Evaluating Thin Film Deposition Techniques for Perovskite Catalysts

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Catalyst Thin Film Technology Background and Objectives

Perovskite materials have emerged as revolutionary catalysts in various chemical processes due to their unique crystal structure and exceptional electronic properties. The history of perovskite research dates back to the 19th century, but their application as catalysts has gained significant momentum only in the past two decades. The technological evolution has shifted from bulk perovskite materials to thin films, which offer enhanced surface area, reduced material consumption, and improved catalytic efficiency.

The development of thin film deposition techniques for perovskite catalysts represents a critical advancement in heterogeneous catalysis, energy conversion, and environmental remediation. Traditional methods such as solid-state reactions often resulted in bulk materials with limited surface area and catalytic activity. The transition to thin film technologies has opened new possibilities for precise control over composition, thickness, and microstructure, leading to superior catalytic performance.

Current research trends indicate a growing interest in nanoscale engineering of perovskite thin films to maximize active sites and optimize electron transfer processes. The field is witnessing a convergence of materials science, surface chemistry, and advanced manufacturing techniques to develop next-generation catalytic systems. Particular attention is being paid to the development of stable perovskite compositions that can withstand harsh reaction conditions while maintaining high activity.

The primary technical objectives of this research include evaluating various thin film deposition techniques such as physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and solution-based methods for their suitability in creating high-performance perovskite catalyst layers. Each technique offers distinct advantages in terms of film quality, scalability, and process control, necessitating a comprehensive assessment to identify optimal approaches for specific applications.

Another critical objective is to establish correlations between deposition parameters and the resulting catalytic properties. This includes understanding how factors such as substrate temperature, deposition rate, and post-deposition treatments influence the crystal structure, surface morphology, and ultimately the catalytic activity of perovskite thin films. Such knowledge is essential for developing reproducible manufacturing protocols that can be scaled for industrial implementation.

Furthermore, this research aims to explore novel perovskite compositions and doping strategies that can be effectively realized through thin film technologies. The flexibility of thin film deposition methods allows for precise control over elemental composition and layer architecture, enabling the creation of complex perovskite structures with tailored catalytic properties for specific reactions of interest.

The ultimate goal is to develop a roadmap for the industrial application of perovskite thin film catalysts, identifying the most promising deposition techniques and material compositions for commercialization. This includes considerations of cost-effectiveness, scalability, and environmental impact, ensuring that the developed technologies align with sustainable manufacturing principles.

The development of thin film deposition techniques for perovskite catalysts represents a critical advancement in heterogeneous catalysis, energy conversion, and environmental remediation. Traditional methods such as solid-state reactions often resulted in bulk materials with limited surface area and catalytic activity. The transition to thin film technologies has opened new possibilities for precise control over composition, thickness, and microstructure, leading to superior catalytic performance.

Current research trends indicate a growing interest in nanoscale engineering of perovskite thin films to maximize active sites and optimize electron transfer processes. The field is witnessing a convergence of materials science, surface chemistry, and advanced manufacturing techniques to develop next-generation catalytic systems. Particular attention is being paid to the development of stable perovskite compositions that can withstand harsh reaction conditions while maintaining high activity.

The primary technical objectives of this research include evaluating various thin film deposition techniques such as physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and solution-based methods for their suitability in creating high-performance perovskite catalyst layers. Each technique offers distinct advantages in terms of film quality, scalability, and process control, necessitating a comprehensive assessment to identify optimal approaches for specific applications.

Another critical objective is to establish correlations between deposition parameters and the resulting catalytic properties. This includes understanding how factors such as substrate temperature, deposition rate, and post-deposition treatments influence the crystal structure, surface morphology, and ultimately the catalytic activity of perovskite thin films. Such knowledge is essential for developing reproducible manufacturing protocols that can be scaled for industrial implementation.

Furthermore, this research aims to explore novel perovskite compositions and doping strategies that can be effectively realized through thin film technologies. The flexibility of thin film deposition methods allows for precise control over elemental composition and layer architecture, enabling the creation of complex perovskite structures with tailored catalytic properties for specific reactions of interest.

