Evaluating Environmental Impact of Thermite Reactions

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Reaction Background and Objectives

Thermite reactions, discovered in the late 19th century, have been a subject of fascination and practical application in various fields. These highly exothermic reactions involve the reduction of metal oxides by a more reactive metal, typically aluminum, resulting in the production of a pure metal and aluminum oxide. The intense heat and light generated during these reactions have led to their widespread use in welding, incendiary devices, and pyrotechnics.

The evolution of thermite technology has been marked by continuous refinement and diversification of applications. From its initial use in railway welding to modern applications in materials science and nanotechnology, thermite reactions have demonstrated remarkable versatility. However, as environmental concerns have gained prominence, the need for a comprehensive evaluation of their ecological impact has become increasingly urgent.

The primary objective of this technical research report is to conduct an in-depth analysis of the environmental implications associated with thermite reactions. This evaluation aims to bridge the gap between the well-established practical applications of thermite and the less-explored realm of their environmental consequences. By examining the entire lifecycle of thermite reactions, from raw material extraction to post-reaction residues, we seek to provide a holistic understanding of their ecological footprint.

Key areas of focus include the assessment of air, soil, and water pollution resulting from thermite reactions, as well as the potential long-term effects on local ecosystems. Additionally, this research aims to explore the energy efficiency of thermite processes compared to alternative technologies, considering both the immediate reaction and the broader production chain.

Furthermore, this study will investigate the potential for developing more environmentally friendly thermite formulations. By exploring alternative reactants and catalysts, we aim to identify pathways for reducing harmful emissions and improving overall sustainability. This research will also consider the recyclability and safe disposal of thermite reaction products, addressing concerns related to waste management and resource conservation.

The findings of this technical research are expected to inform future regulatory frameworks, guide industrial best practices, and inspire innovative approaches to mitigating the environmental impact of thermite reactions. By providing a comprehensive analysis of both the benefits and potential drawbacks of thermite technology from an environmental perspective, this report aims to contribute to the sustainable development of this powerful and versatile chemical process.

The evolution of thermite technology has been marked by continuous refinement and diversification of applications. From its initial use in railway welding to modern applications in materials science and nanotechnology, thermite reactions have demonstrated remarkable versatility. However, as environmental concerns have gained prominence, the need for a comprehensive evaluation of their ecological impact has become increasingly urgent.

The primary objective of this technical research report is to conduct an in-depth analysis of the environmental implications associated with thermite reactions. This evaluation aims to bridge the gap between the well-established practical applications of thermite and the less-explored realm of their environmental consequences. By examining the entire lifecycle of thermite reactions, from raw material extraction to post-reaction residues, we seek to provide a holistic understanding of their ecological footprint.

Key areas of focus include the assessment of air, soil, and water pollution resulting from thermite reactions, as well as the potential long-term effects on local ecosystems. Additionally, this research aims to explore the energy efficiency of thermite processes compared to alternative technologies, considering both the immediate reaction and the broader production chain.

Furthermore, this study will investigate the potential for developing more environmentally friendly thermite formulations. By exploring alternative reactants and catalysts, we aim to identify pathways for reducing harmful emissions and improving overall sustainability. This research will also consider the recyclability and safe disposal of thermite reaction products, addressing concerns related to waste management and resource conservation.

The findings of this technical research are expected to inform future regulatory frameworks, guide industrial best practices, and inspire innovative approaches to mitigating the environmental impact of thermite reactions. By providing a comprehensive analysis of both the benefits and potential drawbacks of thermite technology from an environmental perspective, this report aims to contribute to the sustainable development of this powerful and versatile chemical process.

Market Analysis for Thermite Applications

The market for thermite applications has shown significant growth in recent years, driven by increasing demand across various industries. Thermite reactions, known for their high-temperature exothermic properties, have found applications in welding, metal purification, and pyrotechnics. The global market for thermite-based products and services is expected to continue expanding due to advancements in material science and growing industrial needs.

