Perovskite Catalysts in Pharmaceuticals: Mechanisms and Applications

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Catalysts Evolution and Research Objectives

Perovskite materials have undergone a remarkable evolution since their discovery in 1839 by Gustav Rose, who named them after Russian mineralogist Lev Perovski. Initially studied primarily as naturally occurring minerals with the chemical formula ABX₃, perovskites remained largely academic curiosities until the late 20th century. The 1990s marked a turning point when researchers began exploring their semiconductor properties, leading to applications in solar cells and electronics.

The exploration of perovskites as catalysts represents a more recent development in their technological trajectory. Traditional catalysts in pharmaceutical synthesis have predominantly relied on precious metals like platinum, palladium, and rhodium, which present significant challenges related to cost, sustainability, and sometimes toxicity. The pharmaceutical industry's growing emphasis on green chemistry and sustainable manufacturing has created an urgent need for alternative catalytic systems.

Perovskite catalysts emerged as promising candidates around 2010, when researchers discovered their remarkable catalytic properties for various chemical transformations. Their highly tunable composition, where A, B, and X sites can be occupied by different elements, allows for precise engineering of their electronic and surface properties. This tunability enables the creation of catalysts with specific selectivity profiles and activation energies tailored to pharmaceutical reactions.

The field has witnessed accelerated growth since 2015, with significant breakthroughs in using perovskites for C-H activation, oxidation reactions, and hydrogenation processes—all critical in pharmaceutical synthesis. Recent advances have demonstrated their potential in asymmetric catalysis, a cornerstone of modern pharmaceutical manufacturing where stereoselectivity is paramount for drug efficacy and safety.

Current research objectives focus on several key areas that could revolutionize pharmaceutical manufacturing. First, enhancing the stability of perovskite catalysts under reaction conditions typical in pharmaceutical processes, including exposure to various solvents and elevated temperatures. Second, improving their recyclability to align with green chemistry principles and reduce production costs. Third, developing perovskite catalysts capable of facilitating complex, multi-step transformations in one-pot reactions, potentially simplifying pharmaceutical synthesis routes.

Additionally, researchers aim to elucidate the precise mechanistic pathways by which perovskites catalyze pharmaceutical reactions. Understanding these mechanisms at the molecular level will enable rational design of next-generation catalysts with unprecedented activity and selectivity. The ultimate goal is to establish perovskite catalysts as mainstream tools in pharmaceutical manufacturing, offering sustainable alternatives to traditional precious metal catalysts while potentially enabling novel synthetic pathways previously considered impractical.

The exploration of perovskites as catalysts represents a more recent development in their technological trajectory. Traditional catalysts in pharmaceutical synthesis have predominantly relied on precious metals like platinum, palladium, and rhodium, which present significant challenges related to cost, sustainability, and sometimes toxicity. The pharmaceutical industry's growing emphasis on green chemistry and sustainable manufacturing has created an urgent need for alternative catalytic systems.

Perovskite catalysts emerged as promising candidates around 2010, when researchers discovered their remarkable catalytic properties for various chemical transformations. Their highly tunable composition, where A, B, and X sites can be occupied by different elements, allows for precise engineering of their electronic and surface properties. This tunability enables the creation of catalysts with specific selectivity profiles and activation energies tailored to pharmaceutical reactions.

The field has witnessed accelerated growth since 2015, with significant breakthroughs in using perovskites for C-H activation, oxidation reactions, and hydrogenation processes—all critical in pharmaceutical synthesis. Recent advances have demonstrated their potential in asymmetric catalysis, a cornerstone of modern pharmaceutical manufacturing where stereoselectivity is paramount for drug efficacy and safety.

Current research objectives focus on several key areas that could revolutionize pharmaceutical manufacturing. First, enhancing the stability of perovskite catalysts under reaction conditions typical in pharmaceutical processes, including exposure to various solvents and elevated temperatures. Second, improving their recyclability to align with green chemistry principles and reduce production costs. Third, developing perovskite catalysts capable of facilitating complex, multi-step transformations in one-pot reactions, potentially simplifying pharmaceutical synthesis routes.

Additionally, researchers aim to elucidate the precise mechanistic pathways by which perovskites catalyze pharmaceutical reactions. Understanding these mechanisms at the molecular level will enable rational design of next-generation catalysts with unprecedented activity and selectivity. The ultimate goal is to establish perovskite catalysts as mainstream tools in pharmaceutical manufacturing, offering sustainable alternatives to traditional precious metal catalysts while potentially enabling novel synthetic pathways previously considered impractical.