The ultimate goal is to develop a roadmap for the industrial application of perovskite thin film catalysts, identifying the most promising deposition techniques and material compositions for commercialization. This includes considerations of cost-effectiveness, scalability, and environmental impact, ensuring that the developed technologies align with sustainable manufacturing principles.

Market Applications and Demand Analysis for Perovskite Catalyst Films

Perovskite catalyst films have emerged as a promising material class with significant market potential across multiple industries. The global catalyst market, valued at approximately $33.5 billion in 2022, is projected to grow at a CAGR of 4.8% through 2030, with perovskite-based catalysts representing an increasingly important segment due to their superior performance characteristics.

The automotive sector represents the largest current market for perovskite catalyst films, driven primarily by stringent emission regulations worldwide. These materials demonstrate exceptional efficiency in converting harmful exhaust gases into less harmful substances, outperforming traditional platinum-group metal catalysts in both performance and cost-effectiveness. The transition toward electric vehicles has not diminished demand, as hybrid vehicles continue to require advanced catalytic converters.

In the renewable energy sector, perovskite catalyst films are gaining traction for hydrogen production applications. The global green hydrogen market is expanding rapidly, with projections indicating growth from $2.1 billion in 2021 to $89.2 billion by 2030. Perovskite catalysts offer enhanced efficiency in water splitting processes, potentially reducing production costs and accelerating hydrogen economy development.

The chemical manufacturing industry represents another significant market, where perovskite catalyst films facilitate more efficient and selective chemical transformations. Their application in processes such as methane reforming and CO2 conversion aligns with industry sustainability goals while offering economic advantages through reduced energy requirements and improved yields.

Environmental remediation applications constitute an emerging market segment, with perovskite catalysts showing promise for water purification and air quality improvement. Their ability to operate effectively at lower temperatures than conventional catalysts translates to energy savings in pollution control systems.

Market analysis indicates regional variations in demand patterns. Asia-Pacific, particularly China and Japan, leads in adoption for industrial applications, while North American and European markets focus primarily on automotive and environmental applications. This regional specialization reflects differences in industrial policy priorities and regulatory frameworks.

Customer requirements across these markets emphasize several key performance attributes: catalytic activity, stability under operating conditions, cost-effectiveness, and compatibility with existing manufacturing processes. The ability to deposit uniform, well-controlled perovskite films at industrial scale represents a critical factor limiting broader market penetration.

Pricing sensitivity varies by application sector, with automotive applications demonstrating greater price elasticity than specialized industrial applications where performance advantages can justify premium pricing. As production technologies mature and economies of scale improve, decreasing costs are expected to expand addressable markets significantly.

The automotive sector represents the largest current market for perovskite catalyst films, driven primarily by stringent emission regulations worldwide. These materials demonstrate exceptional efficiency in converting harmful exhaust gases into less harmful substances, outperforming traditional platinum-group metal catalysts in both performance and cost-effectiveness. The transition toward electric vehicles has not diminished demand, as hybrid vehicles continue to require advanced catalytic converters.

In the renewable energy sector, perovskite catalyst films are gaining traction for hydrogen production applications. The global green hydrogen market is expanding rapidly, with projections indicating growth from $2.1 billion in 2021 to $89.2 billion by 2030. Perovskite catalysts offer enhanced efficiency in water splitting processes, potentially reducing production costs and accelerating hydrogen economy development.

The chemical manufacturing industry represents another significant market, where perovskite catalyst films facilitate more efficient and selective chemical transformations. Their application in processes such as methane reforming and CO2 conversion aligns with industry sustainability goals while offering economic advantages through reduced energy requirements and improved yields.

Environmental remediation applications constitute an emerging market segment, with perovskite catalysts showing promise for water purification and air quality improvement. Their ability to operate effectively at lower temperatures than conventional catalysts translates to energy savings in pollution control systems.

Market analysis indicates regional variations in demand patterns. Asia-Pacific, particularly China and Japan, leads in adoption for industrial applications, while North American and European markets focus primarily on automotive and environmental applications. This regional specialization reflects differences in industrial policy priorities and regulatory frameworks.

Customer requirements across these markets emphasize several key performance attributes: catalytic activity, stability under operating conditions, cost-effectiveness, and compatibility with existing manufacturing processes. The ability to deposit uniform, well-controlled perovskite films at industrial scale represents a critical factor limiting broader market penetration.

