries including textiles, packaging, and consumer goods.

In the textile industry, cellulose acetate fibers are gaining traction as a sustainable alternative to synthetic fibers. Consumers are increasingly seeking clothing and fabrics made from natural, biodegradable materials, leading to a rise in demand for cellulose acetate-based textiles. This trend is particularly evident in the fashion and apparel sectors, where brands are incorporating eco-friendly materials to appeal to environmentally conscious consumers.

The packaging industry represents another significant market for cellulose acetate. With growing concerns over plastic pollution, there is a strong push for biodegradable packaging solutions. Cellulose acetate films and sheets are being adopted for food packaging, pharmaceutical blister packs, and other consumer goods packaging. The material's transparency, flexibility, and biodegradability make it an attractive option for manufacturers looking to reduce their environmental footprint.

In the consumer goods sector, cellulose acetate is finding applications in products such as eyewear frames, toothbrushes, and disposable cutlery. The material's versatility and ability to mimic the properties of conventional plastics while offering improved environmental credentials have led to increased adoption across various product categories.

The automotive industry is also exploring the use of cellulose acetate in interior components and trim, as part of efforts to increase the use of sustainable materials in vehicle manufacturing. This trend is driven by both consumer demand for eco-friendly vehicles and regulatory pressures to reduce the environmental impact of automotive production.

The market demand for cellulose acetate is further bolstered by its potential in advanced applications such as membrane technology for water treatment and gas separation. As water scarcity becomes a pressing global issue, the demand for efficient and sustainable water treatment solutions is expected to drive growth in this segment.

While the market outlook for cellulose acetate is generally positive, challenges remain in terms of production costs and performance limitations compared to some synthetic materials. However, ongoing research and development efforts are focused on improving the material's properties and production efficiency, which is likely to enhance its competitiveness and expand its market potential in the coming years.

Current Challenges in Cellulose Acetate Applications

Cellulose acetate, despite its widespread use and environmental benefits, faces several significant challenges in its current applications. One of the primary issues is its limited biodegradability in certain environments. While cellulose acetate is often marketed as a biodegradable material, its decomposition rate can vary greatly depending on environmental conditions. In marine environments, for instance, the material may persist for extended periods, contributing to plastic pollution in oceans and waterways.

Another challenge lies in the mechanical properties of cellulose acetate. Although it offers advantages in terms of flexibility and optical clarity, it often falls short in strength and durability compared to conventional plastics. This limitation restricts its use in applications requiring high structural integrity or long-term durability, such as in certain packaging or construction materials.

The production process of cellulose acetate also presents challenges. The acetylation of cellulose requires the use of acetic anhydride and sulfuric acid as catalysts, which can pose environmental and safety concerns if not properly managed. Additionally, the process is energy-intensive, potentially offsetting some of the material's environmental benefits.

Moisture sensitivity is another significant issue for cellulose acetate applications. The material tends to absorb moisture from the environment, which can lead to dimensional instability and degradation of mechanical properties over time. This characteristic limits its use in high-humidity environments or applications where moisture resistance is crucial.

Furthermore, the recycling of cellulose acetate products remains a challenge. While theoretically recyclable, the infrastructure and processes for effectively collecting and recycling cellulose acetate products are not widely established. This gap in the recycling ecosystem hinders the material's potential for a circular economy approach.

Lastly, the cost of cellulose acetate production, particularly for high-quality grades, can be higher than that of conventional plastics. This economic factor often limits its adoption in price-sensitive markets or applications where cost is a primary consideration.

Addressing these challenges is crucial for expanding the use of cellulose acetate in environmental solutions. Research efforts are ongoing to improve its biodegradability, enhance mechanical properties, develop more eco-friendly production processes, and establish effective recycling systems. Overcoming these hurdles will be key to realizing the full potential of cellulose acetate as a sustainable alternative in various applications.

Existing Cellulose Acetate Environmental Solutions

01 Production methods for cellulose acetate

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in a wide range of applications, including textiles, filters, and composite materials. The patents discuss novel fiber compositions, manufacturing techniques, and treatments to enhance the performance and properties of cellulose acetate fibers for specific end-uses.

- Cellulose acetate film and membrane technology: Innovations in cellulose acetate film and membrane technology are presented, covering areas such as improved formulations, manufacturing processes, and surface modifications. These advancements aim to enhance the performance of cellulose acetate in applications like separation membranes, packaging materials, and optical films.

- Cellulose acetate blends and composites: The development of cellulose acetate blends and composites with other materials is explored to create products with enhanced properties. These innovations focus on improving characteristics such as biodegradability, mechanical strength, and thermal stability for various industrial and consumer applications.

- Cellulose acetate modification and functionalization: Chemical and physical modifications of cellulose acetate are described to impart new functionalities or improve existing properties. These modifications include grafting, crosslinking, and surface treatments, aimed at expanding the range of applications for cellulose acetate-based materials.

02 Cellulose acetate fibers and films

Techniques for manufacturing cellulose acetate fibers and films are presented, focusing on improving their properties such as strength, flexibility, and durability. These innovations are applicable in textile, packaging, and membrane technologies.Expand Specific Solutions03 Cellulose acetate composites and blends

Development of cellulose acetate-based composites and blends with other materials to enhance performance characteristics. These innovations aim to create materials with improved mechanical, thermal, or barrier properties for various industrial applications.Expand Specific Solutions04 Modification and functionalization of cellulose acetate

Methods for modifying and functionalizing cellulose acetate to impart specific properties or introduce new functionalities. These techniques enable the creation of tailored materials for specialized applications in fields such as biomedical, environmental, and advanced materials.Expand Specific Solutions05 Cellulose acetate in sustainable and biodegradable applications

Utilization of cellulose acetate in environmentally friendly and biodegradable products. This includes the development of sustainable packaging materials, filters, and other eco-friendly alternatives to conventional plastics.Expand Specific Solutions

Key Players in Cellulose Acetate Industry

The market for cellulose acetate in environmental solutions is in a growth phase, driven by increasing demand for sustainable materials. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, cellulose acetate is mature but evolving, with companies like Daicel Corp., Eastman Chemical Co., and Nantong Cellulose Fibers Co. Ltd. leading innovation. These firms, along with others such as Zhuhai Cellulose Fibers Co. Ltd. and Kunming Acetate Fiber Co. Ltd., are advancing applications in areas like biodegradable plastics and water filtration. Research institutions like Beijing Forestry University and the Institute of Process Engineering, Chinese Academy of Sciences, are contributing to technological advancements, fostering a competitive landscape that balances established players with emerging innovators.