In the welding sector, thermite reactions are widely used for rail track welding, pipeline repairs, and large-scale structural connections. The railway industry, in particular, has been a major consumer of thermite welding technology, with ongoing infrastructure development projects worldwide contributing to market growth. The automotive and aerospace industries also utilize thermite-based welding techniques for specialized applications, further driving market demand.

The metal purification segment has seen increased adoption of thermite reactions, especially in the production of high-purity metals such as chromium, manganese, and vanadium. This application has gained traction in the metallurgical industry, where the demand for ultra-pure metals for advanced manufacturing processes continues to rise.

The pyrotechnics industry represents another significant market for thermite applications. Thermite compositions are used in various pyrotechnic devices, including fireworks, emergency flares, and military applications. The entertainment sector's demand for spectacular visual effects has contributed to the growth of this segment.

Market analysis indicates that the Asia-Pacific region is the fastest-growing market for thermite applications, driven by rapid industrialization, infrastructure development, and increasing manufacturing activities. North America and Europe remain significant markets, with a focus on advanced applications and research into new thermite compositions.

Environmental concerns and regulations regarding the use of thermite reactions have emerged as key factors influencing market dynamics. As awareness of the environmental impact of these reactions grows, there is an increasing demand for eco-friendly alternatives and improved waste management practices in thermite-based processes.

The competitive landscape of the thermite applications market is characterized by a mix of established players and innovative startups. Key market players are investing in research and development to enhance the efficiency and safety of thermite reactions while reducing their environmental footprint. This trend is expected to drive technological advancements and create new market opportunities in the coming years.

In the welding sector, thermite reactions are widely used for rail track welding, pipeline repairs, and large-scale structural connections. The railway industry, in particular, has been a major consumer of thermite welding technology, with ongoing infrastructure development projects worldwide contributing to market growth. The automotive and aerospace industries also utilize thermite-based welding techniques for specialized applications, further driving market demand.

The metal purification segment has seen increased adoption of thermite reactions, especially in the production of high-purity metals such as chromium, manganese, and vanadium. This application has gained traction in the metallurgical industry, where the demand for ultra-pure metals for advanced manufacturing processes continues to rise.

The pyrotechnics industry represents another significant market for thermite applications. Thermite compositions are used in various pyrotechnic devices, including fireworks, emergency flares, and military applications. The entertainment sector's demand for spectacular visual effects has contributed to the growth of this segment.

Market analysis indicates that the Asia-Pacific region is the fastest-growing market for thermite applications, driven by rapid industrialization, infrastructure development, and increasing manufacturing activities. North America and Europe remain significant markets, with a focus on advanced applications and research into new thermite compositions.

Environmental concerns and regulations regarding the use of thermite reactions have emerged as key factors influencing market dynamics. As awareness of the environmental impact of these reactions grows, there is an increasing demand for eco-friendly alternatives and improved waste management practices in thermite-based processes.

The competitive landscape of the thermite applications market is characterized by a mix of established players and innovative startups. Key market players are investing in research and development to enhance the efficiency and safety of thermite reactions while reducing their environmental footprint. This trend is expected to drive technological advancements and create new market opportunities in the coming years.

Current Challenges in Thermite Environmental Assessment

The environmental assessment of thermite reactions presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary difficulties lies in accurately quantifying the emissions and byproducts generated during these highly exothermic reactions. The intense heat and rapid nature of thermite reactions make it challenging to capture and analyze all the potential environmental contaminants produced.

Another major hurdle is the lack of standardized methodologies for evaluating the environmental impact of thermite reactions. Different research groups and industries often employ varied approaches, making it difficult to compare results and draw conclusive insights across studies. This inconsistency hampers the development of comprehensive environmental guidelines and regulations specific to thermite applications.

The complex composition of thermite mixtures further complicates environmental assessments. The wide range of metal oxides and reducing agents used in different thermite formulations results in diverse reaction products and potential pollutants. This variability makes it challenging to develop universal assessment protocols that can accurately account for all possible environmental impacts across different thermite compositions.