Pricing sensitivity varies by application sector, with automotive applications demonstrating greater price elasticity than specialized industrial applications where performance advantages can justify premium pricing. As production technologies mature and economies of scale improve, decreasing costs are expected to expand addressable markets significantly.

Current Deposition Techniques and Technical Barriers

Perovskite catalysts have garnered significant attention in recent years due to their exceptional catalytic properties and potential applications in various industrial processes. The deposition of thin films of perovskite materials represents a critical step in catalyst fabrication, directly influencing performance characteristics such as activity, selectivity, and stability. Currently, several deposition techniques dominate the landscape, each with distinct advantages and limitations.

Physical vapor deposition (PVD) methods, including sputtering and thermal evaporation, offer precise control over film thickness and composition. Sputtering enables the deposition of uniform perovskite films with excellent adhesion to substrates, though challenges persist in maintaining stoichiometric composition due to differential sputtering yields of constituent elements. Thermal evaporation provides high purity films but struggles with complex multi-element perovskites due to varying vapor pressures of different precursors.

Chemical vapor deposition (CVD) techniques have demonstrated considerable promise for perovskite catalyst fabrication. Atomic layer deposition (ALD), a specialized form of CVD, enables atomic-level control over film growth through sequential self-limiting reactions. While ALD offers unparalleled conformality and thickness precision, the limited availability of suitable precursors for complex perovskite compositions remains a significant technical barrier.

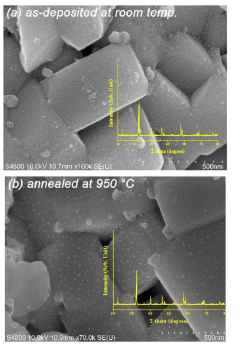

Solution-based methods represent another important category, including sol-gel processing, spin coating, and spray pyrolysis. These approaches offer cost-effectiveness and scalability advantages but face challenges in achieving uniform morphology and phase purity. The sol-gel method, while versatile for various perovskite compositions, often requires high-temperature post-deposition annealing that can lead to undesired phase segregation or substrate degradation.

Pulsed laser deposition (PLD) stands out for its ability to maintain stoichiometric transfer from target to substrate, making it particularly valuable for complex perovskite compositions. However, PLD systems require sophisticated vacuum equipment and precise laser control, limiting widespread industrial adoption.

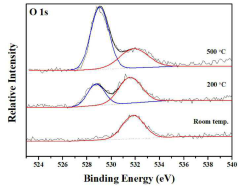

A critical technical barrier across all deposition techniques is the challenge of controlling crystallinity and phase purity of perovskite catalysts. Many perovskites require precise oxygen stoichiometry for optimal catalytic performance, yet maintaining this stoichiometry during deposition remains difficult. Additionally, substrate-film interface effects can significantly influence catalyst performance but are poorly understood and difficult to control systematically.

Scalability presents another major challenge, as techniques that excel in laboratory settings often face significant hurdles in industrial implementation. Methods like ALD and PLD offer excellent control but suffer from low deposition rates and high equipment costs. Conversely, more scalable techniques like spray pyrolysis typically sacrifice precision in composition and morphology control.

Physical vapor deposition (PVD) methods, including sputtering and thermal evaporation, offer precise control over film thickness and composition. Sputtering enables the deposition of uniform perovskite films with excellent adhesion to substrates, though challenges persist in maintaining stoichiometric composition due to differential sputtering yields of constituent elements. Thermal evaporation provides high purity films but struggles with complex multi-element perovskites due to varying vapor pressures of different precursors.

Chemical vapor deposition (CVD) techniques have demonstrated considerable promise for perovskite catalyst fabrication. Atomic layer deposition (ALD), a specialized form of CVD, enables atomic-level control over film growth through sequential self-limiting reactions. While ALD offers unparalleled conformality and thickness precision, the limited availability of suitable precursors for complex perovskite compositions remains a significant technical barrier.

Solution-based methods represent another important category, including sol-gel processing, spin coating, and spray pyrolysis. These approaches offer cost-effectiveness and scalability advantages but face challenges in achieving uniform morphology and phase purity. The sol-gel method, while versatile for various perovskite compositions, often requires high-temperature post-deposition annealing that can lead to undesired phase segregation or substrate degradation.

