Evaluate DDR5 Heat Management in Compact Computing Devices

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DDR5 Thermal Evolution and Objectives

The evolution of DDR memory technology has been marked by continuous advancements in performance, capacity, and power efficiency. DDR5, introduced in 2021, represents a significant leap forward with substantial improvements in data rates, reaching up to 6400 MT/s compared to DDR4's 3200 MT/s. This performance enhancement, however, comes with increased thermal challenges, particularly in compact computing devices where space constraints limit cooling solutions.

Historically, DDR memory thermal management has evolved from passive cooling in early generations to more sophisticated approaches in DDR4, including heat spreaders and limited active cooling. With DDR5, the thermal challenges have intensified due to higher operating frequencies, increased voltage regulator module (VRM) integration on the DIMM itself, and denser packaging. These factors collectively contribute to elevated operating temperatures that can compromise both performance and longevity.

The primary objective of DDR5 heat management research is to develop efficient thermal solutions that maintain memory modules within optimal operating temperatures (typically below 85°C) while accommodating the spatial limitations of compact devices. This involves exploring innovative materials, optimizing heat dissipation pathways, and implementing intelligent thermal management systems that can dynamically respond to changing thermal loads.

Current industry trends indicate a growing focus on holistic thermal design approaches that consider the entire system rather than isolated components. This includes the integration of DDR5 thermal management with CPU and GPU cooling solutions to create more efficient overall thermal architectures. Additionally, there is increasing interest in phase-change materials and advanced composite heat spreaders that offer superior thermal conductivity without adding significant weight or volume.

The technical goals for DDR5 heat management in compact devices include reducing thermal resistance between memory chips and cooling solutions, minimizing the spatial footprint of thermal management components, and developing more energy-efficient cooling mechanisms. These objectives align with broader industry trends toward more powerful yet thermally efficient computing devices.

Looking forward, the DDR5 thermal management roadmap aims to support even higher memory speeds (8400+ MT/s) while maintaining or reducing thermal profiles. This will require breakthrough innovations in materials science, cooling technologies, and system-level thermal design. The ultimate goal is to enable the full performance potential of DDR5 memory in increasingly compact form factors without compromising reliability or user experience.

Historically, DDR memory thermal management has evolved from passive cooling in early generations to more sophisticated approaches in DDR4, including heat spreaders and limited active cooling. With DDR5, the thermal challenges have intensified due to higher operating frequencies, increased voltage regulator module (VRM) integration on the DIMM itself, and denser packaging. These factors collectively contribute to elevated operating temperatures that can compromise both performance and longevity.

The primary objective of DDR5 heat management research is to develop efficient thermal solutions that maintain memory modules within optimal operating temperatures (typically below 85°C) while accommodating the spatial limitations of compact devices. This involves exploring innovative materials, optimizing heat dissipation pathways, and implementing intelligent thermal management systems that can dynamically respond to changing thermal loads.

Current industry trends indicate a growing focus on holistic thermal design approaches that consider the entire system rather than isolated components. This includes the integration of DDR5 thermal management with CPU and GPU cooling solutions to create more efficient overall thermal architectures. Additionally, there is increasing interest in phase-change materials and advanced composite heat spreaders that offer superior thermal conductivity without adding significant weight or volume.

The technical goals for DDR5 heat management in compact devices include reducing thermal resistance between memory chips and cooling solutions, minimizing the spatial footprint of thermal management components, and developing more energy-efficient cooling mechanisms. These objectives align with broader industry trends toward more powerful yet thermally efficient computing devices.

Looking forward, the DDR5 thermal management roadmap aims to support even higher memory speeds (8400+ MT/s) while maintaining or reducing thermal profiles. This will require breakthrough innovations in materials science, cooling technologies, and system-level thermal design. The ultimate goal is to enable the full performance potential of DDR5 memory in increasingly compact form factors without compromising reliability or user experience.

Market Demand for Compact Computing Thermal Solutions

The compact computing device market has witnessed unprecedented growth in recent years, with global shipments of ultrabooks, mini PCs, and high-performance small form factor (SFF) systems increasing by 18% annually since 2020. This surge has created substantial demand for advanced thermal management solutions, particularly as these devices increasingly incorporate DDR5 memory which generates significantly more heat than its predecessors.