Additionally, the scale-up from laboratory experiments to industrial applications introduces new variables that affect environmental impact. Factors such as reaction containment, heat dissipation, and byproduct management become increasingly critical at larger scales. Current assessment methods often struggle to accurately predict and model these scale-dependent effects, leading to potential discrepancies between laboratory findings and real-world environmental impacts.

The long-term environmental fate of thermite reaction products is another area of concern that presents significant challenges. Many of the metal oxides and other byproducts generated during thermite reactions can persist in the environment for extended periods. Assessing their long-term behavior, potential for bioaccumulation, and impacts on ecosystems requires prolonged studies and sophisticated modeling techniques that are still being developed.

Furthermore, the interdisciplinary nature of thermite environmental assessment necessitates collaboration between chemists, environmental scientists, toxicologists, and engineers. Coordinating these diverse expertise and integrating their findings into a cohesive assessment framework remains a challenge. This interdisciplinary complexity often leads to knowledge gaps and potential oversights in comprehensive environmental evaluations.

Lastly, the development of more environmentally friendly thermite formulations is an ongoing challenge. While efforts are being made to create "green" thermites with reduced environmental impact, balancing performance requirements with environmental considerations is a delicate task. Assessing the true environmental benefits of these alternative formulations, especially in comparison to traditional thermites, requires robust and reliable evaluation methods that are still evolving.

Another major hurdle is the lack of standardized methodologies for evaluating the environmental impact of thermite reactions. Different research groups and industries often employ varied approaches, making it difficult to compare results and draw conclusive insights across studies. This inconsistency hampers the development of comprehensive environmental guidelines and regulations specific to thermite applications.

The complex composition of thermite mixtures further complicates environmental assessments. The wide range of metal oxides and reducing agents used in different thermite formulations results in diverse reaction products and potential pollutants. This variability makes it challenging to develop universal assessment protocols that can accurately account for all possible environmental impacts across different thermite compositions.

Additionally, the scale-up from laboratory experiments to industrial applications introduces new variables that affect environmental impact. Factors such as reaction containment, heat dissipation, and byproduct management become increasingly critical at larger scales. Current assessment methods often struggle to accurately predict and model these scale-dependent effects, leading to potential discrepancies between laboratory findings and real-world environmental impacts.

The long-term environmental fate of thermite reaction products is another area of concern that presents significant challenges. Many of the metal oxides and other byproducts generated during thermite reactions can persist in the environment for extended periods. Assessing their long-term behavior, potential for bioaccumulation, and impacts on ecosystems requires prolonged studies and sophisticated modeling techniques that are still being developed.

Furthermore, the interdisciplinary nature of thermite environmental assessment necessitates collaboration between chemists, environmental scientists, toxicologists, and engineers. Coordinating these diverse expertise and integrating their findings into a cohesive assessment framework remains a challenge. This interdisciplinary complexity often leads to knowledge gaps and potential oversights in comprehensive environmental evaluations.

Lastly, the development of more environmentally friendly thermite formulations is an ongoing challenge. While efforts are being made to create "green" thermites with reduced environmental impact, balancing performance requirements with environmental considerations is a delicate task. Assessing the true environmental benefits of these alternative formulations, especially in comparison to traditional thermites, requires robust and reliable evaluation methods that are still evolving.

Existing Environmental Impact Mitigation Strategies

01 Environmental impact of thermite reactions in welding

Thermite reactions used in welding processes can have environmental impacts. These reactions produce high temperatures and molten metal, which may release fumes and particulates into the atmosphere. Proper containment and ventilation systems are necessary to minimize air pollution and protect workers' health. Additionally, the disposal of slag and other byproducts requires careful management to prevent soil and water contamination.- Environmental impact of thermite reactions: Thermite reactions can have significant environmental impacts due to the high temperatures and byproducts produced. These reactions may release harmful gases, particulate matter, and residues that can affect air quality, soil composition, and water sources. Proper containment and disposal methods are crucial to minimize environmental damage.

