Evaluating Cost-Effectiveness of Lithium Bromide Use in HVAC

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr HVAC Technology Background and Objectives

Lithium Bromide (LiBr) absorption refrigeration technology has evolved significantly since its inception in the early 20th century. Initially developed as an alternative to vapor compression systems, LiBr-based Heating, Ventilation, and Air Conditioning (HVAC) systems have gained prominence due to their ability to utilize low-grade thermal energy sources. The technology leverages the hygroscopic properties of lithium bromide solution to create a refrigeration effect through an absorption-desorption cycle, offering a thermally-driven alternative to conventional electrically-powered cooling systems.

The historical trajectory of LiBr HVAC systems shows steady improvement in efficiency and reliability. The 1950s and 1960s marked significant advancements with the introduction of double-effect absorption chillers, substantially improving coefficient of performance (COP) values. Recent decades have witnessed further refinements in system design, corrosion prevention, and crystallization control, addressing key limitations that previously hindered widespread adoption.

Current technological trends in LiBr HVAC systems focus on enhancing energy efficiency, reducing environmental impact, and improving system integration capabilities. Triple-effect and even quadruple-effect cycles are being developed to achieve higher COPs, while hybrid systems combining absorption technology with conventional vapor compression are emerging as promising solutions for specific applications. Additionally, research into advanced heat and mass transfer enhancement techniques aims to reduce equipment size and capital costs.

The primary objective of evaluating LiBr HVAC cost-effectiveness is to determine the economic viability of these systems compared to conventional alternatives across various operational contexts. This includes quantifying both direct costs (equipment, installation, maintenance) and indirect benefits (primary energy savings, emissions reduction, peak load management). The assessment must consider the full lifecycle perspective, accounting for regional energy pricing structures, available waste heat resources, and potential policy incentives.

Technical objectives include identifying optimal system configurations for different application scenarios, determining threshold conditions where LiBr systems become economically advantageous, and exploring innovative approaches to overcome existing limitations. This encompasses research into advanced materials for heat exchangers, improved working fluid formulations to prevent crystallization, and enhanced control strategies to optimize performance under varying load conditions.

The evaluation also aims to establish standardized methodologies for assessing the economic performance of LiBr systems, enabling more accurate comparisons across different technologies and applications. This includes developing comprehensive models that account for both technical performance parameters and economic factors, providing decision-makers with robust tools for investment planning and technology selection.

The historical trajectory of LiBr HVAC systems shows steady improvement in efficiency and reliability. The 1950s and 1960s marked significant advancements with the introduction of double-effect absorption chillers, substantially improving coefficient of performance (COP) values. Recent decades have witnessed further refinements in system design, corrosion prevention, and crystallization control, addressing key limitations that previously hindered widespread adoption.

Current technological trends in LiBr HVAC systems focus on enhancing energy efficiency, reducing environmental impact, and improving system integration capabilities. Triple-effect and even quadruple-effect cycles are being developed to achieve higher COPs, while hybrid systems combining absorption technology with conventional vapor compression are emerging as promising solutions for specific applications. Additionally, research into advanced heat and mass transfer enhancement techniques aims to reduce equipment size and capital costs.

The primary objective of evaluating LiBr HVAC cost-effectiveness is to determine the economic viability of these systems compared to conventional alternatives across various operational contexts. This includes quantifying both direct costs (equipment, installation, maintenance) and indirect benefits (primary energy savings, emissions reduction, peak load management). The assessment must consider the full lifecycle perspective, accounting for regional energy pricing structures, available waste heat resources, and potential policy incentives.

Technical objectives include identifying optimal system configurations for different application scenarios, determining threshold conditions where LiBr systems become economically advantageous, and exploring innovative approaches to overcome existing limitations. This encompasses research into advanced materials for heat exchangers, improved working fluid formulations to prevent crystallization, and enhanced control strategies to optimize performance under varying load conditions.