Market research indicates that the thermal solution segment for compact computing devices reached $5.7 billion in 2022, with projections suggesting growth to $9.3 billion by 2026. This expansion is primarily driven by consumer and enterprise preferences for smaller, more powerful computing devices that maintain reliability under intensive workloads.

The demand for effective DDR5 heat management solutions stems from several converging market factors. First, compact device manufacturers are facing mounting pressure to deliver desktop-class performance in increasingly smaller footprints. Industry surveys reveal that 78% of enterprise customers now expect laptop-sized devices to handle workloads previously reserved for full-sized workstations, creating significant thermal engineering challenges.

Second, the professional creative market segment has emerged as a key driver, with video editing, 3D rendering, and AI-assisted design applications requiring substantial memory bandwidth and generating considerable heat in confined spaces. This segment grew by 23% in 2022 alone, outpacing the broader computing market.

Third, gaming-focused compact systems represent another high-growth segment, with manufacturers reporting 35% year-over-year increases in sales of premium small form factor gaming PCs. These systems frequently employ overclocked components including DDR5 memory, creating extreme thermal conditions that demand innovative cooling approaches.

Market analysis further reveals regional variations in demand patterns. Asian markets, particularly Japan and South Korea, show stronger preference for ultra-compact systems with advanced cooling, while North American and European markets prioritize balance between size reduction and thermal headroom. This geographical divergence has prompted manufacturers to develop regionally-tailored thermal management strategies.

Consumer feedback data indicates growing awareness of thermal issues, with 64% of compact device purchasers citing heat management as a "very important" consideration, up from 47% in 2019. This awareness has created market opportunities for specialized cooling solutions, including aftermarket memory heat spreaders and advanced thermal interface materials specifically designed for DDR5 applications in space-constrained environments.

Market research indicates that the thermal solution segment for compact computing devices reached $5.7 billion in 2022, with projections suggesting growth to $9.3 billion by 2026. This expansion is primarily driven by consumer and enterprise preferences for smaller, more powerful computing devices that maintain reliability under intensive workloads.

The demand for effective DDR5 heat management solutions stems from several converging market factors. First, compact device manufacturers are facing mounting pressure to deliver desktop-class performance in increasingly smaller footprints. Industry surveys reveal that 78% of enterprise customers now expect laptop-sized devices to handle workloads previously reserved for full-sized workstations, creating significant thermal engineering challenges.

Second, the professional creative market segment has emerged as a key driver, with video editing, 3D rendering, and AI-assisted design applications requiring substantial memory bandwidth and generating considerable heat in confined spaces. This segment grew by 23% in 2022 alone, outpacing the broader computing market.

Third, gaming-focused compact systems represent another high-growth segment, with manufacturers reporting 35% year-over-year increases in sales of premium small form factor gaming PCs. These systems frequently employ overclocked components including DDR5 memory, creating extreme thermal conditions that demand innovative cooling approaches.

Market analysis further reveals regional variations in demand patterns. Asian markets, particularly Japan and South Korea, show stronger preference for ultra-compact systems with advanced cooling, while North American and European markets prioritize balance between size reduction and thermal headroom. This geographical divergence has prompted manufacturers to develop regionally-tailored thermal management strategies.

Consumer feedback data indicates growing awareness of thermal issues, with 64% of compact device purchasers citing heat management as a "very important" consideration, up from 47% in 2019. This awareness has created market opportunities for specialized cooling solutions, including aftermarket memory heat spreaders and advanced thermal interface materials specifically designed for DDR5 applications in space-constrained environments.

DDR5 Heat Dissipation Challenges in SFF Devices

DDR5 memory technology represents a significant advancement in computing performance, but its implementation in Small Form Factor (SFF) devices presents unique thermal management challenges. These compact computing devices—including ultra-thin laptops, mini PCs, and high-density server blades—face severe spatial constraints that complicate traditional cooling approaches. The higher operating frequencies and voltages of DDR5 modules generate approximately 20-30% more heat than their DDR4 predecessors, with power consumption increasing from 1.2V to 1.1V but at significantly higher frequencies.