Pulsed laser deposition (PLD) stands out for its ability to maintain stoichiometric transfer from target to substrate, making it particularly valuable for complex perovskite compositions. However, PLD systems require sophisticated vacuum equipment and precise laser control, limiting widespread industrial adoption.

A critical technical barrier across all deposition techniques is the challenge of controlling crystallinity and phase purity of perovskite catalysts. Many perovskites require precise oxygen stoichiometry for optimal catalytic performance, yet maintaining this stoichiometry during deposition remains difficult. Additionally, substrate-film interface effects can significantly influence catalyst performance but are poorly understood and difficult to control systematically.

Scalability presents another major challenge, as techniques that excel in laboratory settings often face significant hurdles in industrial implementation. Methods like ALD and PLD offer excellent control but suffer from low deposition rates and high equipment costs. Conversely, more scalable techniques like spray pyrolysis typically sacrifice precision in composition and morphology control.

Comparative Analysis of Current Deposition Techniques

01 Physical Vapor Deposition Techniques for Perovskite Catalysts

Physical vapor deposition (PVD) techniques, including sputtering, thermal evaporation, and pulsed laser deposition, are effective methods for creating thin films of perovskite catalysts. These techniques allow for precise control over film thickness and composition, resulting in high-quality, uniform perovskite catalyst layers. PVD methods are particularly advantageous for creating epitaxial films with specific crystalline orientations that enhance catalytic performance.- Physical Vapor Deposition Techniques for Perovskite Catalysts: Physical vapor deposition (PVD) techniques are widely used for depositing thin films of perovskite catalysts. These methods include sputtering, thermal evaporation, and pulsed laser deposition. PVD techniques offer precise control over film thickness and composition, allowing for the creation of high-quality perovskite catalyst layers with excellent uniformity. These methods are particularly advantageous for creating catalysts with specific crystalline structures and surface properties that enhance catalytic activity.

- Chemical Vapor Deposition Methods for Perovskite Catalysts: Chemical vapor deposition (CVD) techniques involve the reaction of volatile precursors that decompose on the substrate surface to form thin films of perovskite catalysts. These methods include atomic layer deposition (ALD), metal-organic chemical vapor deposition (MOCVD), and plasma-enhanced CVD. CVD techniques allow for excellent step coverage, conformal coating, and the ability to deposit films on complex geometries. These methods enable precise control over the stoichiometry and phase purity of perovskite catalysts, which is crucial for their catalytic performance.

- Solution-Based Deposition Techniques for Perovskite Catalysts: Solution-based deposition techniques offer cost-effective and scalable methods for fabricating perovskite catalyst thin films. These methods include spin coating, dip coating, spray pyrolysis, and sol-gel processing. Solution-based approaches allow for easy doping and composition tuning of perovskite catalysts. The precursor solutions can be modified to control film morphology, porosity, and surface area, which are important parameters for catalytic applications. These techniques are particularly suitable for large-area deposition and can be implemented using simple equipment.

- Electrochemical Deposition Methods for Perovskite Catalysts: Electrochemical deposition techniques involve the use of electrical current to reduce metal ions from a solution onto a conductive substrate, forming perovskite catalyst thin films. These methods include electrodeposition, electroplating, and anodization. Electrochemical approaches offer advantages such as room-temperature processing, precise thickness control, and the ability to deposit on complex geometries. These techniques can produce perovskite catalysts with high surface area and unique nanostructures that enhance catalytic activity and selectivity.

- Hybrid and Advanced Deposition Techniques for Perovskite Catalysts: Hybrid and advanced deposition techniques combine multiple methods or incorporate novel approaches for depositing perovskite catalyst thin films. These include inkjet printing, aerosol-assisted deposition, flame spray pyrolysis, and molecular beam epitaxy. These advanced techniques offer unique advantages such as digital patterning, rapid processing, and precise control over film microstructure. They enable the fabrication of complex perovskite catalyst architectures with tailored properties for specific catalytic applications, including hierarchical structures and gradient compositions.