The evaluation also aims to establish standardized methodologies for assessing the economic performance of LiBr systems, enabling more accurate comparisons across different technologies and applications. This includes developing comprehensive models that account for both technical performance parameters and economic factors, providing decision-makers with robust tools for investment planning and technology selection.

Market Analysis for LiBr Absorption Cooling Systems

The global market for Lithium Bromide (LiBr) absorption cooling systems has been experiencing steady growth, driven primarily by increasing energy costs and environmental regulations. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate (CAGR) of 6.7%. This growth trajectory is supported by the rising demand for energy-efficient HVAC solutions across commercial, industrial, and residential sectors.

Asia-Pacific currently dominates the market, accounting for over 40% of the global share, with China and Japan being the largest contributors. This regional dominance is attributed to rapid industrialization, favorable government policies promoting green technologies, and significant investments in sustainable infrastructure. North America and Europe follow, collectively representing about 35% of the market, where stringent environmental regulations and sustainability goals are driving adoption.

Commercial applications constitute the largest segment, with approximately 45% market share, followed by industrial applications at 30%. The hospitality sector, particularly luxury hotels and resorts, has emerged as a significant end-user, valuing the quiet operation and energy efficiency of LiBr systems. Healthcare facilities and data centers are also increasingly adopting these systems due to their reliable cooling capabilities and reduced carbon footprint.

The market is witnessing a shift toward integrated systems that combine LiBr absorption chillers with renewable energy sources such as solar thermal collectors or waste heat recovery systems. This integration enhances the cost-effectiveness and environmental benefits, making these systems more attractive to environmentally conscious consumers and organizations with net-zero carbon goals.

Key market drivers include rising electricity costs, which have increased by an average of 3.5% annually in developed markets, making the operational cost advantages of LiBr systems more pronounced. Additionally, government incentives for energy-efficient technologies, including tax rebates and subsidies in regions like the European Union and parts of Asia, are accelerating market penetration.

Challenges in the market include high initial capital costs, which can be 30-50% higher than conventional vapor compression systems, creating a barrier to entry for small and medium-sized enterprises. Limited awareness about the technology's benefits and misconceptions regarding maintenance requirements also hinder market growth in emerging economies.

The competitive landscape is characterized by a mix of established HVAC manufacturers and specialized absorption chiller providers. Market consolidation through mergers and acquisitions has been observed, as companies seek to expand their technological capabilities and geographical presence to capitalize on the growing demand for sustainable cooling solutions.

Asia-Pacific currently dominates the market, accounting for over 40% of the global share, with China and Japan being the largest contributors. This regional dominance is attributed to rapid industrialization, favorable government policies promoting green technologies, and significant investments in sustainable infrastructure. North America and Europe follow, collectively representing about 35% of the market, where stringent environmental regulations and sustainability goals are driving adoption.

Commercial applications constitute the largest segment, with approximately 45% market share, followed by industrial applications at 30%. The hospitality sector, particularly luxury hotels and resorts, has emerged as a significant end-user, valuing the quiet operation and energy efficiency of LiBr systems. Healthcare facilities and data centers are also increasingly adopting these systems due to their reliable cooling capabilities and reduced carbon footprint.

The market is witnessing a shift toward integrated systems that combine LiBr absorption chillers with renewable energy sources such as solar thermal collectors or waste heat recovery systems. This integration enhances the cost-effectiveness and environmental benefits, making these systems more attractive to environmentally conscious consumers and organizations with net-zero carbon goals.

Key market drivers include rising electricity costs, which have increased by an average of 3.5% annually in developed markets, making the operational cost advantages of LiBr systems more pronounced. Additionally, government incentives for energy-efficient technologies, including tax rebates and subsidies in regions like the European Union and parts of Asia, are accelerating market penetration.

Challenges in the market include high initial capital costs, which can be 30-50% higher than conventional vapor compression systems, creating a barrier to entry for small and medium-sized enterprises. Limited awareness about the technology's benefits and misconceptions regarding maintenance requirements also hinder market growth in emerging economies.

