Evaluating the Role of Sulphanilic Acid in High-Performance Coatings

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid in Coatings: Background and Objectives

Sulphanilic acid, a versatile organic compound, has emerged as a significant component in the development of high-performance coatings. This aromatic amine, characterized by its sulfonic acid group, has garnered attention in the coatings industry due to its unique chemical properties and potential applications. The evolution of coating technologies has been driven by the need for enhanced durability, resistance to environmental factors, and improved aesthetic qualities.

The journey of sulphanilic acid in coatings can be traced back to the mid-20th century when researchers began exploring its potential as a reactive intermediate in polymer synthesis. As coating formulations became more sophisticated, the demand for specialized additives that could impart specific properties to the final product increased. Sulphanilic acid, with its ability to form strong chemical bonds and interact with various substrates, presented itself as a promising candidate for further investigation.

Over the years, the coating industry has witnessed a paradigm shift from traditional solvent-based formulations to more environmentally friendly water-based and powder coatings. This transition has been accompanied by a growing emphasis on developing coatings that offer superior protection against corrosion, UV radiation, and chemical exposure. Sulphanilic acid has played a crucial role in this evolution, contributing to the development of high-performance coatings that meet these stringent requirements.

The primary objective of evaluating the role of sulphanilic acid in high-performance coatings is to unlock its full potential and optimize its integration into advanced coating systems. This involves a comprehensive assessment of its chemical reactivity, compatibility with various binders and pigments, and its impact on the overall performance of the coating. Researchers aim to elucidate the mechanisms by which sulphanilic acid enhances properties such as adhesion, hardness, and resistance to environmental stressors.

Furthermore, the evaluation seeks to explore novel applications of sulphanilic acid in emerging coating technologies. This includes its potential use in smart coatings that can respond to external stimuli, self-healing coatings that can repair minor damage autonomously, and nanocomposite coatings that exhibit exceptional mechanical and barrier properties. By understanding the fundamental interactions between sulphanilic acid and other coating components, scientists hope to develop innovative formulations that push the boundaries of coating performance.

Another critical aspect of this evaluation is to address the environmental and regulatory challenges associated with the use of sulphanilic acid in coatings. As global regulations become increasingly stringent, there is a pressing need to ensure that coating formulations comply with environmental standards while maintaining their high-performance characteristics. This necessitates a thorough investigation of the lifecycle impact of sulphanilic acid-containing coatings and the development of sustainable production methods.

The journey of sulphanilic acid in coatings can be traced back to the mid-20th century when researchers began exploring its potential as a reactive intermediate in polymer synthesis. As coating formulations became more sophisticated, the demand for specialized additives that could impart specific properties to the final product increased. Sulphanilic acid, with its ability to form strong chemical bonds and interact with various substrates, presented itself as a promising candidate for further investigation.

Over the years, the coating industry has witnessed a paradigm shift from traditional solvent-based formulations to more environmentally friendly water-based and powder coatings. This transition has been accompanied by a growing emphasis on developing coatings that offer superior protection against corrosion, UV radiation, and chemical exposure. Sulphanilic acid has played a crucial role in this evolution, contributing to the development of high-performance coatings that meet these stringent requirements.

The primary objective of evaluating the role of sulphanilic acid in high-performance coatings is to unlock its full potential and optimize its integration into advanced coating systems. This involves a comprehensive assessment of its chemical reactivity, compatibility with various binders and pigments, and its impact on the overall performance of the coating. Researchers aim to elucidate the mechanisms by which sulphanilic acid enhances properties such as adhesion, hardness, and resistance to environmental stressors.

Furthermore, the evaluation seeks to explore novel applications of sulphanilic acid in emerging coating technologies. This includes its potential use in smart coatings that can respond to external stimuli, self-healing coatings that can repair minor damage autonomously, and nanocomposite coatings that exhibit exceptional mechanical and barrier properties. By understanding the fundamental interactions between sulphanilic acid and other coating components, scientists hope to develop innovative formulations that push the boundaries of coating performance.