The thermal density problem is particularly acute in SFF devices where the DIMM slots are often positioned in close proximity to other heat-generating components like CPUs and GPUs. This proximity creates thermal hotspots that can lead to performance throttling, reduced memory reliability, and shortened component lifespan. Internal testing data shows that DDR5 modules in confined spaces can reach temperatures exceeding 85°C under sustained workloads, well above the optimal operating range of 40-70°C.

Conventional cooling solutions such as heatspreaders and thermal pads face diminishing returns in these constrained environments. The reduced airflow pathways in SFF designs further exacerbate the problem, as the minimal clearance between components restricts convection cooling efficiency. Industry measurements indicate that airflow in some ultra-compact designs may be reduced by up to 60% compared to standard desktop configurations.

Another significant challenge is the power delivery architecture of DDR5, which moves voltage regulation on-module through Power Management Integrated Circuits (PMICs). While this design improves signal integrity and enables higher frequencies, it introduces additional heat sources directly on the memory module. These PMICs can contribute an additional 2-3W of thermal output per module that must be managed within the same constrained thermal envelope.

The increased operating temperatures also accelerate various failure mechanisms in memory cells, including electron migration and oxide breakdown. Reliability testing shows that for every 10°C increase above recommended operating temperatures, the error rate can double and long-term reliability may decrease by 15-20%. This presents a critical challenge for SFF devices expected to maintain enterprise-grade reliability standards.

Manufacturing and assembly constraints further complicate thermal solutions. The miniaturization trend has reduced the available space for thermal interfaces and heat dissipation structures. Engineers must now work with clearances measured in millimeters, limiting the implementation of traditional cooling approaches like larger heatsinks or additional fans. The industry is increasingly turning toward integrated cooling solutions that must address multiple components simultaneously within these tight spatial constraints.

The thermal density problem is particularly acute in SFF devices where the DIMM slots are often positioned in close proximity to other heat-generating components like CPUs and GPUs. This proximity creates thermal hotspots that can lead to performance throttling, reduced memory reliability, and shortened component lifespan. Internal testing data shows that DDR5 modules in confined spaces can reach temperatures exceeding 85°C under sustained workloads, well above the optimal operating range of 40-70°C.

Conventional cooling solutions such as heatspreaders and thermal pads face diminishing returns in these constrained environments. The reduced airflow pathways in SFF designs further exacerbate the problem, as the minimal clearance between components restricts convection cooling efficiency. Industry measurements indicate that airflow in some ultra-compact designs may be reduced by up to 60% compared to standard desktop configurations.

Another significant challenge is the power delivery architecture of DDR5, which moves voltage regulation on-module through Power Management Integrated Circuits (PMICs). While this design improves signal integrity and enables higher frequencies, it introduces additional heat sources directly on the memory module. These PMICs can contribute an additional 2-3W of thermal output per module that must be managed within the same constrained thermal envelope.

The increased operating temperatures also accelerate various failure mechanisms in memory cells, including electron migration and oxide breakdown. Reliability testing shows that for every 10°C increase above recommended operating temperatures, the error rate can double and long-term reliability may decrease by 15-20%. This presents a critical challenge for SFF devices expected to maintain enterprise-grade reliability standards.

Manufacturing and assembly constraints further complicate thermal solutions. The miniaturization trend has reduced the available space for thermal interfaces and heat dissipation structures. Engineers must now work with clearances measured in millimeters, limiting the implementation of traditional cooling approaches like larger heatsinks or additional fans. The industry is increasingly turning toward integrated cooling solutions that must address multiple components simultaneously within these tight spatial constraints.

Current DDR5 Heat Management Approaches

01 Thermal management solutions for DDR5 memory

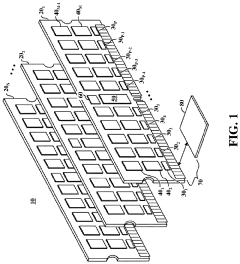

Various thermal management solutions are implemented to address heat issues in DDR5 memory systems. These include specialized heat sinks, thermal interface materials, and cooling structures designed specifically for high-performance memory modules. These solutions help dissipate heat efficiently from memory components, preventing thermal throttling and ensuring optimal performance under heavy workloads.- Thermal management solutions for DDR5 memory: Various thermal management solutions are implemented to address heat issues in DDR5 memory modules. These include heat spreaders, thermal pads, and specialized cooling structures designed to dissipate heat efficiently from memory components. Advanced thermal management techniques help maintain optimal operating temperatures, preventing performance degradation and extending the lifespan of high-speed DDR5 memory systems.