02 Chemical Vapor Deposition Methods for Perovskite Thin Films

Chemical vapor deposition (CVD) and its variants, such as metal-organic chemical vapor deposition (MOCVD), are widely used for depositing perovskite catalyst thin films. These methods involve the reaction of volatile precursors on a heated substrate surface to form a solid film. CVD techniques offer advantages including excellent step coverage, high purity films, and the ability to create complex multi-component perovskite structures with controlled stoichiometry, which is crucial for catalytic applications.Expand Specific Solutions03 Solution-Based Deposition Techniques for Perovskite Catalysts

Solution-based methods such as spin coating, dip coating, and spray pyrolysis offer cost-effective approaches for depositing perovskite catalyst thin films. These techniques involve the preparation of precursor solutions that are applied to substrates and subsequently heat-treated to form crystalline perovskite structures. Solution processing allows for large-area deposition and easy doping of the perovskite structure with various elements to enhance catalytic activity and selectivity.Expand Specific Solutions04 Atomic Layer Deposition for Precise Perovskite Catalyst Fabrication

Atomic Layer Deposition (ALD) enables the creation of ultra-thin, conformal perovskite catalyst films with atomic-level precision. This technique involves sequential, self-limiting surface reactions that allow for precise control over film thickness and composition. ALD is particularly valuable for creating perovskite catalysts on high-surface-area substrates and complex geometries, resulting in enhanced catalytic performance due to maximized active surface area and optimized material utilization.Expand Specific Solutions05 Post-Deposition Treatment and Modification of Perovskite Catalyst Films

Various post-deposition treatments, including thermal annealing, plasma treatment, and chemical etching, can significantly enhance the catalytic properties of perovskite thin films. These processes optimize crystal structure, surface morphology, and chemical composition of the catalyst layers. Post-deposition modifications can create oxygen vacancies, expose specific crystal facets, and introduce surface defects that serve as active sites for catalytic reactions, thereby improving overall catalytic efficiency and selectivity.Expand Specific Solutions

Leading Research Institutions and Industrial Manufacturers

The thin film deposition techniques for perovskite catalysts market is currently in a growth phase, with increasing research interest transitioning toward commercial applications. The global market size is expanding rapidly, driven by applications in renewable energy, particularly solar cells. Technologically, the field shows moderate maturity with established techniques but significant room for innovation. Leading players include Microquanta (Hangzhou Xianna), which has achieved mass production of perovskite photovoltaic modules, alongside established equipment manufacturers like JUSUNG ENGINEERING, Tokyo Electron, and Canon. Academic institutions including MIT, Fudan University, and Nanyang Technological University are advancing fundamental research, while industrial players like Samsung Electronics and Mitsubishi Materials are developing commercial applications. The collaboration between research institutions and commercial entities indicates a maturing ecosystem poised for significant technological breakthroughs.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed several cutting-edge thin film deposition techniques specifically optimized for perovskite catalysts. Their pulsed laser deposition (PLD) system utilizes a high-energy KrF excimer laser (248 nm) with precisely controlled fluence (1-2 J/cm²) to ablate complex oxide targets, enabling stoichiometric transfer of material to substrates. This approach allows deposition of epitaxial perovskite films with thicknesses ranging from 5-500 nm and crystallinity comparable to single crystals. Argonne has also pioneered a modified molecular beam epitaxy (MBE) technique incorporating oxygen plasma sources that achieve oxygen partial pressures up to 10^-5 Torr, critical for controlling oxygen stoichiometry in perovskite structures. Their advanced in-situ characterization suite includes reflection high-energy electron diffraction (RHEED) and X-ray photoelectron spectroscopy, enabling real-time monitoring of film growth and composition. Recent innovations include a hybrid sputtering/ALD approach that allows precise control of A-site/B-site cation ratios in complex perovskites, demonstrating enhanced catalytic activity for water splitting reactions.