The competitive landscape is characterized by a mix of established HVAC manufacturers and specialized absorption chiller providers. Market consolidation through mergers and acquisitions has been observed, as companies seek to expand their technological capabilities and geographical presence to capitalize on the growing demand for sustainable cooling solutions.

Current State and Challenges in LiBr HVAC Applications

Lithium bromide (LiBr) absorption systems represent a significant segment of the global HVAC market, particularly in industrial and large commercial applications. Currently, these systems are deployed across various regions with notable concentrations in Asia-Pacific, North America, and Europe. The technology has reached maturity in certain applications, particularly in large-scale cooling for industrial processes and district cooling systems, where its efficiency advantages are most pronounced.

The current state of LiBr HVAC technology faces several technical challenges that impact its broader adoption. Crystallization remains a persistent issue, occurring when the LiBr solution concentration exceeds solubility limits, leading to system blockages and performance degradation. This phenomenon typically happens during low-temperature operation or power fluctuations, requiring sophisticated control systems to prevent occurrence.

Corrosion presents another significant challenge, as LiBr solutions are inherently corrosive to many common metals used in HVAC systems. While manufacturers have developed specialized materials and inhibitors to mitigate this issue, these solutions add to system complexity and cost. The corrosion challenge necessitates regular maintenance and monitoring, increasing the total cost of ownership.

Energy efficiency limitations also constrain wider adoption. While LiBr systems offer advantages in utilizing waste heat or renewable thermal energy, their coefficient of performance (COP) typically ranges from 0.7 to 1.2 for single-effect systems, lower than conventional vapor compression systems. Double and triple-effect systems achieve higher efficiencies but at significantly increased capital costs and complexity.

Market penetration faces additional barriers related to system size and installation requirements. LiBr absorption chillers generally require more physical space than equivalent capacity vapor compression systems, limiting their application in space-constrained environments. The systems also demand specialized knowledge for installation, operation, and maintenance, creating workforce challenges in regions where such expertise is limited.

Recent technological developments have focused on addressing these limitations through advanced control algorithms to prevent crystallization, development of more corrosion-resistant materials, and hybrid systems that combine absorption and vapor compression technologies. Manufacturers are also working on modular designs to reduce installation complexity and footprint requirements.

The economic viability of LiBr systems remains highly context-dependent, with the most favorable conditions occurring where waste heat is abundant, electricity costs are high, or environmental regulations favor lower-emission technologies. The technology's market share has remained relatively stable in recent years, with growth primarily in regions implementing carbon reduction initiatives or facing electricity supply constraints.

The current state of LiBr HVAC technology faces several technical challenges that impact its broader adoption. Crystallization remains a persistent issue, occurring when the LiBr solution concentration exceeds solubility limits, leading to system blockages and performance degradation. This phenomenon typically happens during low-temperature operation or power fluctuations, requiring sophisticated control systems to prevent occurrence.

Corrosion presents another significant challenge, as LiBr solutions are inherently corrosive to many common metals used in HVAC systems. While manufacturers have developed specialized materials and inhibitors to mitigate this issue, these solutions add to system complexity and cost. The corrosion challenge necessitates regular maintenance and monitoring, increasing the total cost of ownership.

Energy efficiency limitations also constrain wider adoption. While LiBr systems offer advantages in utilizing waste heat or renewable thermal energy, their coefficient of performance (COP) typically ranges from 0.7 to 1.2 for single-effect systems, lower than conventional vapor compression systems. Double and triple-effect systems achieve higher efficiencies but at significantly increased capital costs and complexity.

Market penetration faces additional barriers related to system size and installation requirements. LiBr absorption chillers generally require more physical space than equivalent capacity vapor compression systems, limiting their application in space-constrained environments. The systems also demand specialized knowledge for installation, operation, and maintenance, creating workforce challenges in regions where such expertise is limited.