- Mitigation strategies for thermite reaction effects: Various mitigation strategies have been developed to reduce the environmental impact of thermite reactions. These include using environmentally friendly reactants, implementing containment systems, and developing methods for capturing and treating byproducts. Advanced filtration and scrubbing technologies can help minimize the release of harmful substances into the environment.

- Recycling and reuse of thermite reaction products: To minimize waste and environmental impact, efforts have been made to recycle and reuse the products of thermite reactions. This includes recovering valuable metals from the reaction slag and repurposing byproducts for other industrial applications. Implementing closed-loop systems can significantly reduce the overall environmental footprint of thermite processes.

- Monitoring and assessment of environmental effects: Developing and implementing robust monitoring systems is crucial for assessing the environmental impact of thermite reactions. This includes real-time air quality monitoring, soil and water testing, and long-term ecological studies. Advanced sensors and data analysis techniques help in early detection of potential environmental issues and inform mitigation efforts.

- Regulatory compliance and environmental standards: Ensuring compliance with environmental regulations and standards is essential when conducting thermite reactions. This involves adhering to emission limits, proper waste management practices, and implementing safety measures to prevent accidental releases. Continuous improvement of processes and technologies is necessary to meet increasingly stringent environmental requirements.

02 Eco-friendly alternatives to traditional thermite reactions

Research is being conducted to develop more environmentally friendly alternatives to traditional thermite reactions. These include using less harmful reactants, optimizing reaction efficiency to reduce waste, and exploring new compositions that produce fewer toxic byproducts. Some innovations focus on incorporating recyclable materials or biodegradable components to minimize long-term environmental impact.Expand Specific Solutions03 Waste management and recycling of thermite reaction byproducts

Proper waste management and recycling strategies are crucial for mitigating the environmental impact of thermite reactions. This includes developing methods for safely collecting and processing slag and other byproducts, as well as exploring ways to reuse these materials in other industrial processes. Implementing closed-loop systems can help reduce the overall environmental footprint of thermite-based operations.Expand Specific Solutions04 Monitoring and control systems for environmental protection

Advanced monitoring and control systems are being developed to minimize the environmental impact of thermite reactions. These systems can include real-time air quality sensors, automated ventilation controls, and precise reactant dosing mechanisms. By optimizing reaction conditions and quickly responding to potential environmental hazards, these technologies help reduce emissions and improve overall safety.Expand Specific Solutions05 Life cycle assessment of thermite-based processes

Conducting comprehensive life cycle assessments of thermite-based processes is essential for understanding their full environmental impact. This involves analyzing the entire supply chain, from raw material extraction to final product disposal. By identifying key areas of environmental concern, researchers and engineers can develop targeted solutions to reduce the overall ecological footprint of thermite reactions and related industrial applications.Expand Specific Solutions

Key Industry Players in Thermite Production

The evaluation of environmental impact from thermite reactions is in a developing stage, with growing market interest due to increased environmental concerns. The market size is expanding as industries seek sustainable solutions. Technologically, it's progressing from basic research to practical applications. Companies like Xi'an Thermal Power Research Institute and China Academy of Building Research are advancing thermal analysis techniques, while Lockheed Martin and Battelle Memorial Institute focus on industrial applications. Universities such as Xi'an Jiaotong and Zhejiang are contributing to fundamental research. Environmental firms like GSI Environmental are developing assessment methodologies, indicating a multidisciplinary approach to this complex issue. The field is characterized by collaboration between academic institutions, research organizations, and industry players, suggesting a maturing but not yet fully established technological landscape.

Battelle Memorial Institute

Technical Solution: Battelle has developed a multi-faceted approach to evaluating the environmental impact of thermite reactions. Their methodology incorporates advanced analytical techniques such as high-resolution mass spectrometry and electron microscopy to characterize reaction products at the molecular level. They've created a database of thermite reaction signatures, allowing for rapid identification of potential environmental contaminants. Battelle's research also extends to the development of eco-friendly thermite formulations, exploring the use of biodegradable binders and non-toxic oxidizers. They've implemented a risk assessment framework that considers both immediate and long-term environmental effects, including soil and water contamination potential.