Strengths: Exceptional control over film crystallinity and orientation, ability to create complex heterostructures with atomically sharp interfaces, and comprehensive in-situ characterization capabilities. Their techniques produce films with minimal defect concentrations and precisely controlled oxygen vacancy distributions. Weaknesses: Limited scalability for industrial applications, relatively low deposition rates (typically 0.1-1 nm/min), and high equipment costs that restrict widespread adoption.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed sophisticated thin film deposition techniques specifically tailored for perovskite catalysts. Their primary approach combines radio frequency magnetron sputtering with precise control of substrate temperature (25-700°C) and oxygen partial pressure (10^-6 to 10^-2 mbar) during deposition. This system achieves growth rates of 5-15 nm/min while maintaining excellent stoichiometric control. CEA has pioneered a multi-target co-sputtering technique that enables continuous composition gradients across substrates, facilitating rapid screening of perovskite compositions for catalytic activity. Their proprietary "Plasma-Enhanced Atomic Layer Deposition" system incorporates in-situ ellipsometry for real-time thickness monitoring, achieving thickness control with precision better than ±0.2 nm. CEA researchers have also developed innovative post-deposition treatments, including controlled atmosphere annealing with precisely regulated oxygen partial pressures, which has been shown to enhance catalytic activity by optimizing oxygen vacancy concentrations at perovskite surfaces.

Strengths: Exceptional control over film crystallinity and orientation, ability to create complex compositional gradients, and excellent reproducibility across multiple deposition runs. Their techniques produce films with minimal impurities and precisely controlled microstructure. Weaknesses: Relatively high equipment costs, moderate throughput limitations for industrial scaling, and complex parameter optimization requirements for each new material system.

Key Patents and Scientific Breakthroughs in Perovskite Film Deposition

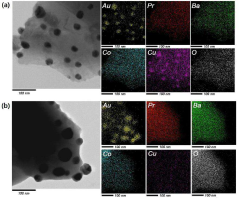

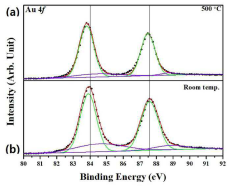

Perovskite catalyst comprising gold nanoparticle and manufacturing method of the perovskite

PatentInactiveKR1020190037904A

Innovation

- A perovskite catalyst with a Praseodymium-Barium-Cobalt-Oxygen structure doped with copper and featuring gold nanoparticles formed through sputtering and heat-treatment, allowing stable gold nanoparticle formation on the surface.

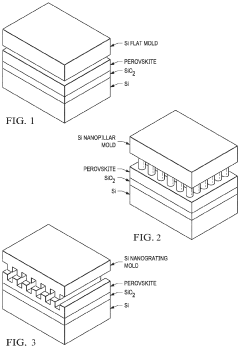

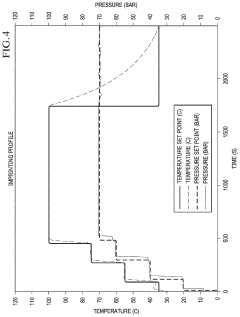

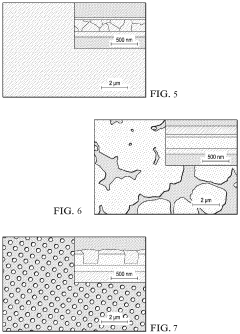

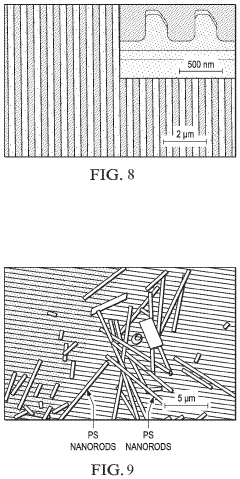

Nanoimprinting organo-metal perovskites for optoelectronic and photovoltaic applications

PatentInactiveUS20210308934A1

Innovation

- A method involving nanoimprinting of organometal halide perovskite thin films using a mold with increasing pressure and temperature, resulting in imprinted patterns like nanogratings or nanoholes, which enhances crystallinity and optoelectronic properties by improving charge carrier transport and photon absorption.

Scalability and Cost-Effectiveness Assessment

The scalability of thin film deposition techniques for perovskite catalysts represents a critical factor in determining their industrial viability. Current laboratory-scale processes demonstrate promising performance characteristics but face significant challenges when transitioning to mass production environments. Analysis of production throughput indicates that physical vapor deposition (PVD) methods offer moderate scalability with deposition rates of 1-10 nm/min, while chemical vapor deposition (CVD) techniques can achieve 5-20 nm/min under optimized conditions. However, solution-based methods such as spin coating and spray pyrolysis demonstrate superior throughput potential at 20-100 nm/min.

