Ensuring Biocompatibility of Cellulose Acetate Devices in Healthcare

Cellulose Acetate Biocompatibility Challenges

Cellulose acetate has gained significant attention in healthcare applications due to its biocompatibility, biodegradability, and versatile properties. However, ensuring the biocompatibility of cellulose acetate devices in healthcare settings presents several challenges that need to be addressed for safe and effective use.

One of the primary challenges is the potential for immune responses and inflammation when cellulose acetate comes into contact with biological tissues. While generally considered biocompatible, individual variations in patient responses can lead to adverse reactions in some cases. This necessitates thorough testing and optimization of cellulose acetate formulations to minimize the risk of immunogenic reactions.

Surface modification of cellulose acetate devices is another critical challenge. The inherent hydrophobicity of cellulose acetate can lead to protein adsorption and subsequent biofilm formation, potentially compromising device functionality and increasing infection risks. Developing effective surface modification techniques to enhance hydrophilicity and reduce protein adhesion is essential for improving long-term biocompatibility.

The degradation behavior of cellulose acetate in physiological environments poses additional challenges. While biodegradability is often desirable, controlling the rate and products of degradation is crucial to prevent unintended effects on surrounding tissues. Balancing the degradation rate with the intended lifespan of the medical device requires careful consideration and engineering of the cellulose acetate structure.

Sterilization processes present another hurdle in ensuring biocompatibility. Traditional sterilization methods, such as high-temperature autoclaving or ethylene oxide treatment, can potentially alter the physical and chemical properties of cellulose acetate, affecting its biocompatibility profile. Developing sterilization protocols that maintain the integrity of cellulose acetate while ensuring complete microbial elimination is a significant challenge.

The release of potentially harmful substances during the use or degradation of cellulose acetate devices is a concern that needs to be addressed. Residual solvents, unreacted monomers, or degradation products may leach out and interact with biological systems, potentially causing toxicity or other adverse effects. Rigorous testing and purification processes are necessary to minimize these risks and ensure the safety of cellulose acetate-based medical devices.

Achieving consistent quality and reproducibility in cellulose acetate production for healthcare applications is another challenge. Variations in raw materials, processing conditions, and manufacturing techniques can lead to inconsistencies in the final product's properties, potentially affecting its biocompatibility. Establishing robust quality control measures and standardized production protocols is essential to ensure reliable and safe cellulose acetate devices.

Healthcare Market Demand for Biocompatible Materials

The healthcare industry is experiencing a growing demand for biocompatible materials, particularly in the development of medical devices and implants. Cellulose acetate, a versatile and biocompatible polymer, has gained significant attention in this sector due to its unique properties and potential applications. The market for biocompatible materials in healthcare is projected to expand rapidly in the coming years, driven by factors such as an aging population, increasing prevalence of chronic diseases, and advancements in medical technology.

One of the key drivers of demand for biocompatible cellulose acetate devices is the rising need for minimally invasive surgical procedures. These procedures require materials that can be safely implanted in the human body without causing adverse reactions or complications. Cellulose acetate's biocompatibility and ability to be processed into various forms make it an attractive option for such applications.

The orthopedic and dental sectors represent significant market opportunities for cellulose acetate-based devices. With the growing incidence of bone and joint disorders, there is a rising demand for biocompatible materials that can be used in implants, scaffolds, and tissue engineering applications. Cellulose acetate's mechanical properties and biodegradability make it suitable for these purposes, potentially leading to improved patient outcomes and reduced healthcare costs.

In the field of drug delivery, cellulose acetate is gaining traction as a material for controlled release systems. The pharmaceutical industry is increasingly focusing on developing targeted and sustained-release formulations, which require biocompatible carriers. Cellulose acetate's ability to form porous membranes and its compatibility with various drugs make it an attractive option for this application, driving market demand in the pharmaceutical sector.

The wound care segment is another area where biocompatible cellulose acetate devices are seeing increased adoption. Advanced wound dressings that promote healing and prevent infections are in high demand, particularly for chronic wounds associated with conditions such as diabetes. Cellulose acetate's ability to be processed into films and fibers with tailored properties makes it suitable for developing innovative wound care products.