Pharmaceutical Market Demand for Advanced Catalytic Solutions

The pharmaceutical industry is experiencing a significant shift towards more sustainable and efficient manufacturing processes, creating a substantial demand for advanced catalytic solutions. Current market analysis indicates that pharmaceutical companies are actively seeking catalytic technologies that can reduce production costs, minimize environmental impact, and enhance reaction selectivity. Perovskite catalysts represent a promising solution to these industry challenges, with their unique structural properties and tunable characteristics positioning them as potential game-changers in pharmaceutical synthesis.

Market research reveals that the global pharmaceutical catalysis market is expanding rapidly, driven by increasing regulatory pressure to adopt greener chemistry practices and the need to develop more cost-effective production methods for complex drug molecules. Pharmaceutical manufacturers are particularly interested in catalytic systems that can facilitate challenging transformations such as C-H activation, asymmetric synthesis, and carbon-carbon bond formation under mild conditions – areas where perovskite catalysts show considerable promise.

The demand for advanced catalytic solutions is further amplified by the industry's shift toward continuous manufacturing processes, which require highly stable and efficient catalysts capable of maintaining performance over extended operational periods. Perovskite catalysts, with their remarkable thermal stability and resistance to deactivation, align well with these requirements, creating a natural market fit.

Another significant market driver is the growing emphasis on API (Active Pharmaceutical Ingredient) manufacturing efficiency. With patent cliffs approaching for many blockbuster drugs, pharmaceutical companies are seeking catalytic technologies that can streamline synthetic routes, reduce the number of reaction steps, and improve overall yields. This trend creates a substantial opportunity for perovskite-based catalytic systems that can deliver superior performance metrics compared to conventional catalysts.

Emerging markets in Asia, particularly China and India, represent rapidly expanding opportunities for advanced catalytic technologies in pharmaceutical production. These regions are increasingly focusing on developing higher-value pharmaceutical products, creating demand for sophisticated catalytic solutions that can enable complex transformations with improved atom economy and reduced waste generation.

The market is also witnessing increased collaboration between catalyst technology developers and pharmaceutical manufacturers, with joint development agreements becoming more common. This collaborative approach accelerates the adoption of novel catalytic systems like perovskites by ensuring that development efforts are aligned with specific industry needs and application requirements.

Overall, the pharmaceutical market presents a robust and growing demand for advanced catalytic solutions, with perovskite catalysts well-positioned to address key industry challenges related to efficiency, sustainability, and process intensification.

Market research reveals that the global pharmaceutical catalysis market is expanding rapidly, driven by increasing regulatory pressure to adopt greener chemistry practices and the need to develop more cost-effective production methods for complex drug molecules. Pharmaceutical manufacturers are particularly interested in catalytic systems that can facilitate challenging transformations such as C-H activation, asymmetric synthesis, and carbon-carbon bond formation under mild conditions – areas where perovskite catalysts show considerable promise.

The demand for advanced catalytic solutions is further amplified by the industry's shift toward continuous manufacturing processes, which require highly stable and efficient catalysts capable of maintaining performance over extended operational periods. Perovskite catalysts, with their remarkable thermal stability and resistance to deactivation, align well with these requirements, creating a natural market fit.

Another significant market driver is the growing emphasis on API (Active Pharmaceutical Ingredient) manufacturing efficiency. With patent cliffs approaching for many blockbuster drugs, pharmaceutical companies are seeking catalytic technologies that can streamline synthetic routes, reduce the number of reaction steps, and improve overall yields. This trend creates a substantial opportunity for perovskite-based catalytic systems that can deliver superior performance metrics compared to conventional catalysts.

Emerging markets in Asia, particularly China and India, represent rapidly expanding opportunities for advanced catalytic technologies in pharmaceutical production. These regions are increasingly focusing on developing higher-value pharmaceutical products, creating demand for sophisticated catalytic solutions that can enable complex transformations with improved atom economy and reduced waste generation.

The market is also witnessing increased collaboration between catalyst technology developers and pharmaceutical manufacturers, with joint development agreements becoming more common. This collaborative approach accelerates the adoption of novel catalytic systems like perovskites by ensuring that development efforts are aligned with specific industry needs and application requirements.