Recent technological developments have focused on addressing these limitations through advanced control algorithms to prevent crystallization, development of more corrosion-resistant materials, and hybrid systems that combine absorption and vapor compression technologies. Manufacturers are also working on modular designs to reduce installation complexity and footprint requirements.

The economic viability of LiBr systems remains highly context-dependent, with the most favorable conditions occurring where waste heat is abundant, electricity costs are high, or environmental regulations favor lower-emission technologies. The technology's market share has remained relatively stable in recent years, with growth primarily in regions implementing carbon reduction initiatives or facing electricity supply constraints.

Current Cost-Benefit Analysis Methods for LiBr Systems

01 Cost-effective lithium bromide absorption refrigeration systems

Lithium bromide is widely used as an absorbent in absorption refrigeration systems due to its cost-effectiveness compared to other refrigerants. These systems utilize lithium bromide solution to absorb refrigerant vapor, enabling efficient cooling with lower energy consumption. Innovations in system design have improved the economic viability of lithium bromide-based refrigeration by reducing operational costs and increasing efficiency, making them particularly suitable for industrial and commercial applications where energy costs are significant.- Cost-effective lithium bromide absorption refrigeration systems: Lithium bromide is widely used in absorption refrigeration systems due to its cost-effectiveness compared to other refrigerants. These systems utilize lithium bromide as an absorbent for water vapor, creating an efficient cooling cycle. Innovations in system design have improved energy efficiency and reduced operational costs, making lithium bromide-based refrigeration systems economically viable for commercial and industrial applications. These systems typically feature optimized heat exchangers and regeneration processes to maximize performance while minimizing lithium bromide consumption.

- Economic analysis of lithium bromide in energy storage applications: Lithium bromide offers cost-effective solutions for energy storage applications, particularly in thermal energy storage systems. Economic analyses demonstrate favorable cost-to-performance ratios when compared to alternative materials. The long lifecycle and stability of lithium bromide solutions contribute to reduced replacement costs over time. Implementation in grid-scale energy storage shows promising return on investment, especially when integrated with renewable energy sources to manage intermittent power generation. The economic benefits include reduced peak demand charges and improved energy utilization efficiency.

- Production methods affecting lithium bromide cost-efficiency: Various production methods significantly impact the cost-efficiency of lithium bromide. Advanced manufacturing techniques have been developed to reduce production costs while maintaining high purity levels. Recycling processes for lithium bromide solutions extend the useful life of the material and decrease overall operational expenses. Innovations in synthesis methods have led to more economical production pathways, including optimized reaction conditions and improved separation techniques. These advancements contribute to making lithium bromide more economically viable for various industrial applications.

- Comparative cost analysis of lithium bromide in HVAC systems: Cost analyses comparing lithium bromide-based absorption cooling systems with conventional HVAC technologies demonstrate competitive lifecycle costs despite higher initial investment. The operational efficiency and reduced energy consumption of lithium bromide systems result in significant cost savings over time. Maintenance requirements and associated costs are generally lower than for mechanical compression systems. The economic advantages become more pronounced in applications with access to waste heat or low-cost thermal energy sources. Integration with solar thermal collectors further enhances cost-effectiveness by utilizing renewable energy for the regeneration process.

- Additives and formulations for improving lithium bromide economic performance: Various additives and formulation techniques have been developed to enhance the economic performance of lithium bromide solutions. Corrosion inhibitors extend equipment life and reduce maintenance costs associated with lithium bromide systems. Stabilizing agents improve the longevity of lithium bromide solutions, reducing replacement frequency and associated expenses. Performance enhancers increase the absorption efficiency, allowing for reduced lithium bromide concentrations while maintaining system effectiveness. These formulation improvements contribute significantly to the overall cost-effectiveness of lithium bromide in industrial applications.