Strengths: Comprehensive analytical capabilities, focus on developing environmentally friendly alternatives. Weaknesses: Potential high costs associated with advanced analytical techniques, challenges in predicting long-term environmental effects.

Elektro-Thermit GmbH & Co. KG

Technical Solution: Elektro-Thermit has developed a specialized thermite welding process for railway tracks, which involves a controlled exothermic reaction. Their technology uses a precise mixture of aluminum powder and iron oxide, ignited in a mold surrounding the rail joint. This reaction produces molten steel that fuses the rails together, creating a continuous, seamless track. The company has refined this process to ensure optimal heat distribution, minimizing thermal stress on the surrounding rail material. They've also incorporated advanced temperature monitoring systems to ensure consistent weld quality across various environmental conditions.

Strengths: Specialized expertise in thermite welding for railways, proven track record in the industry, advanced process control. Weaknesses: Limited application beyond rail sector, potential environmental concerns due to emissions from the reaction.

Innovative Approaches to Eco-Friendly Thermite Reactions

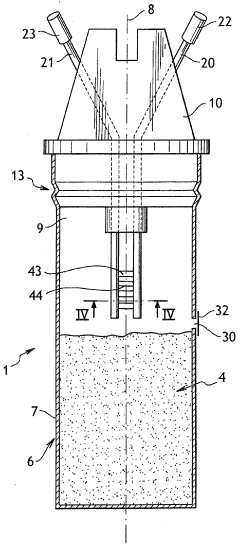

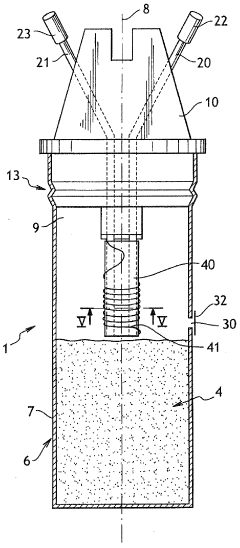

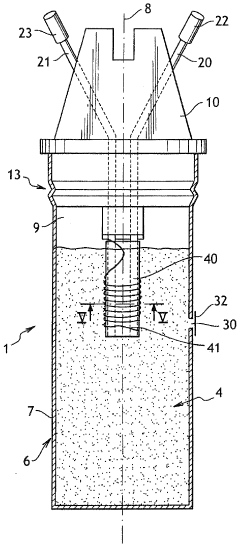

Expanding Thermite Reactions for Downhole Applications

PatentActiveUS20200208494A1

Innovation

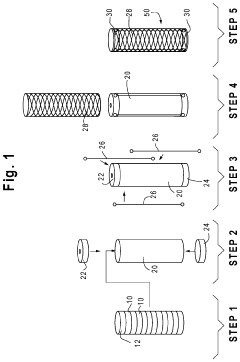

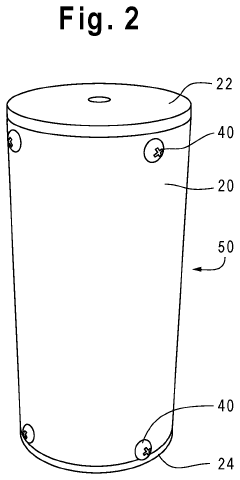

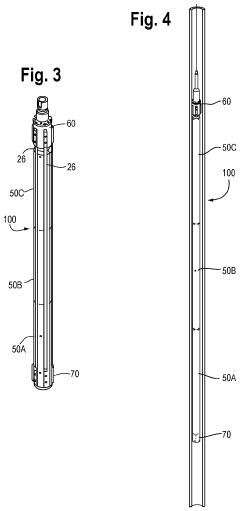

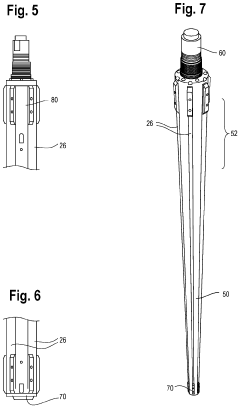

- A thermite reaction package with a cylindrical housing and ignition module, featuring gas-generating materials and additives like silicon carbide to control porosity and iron distribution, and a flexible or rigid structure to constrain longitudinal expansion and promote lateral expansion, forming a ceramic bridge plug or screen within the well.