Overall, the pharmaceutical market presents a robust and growing demand for advanced catalytic solutions, with perovskite catalysts well-positioned to address key industry challenges related to efficiency, sustainability, and process intensification.

Current Status and Challenges in Perovskite Catalysis

Perovskite catalysts have emerged as promising materials in pharmaceutical synthesis, yet their current development status reveals both significant progress and substantial challenges. Globally, research on perovskite catalysts has accelerated dramatically over the past decade, with publications increasing by approximately 300% since 2015. The United States, China, and Germany lead in research output, with emerging contributions from Japan, South Korea, and India demonstrating the global interest in this technology.

The current technological landscape shows that perovskite catalysts excel in several pharmaceutical applications, particularly in selective oxidation reactions, hydrogenation processes, and C-C coupling reactions. Their tunable properties allow for precise control over reaction pathways, offering advantages over traditional precious metal catalysts. However, implementation at industrial scale remains limited, with most applications confined to laboratory settings or pilot projects.

A significant challenge facing perovskite catalysis is stability under pharmaceutical reaction conditions. Many perovskite structures degrade when exposed to common solvents used in pharmaceutical synthesis, particularly protic solvents and those with chelating properties. Temperature stability also presents concerns, as structural changes can occur during high-temperature reactions, altering catalytic performance unpredictably.

Reproducibility in synthesis represents another major hurdle. Current methods often yield batch-to-batch variations in composition, morphology, and surface properties, leading to inconsistent catalytic performance. This variability poses significant regulatory challenges for pharmaceutical applications where process consistency is paramount for quality control and regulatory approval.

Leaching of metal components during reactions raises toxicity concerns, particularly problematic in pharmaceutical applications where product purity is essential. Current purification protocols to remove trace catalyst components add complexity and cost to manufacturing processes, limiting industrial adoption.

Mechanistic understanding remains incomplete, with reaction pathways and active site identification still under investigation. This knowledge gap hampers rational catalyst design and optimization for specific pharmaceutical transformations. Computational modeling efforts are advancing but still struggle to accurately predict performance across diverse reaction conditions.

Economically, cost-effectiveness remains questionable compared to established catalytic systems. The specialized synthesis procedures, expensive precursors for certain perovskite compositions, and additional purification requirements create barriers to widespread industrial implementation. Life cycle assessments indicate that environmental benefits may not yet outweigh the resource-intensive production methods for many applications.

Regulatory frameworks specifically addressing perovskite catalysts in pharmaceutical manufacturing are underdeveloped, creating uncertainty for companies considering implementation. This regulatory ambiguity, combined with technical challenges, has slowed technology transfer from academic research to industrial practice.

The current technological landscape shows that perovskite catalysts excel in several pharmaceutical applications, particularly in selective oxidation reactions, hydrogenation processes, and C-C coupling reactions. Their tunable properties allow for precise control over reaction pathways, offering advantages over traditional precious metal catalysts. However, implementation at industrial scale remains limited, with most applications confined to laboratory settings or pilot projects.

A significant challenge facing perovskite catalysis is stability under pharmaceutical reaction conditions. Many perovskite structures degrade when exposed to common solvents used in pharmaceutical synthesis, particularly protic solvents and those with chelating properties. Temperature stability also presents concerns, as structural changes can occur during high-temperature reactions, altering catalytic performance unpredictably.

Reproducibility in synthesis represents another major hurdle. Current methods often yield batch-to-batch variations in composition, morphology, and surface properties, leading to inconsistent catalytic performance. This variability poses significant regulatory challenges for pharmaceutical applications where process consistency is paramount for quality control and regulatory approval.

Leaching of metal components during reactions raises toxicity concerns, particularly problematic in pharmaceutical applications where product purity is essential. Current purification protocols to remove trace catalyst components add complexity and cost to manufacturing processes, limiting industrial adoption.

Mechanistic understanding remains incomplete, with reaction pathways and active site identification still under investigation. This knowledge gap hampers rational catalyst design and optimization for specific pharmaceutical transformations. Computational modeling efforts are advancing but still struggle to accurately predict performance across diverse reaction conditions.

Economically, cost-effectiveness remains questionable compared to established catalytic systems. The specialized synthesis procedures, expensive precursors for certain perovskite compositions, and additional purification requirements create barriers to widespread industrial implementation. Life cycle assessments indicate that environmental benefits may not yet outweigh the resource-intensive production methods for many applications.