02 Economic analysis of lithium bromide in energy storage applications

Lithium bromide offers cost-effective solutions for energy storage applications, particularly in thermal energy storage systems. Economic analyses demonstrate favorable cost-benefit ratios when using lithium bromide in absorption heat pumps and energy storage units. The compound's ability to store and release thermal energy efficiently contributes to reduced operational costs in heating and cooling systems, providing economic advantages over alternative materials despite its initial procurement cost.Expand Specific Solutions03 Manufacturing process optimization for cost reduction

Various manufacturing process optimizations have been developed to reduce the production cost of lithium bromide. These innovations include improved synthesis methods, recycling techniques, and purification processes that minimize waste and energy consumption. By optimizing production parameters and implementing more efficient manufacturing techniques, the overall cost of lithium bromide can be significantly reduced while maintaining or improving product quality, making it more economically viable for various applications.Expand Specific Solutions04 Comparative cost analysis with alternative absorbents

Economic comparisons between lithium bromide and alternative absorbents demonstrate its cost-effectiveness in specific applications. While the initial procurement cost of lithium bromide may be higher than some alternatives, its superior absorption properties, longer service life, and lower maintenance requirements often result in better long-term economic performance. The total cost of ownership analysis shows that lithium bromide systems can provide significant savings over the operational lifetime compared to systems using other absorbents.Expand Specific Solutions05 Energy efficiency improvements enhancing economic viability

Technological advancements have improved the energy efficiency of lithium bromide systems, enhancing their economic viability. These improvements include better heat exchange designs, advanced control systems, and optimized solution concentrations that reduce energy consumption. By increasing the coefficient of performance and reducing operational energy requirements, these innovations make lithium bromide systems more cost-effective despite the compound's procurement price, particularly in large-scale industrial applications where energy costs represent a significant portion of operational expenses.Expand Specific Solutions

Major Manufacturers and Suppliers in LiBr HVAC Industry

The lithium bromide HVAC market is currently in a growth phase, with increasing adoption driven by energy efficiency demands and sustainability goals. The global market size for absorption cooling systems using lithium bromide is projected to expand significantly, particularly in commercial and industrial applications. Technologically, the field shows varying maturity levels, with established players like Carrier Corp. and Johnson Controls offering commercial solutions, while research institutions such as Tianjin University and CSIC are advancing next-generation systems. Shuangliang Eco-Energy Systems leads in industrial waste heat recovery applications, while DuPont and Evonik Operations contribute material innovations. Emerging players like Sunamp are integrating lithium bromide technology with thermal storage solutions, indicating a diversifying competitive landscape with opportunities for cost-optimization and efficiency improvements.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang Eco-Energy Systems has developed advanced lithium bromide absorption chillers that utilize waste heat or solar energy as primary energy sources. Their technology employs a double-effect absorption cycle that achieves a coefficient of performance (COP) of up to 1.4, significantly higher than traditional single-effect systems. The company has implemented corrosion inhibitors and specialized materials in their heat exchangers to address the corrosive nature of lithium bromide solutions, extending system lifespan to over 20 years. Their vacuum-sealed design minimizes crystallization risks while their patented solution distribution system ensures optimal wetting of heat exchange surfaces, improving thermal efficiency by approximately 15% compared to conventional designs. Shuangliang has also integrated advanced automation controls that optimize lithium bromide concentration based on real-time operating conditions, reducing energy consumption by up to 20% during partial load operations.

Strengths: High energy efficiency with superior COP values; excellent integration with renewable energy sources; robust corrosion resistance technology; advanced control systems for optimal performance across varying conditions. Weaknesses: Higher initial capital investment compared to conventional cooling systems; requires specialized maintenance expertise; performance can be affected by ambient conditions in extreme environments.

Carrier Corp.