Capital expenditure requirements vary substantially across deposition technologies. High-vacuum systems necessary for PVD and some CVD processes require initial investments of $500,000-2,000,000 for industrial-scale equipment, creating significant barriers to entry for smaller manufacturers. In contrast, solution-based approaches typically require $50,000-300,000 for comparable production capacity, representing a more accessible entry point for commercial development.

Operational costs present another dimension for assessment, with energy consumption ranging from 5-15 kWh/m² for solution processes to 20-50 kWh/m² for vacuum-based techniques. Precursor utilization efficiency further differentiates these approaches, with PVD methods achieving 30-60% material utilization compared to 70-90% for advanced solution deposition systems. This efficiency differential translates directly to production costs, particularly when utilizing precious metal components in perovskite formulations.

Manufacturing yield rates demonstrate significant variability across deposition techniques. Atomic layer deposition (ALD) achieves exceptional uniformity with defect densities below 0.1/cm², but at the expense of deposition rates typically below 1 nm/min. Sputtering processes offer a balanced compromise with moderate defect densities (0.5-2/cm²) and acceptable deposition rates. Solution methods generally exhibit higher defect rates (2-10/cm²) but compensate through substantially lower production costs and higher throughput.

The environmental footprint of these manufacturing processes must also factor into scalability assessments. Vacuum-based techniques generate minimal waste streams but consume substantial energy, while solution methods produce chemical waste requiring treatment but operate at lower energy intensities. Recent innovations in solvent recovery systems have improved the sustainability profile of solution deposition approaches, reducing waste generation by 60-80% compared to conventional implementations.

Integration with existing manufacturing infrastructure represents the final consideration in scalability assessment. Roll-to-roll compatible techniques such as slot-die coating and spray deposition offer seamless integration with established production lines, while batch processes like ALD and some PVD methods require significant modifications to existing manufacturing workflows, potentially increasing implementation costs by 30-50%.

Capital expenditure requirements vary substantially across deposition technologies. High-vacuum systems necessary for PVD and some CVD processes require initial investments of $500,000-2,000,000 for industrial-scale equipment, creating significant barriers to entry for smaller manufacturers. In contrast, solution-based approaches typically require $50,000-300,000 for comparable production capacity, representing a more accessible entry point for commercial development.

Operational costs present another dimension for assessment, with energy consumption ranging from 5-15 kWh/m² for solution processes to 20-50 kWh/m² for vacuum-based techniques. Precursor utilization efficiency further differentiates these approaches, with PVD methods achieving 30-60% material utilization compared to 70-90% for advanced solution deposition systems. This efficiency differential translates directly to production costs, particularly when utilizing precious metal components in perovskite formulations.

Manufacturing yield rates demonstrate significant variability across deposition techniques. Atomic layer deposition (ALD) achieves exceptional uniformity with defect densities below 0.1/cm², but at the expense of deposition rates typically below 1 nm/min. Sputtering processes offer a balanced compromise with moderate defect densities (0.5-2/cm²) and acceptable deposition rates. Solution methods generally exhibit higher defect rates (2-10/cm²) but compensate through substantially lower production costs and higher throughput.

The environmental footprint of these manufacturing processes must also factor into scalability assessments. Vacuum-based techniques generate minimal waste streams but consume substantial energy, while solution methods produce chemical waste requiring treatment but operate at lower energy intensities. Recent innovations in solvent recovery systems have improved the sustainability profile of solution deposition approaches, reducing waste generation by 60-80% compared to conventional implementations.

Integration with existing manufacturing infrastructure represents the final consideration in scalability assessment. Roll-to-roll compatible techniques such as slot-die coating and spray deposition offer seamless integration with established production lines, while batch processes like ALD and some PVD methods require significant modifications to existing manufacturing workflows, potentially increasing implementation costs by 30-50%.