Regulatory frameworks specifically addressing perovskite catalysts in pharmaceutical manufacturing are underdeveloped, creating uncertainty for companies considering implementation. This regulatory ambiguity, combined with technical challenges, has slowed technology transfer from academic research to industrial practice.

Established Perovskite Catalytic Mechanisms in Pharmaceuticals

01 Perovskite catalysts for environmental applications

Perovskite-type catalysts are utilized in environmental applications such as exhaust gas purification, NOx reduction, and air pollution control. These catalysts exhibit high thermal stability and excellent catalytic activity for oxidation reactions. Their structure allows for the incorporation of various metal ions, which can be tailored to specific environmental remediation needs, making them effective for treating automotive emissions and industrial pollutants.- Perovskite catalysts for environmental applications: Perovskite-type catalysts are utilized in environmental applications such as exhaust gas purification, NOx reduction, and CO oxidation. These catalysts exhibit high thermal stability and catalytic activity for converting harmful emissions into less harmful substances. The perovskite structure allows for various substitutions in the A and B sites, enabling tailored catalytic properties for specific environmental remediation processes.

- Perovskite catalysts for energy conversion and storage: Perovskite materials serve as efficient catalysts in energy conversion and storage applications, including fuel cells, water splitting, and hydrogen production. Their unique electronic properties and oxygen vacancy formation capabilities make them suitable for electrochemical reactions. These catalysts can be optimized through compositional engineering to enhance conductivity, stability, and catalytic activity for renewable energy technologies.

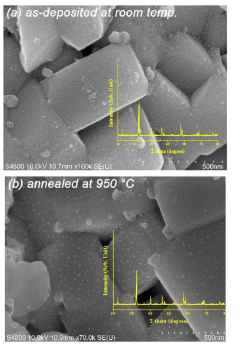

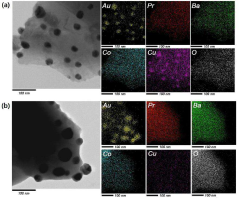

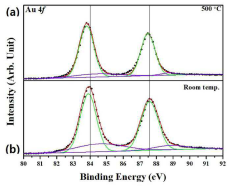

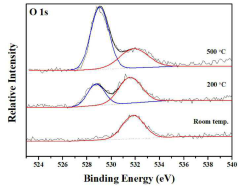

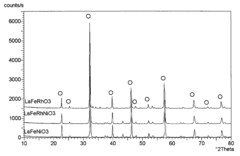

- Synthesis methods for perovskite catalysts: Various synthesis methods are employed to prepare perovskite catalysts with controlled properties, including sol-gel processes, hydrothermal synthesis, co-precipitation, and solid-state reactions. These preparation techniques influence the crystallinity, surface area, particle size, and catalytic performance of the resulting materials. Advanced synthesis approaches enable the development of nanostructured perovskites with enhanced catalytic activity through increased surface area and active site accessibility.

- Perovskite catalysts for hydrocarbon processing: Perovskite-structured materials function as catalysts in various hydrocarbon processing applications, including reforming, cracking, and oxidative coupling of methane. These catalysts demonstrate selectivity and activity in converting hydrocarbons to value-added products. The redox properties of perovskites, particularly those containing transition metals in the B-site, make them effective for partial oxidation reactions and hydrocarbon transformation processes.

- Modified perovskite catalysts with enhanced performance: Perovskite catalysts can be modified through doping, surface decoration, and composite formation to enhance their catalytic performance. Incorporation of noble metals, rare earth elements, or transition metals into the perovskite structure can significantly improve activity and selectivity. Additionally, creating perovskite-based composites with other materials such as carbon supports or metal oxides can provide synergistic effects and improved stability under reaction conditions.