Another critical aspect of this evaluation is to address the environmental and regulatory challenges associated with the use of sulphanilic acid in coatings. As global regulations become increasingly stringent, there is a pressing need to ensure that coating formulations comply with environmental standards while maintaining their high-performance characteristics. This necessitates a thorough investigation of the lifecycle impact of sulphanilic acid-containing coatings and the development of sustainable production methods.

Market Analysis for High-Performance Coatings

The high-performance coatings market has experienced significant growth in recent years, driven by increasing demand across various industries such as automotive, aerospace, construction, and marine. The global market for high-performance coatings was valued at approximately $80 billion in 2020 and is projected to reach $105 billion by 2025, growing at a CAGR of 5.5% during the forecast period.

The automotive sector remains a key driver for high-performance coatings, accounting for nearly 30% of the market share. The growing emphasis on vehicle aesthetics, durability, and corrosion resistance has fueled the demand for advanced coating solutions. Additionally, the aerospace industry has emerged as a rapidly growing segment, with a projected CAGR of 6.8% from 2020 to 2025, driven by the need for lightweight and high-performance coatings that can withstand extreme conditions.

In the context of sulphanilic acid's role in high-performance coatings, the market analysis reveals a growing interest in eco-friendly and sustainable coating solutions. Sulphanilic acid, known for its excellent dispersing properties and ability to enhance coating performance, is gaining traction in the development of low-VOC and water-based coatings. This trend aligns with the increasing regulatory pressure to reduce environmental impact and improve worker safety in coating applications.

The Asia-Pacific region dominates the high-performance coatings market, accounting for over 40% of the global market share. China and India are the primary growth engines, driven by rapid industrialization, infrastructure development, and increasing automotive production. North America and Europe follow closely, with a strong focus on technological advancements and stringent environmental regulations shaping the market landscape.

Key players in the high-performance coatings market, including PPG Industries, AkzoNobel, and Sherwin-Williams, are investing heavily in R&D to develop innovative coating solutions incorporating sulphanilic acid and other advanced materials. These companies are also expanding their product portfolios through strategic acquisitions and partnerships to strengthen their market position and cater to evolving customer demands.

The market analysis indicates a growing demand for multi-functional coatings that offer a combination of properties such as corrosion resistance, chemical resistance, and thermal stability. Sulphanilic acid's versatility in enhancing these properties positions it as a valuable component in the formulation of next-generation high-performance coatings. As a result, manufacturers are increasingly exploring the potential of sulphanilic acid to develop coatings that meet the stringent performance requirements of various industries while addressing environmental concerns.

The automotive sector remains a key driver for high-performance coatings, accounting for nearly 30% of the market share. The growing emphasis on vehicle aesthetics, durability, and corrosion resistance has fueled the demand for advanced coating solutions. Additionally, the aerospace industry has emerged as a rapidly growing segment, with a projected CAGR of 6.8% from 2020 to 2025, driven by the need for lightweight and high-performance coatings that can withstand extreme conditions.

In the context of sulphanilic acid's role in high-performance coatings, the market analysis reveals a growing interest in eco-friendly and sustainable coating solutions. Sulphanilic acid, known for its excellent dispersing properties and ability to enhance coating performance, is gaining traction in the development of low-VOC and water-based coatings. This trend aligns with the increasing regulatory pressure to reduce environmental impact and improve worker safety in coating applications.

The Asia-Pacific region dominates the high-performance coatings market, accounting for over 40% of the global market share. China and India are the primary growth engines, driven by rapid industrialization, infrastructure development, and increasing automotive production. North America and Europe follow closely, with a strong focus on technological advancements and stringent environmental regulations shaping the market landscape.