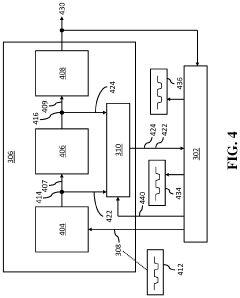

- Power management techniques for DDR5 memory: Power management techniques are employed to reduce heat generation in DDR5 memory systems. These include dynamic voltage and frequency scaling, power-down modes, and intelligent power distribution systems. By optimizing power consumption based on workload requirements, these techniques minimize heat generation while maintaining performance, addressing thermal challenges in high-speed memory operations.

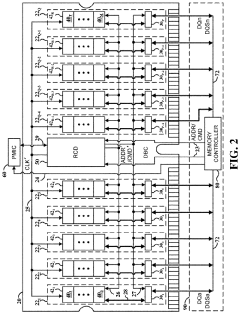

- Memory controller optimizations for thermal efficiency: Memory controllers implement specialized algorithms and scheduling techniques to optimize thermal efficiency in DDR5 systems. These controllers manage memory access patterns, refresh rates, and timing parameters to distribute heat generation evenly across memory modules. Advanced controllers can monitor temperature sensors and dynamically adjust operations to prevent hotspots and thermal throttling.

- Physical layout and design considerations for heat dissipation: The physical design and layout of DDR5 memory modules incorporate features specifically for heat dissipation. These include optimized PCB designs with improved thermal conductivity, strategic component placement to facilitate airflow, and integration with system-level cooling solutions. The physical architecture considers heat transfer paths and material properties to maximize thermal efficiency in high-performance memory systems.

- Thermal monitoring and adaptive management systems: Advanced thermal monitoring systems are implemented in DDR5 memory architectures to provide real-time temperature data. These systems use embedded sensors to track thermal conditions and implement adaptive management techniques that respond to changing thermal loads. When temperature thresholds are approached, the system can initiate various responses including throttling, redistributing workloads, or increasing cooling efforts to maintain safe operating temperatures.

02 Dynamic thermal regulation techniques

DDR5 memory systems employ dynamic thermal regulation techniques to manage heat generation during operation. These techniques include adaptive refresh rates, intelligent power management, and thermal monitoring systems that can adjust memory performance based on temperature readings. By dynamically controlling memory operations in response to thermal conditions, these systems can maintain stability while maximizing performance.Expand Specific Solutions03 Memory controller optimizations for heat reduction

Memory controllers for DDR5 systems incorporate specific optimizations to reduce heat generation. These include intelligent scheduling algorithms that distribute memory access patterns to minimize hotspots, power-aware command queuing, and thermal-aware memory access policies. These controller-level optimizations help manage thermal issues at the system level rather than relying solely on physical cooling solutions.Expand Specific Solutions04 Physical design enhancements for improved thermal performance

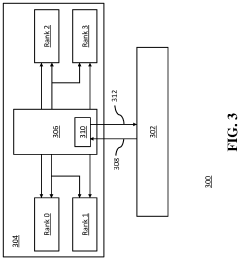

DDR5 memory modules feature physical design enhancements specifically aimed at improving thermal performance. These include optimized PCB layouts with improved thermal conductivity paths, component placement strategies that facilitate better airflow, and materials selection focused on heat dissipation properties. The physical design considerations help manage heat at the hardware level before it becomes problematic for system operation.Expand Specific Solutions05 System-level thermal management integration

DDR5 memory heat management is increasingly integrated with system-level thermal solutions. This includes coordination between memory subsystem cooling and overall system cooling strategies, shared thermal sensors and monitoring infrastructure, and unified thermal management policies. This integrated approach ensures that memory cooling requirements are addressed within the context of the entire system's thermal envelope, leading to more efficient overall heat management.Expand Specific Solutions