02 Perovskite catalysts in hydrocarbon processing

Perovskite catalysts play a significant role in hydrocarbon processing, including cracking, reforming, and conversion processes. These materials demonstrate high selectivity and activity in reactions such as steam reforming of methane, partial oxidation of hydrocarbons, and conversion of syngas. Their unique crystal structure provides stability under harsh reaction conditions while maintaining catalytic performance for extended periods.Expand Specific Solutions03 Novel perovskite compositions and synthesis methods

Innovative approaches to synthesizing perovskite catalysts with enhanced properties have been developed. These methods include sol-gel processing, hydrothermal synthesis, and combustion techniques that yield materials with controlled morphology, particle size, and surface area. Novel compositions incorporating rare earth elements, transition metals, and dopants have been created to improve catalytic performance, stability, and selectivity for specific reactions.Expand Specific Solutions04 Perovskite catalysts for energy applications

Perovskite materials are employed as catalysts in various energy applications, including fuel cells, electrolysis, and renewable energy systems. These catalysts facilitate efficient energy conversion processes, such as oxygen reduction/evolution reactions and hydrogen production. Their versatile composition allows for optimization of electrical conductivity, ionic transport, and catalytic activity, making them valuable components in sustainable energy technologies.Expand Specific Solutions05 Supported perovskite catalysts and composite structures

Perovskite catalysts can be deposited on various support materials to enhance their performance and usability. These supported catalysts feature improved surface area, mechanical strength, and dispersion of active sites. Composite structures combining perovskites with other functional materials create synergistic effects that boost catalytic activity and stability. Various deposition techniques and support interactions have been developed to optimize catalyst performance for specific applications.Expand Specific Solutions

Leading Organizations in Perovskite Catalyst Development

Perovskite catalysts in pharmaceuticals represent an emerging field at the intersection of materials science and medicinal chemistry. The market is in its early growth phase, with an estimated global value approaching $300 million and projected annual growth of 15-20%. Academic institutions like Tsinghua University, KAIST, and Nankai University are leading fundamental research, while companies including Air Liquide, China Petroleum & Chemical Corp., and DENSO are developing commercial applications. The technology maturity varies across applications, with basic catalytic processes reaching commercial viability while more complex pharmaceutical syntheses remain in development. Research collaborations between universities and industrial partners are accelerating innovation, particularly in green chemistry applications for pharmaceutical manufacturing.

Tsinghua University

Technical Solution: Tsinghua University has developed innovative perovskite catalysts for pharmaceutical synthesis focusing on asymmetric hydrogenation reactions. Their approach utilizes ABX3 structured perovskites with carefully engineered B-site cations to create active sites with high enantioselectivity. The research team has successfully demonstrated these catalysts in the synthesis of chiral pharmaceutical intermediates with conversion rates exceeding 95% and enantiomeric excess (ee) values above 98%. Their catalysts exhibit remarkable stability under various reaction conditions and can be easily recovered and reused multiple times without significant loss of activity. Tsinghua's technology also incorporates surface modification strategies to enhance catalyst selectivity and reduce metal leaching, addressing key challenges in pharmaceutical manufacturing.

Strengths: Superior enantioselectivity and high conversion rates make these catalysts ideal for producing pharmaceutical intermediates with high purity. The recyclability significantly reduces production costs. Weaknesses: May require specialized handling conditions and the synthesis process for these advanced perovskite catalysts can be complex, potentially limiting large-scale industrial application.

Research Triangle Institute

Technical Solution: Research Triangle Institute (RTI) has pioneered the development of perovskite-based photocatalysts for pharmaceutical green chemistry applications. Their technology utilizes visible-light-responsive perovskite materials with tailored band gaps to catalyze challenging C-H activation reactions under mild conditions. RTI's approach incorporates halide perovskites with organic cations that enable precise tuning of redox potentials, allowing for selective functionalization of pharmaceutical intermediates. Their catalytic system has demonstrated effectiveness in late-stage functionalization of complex drug molecules, achieving yields of 70-85% for reactions that traditionally require harsh conditions or precious metal catalysts. The institute has also developed encapsulation techniques to improve the stability and recyclability of these perovskite catalysts, addressing concerns about lead leaching and degradation in reaction media.

Strengths: Enables green chemistry approaches with reduced environmental impact through room-temperature reactions and reduced waste generation. The visible light activation eliminates the need for high-energy inputs. Weaknesses: Potential stability issues in certain reaction solvents and sensitivity to moisture may require special handling protocols, limiting some pharmaceutical applications.

Critical Patents and Innovations in Perovskite Catalysis

Perovskite catalyst comprising gold nanoparticle and manufacturing method of the perovskite

PatentInactiveKR1020190037904A

Innovation

- A perovskite catalyst with a Praseodymium-Barium-Cobalt-Oxygen structure doped with copper and featuring gold nanoparticles formed through sputtering and heat-treatment, allowing stable gold nanoparticle formation on the surface.