Device for igniting an alumino-thermal composition, crucible containing same and related methods

PatentWO2008113653A1

Innovation

- A device comprising an electrical resistor connecting two electrodes, exposed to a medium with oxygen and carbon, generates carbon monoxide through Joule heating, triggering an exothermic reaction that ignites the thermite composition, with a design that prevents direct contact between electrodes and the thermite charge to avoid short circuits and uncontrolled reactions.

Regulatory Framework for Thermite Use and Disposal

The regulatory framework for thermite use and disposal is a critical aspect of managing the environmental impact of thermite reactions. Governments and international organizations have established comprehensive guidelines to ensure the safe handling, use, and disposal of thermite materials. These regulations typically cover various stages of the thermite lifecycle, from production and transportation to application and waste management.

In many countries, the use of thermite is strictly controlled due to its potential hazards. Regulatory bodies often require permits or licenses for the possession, transportation, and use of thermite materials. These permits are usually granted only to qualified professionals or organizations with demonstrated expertise in handling such substances. The licensing process often involves rigorous background checks, safety training, and periodic audits to ensure compliance with established protocols.

Environmental protection agencies play a crucial role in setting standards for the use of thermite in industrial applications. These standards typically address issues such as air quality, soil contamination, and water pollution. For instance, regulations may specify maximum allowable emission levels for particulate matter and toxic gases produced during thermite reactions. Companies using thermite are often required to implement pollution control measures, such as filtration systems or containment structures, to minimize environmental impact.

Disposal of thermite waste presents unique challenges due to its reactive nature and potential environmental hazards. Regulatory frameworks often mandate specific disposal procedures for thermite residues and byproducts. These may include requirements for neutralization, stabilization, or encapsulation of waste materials before disposal. In many jurisdictions, thermite waste is classified as hazardous material, necessitating specialized handling and disposal at designated facilities.

International agreements and conventions also influence the regulatory landscape for thermite use and disposal. These agreements aim to harmonize standards across borders and prevent the transboundary movement of hazardous wastes. For example, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous materials, including thermite-related waste.

Regulatory bodies often collaborate with industry stakeholders to develop best practices and guidelines for thermite use. These collaborations result in the creation of industry standards that complement existing regulations. Such standards may cover aspects like equipment specifications, safety protocols, and environmental monitoring procedures. Adherence to these standards is often voluntary but can become de facto requirements in many industries.

In many countries, the use of thermite is strictly controlled due to its potential hazards. Regulatory bodies often require permits or licenses for the possession, transportation, and use of thermite materials. These permits are usually granted only to qualified professionals or organizations with demonstrated expertise in handling such substances. The licensing process often involves rigorous background checks, safety training, and periodic audits to ensure compliance with established protocols.

Environmental protection agencies play a crucial role in setting standards for the use of thermite in industrial applications. These standards typically address issues such as air quality, soil contamination, and water pollution. For instance, regulations may specify maximum allowable emission levels for particulate matter and toxic gases produced during thermite reactions. Companies using thermite are often required to implement pollution control measures, such as filtration systems or containment structures, to minimize environmental impact.

Disposal of thermite waste presents unique challenges due to its reactive nature and potential environmental hazards. Regulatory frameworks often mandate specific disposal procedures for thermite residues and byproducts. These may include requirements for neutralization, stabilization, or encapsulation of waste materials before disposal. In many jurisdictions, thermite waste is classified as hazardous material, necessitating specialized handling and disposal at designated facilities.

International agreements and conventions also influence the regulatory landscape for thermite use and disposal. These agreements aim to harmonize standards across borders and prevent the transboundary movement of hazardous wastes. For example, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous materials, including thermite-related waste.