As healthcare systems worldwide focus on improving patient outcomes and reducing hospital-acquired infections, there is a growing demand for biocompatible materials in medical equipment and disposables. Cellulose acetate's antimicrobial properties and ease of sterilization make it an attractive option for manufacturing various healthcare products, from diagnostic tools to disposable medical supplies.

The market demand for biocompatible cellulose acetate devices is also influenced by regulatory trends and increasing emphasis on sustainable healthcare solutions. As regulatory bodies worldwide tighten standards for medical device safety and biocompatibility, materials like cellulose acetate that meet these requirements are likely to see increased adoption. Additionally, the biodegradability of cellulose acetate aligns with the growing focus on environmentally friendly healthcare solutions, further driving market demand.

Current State of Cellulose Acetate in Medical Devices

Cellulose acetate has emerged as a promising material in the medical device industry, offering a unique combination of properties that make it suitable for various healthcare applications. Currently, cellulose acetate is being utilized in a range of medical devices, including dialysis membranes, wound dressings, and drug delivery systems. Its biocompatibility, coupled with its versatile physical and chemical properties, has positioned it as a valuable alternative to traditional materials in certain medical applications.

In the field of hemodialysis, cellulose acetate membranes have gained significant traction due to their excellent filtration capabilities and reduced immune response compared to earlier cellulosic materials. These membranes demonstrate improved biocompatibility, resulting in fewer adverse reactions during dialysis treatments. The current state of cellulose acetate in this application continues to evolve, with ongoing research focused on enhancing membrane performance and patient outcomes.

Wound care is another area where cellulose acetate has made substantial progress. Modern wound dressings incorporating cellulose acetate fibers or films exhibit superior moisture management properties, promoting an optimal healing environment while maintaining breathability. These dressings have shown promise in managing both acute and chronic wounds, with current developments aimed at incorporating antimicrobial agents and growth factors to further improve healing outcomes.

In the realm of drug delivery, cellulose acetate is being explored for its potential in controlled release systems. Current research is investigating its use in oral dosage forms, transdermal patches, and implantable devices. The material's ability to be tailored for specific release profiles makes it an attractive option for developing advanced drug delivery platforms.

Despite these advancements, challenges remain in fully optimizing cellulose acetate for medical applications. Current efforts are focused on improving its long-term stability in physiological environments, enhancing its mechanical properties for specific device requirements, and developing more efficient manufacturing processes to reduce production costs.

The regulatory landscape surrounding cellulose acetate medical devices is evolving, with ongoing assessments of its long-term safety and performance. Current standards and guidelines for biocompatibility testing are being applied to cellulose acetate devices, with some regulatory bodies calling for additional studies to fully understand its interactions with biological systems over extended periods.

Collaboration between material scientists, medical researchers, and device manufacturers is driving the current state of cellulose acetate in medical devices forward. Interdisciplinary approaches are being employed to address existing limitations and unlock new potential applications. As the understanding of cellulose acetate's behavior in biological environments deepens, its role in healthcare is expected to expand, potentially revolutionizing certain aspects of medical device design and functionality.

Existing Biocompatibility Enhancement Methods

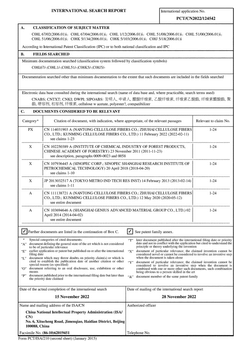

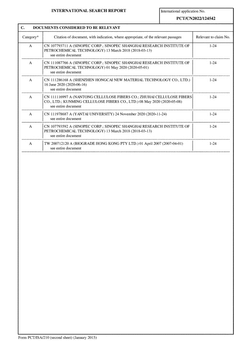

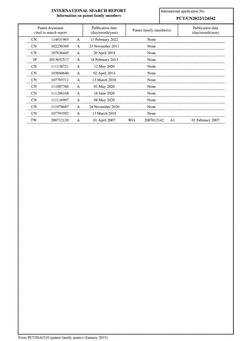

01 Biocompatible cellulose acetate materials for medical devices

Development of cellulose acetate materials with enhanced biocompatibility for use in medical devices. These materials are designed to minimize adverse reactions when in contact with biological tissues, making them suitable for implants, drug delivery systems, and other biomedical applications.- Biocompatible cellulose acetate materials for medical devices: Development of cellulose acetate-based materials with enhanced biocompatibility for use in medical devices. These materials are designed to minimize adverse reactions when in contact with biological tissues, making them suitable for implants, drug delivery systems, and other biomedical applications.