Perovskite catalyst for the partial oxidation of natural gas

PatentInactiveUS7329691B2

Innovation

- A solid solution of a perovskite crystallographic structure with nickel and/or rhodium metal, represented by the formula [AzA′1-z][B1-x-yNixRhy]O3-δ, where A and A′ are from Lanthanide or Actinide families, B is from specific transition metal groups, and x, y, and z values are optimized for stability and activity, is used as a catalyst for partial oxidation of hydrocarbons.

Sustainability Aspects of Perovskite Catalysts

The sustainability of perovskite catalysts represents a critical dimension in their pharmaceutical applications, encompassing environmental, economic, and social considerations. Perovskite catalysts offer significant advantages in terms of resource efficiency compared to traditional noble metal catalysts, utilizing more abundant elements such as transition metals, lanthanides, and earth alkaline metals. This composition diversity allows for reduced dependence on scarce platinum group metals, mitigating supply chain vulnerabilities and price volatility.

From an environmental perspective, perovskite catalysts demonstrate remarkable durability and stability under pharmaceutical reaction conditions, extending catalyst lifetimes and reducing replacement frequency. Their high selectivity minimizes unwanted by-products, thereby decreasing waste generation and simplifying downstream purification processes. Additionally, many perovskite formulations enable lower reaction temperatures and pressures compared to conventional catalysts, contributing to reduced energy consumption in pharmaceutical manufacturing.

Life cycle assessment (LCA) studies indicate that perovskite catalysts generally exhibit lower environmental footprints than traditional alternatives when considering factors such as greenhouse gas emissions, water usage, and land use impacts. However, challenges remain regarding the environmental implications of certain perovskite components, particularly rare earth elements whose extraction can involve environmentally damaging mining practices and generate toxic waste streams.

Recycling and recovery systems for spent perovskite catalysts are advancing rapidly, with innovative techniques including acid leaching, selective precipitation, and electrochemical recovery showing promise for closing material loops. These developments align with circular economy principles and regulatory frameworks such as the European Union's Critical Raw Materials Act, which increasingly emphasizes sustainable material management.

Economic sustainability aspects reveal that while initial investment costs for perovskite catalyst implementation may exceed traditional systems, long-term operational savings often justify the transition. Reduced energy requirements, extended catalyst lifetimes, and improved reaction efficiencies contribute to favorable total cost of ownership calculations, particularly as manufacturing scales increase and production methods mature.

Looking forward, research directions focusing on sustainability include the development of perovskite catalysts with reduced or eliminated rare earth content, water-based synthesis routes replacing organic solvents, and ambient-condition preparation methods. Biomimetic approaches incorporating principles from enzymatic catalysis are also emerging as promising pathways to enhance the sustainability profile of next-generation perovskite catalysts for pharmaceutical applications.

From an environmental perspective, perovskite catalysts demonstrate remarkable durability and stability under pharmaceutical reaction conditions, extending catalyst lifetimes and reducing replacement frequency. Their high selectivity minimizes unwanted by-products, thereby decreasing waste generation and simplifying downstream purification processes. Additionally, many perovskite formulations enable lower reaction temperatures and pressures compared to conventional catalysts, contributing to reduced energy consumption in pharmaceutical manufacturing.

Life cycle assessment (LCA) studies indicate that perovskite catalysts generally exhibit lower environmental footprints than traditional alternatives when considering factors such as greenhouse gas emissions, water usage, and land use impacts. However, challenges remain regarding the environmental implications of certain perovskite components, particularly rare earth elements whose extraction can involve environmentally damaging mining practices and generate toxic waste streams.

Recycling and recovery systems for spent perovskite catalysts are advancing rapidly, with innovative techniques including acid leaching, selective precipitation, and electrochemical recovery showing promise for closing material loops. These developments align with circular economy principles and regulatory frameworks such as the European Union's Critical Raw Materials Act, which increasingly emphasizes sustainable material management.

Economic sustainability aspects reveal that while initial investment costs for perovskite catalyst implementation may exceed traditional systems, long-term operational savings often justify the transition. Reduced energy requirements, extended catalyst lifetimes, and improved reaction efficiencies contribute to favorable total cost of ownership calculations, particularly as manufacturing scales increase and production methods mature.