Environmental Impact and Sustainability Considerations

The environmental impact of thin film deposition techniques for perovskite catalysts represents a critical consideration in their industrial adoption and long-term viability. Traditional deposition methods often involve hazardous precursors, high energy consumption, and significant waste generation. Particularly concerning are lead-based perovskites, which pose substantial environmental and health risks throughout their lifecycle, from manufacturing to disposal.

Energy consumption varies dramatically across deposition techniques. Physical vapor deposition (PVD) methods typically require high vacuum conditions and elevated temperatures, resulting in substantial energy inputs. In contrast, solution-based methods like spin coating operate under ambient conditions with lower energy demands, though they often utilize environmentally problematic solvents such as dimethylformamide (DMF) and dimethyl sulfoxide (DMSO).

Waste generation constitutes another significant environmental concern. Spin coating, while widely used in laboratory settings, exhibits material utilization efficiency as low as 2-5%, with the majority of precursor solutions wasted during the spinning process. Spray pyrolysis and inkjet printing demonstrate substantially improved material efficiency, with utilization rates potentially exceeding 80% when optimized.

Recent sustainability innovations focus on developing lead-free perovskite alternatives, incorporating elements such as tin, bismuth, and antimony. Though promising, these substitutes currently exhibit lower catalytic performance and stability compared to their lead-based counterparts. Additionally, green chemistry approaches are emerging, replacing toxic solvents with environmentally benign alternatives like water, ethanol, and supercritical CO2.

Life cycle assessment (LCA) studies reveal that the environmental footprint of perovskite catalysts extends beyond manufacturing to include raw material extraction, transportation, operational lifetime, and end-of-life management. Techniques with longer catalyst lifespans and regeneration capabilities, such as atomic layer deposition (ALD), may offer superior sustainability profiles despite higher initial production impacts.

Regulatory frameworks increasingly influence deposition technique selection, with restrictions on hazardous substances like lead becoming more stringent globally. The European Union's RoHS and REACH regulations particularly impact material choices and processing methods. Forward-looking manufacturers are proactively developing compliant deposition technologies to maintain market access.

Circular economy principles are gradually being applied to perovskite catalyst production, with emerging recycling technologies capable of recovering precious metals and rare earth elements from spent catalysts. Deposition techniques that facilitate easier separation and recovery of these materials at end-of-life are gaining attention for their contribution to resource conservation and waste reduction.

Energy consumption varies dramatically across deposition techniques. Physical vapor deposition (PVD) methods typically require high vacuum conditions and elevated temperatures, resulting in substantial energy inputs. In contrast, solution-based methods like spin coating operate under ambient conditions with lower energy demands, though they often utilize environmentally problematic solvents such as dimethylformamide (DMF) and dimethyl sulfoxide (DMSO).

Waste generation constitutes another significant environmental concern. Spin coating, while widely used in laboratory settings, exhibits material utilization efficiency as low as 2-5%, with the majority of precursor solutions wasted during the spinning process. Spray pyrolysis and inkjet printing demonstrate substantially improved material efficiency, with utilization rates potentially exceeding 80% when optimized.

Recent sustainability innovations focus on developing lead-free perovskite alternatives, incorporating elements such as tin, bismuth, and antimony. Though promising, these substitutes currently exhibit lower catalytic performance and stability compared to their lead-based counterparts. Additionally, green chemistry approaches are emerging, replacing toxic solvents with environmentally benign alternatives like water, ethanol, and supercritical CO2.

Life cycle assessment (LCA) studies reveal that the environmental footprint of perovskite catalysts extends beyond manufacturing to include raw material extraction, transportation, operational lifetime, and end-of-life management. Techniques with longer catalyst lifespans and regeneration capabilities, such as atomic layer deposition (ALD), may offer superior sustainability profiles despite higher initial production impacts.

Regulatory frameworks increasingly influence deposition technique selection, with restrictions on hazardous substances like lead becoming more stringent globally. The European Union's RoHS and REACH regulations particularly impact material choices and processing methods. Forward-looking manufacturers are proactively developing compliant deposition technologies to maintain market access.

Circular economy principles are gradually being applied to perovskite catalyst production, with emerging recycling technologies capable of recovering precious metals and rare earth elements from spent catalysts. Deposition techniques that facilitate easier separation and recovery of these materials at end-of-life are gaining attention for their contribution to resource conservation and waste reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!