Technical Solution: Carrier Corporation has pioneered lithium bromide absorption chillers with their Absorption Series, specifically designed for commercial and industrial applications. Their technology utilizes a two-stage absorption cycle that recovers internal heat to improve efficiency, achieving COPs of 1.2-1.5 when powered by steam or hot water. Carrier's systems incorporate proprietary solution flow control mechanisms that automatically adjust lithium bromide concentration based on cooling demand, optimizing performance while preventing crystallization issues. Their heat exchangers feature enhanced surface designs that improve heat transfer efficiency by up to 25% compared to conventional tube designs. Carrier has also developed smart diagnostic systems that continuously monitor solution chemistry, automatically adjusting operating parameters to maintain optimal lithium bromide concentration and pH levels, which has been shown to reduce maintenance costs by approximately 30% over the system lifecycle. Their latest models incorporate low-flow solution pumps that reduce electrical consumption by up to 40% compared to earlier generations.

Strengths: Extensive global service network providing reliable maintenance support; sophisticated control systems that optimize lithium bromide concentration; proven reliability with documented system lifespans exceeding 25 years; compatibility with multiple heat sources including natural gas, steam, and hot water. Weaknesses: Higher upfront costs compared to conventional electric chillers; performance degradation in environments with limited water availability; requires specialized technical expertise for optimal operation and maintenance.

Key Technical Innovations in LiBr Absorption Technology

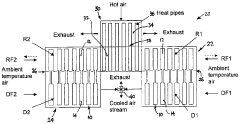

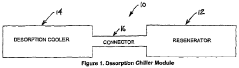

Apparatus and method for transferring heat

PatentInactiveUS8256235B2

Innovation

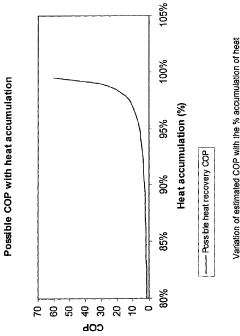

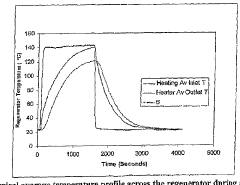

- The apparatus comprises first and second heat transfer units with a thermally connected heat exchanger, allowing for heat accumulation and simultaneous adsorption/desorption in both units, eliminating the need for additional heat exchangers and pumps, and enhancing thermal isolation between adsorbent materials to achieve a COP of up to 12.

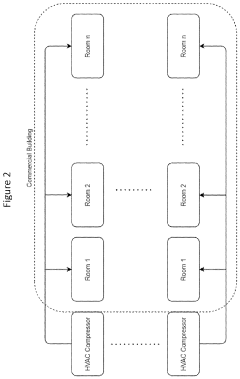

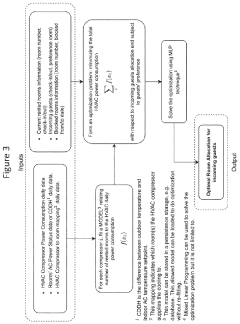

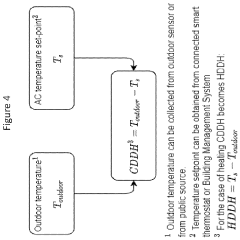

A Method of Reducing Energy Consumption of Heating, Ventilation and Air Conditioning (HVAC) Equipment in a Multi-Room Building

PatentInactiveUS20240085045A1

Innovation

- A method that involves obtaining energy usage profiles for each room, assigning energy efficiency scores, and allocating rooms based on the most energy-efficient unoccupied rooms to minimize overall HVAC energy consumption, using smart thermostats and energy meters to collect data and apply mathematical modeling for optimal allocation.

Energy Efficiency Comparison with Alternative Refrigerants

When comparing the energy efficiency of lithium bromide absorption systems with alternative refrigerants in HVAC applications, several key performance metrics must be considered. Lithium bromide systems typically achieve a Coefficient of Performance (COP) ranging from 0.7 to 1.2 for single-effect systems, while double-effect systems can reach COPs of 1.2 to 1.5. These values generally fall below the energy efficiency of conventional vapor compression systems using HFC refrigerants, which commonly achieve COPs of 3.0 to 5.0 under optimal conditions.