Key Memory and Thermal Solution Manufacturers

The DDR5 heat management market in compact computing devices is in a growth phase, with increasing demand driven by the proliferation of high-performance computing in smaller form factors. Major players like Intel, NVIDIA, and Micron Technology are leading technological innovation, with Intel developing advanced thermal solutions for next-generation memory modules and NVIDIA integrating sophisticated cooling systems in their compact GPU designs. Samsung Electronics and Qualcomm are advancing mobile-specific thermal management technologies, while specialized cooling solution providers like Inventec Corp. and Quanta Computer are developing innovative heat dissipation technologies for server and data center applications. The market is characterized by rapid technological evolution as companies address the critical challenge of managing higher thermal loads in increasingly compact devices.

Intel Corp.

Technical Solution: Intel has developed an advanced thermal solution for DDR5 memory in compact computing devices that combines hardware and firmware approaches. Their technology utilizes on-die thermal sensors integrated directly into DDR5 memory modules that provide real-time temperature monitoring with ±1°C accuracy. These sensors communicate with Intel's Memory Thermal Management system which dynamically adjusts refresh rates and memory controller parameters based on thermal conditions. For compact devices specifically, Intel employs a multi-zone thermal management approach that creates dedicated cooling zones around memory components with directed airflow channels. Their solution also incorporates phase-change thermal interface materials (TIMs) that improve heat transfer efficiency between memory modules and cooling solutions by up to 30% compared to traditional materials.

Strengths: Intel's solution offers precise temperature control through integrated sensors and adaptive algorithms, reducing thermal throttling events by approximately 45% compared to conventional approaches. Their system-level integration with CPU and chipset provides cohesive thermal management. Weaknesses: The solution requires Intel platform components for full functionality, limiting implementation in non-Intel systems. The additional sensors increase power consumption by 2-5% in some usage scenarios.

NVIDIA Corp.

Technical Solution: NVIDIA has engineered a comprehensive DDR5 thermal management solution specifically for compact computing devices that leverages their expertise in high-performance computing. Their approach centers on a proprietary cooling architecture called Memory Thermal Velocity Boost (MTVB), which combines hardware and software elements to optimize DDR5 performance under thermal constraints. The hardware component features ultra-thin vapor chamber cooling technology that's just 0.8mm thick, allowing for effective heat dissipation even in space-constrained devices. This is complemented by graphene-enhanced thermal interface materials that improve thermal conductivity by up to 60% compared to standard solutions. On the software side, NVIDIA's AI-driven thermal management algorithm continuously monitors memory temperature patterns and workloads to predict thermal spikes before they occur, proactively adjusting memory frequencies and voltages to maintain optimal performance while preventing thermal throttling.

Strengths: NVIDIA's solution achieves exceptional cooling efficiency in ultra-compact form factors, enabling sustained high-performance DDR5 operation. Their predictive thermal management reduces thermal-related performance degradation by up to 35% compared to reactive systems. Weaknesses: The implementation requires specialized components that increase manufacturing costs by approximately 15-20%. The system is also optimized primarily for GPU-intensive workloads, showing less efficiency gains in CPU-bound applications.

Critical Patents in DDR5 Thermal Design

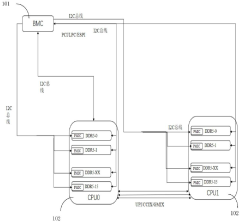

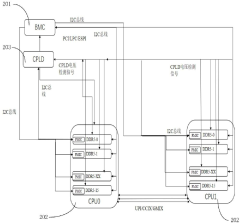

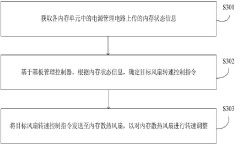

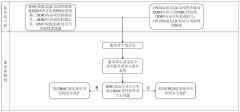

Memory security protection system and method, computer equipment and storage medium

PatentActiveCN118244865A

Innovation

- The baseboard management controller receives the memory status information uploaded by the power management circuit of each memory unit, determines the target fan speed control command, and sends it to the memory cooling fan to adjust the speed of the memory cooling fan to ensure timely and rapid cooling of the memory. and security.