- Surface modification of cellulose acetate for improved biocompatibility: Techniques for modifying the surface of cellulose acetate devices to enhance their biocompatibility. This may include coating with biocompatible polymers, plasma treatment, or chemical modifications to improve cell adhesion, reduce inflammation, and prevent foreign body reactions.

- Cellulose acetate composites for tissue engineering: Development of biocompatible cellulose acetate composites for tissue engineering applications. These composites may incorporate other materials or bioactive agents to promote cell growth, tissue regeneration, and integration with host tissues.

- Biodegradable cellulose acetate devices: Creation of biodegradable cellulose acetate devices that maintain biocompatibility while gradually breaking down in the body. This approach is particularly useful for temporary implants or drug delivery systems, reducing the need for removal procedures and minimizing long-term foreign body responses.

- Biocompatibility testing methods for cellulose acetate devices: Development and standardization of biocompatibility testing methods specifically tailored for cellulose acetate devices. These methods assess the material's interaction with living tissues, potential toxicity, inflammatory responses, and long-term compatibility to ensure safety and efficacy in medical applications.

02 Surface modification of cellulose acetate for improved biocompatibility

Techniques for modifying the surface of cellulose acetate devices to enhance their biocompatibility. This may include coating with biocompatible polymers, plasma treatment, or chemical modifications to improve cell adhesion, reduce protein adsorption, and minimize inflammatory responses.Expand Specific Solutions03 Cellulose acetate composites for tissue engineering

Development of cellulose acetate-based composite materials for tissue engineering applications. These composites combine the biocompatibility of cellulose acetate with other materials to create scaffolds that support cell growth and tissue regeneration.Expand Specific Solutions04 Biodegradable cellulose acetate devices

Creation of biodegradable cellulose acetate devices for temporary medical applications. These devices are designed to maintain biocompatibility while gradually breaking down in the body, eliminating the need for removal and reducing long-term complications.Expand Specific Solutions05 Biocompatibility testing methods for cellulose acetate devices

Development and standardization of testing methods to assess the biocompatibility of cellulose acetate devices. These methods may include in vitro cell culture assays, animal studies, and long-term implantation tests to evaluate tissue responses and potential adverse effects.Expand Specific Solutions

Key Players in Biocompatible Material Development

The biocompatibility of cellulose acetate devices in healthcare represents a mature yet evolving field, with the market in a growth phase. The global market for biocompatible materials is expanding, driven by increasing demand for advanced medical devices. Companies like Daicel Corp., Eastman Chemical Co., and W. L. Gore & Associates, Inc. are at the forefront of developing cellulose acetate-based healthcare solutions. The technology's maturity is evident in its widespread application, but ongoing research by institutions such as the University of Tokyo and Industrial Technology Research Institute indicates potential for further innovation. Collaborations between academic institutions and industry players, such as Medtronic Vascular, Inc. and ViaCyte, Inc., are pushing the boundaries of biocompatibility and functionality in cellulose acetate devices.

W. L. Gore & Associates, Inc.

ViaCyte, Inc.

Innovations in Cellulose Acetate Modification

- A coating system utilizing cellulose compounds or derivatives, combined with pharmaceutical ingredients, applied through a method involving solvent mixtures and application techniques like microspraying, to enhance biocompatibility, mechanical properties, and adjust drug release profiles, while using sustainable materials.

- Incorporating a compatibilizer with active multifunctional groups, such as epoxy or maleic anhydride, to enhance the interfacial compatibility and mechanical properties of cellulose acetate and biodegradable polyester blends through reaction extrusion, allowing for improved thermal processing and film production.