The primary advantage of lithium bromide systems lies in their ability to utilize low-grade thermal energy sources such as waste heat, solar thermal energy, or district heating networks. This capability creates significant primary energy savings when waste heat recovery is implemented, potentially offsetting the lower nominal COP values compared to conventional systems.

Ammonia-water absorption systems represent the main alternative absorption technology, offering COPs of 0.5 to 0.7. While less efficient than lithium bromide systems, ammonia-water pairs can operate at lower temperatures and provide both heating and cooling capabilities, making them suitable for specific applications where lithium bromide systems cannot function effectively.

When examining synthetic refrigerants, R-134a and R-410A remain common in conventional vapor compression systems. These refrigerants deliver higher energy efficiency but require significant electrical input rather than thermal energy. The Global Warming Potential (GWP) of these synthetic refrigerants ranges from 1,300 to 2,088, substantially higher than the near-zero GWP of lithium bromide solutions.

Natural refrigerants like propane (R-290) and CO2 (R-744) have gained attention as environmentally friendly alternatives. Propane systems can achieve COPs comparable to conventional HFCs but with significantly lower environmental impact. CO2 systems, while less efficient in high ambient temperatures, excel in heat recovery applications and integrated heating/cooling scenarios.

From a lifecycle energy perspective, lithium bromide systems demonstrate superior performance when waste heat utilization is factored into the analysis. Studies indicate that lithium bromide absorption chillers powered by waste heat can reduce primary energy consumption by 30-45% compared to conventional electric chillers, despite their lower nominal efficiency. This advantage becomes particularly significant in industrial settings or district energy systems where waste heat is readily available.

The energy efficiency comparison must also consider part-load performance, as HVAC systems rarely operate at full capacity. Lithium bromide systems typically maintain relatively stable efficiency across varying loads, while vapor compression systems may experience more significant efficiency degradation at partial loads, depending on the control strategy implemented.

The primary advantage of lithium bromide systems lies in their ability to utilize low-grade thermal energy sources such as waste heat, solar thermal energy, or district heating networks. This capability creates significant primary energy savings when waste heat recovery is implemented, potentially offsetting the lower nominal COP values compared to conventional systems.

Ammonia-water absorption systems represent the main alternative absorption technology, offering COPs of 0.5 to 0.7. While less efficient than lithium bromide systems, ammonia-water pairs can operate at lower temperatures and provide both heating and cooling capabilities, making them suitable for specific applications where lithium bromide systems cannot function effectively.

When examining synthetic refrigerants, R-134a and R-410A remain common in conventional vapor compression systems. These refrigerants deliver higher energy efficiency but require significant electrical input rather than thermal energy. The Global Warming Potential (GWP) of these synthetic refrigerants ranges from 1,300 to 2,088, substantially higher than the near-zero GWP of lithium bromide solutions.

Natural refrigerants like propane (R-290) and CO2 (R-744) have gained attention as environmentally friendly alternatives. Propane systems can achieve COPs comparable to conventional HFCs but with significantly lower environmental impact. CO2 systems, while less efficient in high ambient temperatures, excel in heat recovery applications and integrated heating/cooling scenarios.

From a lifecycle energy perspective, lithium bromide systems demonstrate superior performance when waste heat utilization is factored into the analysis. Studies indicate that lithium bromide absorption chillers powered by waste heat can reduce primary energy consumption by 30-45% compared to conventional electric chillers, despite their lower nominal efficiency. This advantage becomes particularly significant in industrial settings or district energy systems where waste heat is readily available.

The energy efficiency comparison must also consider part-load performance, as HVAC systems rarely operate at full capacity. Lithium bromide systems typically maintain relatively stable efficiency across varying loads, while vapor compression systems may experience more significant efficiency degradation at partial loads, depending on the control strategy implemented.