Key players in the high-performance coatings market, including PPG Industries, AkzoNobel, and Sherwin-Williams, are investing heavily in R&D to develop innovative coating solutions incorporating sulphanilic acid and other advanced materials. These companies are also expanding their product portfolios through strategic acquisitions and partnerships to strengthen their market position and cater to evolving customer demands.

The market analysis indicates a growing demand for multi-functional coatings that offer a combination of properties such as corrosion resistance, chemical resistance, and thermal stability. Sulphanilic acid's versatility in enhancing these properties positions it as a valuable component in the formulation of next-generation high-performance coatings. As a result, manufacturers are increasingly exploring the potential of sulphanilic acid to develop coatings that meet the stringent performance requirements of various industries while addressing environmental concerns.

Current Challenges in Sulphanilic Acid Integration

The integration of sulphanilic acid into high-performance coatings presents several significant challenges that researchers and manufacturers must address. One of the primary obstacles is achieving uniform dispersion of sulphanilic acid within the coating matrix. Due to its polar nature, sulphanilic acid tends to agglomerate, leading to inconsistent distribution and potential weak points in the coating structure. This non-uniform dispersion can result in reduced overall performance and compromised protective properties.

Another critical challenge lies in maintaining the stability of sulphanilic acid during the coating formulation and application processes. The compound is sensitive to environmental factors such as temperature and pH, which can affect its chemical structure and functionality. Ensuring that sulphanilic acid remains stable and active throughout the coating's lifecycle is crucial for long-term performance but requires careful control of processing conditions and storage environments.

Compatibility issues between sulphanilic acid and other coating components pose additional difficulties. The acid's reactivity can interfere with curing agents, pigments, or other additives, potentially altering the coating's intended properties or reducing its shelf life. Formulating a balanced composition that leverages the benefits of sulphanilic acid without compromising other essential coating characteristics demands extensive research and testing.

The impact of sulphanilic acid on coating adhesion is another area of concern. While it can enhance certain properties, its presence may affect the coating's ability to bond effectively to various substrates. This is particularly challenging when developing coatings for diverse materials or in applications requiring strong adhesion under extreme conditions.

Furthermore, the potential environmental and health implications of using sulphanilic acid in coatings need careful consideration. As regulations become more stringent, ensuring that coatings containing this compound meet safety standards and environmental guidelines is increasingly important. This includes addressing concerns about leaching, VOC emissions, and long-term ecological impact.

Cost-effectiveness remains a significant hurdle in the widespread adoption of sulphanilic acid in high-performance coatings. The compound's production process and purification can be expensive, potentially increasing the overall cost of the coating. Balancing the enhanced performance benefits against the increased production costs is crucial for commercial viability.

Lastly, scaling up production while maintaining consistent quality presents technical challenges. Ensuring that laboratory-scale successes can be replicated in industrial-scale manufacturing processes without compromising the coating's performance or the stability of sulphanilic acid is a complex task that requires significant investment in process optimization and quality control measures.

Another critical challenge lies in maintaining the stability of sulphanilic acid during the coating formulation and application processes. The compound is sensitive to environmental factors such as temperature and pH, which can affect its chemical structure and functionality. Ensuring that sulphanilic acid remains stable and active throughout the coating's lifecycle is crucial for long-term performance but requires careful control of processing conditions and storage environments.

Compatibility issues between sulphanilic acid and other coating components pose additional difficulties. The acid's reactivity can interfere with curing agents, pigments, or other additives, potentially altering the coating's intended properties or reducing its shelf life. Formulating a balanced composition that leverages the benefits of sulphanilic acid without compromising other essential coating characteristics demands extensive research and testing.

The impact of sulphanilic acid on coating adhesion is another area of concern. While it can enhance certain properties, its presence may affect the coating's ability to bond effectively to various substrates. This is particularly challenging when developing coatings for diverse materials or in applications requiring strong adhesion under extreme conditions.