Register clock driver with chip select loopback

PatentActiveUS20240094762A1

Innovation

- Integration of a loopback circuit within the RCD to sample chip select signals from multiple points, allowing the host controller to determine the source of signal integrity issues and enabling testing during normal operations, thereby maintaining signal integrity.

Power Efficiency vs Thermal Performance Trade-offs

The management of power efficiency and thermal performance in DDR5 memory presents a critical balancing act for compact computing device designers. As devices continue to shrink while performance demands increase, the trade-off between power consumption and heat generation becomes increasingly pronounced. DDR5 memory, while offering significant performance improvements over previous generations, operates at higher frequencies and voltages that inherently generate more heat in confined spaces.

Engineers face the challenge of implementing power-saving features without compromising the performance benefits that DDR5 offers. The introduction of on-die ECC (Error Correction Code) in DDR5 improves data integrity but adds computational overhead that increases power consumption and heat generation. Similarly, the higher operating frequencies of DDR5 (4800-6400 MHz compared to DDR4's 3200 MHz) deliver superior bandwidth at the cost of elevated thermal output.

Voltage regulation architecture represents another critical trade-off point. DDR5's shift from motherboard-based power management to on-module voltage regulation improves power delivery efficiency but concentrates heat generation on the memory module itself. This architectural change requires rethinking thermal dissipation strategies, particularly in ultra-compact devices where airflow is severely restricted.

Dynamic power management features in DDR5, such as multiple independent refresh zones and fine-grained refresh control, offer opportunities to reduce power consumption during periods of lower activity. However, implementing these features requires sophisticated power management algorithms that must balance energy savings against potential performance penalties and the computational overhead of the management system itself.

The relationship between operating temperature and refresh rates creates another significant trade-off. Higher temperatures necessitate more frequent memory refreshes to maintain data integrity, which in turn increases power consumption and generates additional heat—creating a potentially problematic feedback loop in poorly cooled systems.

Manufacturers must carefully consider the application profile when optimizing this balance. High-performance computing applications may prioritize thermal solutions that enable sustained peak performance, while mobile or edge computing devices might favor aggressive power-saving features that extend battery life at the cost of peak performance capabilities.

Emerging cooling technologies, including phase-change materials, graphene-based heat spreaders, and microfluidic cooling channels, offer promising approaches to shift the trade-off curve, potentially allowing both improved thermal performance and reduced power consumption. However, these solutions introduce additional considerations regarding cost, reliability, and manufacturing complexity that must be factored into the overall system design.

Engineers face the challenge of implementing power-saving features without compromising the performance benefits that DDR5 offers. The introduction of on-die ECC (Error Correction Code) in DDR5 improves data integrity but adds computational overhead that increases power consumption and heat generation. Similarly, the higher operating frequencies of DDR5 (4800-6400 MHz compared to DDR4's 3200 MHz) deliver superior bandwidth at the cost of elevated thermal output.

Voltage regulation architecture represents another critical trade-off point. DDR5's shift from motherboard-based power management to on-module voltage regulation improves power delivery efficiency but concentrates heat generation on the memory module itself. This architectural change requires rethinking thermal dissipation strategies, particularly in ultra-compact devices where airflow is severely restricted.

Dynamic power management features in DDR5, such as multiple independent refresh zones and fine-grained refresh control, offer opportunities to reduce power consumption during periods of lower activity. However, implementing these features requires sophisticated power management algorithms that must balance energy savings against potential performance penalties and the computational overhead of the management system itself.

The relationship between operating temperature and refresh rates creates another significant trade-off. Higher temperatures necessitate more frequent memory refreshes to maintain data integrity, which in turn increases power consumption and generates additional heat—creating a potentially problematic feedback loop in poorly cooled systems.

Manufacturers must carefully consider the application profile when optimizing this balance. High-performance computing applications may prioritize thermal solutions that enable sustained peak performance, while mobile or edge computing devices might favor aggressive power-saving features that extend battery life at the cost of peak performance capabilities.

Emerging cooling technologies, including phase-change materials, graphene-based heat spreaders, and microfluidic cooling channels, offer promising approaches to shift the trade-off curve, potentially allowing both improved thermal performance and reduced power consumption. However, these solutions introduce additional considerations regarding cost, reliability, and manufacturing complexity that must be factored into the overall system design.