Regulatory Framework for Medical Device Materials

The regulatory framework for medical device materials plays a crucial role in ensuring the safety and efficacy of healthcare products, particularly those incorporating cellulose acetate. Regulatory bodies worldwide have established comprehensive guidelines and standards to govern the use of materials in medical devices, with a specific focus on biocompatibility.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of medical devices through the Center for Devices and Radiological Health (CDRH). The FDA has implemented a risk-based classification system for medical devices, categorizing them into Class I, II, or III based on their intended use and potential risk to patients. Cellulose acetate devices may fall into different classes depending on their specific application and level of invasiveness.

The FDA requires manufacturers to demonstrate the biocompatibility of their devices through a series of tests outlined in the ISO 10993 standard. This standard provides a framework for evaluating the biological safety of medical devices, including tests for cytotoxicity, sensitization, irritation, and systemic toxicity. For cellulose acetate devices, manufacturers must conduct these tests to ensure that the material does not elicit adverse biological responses when in contact with human tissues.

In the European Union, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) govern the approval and marketing of medical devices. These regulations emphasize the importance of biocompatibility and require manufacturers to conduct a thorough risk assessment of their devices, including the materials used in their construction. The European Medicines Agency (EMA) also plays a role in evaluating the safety of medical devices that incorporate medicinal substances.

International standards, such as those developed by the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM), provide detailed guidelines for assessing the biocompatibility of medical device materials. These standards are often referenced by regulatory bodies and serve as a basis for evaluating the safety of cellulose acetate and other materials used in healthcare applications.

Regulatory agencies also require manufacturers to implement quality management systems, such as those outlined in ISO 13485, to ensure consistent production and maintain the safety and effectiveness of their devices. This includes establishing processes for material selection, supplier management, and ongoing monitoring of device performance in clinical use.

As the field of medical device materials continues to evolve, regulatory frameworks are adapting to address new challenges and technologies. For cellulose acetate devices, this may include considerations for novel manufacturing processes, surface modifications, or composite materials that enhance biocompatibility. Manufacturers must stay informed of these regulatory developments and work closely with regulatory bodies to ensure compliance throughout the product lifecycle.

Environmental Impact of Cellulose Acetate in Healthcare

The environmental impact of cellulose acetate in healthcare is a critical consideration as the industry strives for sustainable practices. Cellulose acetate, derived from natural cellulose, has been widely used in various medical devices and applications due to its biocompatibility and versatile properties. However, its production, use, and disposal have significant environmental implications that warrant careful examination.

The manufacturing process of cellulose acetate involves the use of chemical solvents and energy-intensive procedures, contributing to greenhouse gas emissions and potential chemical pollution. The production of cellulose acetate requires the acetylation of cellulose, typically sourced from wood pulp or cotton linters, which can lead to deforestation and habitat destruction if not managed sustainably.

In healthcare settings, cellulose acetate devices often have a limited lifespan, leading to frequent disposal and replacement. This creates a substantial waste stream that poses challenges for waste management systems. While cellulose acetate is biodegradable under certain conditions, the rate of degradation can be slow, particularly in landfill environments where oxygen is limited.

The disposal of cellulose acetate medical devices also raises concerns about the release of potentially harmful additives and plasticizers into the environment. These substances can leach into soil and water systems, potentially affecting ecosystems and human health. Additionally, the incineration of cellulose acetate waste can release toxic compounds into the atmosphere if not properly controlled.

However, it is important to note that cellulose acetate offers some environmental advantages compared to petroleum-based plastics. Its renewable source material and potential for biodegradation make it a more environmentally friendly option in certain applications. Efforts are underway to improve the sustainability of cellulose acetate production and enhance its end-of-life management.

Research into more eco-friendly production methods, such as using green solvents and optimizing energy efficiency, is ongoing. Additionally, the development of advanced recycling technologies for cellulose acetate shows promise in reducing its environmental footprint. Some healthcare facilities are implementing take-back programs and exploring closed-loop systems to minimize waste and promote the circular economy of cellulose acetate products.

As the healthcare industry continues to prioritize sustainability, the environmental impact of cellulose acetate remains an important area of focus. Balancing its beneficial properties with ecological considerations will be crucial in shaping future policies and practices surrounding its use in medical applications.