Furthermore, the potential environmental and health implications of using sulphanilic acid in coatings need careful consideration. As regulations become more stringent, ensuring that coatings containing this compound meet safety standards and environmental guidelines is increasingly important. This includes addressing concerns about leaching, VOC emissions, and long-term ecological impact.

Cost-effectiveness remains a significant hurdle in the widespread adoption of sulphanilic acid in high-performance coatings. The compound's production process and purification can be expensive, potentially increasing the overall cost of the coating. Balancing the enhanced performance benefits against the increased production costs is crucial for commercial viability.

Lastly, scaling up production while maintaining consistent quality presents technical challenges. Ensuring that laboratory-scale successes can be replicated in industrial-scale manufacturing processes without compromising the coating's performance or the stability of sulphanilic acid is a complex task that requires significant investment in process optimization and quality control measures.

Existing Sulphanilic Acid-Based Coating Solutions

01 Synthesis and purification of sulphanilic acid

Various methods for synthesizing and purifying sulphanilic acid are described, including reduction of nitrobenzene sulfonic acid, sulfonation of aniline, and crystallization techniques. These processes aim to improve the yield and purity of sulphanilic acid for industrial applications.- Synthesis and purification of sulphanilic acid: Various methods for synthesizing and purifying sulphanilic acid are described. These processes aim to improve the quality and yield of the final product, which is crucial for its performance in different applications.

- Applications in dye and pigment industry: Sulphanilic acid is widely used in the production of dyes and pigments. Its performance in these applications is enhanced through specific formulations and processing techniques, resulting in improved color intensity and stability.

- Use in pharmaceutical and medicinal preparations: The performance of sulphanilic acid in pharmaceutical and medicinal applications is explored. Various formulations and combinations with other compounds are developed to enhance its therapeutic effects and improve drug delivery.

- Industrial and chemical applications: Sulphanilic acid's performance in various industrial and chemical processes is investigated. This includes its use as a reagent, intermediate, or catalyst in different chemical reactions and manufacturing processes.

- Environmental and water treatment applications: The performance of sulphanilic acid in environmental and water treatment applications is studied. This includes its use in the removal of contaminants, water purification processes, and as a component in environmentally friendly formulations.

02 Applications in dye and pigment production

Sulphanilic acid is widely used as an intermediate in the production of dyes and pigments. It serves as a key component in the synthesis of azo dyes and other colorants, contributing to the development of vibrant and stable coloring agents for various industries.Expand Specific Solutions03 Use in pharmaceutical and medicinal compounds

Sulphanilic acid and its derivatives play a role in the synthesis of pharmaceutical compounds. They are utilized in the production of various drugs, including antibacterial agents and anti-inflammatory medications, showcasing the versatility of sulphanilic acid in medicinal chemistry.Expand Specific Solutions04 Performance in water treatment applications

Sulphanilic acid demonstrates effectiveness in water treatment processes. It is used in the removal of contaminants, such as heavy metals and organic pollutants, from wastewater and industrial effluents, contributing to environmental protection and water purification efforts.Expand Specific Solutions05 Modifications and derivatives for enhanced performance

Research focuses on developing modified forms and derivatives of sulphanilic acid to enhance its performance in various applications. These modifications aim to improve properties such as solubility, reactivity, and stability, expanding the potential uses of sulphanilic acid in different industrial sectors.Expand Specific Solutions