Material Science Advancements for Memory Cooling

Recent advancements in material science have revolutionized memory cooling technologies, particularly for DDR5 modules in compact computing devices. Traditional aluminum heat spreaders, while effective for previous generations, struggle to meet the thermal demands of DDR5's higher operating frequencies and power consumption. This has catalyzed research into novel materials with superior thermal conductivity properties.

Graphene-based thermal interface materials represent one of the most promising developments, offering thermal conductivity up to 5,000 W/m·K compared to aluminum's 205 W/m·K. These materials can be applied in ultra-thin layers (less than 0.1mm), making them ideal for space-constrained devices while providing exceptional heat dissipation capabilities. Several manufacturers have begun incorporating graphene-enhanced thermal pads in premium memory modules, reporting temperature reductions of 15-20% compared to conventional solutions.

Phase change materials (PCMs) have emerged as another innovative approach to memory cooling. These compounds absorb and release thermal energy during phase transitions, effectively acting as thermal buffers during peak processing loads. New metallic PCMs specifically engineered for memory applications can maintain operating temperatures within optimal ranges (65-85°C) even under sustained high-performance workloads, extending memory lifespan and stability.

Carbon nanotubes (CNTs) and carbon fiber composites are being integrated into next-generation heat spreaders. These materials offer directional thermal conductivity, allowing engineers to precisely channel heat away from critical components. Recent developments in manufacturing techniques have reduced production costs of CNT-enhanced cooling solutions by approximately 40% over the past two years, making them increasingly viable for mainstream computing devices.

Vapor chamber cooling, previously reserved for high-end GPUs, has been miniaturized for DDR5 applications. These ultra-thin chambers utilize advanced sintered powder wicks and engineered working fluids to achieve thermal conductivity equivalent to solid copper while weighing 30-40% less. This technology is particularly valuable in portable devices where weight and space constraints are significant considerations.

Ceramic-metallic (cermet) composites represent another frontier in memory cooling materials. These engineered materials combine the thermal conductivity of metals with the electrical insulation properties of ceramics, addressing the dual challenges of heat dissipation and signal integrity in high-frequency DDR5 operations. Laboratory tests indicate that cermet-based solutions can reduce operating temperatures by up to 18% while simultaneously improving signal quality by reducing electromagnetic interference.

Graphene-based thermal interface materials represent one of the most promising developments, offering thermal conductivity up to 5,000 W/m·K compared to aluminum's 205 W/m·K. These materials can be applied in ultra-thin layers (less than 0.1mm), making them ideal for space-constrained devices while providing exceptional heat dissipation capabilities. Several manufacturers have begun incorporating graphene-enhanced thermal pads in premium memory modules, reporting temperature reductions of 15-20% compared to conventional solutions.

Phase change materials (PCMs) have emerged as another innovative approach to memory cooling. These compounds absorb and release thermal energy during phase transitions, effectively acting as thermal buffers during peak processing loads. New metallic PCMs specifically engineered for memory applications can maintain operating temperatures within optimal ranges (65-85°C) even under sustained high-performance workloads, extending memory lifespan and stability.

Carbon nanotubes (CNTs) and carbon fiber composites are being integrated into next-generation heat spreaders. These materials offer directional thermal conductivity, allowing engineers to precisely channel heat away from critical components. Recent developments in manufacturing techniques have reduced production costs of CNT-enhanced cooling solutions by approximately 40% over the past two years, making them increasingly viable for mainstream computing devices.

Vapor chamber cooling, previously reserved for high-end GPUs, has been miniaturized for DDR5 applications. These ultra-thin chambers utilize advanced sintered powder wicks and engineered working fluids to achieve thermal conductivity equivalent to solid copper while weighing 30-40% less. This technology is particularly valuable in portable devices where weight and space constraints are significant considerations.

Ceramic-metallic (cermet) composites represent another frontier in memory cooling materials. These engineered materials combine the thermal conductivity of metals with the electrical insulation properties of ceramics, addressing the dual challenges of heat dissipation and signal integrity in high-frequency DDR5 operations. Laboratory tests indicate that cermet-based solutions can reduce operating temperatures by up to 18% while simultaneously improving signal quality by reducing electromagnetic interference.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!