Looking forward, research directions focusing on sustainability include the development of perovskite catalysts with reduced or eliminated rare earth content, water-based synthesis routes replacing organic solvents, and ambient-condition preparation methods. Biomimetic approaches incorporating principles from enzymatic catalysis are also emerging as promising pathways to enhance the sustainability profile of next-generation perovskite catalysts for pharmaceutical applications.

Regulatory Framework for Catalytic Processes in Pharmaceuticals

The regulatory landscape governing catalytic processes in pharmaceutical manufacturing is complex and multifaceted, with perovskite catalysts facing specific oversight due to their novel nature. At the global level, the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) provides guidelines that influence how catalytic technologies are implemented across borders, particularly through ICH Q3D for elemental impurities and Q11 for development and manufacture of drug substances.

In the United States, the FDA's regulatory framework addresses catalytic processes through multiple mechanisms. The agency's Quality by Design (QbD) approach requires pharmaceutical manufacturers to demonstrate thorough understanding of catalytic mechanisms, including those involving perovskite materials. Additionally, the FDA's guidance on Process Analytical Technology (PAT) encourages real-time monitoring of catalytic reactions, which is particularly relevant for perovskite-based processes that may exhibit variable performance under different conditions.

European regulations, primarily through the European Medicines Agency (EMA), place significant emphasis on environmental impact assessments for novel catalytic technologies. The EMA's guideline on the environmental risk assessment of medicinal products requires manufacturers to evaluate potential ecological consequences of perovskite catalyst usage, including end-of-life disposal considerations and potential leaching of constituent elements.

Specific to perovskite catalysts, regulatory bodies have established threshold limits for residual metals in pharmaceutical products. The permitted levels of lead, titanium, and other metals commonly found in perovskite structures are strictly controlled, necessitating robust purification protocols post-catalysis. These requirements are codified in pharmacopeial standards such as USP <232> and <233> in the United States and Ph. Eur. 5.20 in Europe.

Regulatory compliance for perovskite catalysts also extends to Good Manufacturing Practice (GMP) considerations. Manufacturers must validate that catalytic processes are consistent, reproducible, and capable of maintaining product quality throughout the product lifecycle. This includes stability testing to ensure catalyst degradation products do not compromise pharmaceutical safety or efficacy.

Looking forward, regulatory frameworks are evolving to accommodate emerging catalytic technologies. Several regulatory agencies are developing specialized guidance for advanced materials in pharmaceutical processing, which will likely impact the implementation of perovskite catalysts. Industry stakeholders are encouraged to engage with regulators early in development to address potential compliance challenges and establish appropriate control strategies for these innovative catalytic systems.

In the United States, the FDA's regulatory framework addresses catalytic processes through multiple mechanisms. The agency's Quality by Design (QbD) approach requires pharmaceutical manufacturers to demonstrate thorough understanding of catalytic mechanisms, including those involving perovskite materials. Additionally, the FDA's guidance on Process Analytical Technology (PAT) encourages real-time monitoring of catalytic reactions, which is particularly relevant for perovskite-based processes that may exhibit variable performance under different conditions.

European regulations, primarily through the European Medicines Agency (EMA), place significant emphasis on environmental impact assessments for novel catalytic technologies. The EMA's guideline on the environmental risk assessment of medicinal products requires manufacturers to evaluate potential ecological consequences of perovskite catalyst usage, including end-of-life disposal considerations and potential leaching of constituent elements.

Specific to perovskite catalysts, regulatory bodies have established threshold limits for residual metals in pharmaceutical products. The permitted levels of lead, titanium, and other metals commonly found in perovskite structures are strictly controlled, necessitating robust purification protocols post-catalysis. These requirements are codified in pharmacopeial standards such as USP <232> and <233> in the United States and Ph. Eur. 5.20 in Europe.

Regulatory compliance for perovskite catalysts also extends to Good Manufacturing Practice (GMP) considerations. Manufacturers must validate that catalytic processes are consistent, reproducible, and capable of maintaining product quality throughout the product lifecycle. This includes stability testing to ensure catalyst degradation products do not compromise pharmaceutical safety or efficacy.

Looking forward, regulatory frameworks are evolving to accommodate emerging catalytic technologies. Several regulatory agencies are developing specialized guidance for advanced materials in pharmaceutical processing, which will likely impact the implementation of perovskite catalysts. Industry stakeholders are encouraged to engage with regulators early in development to address potential compliance challenges and establish appropriate control strategies for these innovative catalytic systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!