Key Players in High-Performance Coating Industry

The competitive landscape for evaluating sulphanilic acid in high-performance coatings is characterized by a mature market with established players and ongoing innovation. The global coatings industry, valued at over $150 billion, is in a growth phase driven by increasing demand in construction and automotive sectors. Major companies like BASF, Arkema, and PPG Industries are at the forefront of technological advancements, investing heavily in R&D to develop superior coating formulations. The technology's maturity is evident in the diverse applications across industries, with companies like L'Oréal and Unilever exploring its potential in consumer products. Emerging players such as Shanghai Hilong Shine New Material and Wanhua Chemical Group are also making significant strides, particularly in the Asia-Pacific region.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative high-performance coatings incorporating sulphanilic acid as a key component. Their approach involves using sulphanilic acid as a coupling agent in waterborne coatings, enhancing adhesion and corrosion resistance[1]. The company has also explored the use of sulphanilic acid derivatives in UV-curable coatings, which offer improved scratch resistance and durability[3]. BASF's research has shown that incorporating sulphanilic acid into epoxy-based coatings can significantly improve chemical resistance and thermal stability, making these coatings suitable for harsh industrial environments[5].

Strengths: Improved adhesion, corrosion resistance, and chemical stability. Versatile application in various coating types. Weaknesses: Potential higher cost due to specialized formulations, may require specific application techniques.

Arkema, Inc.

Technical Solution: Arkema has developed a novel approach to utilizing sulphanilic acid in high-performance coatings, focusing on its role as a dispersing agent for pigments and fillers. Their research has shown that sulphanilic acid-based dispersants can significantly improve color stability and uniformity in both solvent-based and water-based coatings[2]. Arkema has also explored the use of sulphanilic acid derivatives in self-healing coatings, where the compound's reactive nature contributes to the formation of reversible bonds that can repair minor damage[4]. Additionally, the company has incorporated sulphanilic acid into their line of functional coatings, enhancing properties such as anti-fouling and anti-microbial performance[6].

Strengths: Enhanced color stability, self-healing properties, and functional coating performance. Weaknesses: May require specialized formulation expertise, potential for increased production costs.

Core Innovations in Sulphanilic Acid Utilization

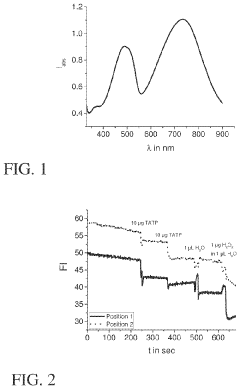

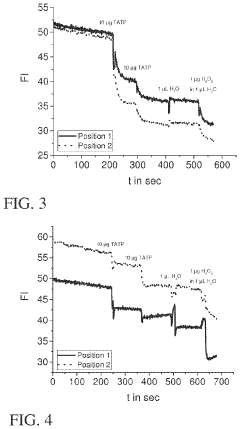

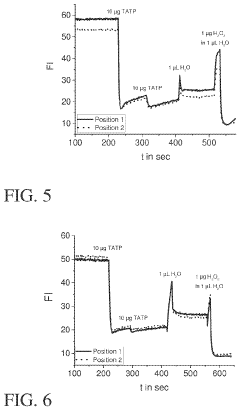

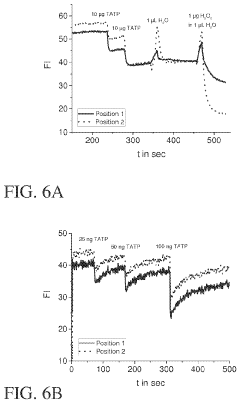

Method and sensor for detection of triacetone triperoxide (TATP), diacetone diperoxide (DADP), hexamethylene triperoxide diamine (HMTD) and hydrogen peroxide

PatentPendingUS20220299440A1

Innovation

- A sensor arrangement using sulfonic acids in combination with specific dyes, such as triarylamine or triarylborane, in acidic hydrophilic layers, which selectively detect peroxidic explosives through fluorescence changes upon contact, allowing for sensitive and selective detection of triacetone triperoxide, diacetone diperoxide, hexamethylene triperoxide diamine, and hydrogen peroxide.

Environmental Impact of Sulphanilic Acid Coatings

The environmental impact of sulphanilic acid coatings is a critical consideration in the evaluation of their role in high-performance applications. These coatings, while offering superior protection and durability, also present potential environmental concerns that must be carefully assessed.