Daicel Corp.

Eastman Chemical Co.

Innovative Cellulose Acetate Modifications

- Incorporating a biodegradation promoting agent like cellulose phosphate or starch phosphate into the cellulose acetate structure, which is soluble in solvents and dispersed as fine particles, along with a photodegradation agent like titanium oxide, to enhance biodegradability without altering the manufacturing process and suppressing acetic acid odor.

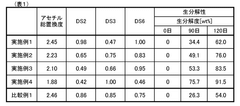

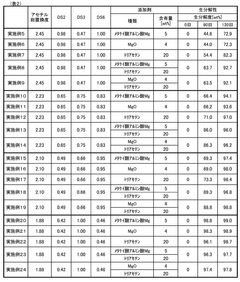

- Introducing acetyl groups heterogeneously into the 2nd, 3rd, and 6th carbon atoms of the glucose ring in cellulose acetate with a total degree of acetyl substitution between 1.75 and 2.55, and at least one position having a degree of acetyl substitution of 0.7 or less, combined with additives like magnesium oxide and triacetin to enhance biodegradability in seawater.

Regulatory Framework for Bioplastics

The regulatory framework for bioplastics, including cellulose acetate-based materials, is evolving rapidly as governments and international organizations recognize the need for sustainable alternatives to conventional plastics. In the European Union, the Single-Use Plastics Directive (EU) 2019/904 has set ambitious targets for reducing plastic waste and promoting the use of biodegradable materials. This directive specifically encourages the development and adoption of bioplastics, including those derived from cellulose acetate.

In the United States, the Sustainable Chemistry Research and Development Act of 2019 aims to promote the research and development of sustainable chemistry technologies, including bioplastics. The Environmental Protection Agency (EPA) has also established guidelines for the labeling and marketing of biodegradable plastics, ensuring that consumers are not misled by false environmental claims.

Many countries have implemented or are considering implementing extended producer responsibility (EPR) schemes for plastic products. These regulations hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. Such policies are likely to drive innovation in biodegradable materials like cellulose acetate-based bioplastics.

International standards organizations play a crucial role in establishing guidelines for bioplastics. The International Organization for Standardization (ISO) has developed standards such as ISO 17088:2012 for compostable plastics and ISO 14855 for determining the biodegradability of plastic materials. These standards provide a framework for assessing the environmental impact and performance of bioplastics, including those based on cellulose acetate.

The regulatory landscape also includes certifications and labeling schemes. Organizations like TÜV Austria and the Biodegradable Products Institute (BPI) offer certification programs for compostable and biodegradable materials. These certifications help manufacturers demonstrate compliance with regulatory requirements and communicate the environmental benefits of their products to consumers.

As the bioplastics industry continues to grow, regulatory bodies are likely to refine and expand their frameworks. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and the promotion of circular economy principles. This evolving regulatory environment presents both challenges and opportunities for the development and commercialization of cellulose acetate-based environmental solutions.

Life Cycle Assessment of Cellulose Acetate Products

Life Cycle Assessment (LCA) of cellulose acetate products is a crucial component in evaluating the environmental impact and sustainability of these materials. This comprehensive analysis examines the entire lifecycle of cellulose acetate products, from raw material extraction to disposal or recycling, providing valuable insights into their overall environmental performance.

The assessment typically begins with the sourcing of raw materials, primarily cellulose derived from wood pulp or cotton linters. This stage evaluates the environmental impacts associated with forestry practices, agricultural processes, and the initial processing of cellulose. The production phase is then scrutinized, focusing on the acetylation process that converts cellulose into cellulose acetate. This step involves analyzing energy consumption, chemical inputs, and emissions generated during manufacturing.

The use phase of cellulose acetate products is also considered, although its impact may vary significantly depending on the specific application. For instance, cellulose acetate fibers used in textiles may have different environmental implications compared to cellulose acetate films used in packaging.

End-of-life scenarios play a critical role in the LCA of cellulose acetate products. This includes assessing various disposal methods such as landfilling, incineration, and recycling. The biodegradability of cellulose acetate under different environmental conditions is a key factor in this analysis, as it influences the material's long-term environmental impact.

Water and energy consumption throughout the lifecycle are carefully measured and evaluated. This includes not only the direct use in manufacturing processes but also indirect consumption in transportation and auxiliary processes. Greenhouse gas emissions are quantified at each stage, contributing to a comprehensive carbon footprint analysis of cellulose acetate products.

The LCA also considers the potential for resource recovery and circular economy principles. This involves examining opportunities for recycling cellulose acetate products, either through mechanical or chemical processes, and assessing the environmental benefits of these recycling methods compared to virgin material production.

By conducting a thorough Life Cycle Assessment, researchers and industry professionals can identify hotspots in the environmental profile of cellulose acetate products. This information is invaluable for developing strategies to enhance the sustainability of these materials, guiding improvements in production processes, and informing policy decisions related to the use and disposal of cellulose acetate products.