Regulatory bodies often collaborate with industry stakeholders to develop best practices and guidelines for thermite use. These collaborations result in the creation of industry standards that complement existing regulations. Such standards may cover aspects like equipment specifications, safety protocols, and environmental monitoring procedures. Adherence to these standards is often voluntary but can become de facto requirements in many industries.

Life Cycle Assessment of Thermite Reactions

Life Cycle Assessment (LCA) of thermite reactions provides a comprehensive evaluation of their environmental impact throughout the entire process, from raw material extraction to final disposal. This assessment begins with the sourcing of aluminum and metal oxide components, typically iron oxide, considering the energy consumption and emissions associated with mining and refining these materials.

The production phase of thermite involves the precise mixing of powdered aluminum and metal oxide. This step requires careful consideration of energy inputs for grinding and blending processes, as well as potential environmental risks from dust generation and handling of reactive materials. The storage and transportation of thermite components also contribute to the overall environmental footprint, necessitating an analysis of packaging materials and fuel consumption during distribution.

During the reaction phase, thermite undergoes an intense exothermic process, releasing significant heat and producing molten metal. The LCA must account for the immediate environmental effects, including air emissions, potential soil contamination, and thermal impacts on surrounding ecosystems. The high temperatures generated may lead to the formation of secondary pollutants, which should be carefully quantified and assessed.

Post-reaction, the disposal or recycling of byproducts presents another critical stage for environmental evaluation. The slag produced, primarily composed of aluminum oxide, may have potential applications in construction or other industries, potentially offsetting some environmental impacts through resource recovery. However, proper handling and treatment of these byproducts are essential to prevent leaching of heavy metals or other contaminants into soil and water systems.

The LCA should also consider the indirect environmental impacts associated with thermite reactions, such as the production of specialized equipment for handling and ignition, as well as the development of safety measures and containment systems. These ancillary processes contribute to the overall environmental footprint and must be factored into a holistic assessment.

By conducting a thorough Life Cycle Assessment, researchers and industry professionals can identify hotspots of environmental impact throughout the thermite reaction process. This analysis enables the development of targeted strategies for impact mitigation, such as optimizing material sourcing, improving reaction efficiency, enhancing byproduct utilization, and implementing more effective pollution control measures. Ultimately, the LCA provides valuable insights for enhancing the sustainability of thermite applications across various industries.

The production phase of thermite involves the precise mixing of powdered aluminum and metal oxide. This step requires careful consideration of energy inputs for grinding and blending processes, as well as potential environmental risks from dust generation and handling of reactive materials. The storage and transportation of thermite components also contribute to the overall environmental footprint, necessitating an analysis of packaging materials and fuel consumption during distribution.

During the reaction phase, thermite undergoes an intense exothermic process, releasing significant heat and producing molten metal. The LCA must account for the immediate environmental effects, including air emissions, potential soil contamination, and thermal impacts on surrounding ecosystems. The high temperatures generated may lead to the formation of secondary pollutants, which should be carefully quantified and assessed.

Post-reaction, the disposal or recycling of byproducts presents another critical stage for environmental evaluation. The slag produced, primarily composed of aluminum oxide, may have potential applications in construction or other industries, potentially offsetting some environmental impacts through resource recovery. However, proper handling and treatment of these byproducts are essential to prevent leaching of heavy metals or other contaminants into soil and water systems.

The LCA should also consider the indirect environmental impacts associated with thermite reactions, such as the production of specialized equipment for handling and ignition, as well as the development of safety measures and containment systems. These ancillary processes contribute to the overall environmental footprint and must be factored into a holistic assessment.

By conducting a thorough Life Cycle Assessment, researchers and industry professionals can identify hotspots of environmental impact throughout the thermite reaction process. This analysis enables the development of targeted strategies for impact mitigation, such as optimizing material sourcing, improving reaction efficiency, enhancing byproduct utilization, and implementing more effective pollution control measures. Ultimately, the LCA provides valuable insights for enhancing the sustainability of thermite applications across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!