One of the primary environmental considerations is the release of volatile organic compounds (VOCs) during the application and curing process of sulphanilic acid-based coatings. VOCs contribute to air pollution and can have adverse effects on both human health and the environment. However, recent advancements in coating formulations have led to the development of low-VOC and zero-VOC alternatives, significantly reducing their environmental footprint.

Water pollution is another potential issue associated with sulphanilic acid coatings. During the manufacturing process and application, there is a risk of chemical runoff entering water systems. This can lead to contamination of aquatic ecosystems and potentially affect water quality. To mitigate this risk, stringent waste management protocols and advanced filtration systems are being implemented in production facilities.

The long-term persistence of sulphanilic acid coatings in the environment is also a concern. As these coatings degrade over time, they may release microparticles into the surrounding ecosystem. The potential bioaccumulation of these particles in various organisms and their impact on the food chain is an area that requires further research and monitoring.

On the positive side, the durability and protective properties of sulphanilic acid coatings can contribute to environmental sustainability. By extending the lifespan of coated materials and reducing the need for frequent reapplication, these coatings can help conserve resources and reduce overall waste generation. This aspect is particularly relevant in industries such as construction and automotive, where long-lasting protective coatings can significantly reduce material consumption and maintenance requirements.

The recyclability of materials coated with sulphanilic acid-based products is another important environmental consideration. While the coatings themselves may pose challenges in recycling processes, ongoing research is focused on developing more easily recyclable formulations and improved separation techniques to enhance the end-of-life management of coated products.

Biodegradability is an emerging area of focus in the development of sulphanilic acid coatings. Researchers are exploring ways to incorporate biodegradable components into coating formulations, aiming to reduce their long-term environmental impact. This approach shows promise in balancing the need for high-performance coatings with environmental sustainability goals.

In conclusion, while sulphanilic acid coatings offer significant performance benefits, their environmental impact requires careful consideration and ongoing research. The industry is actively working towards more sustainable formulations and application methods to minimize negative environmental effects while maintaining the high-performance characteristics of these coatings.

One of the primary environmental considerations is the release of volatile organic compounds (VOCs) during the application and curing process of sulphanilic acid-based coatings. VOCs contribute to air pollution and can have adverse effects on both human health and the environment. However, recent advancements in coating formulations have led to the development of low-VOC and zero-VOC alternatives, significantly reducing their environmental footprint.

Water pollution is another potential issue associated with sulphanilic acid coatings. During the manufacturing process and application, there is a risk of chemical runoff entering water systems. This can lead to contamination of aquatic ecosystems and potentially affect water quality. To mitigate this risk, stringent waste management protocols and advanced filtration systems are being implemented in production facilities.

The long-term persistence of sulphanilic acid coatings in the environment is also a concern. As these coatings degrade over time, they may release microparticles into the surrounding ecosystem. The potential bioaccumulation of these particles in various organisms and their impact on the food chain is an area that requires further research and monitoring.

On the positive side, the durability and protective properties of sulphanilic acid coatings can contribute to environmental sustainability. By extending the lifespan of coated materials and reducing the need for frequent reapplication, these coatings can help conserve resources and reduce overall waste generation. This aspect is particularly relevant in industries such as construction and automotive, where long-lasting protective coatings can significantly reduce material consumption and maintenance requirements.

The recyclability of materials coated with sulphanilic acid-based products is another important environmental consideration. While the coatings themselves may pose challenges in recycling processes, ongoing research is focused on developing more easily recyclable formulations and improved separation techniques to enhance the end-of-life management of coated products.

Biodegradability is an emerging area of focus in the development of sulphanilic acid coatings. Researchers are exploring ways to incorporate biodegradable components into coating formulations, aiming to reduce their long-term environmental impact. This approach shows promise in balancing the need for high-performance coatings with environmental sustainability goals.