Environmental Impact and Sustainability Considerations

The environmental impact of lithium bromide (LiBr) in HVAC systems extends beyond operational efficiency to significant sustainability considerations. LiBr absorption chillers typically consume less electrical energy compared to conventional vapor compression systems, potentially reducing greenhouse gas emissions when powered by waste heat or renewable energy sources. However, the environmental footprint of LiBr must be evaluated across its entire lifecycle, from extraction to disposal.

Mining and processing lithium compounds generate considerable environmental impacts, including water consumption in water-stressed regions, habitat disruption, and energy-intensive refining processes. For every ton of lithium produced, approximately 500,000 gallons of water may be consumed in extraction processes, raising concerns in regions where lithium mining occurs, particularly in South America's "Lithium Triangle."

Bromide compounds present additional environmental challenges. While less toxic than many refrigerants, LiBr solution leakage can cause localized environmental damage, particularly in aquatic ecosystems where it may disrupt osmotic balances. The corrosive nature of LiBr solutions also necessitates the use of corrosion inhibitors, some of which may introduce additional environmental burdens if improperly managed.

From a sustainability perspective, LiBr systems offer several advantages. Their long operational lifespan (often 20+ years) reduces resource consumption associated with equipment replacement. Additionally, LiBr is recoverable and recyclable, though current recovery infrastructure remains underdeveloped in many regions, limiting practical reclamation rates to below 40%.

Recent advancements in closed-loop LiBr management systems have demonstrated potential for reducing environmental impacts. These systems minimize leakage risks and facilitate solution recovery at end-of-life. Several manufacturers have implemented take-back programs, though these initiatives remain voluntary rather than regulatory requirements in most jurisdictions.

Carbon footprint analyses indicate that despite higher embodied energy in manufacturing, LiBr absorption systems can achieve net carbon reductions of 15-30% over their operational lifetime compared to conventional systems when powered by waste heat. This advantage diminishes significantly when primary energy sources are used, highlighting the importance of integration with renewable or waste energy streams to maximize environmental benefits.

Water consumption during operation presents another consideration, as water-cooled LiBr systems typically require 2-4 gallons per ton-hour of cooling. In water-stressed regions, this consumption may offset other environmental benefits, necessitating careful regional assessment of sustainability impacts.

Mining and processing lithium compounds generate considerable environmental impacts, including water consumption in water-stressed regions, habitat disruption, and energy-intensive refining processes. For every ton of lithium produced, approximately 500,000 gallons of water may be consumed in extraction processes, raising concerns in regions where lithium mining occurs, particularly in South America's "Lithium Triangle."

Bromide compounds present additional environmental challenges. While less toxic than many refrigerants, LiBr solution leakage can cause localized environmental damage, particularly in aquatic ecosystems where it may disrupt osmotic balances. The corrosive nature of LiBr solutions also necessitates the use of corrosion inhibitors, some of which may introduce additional environmental burdens if improperly managed.

From a sustainability perspective, LiBr systems offer several advantages. Their long operational lifespan (often 20+ years) reduces resource consumption associated with equipment replacement. Additionally, LiBr is recoverable and recyclable, though current recovery infrastructure remains underdeveloped in many regions, limiting practical reclamation rates to below 40%.

Recent advancements in closed-loop LiBr management systems have demonstrated potential for reducing environmental impacts. These systems minimize leakage risks and facilitate solution recovery at end-of-life. Several manufacturers have implemented take-back programs, though these initiatives remain voluntary rather than regulatory requirements in most jurisdictions.

Carbon footprint analyses indicate that despite higher embodied energy in manufacturing, LiBr absorption systems can achieve net carbon reductions of 15-30% over their operational lifetime compared to conventional systems when powered by waste heat. This advantage diminishes significantly when primary energy sources are used, highlighting the importance of integration with renewable or waste energy streams to maximize environmental benefits.

Water consumption during operation presents another consideration, as water-cooled LiBr systems typically require 2-4 gallons per ton-hour of cooling. In water-stressed regions, this consumption may offset other environmental benefits, necessitating careful regional assessment of sustainability impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!