In conclusion, while sulphanilic acid coatings offer significant performance benefits, their environmental impact requires careful consideration and ongoing research. The industry is actively working towards more sustainable formulations and application methods to minimize negative environmental effects while maintaining the high-performance characteristics of these coatings.

Regulatory Framework for Chemical Coatings

The regulatory framework for chemical coatings plays a crucial role in ensuring the safe and responsible use of sulphanilic acid in high-performance coatings. Governments and international organizations have established comprehensive regulations to address potential health and environmental risks associated with chemical substances used in coating formulations.

In the United States, the Environmental Protection Agency (EPA) regulates the use of chemicals in coatings under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers and importers to submit premanufacture notices for new chemical substances, including those used in coatings. This process allows the EPA to assess potential risks and impose restrictions if necessary.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in coatings. Under REACH, companies must register chemical substances and provide safety data to the European Chemicals Agency (ECHA). Sulphanilic acid and its use in coatings are subject to these registration requirements.

In addition to regional regulations, international standards such as ISO 12944 provide guidelines for the protection of steel structures against corrosion by protective paint systems. These standards influence the formulation of high-performance coatings and may impact the use of sulphanilic acid in specific applications.

Occupational safety regulations also play a significant role in the use of chemical substances in coatings. The Occupational Safety and Health Administration (OSHA) in the United States and similar agencies in other countries set exposure limits and safety protocols for workers handling potentially hazardous chemicals during coating manufacturing and application processes.

Environmental regulations, such as the Clean Air Act in the United States and the Industrial Emissions Directive in the European Union, impose restrictions on volatile organic compound (VOC) emissions from coatings. These regulations drive the development of low-VOC and water-based coating formulations, which may influence the use of sulphanilic acid in high-performance coatings.

As sustainability concerns grow, regulations are evolving to promote the use of more environmentally friendly substances in coatings. This trend may impact the future use of sulphanilic acid, potentially driving research into alternative compounds or modified formulations that meet both performance and environmental requirements.

Compliance with these regulatory frameworks is essential for manufacturers and users of high-performance coatings containing sulphanilic acid. Companies must stay informed about regulatory changes, conduct thorough risk assessments, and implement appropriate safety measures to ensure the responsible use of chemical substances in coating applications.

In the United States, the Environmental Protection Agency (EPA) regulates the use of chemicals in coatings under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers and importers to submit premanufacture notices for new chemical substances, including those used in coatings. This process allows the EPA to assess potential risks and impose restrictions if necessary.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in coatings. Under REACH, companies must register chemical substances and provide safety data to the European Chemicals Agency (ECHA). Sulphanilic acid and its use in coatings are subject to these registration requirements.

In addition to regional regulations, international standards such as ISO 12944 provide guidelines for the protection of steel structures against corrosion by protective paint systems. These standards influence the formulation of high-performance coatings and may impact the use of sulphanilic acid in specific applications.

Occupational safety regulations also play a significant role in the use of chemical substances in coatings. The Occupational Safety and Health Administration (OSHA) in the United States and similar agencies in other countries set exposure limits and safety protocols for workers handling potentially hazardous chemicals during coating manufacturing and application processes.

Environmental regulations, such as the Clean Air Act in the United States and the Industrial Emissions Directive in the European Union, impose restrictions on volatile organic compound (VOC) emissions from coatings. These regulations drive the development of low-VOC and water-based coating formulations, which may influence the use of sulphanilic acid in high-performance coatings.

As sustainability concerns grow, regulations are evolving to promote the use of more environmentally friendly substances in coatings. This trend may impact the future use of sulphanilic acid, potentially driving research into alternative compounds or modified formulations that meet both performance and environmental requirements.

Compliance with these regulatory frameworks is essential for manufacturers and users of high-performance coatings containing sulphanilic acid. Companies must stay informed about regulatory changes, conduct thorough risk assessments, and implement appropriate safety measures to ensure the responsible use of chemical substances in coating applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!