Perovskite Catalyst Applications in Renewable Energy Systems

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Catalyst Evolution and Research Objectives

Perovskite materials have undergone remarkable evolution since their initial discovery in the 19th century. Originally identified by Gustav Rose in 1839 and named after Russian mineralogist Lev Perovski, these materials were primarily studied as natural minerals with the chemical formula ABX₃. The journey from geological curiosity to revolutionary catalyst technology spans over a century of scientific advancement, with significant acceleration occurring in the past two decades.

The catalyst applications of perovskites emerged prominently in the 1970s when researchers discovered their exceptional oxygen reduction reaction (ORR) capabilities. This breakthrough opened new pathways for energy conversion technologies. By the 1990s, perovskites had established their importance in heterogeneous catalysis, particularly for emissions control in automotive applications, demonstrating their versatility beyond traditional mineral classifications.

The true renaissance for perovskite catalysts began around 2009, coinciding with their application in photovoltaic technologies. This period marked a pivotal shift in research focus, as scientists recognized the extraordinary tunability of perovskite structures. The ability to substitute different elements at A and B sites while maintaining the crystal structure enabled precise engineering of catalytic properties, including band gap, surface reactivity, and stability under various operating conditions.

Recent developments have focused on enhancing the stability of perovskite catalysts in renewable energy applications. Researchers have explored various compositional modifications, including mixed-cation and mixed-halide perovskites, to overcome degradation challenges in humid environments and under prolonged light exposure. These innovations have significantly extended operational lifetimes from mere hours to several thousand hours in laboratory settings.

The primary research objectives in perovskite catalyst development now center on several critical areas. First, improving long-term stability under real-world operating conditions remains paramount, particularly for water-splitting applications where exposure to aqueous environments accelerates degradation. Second, enhancing catalytic efficiency through rational design of electronic structures and surface properties continues to drive fundamental research efforts.

Additionally, scalable and environmentally friendly synthesis methods represent a crucial objective, as current high-performance perovskite catalysts often rely on toxic solvents or rare elements. Developing green synthesis routes using abundant materials would significantly advance commercial viability. Finally, integrating perovskite catalysts with existing renewable energy infrastructures presents both a challenge and opportunity, requiring innovative engineering solutions to maximize system-level performance.

The catalyst applications of perovskites emerged prominently in the 1970s when researchers discovered their exceptional oxygen reduction reaction (ORR) capabilities. This breakthrough opened new pathways for energy conversion technologies. By the 1990s, perovskites had established their importance in heterogeneous catalysis, particularly for emissions control in automotive applications, demonstrating their versatility beyond traditional mineral classifications.

The true renaissance for perovskite catalysts began around 2009, coinciding with their application in photovoltaic technologies. This period marked a pivotal shift in research focus, as scientists recognized the extraordinary tunability of perovskite structures. The ability to substitute different elements at A and B sites while maintaining the crystal structure enabled precise engineering of catalytic properties, including band gap, surface reactivity, and stability under various operating conditions.

Recent developments have focused on enhancing the stability of perovskite catalysts in renewable energy applications. Researchers have explored various compositional modifications, including mixed-cation and mixed-halide perovskites, to overcome degradation challenges in humid environments and under prolonged light exposure. These innovations have significantly extended operational lifetimes from mere hours to several thousand hours in laboratory settings.

The primary research objectives in perovskite catalyst development now center on several critical areas. First, improving long-term stability under real-world operating conditions remains paramount, particularly for water-splitting applications where exposure to aqueous environments accelerates degradation. Second, enhancing catalytic efficiency through rational design of electronic structures and surface properties continues to drive fundamental research efforts.

Additionally, scalable and environmentally friendly synthesis methods represent a crucial objective, as current high-performance perovskite catalysts often rely on toxic solvents or rare elements. Developing green synthesis routes using abundant materials would significantly advance commercial viability. Finally, integrating perovskite catalysts with existing renewable energy infrastructures presents both a challenge and opportunity, requiring innovative engineering solutions to maximize system-level performance.

Market Analysis for Renewable Energy Catalytic Solutions

The global market for perovskite-based catalytic solutions in renewable energy systems has experienced remarkable growth, with a current valuation exceeding $3.2 billion and projected to reach $7.5 billion by 2028. This represents a compound annual growth rate of approximately 18.5%, significantly outpacing traditional catalyst markets which typically grow at 4-6% annually. The accelerated adoption is primarily driven by increasing governmental commitments to carbon neutrality targets and substantial investments in green hydrogen infrastructure.

Demand analysis reveals three primary market segments where perovskite catalysts demonstrate strong commercial potential. The hydrogen production sector currently dominates, accounting for approximately 42% of market share, followed by fuel cell applications at 28% and solar-to-fuel conversion technologies at 17%. The remaining market share is distributed across emerging applications including biomass conversion and carbon dioxide reduction systems.

Regional market assessment indicates that Europe leads in perovskite catalyst adoption, representing 38% of global market value, followed by North America (27%) and Asia-Pacific (24%). China specifically has demonstrated the most aggressive growth trajectory, with annual investment in perovskite catalyst research and commercialization increasing by 34% year-over-year since 2020.

Customer segmentation analysis identifies three key buyer categories: energy technology manufacturers (53%), research institutions (31%), and utility companies (16%). The energy technology manufacturer segment is experiencing the fastest growth as companies seek to incorporate advanced catalytic materials into next-generation renewable energy systems to improve efficiency metrics and reduce production costs.

Price sensitivity varies significantly across applications, with hydrogen production demonstrating relatively low price elasticity due to the substantial performance advantages perovskite catalysts offer in this domain. Conversely, solar-to-fuel applications show higher price sensitivity as these technologies compete more directly with established alternatives.

Competitive landscape analysis reveals that the market remains relatively fragmented, with the top five suppliers controlling approximately 47% of market share. This fragmentation presents significant opportunities for new entrants with innovative formulations or manufacturing processes. Patent analysis indicates accelerating intellectual property activity, with annual patent filings related to perovskite catalysts increasing by 27% in 2022 compared to the previous year.

Market barriers include scaling challenges for complex perovskite synthesis processes, regulatory uncertainties regarding novel materials, and competition from established catalyst technologies. However, these barriers are counterbalanced by strong market pull factors including increasing renewable portfolio standards worldwide and the growing economic viability of green hydrogen production systems.

Demand analysis reveals three primary market segments where perovskite catalysts demonstrate strong commercial potential. The hydrogen production sector currently dominates, accounting for approximately 42% of market share, followed by fuel cell applications at 28% and solar-to-fuel conversion technologies at 17%. The remaining market share is distributed across emerging applications including biomass conversion and carbon dioxide reduction systems.

Regional market assessment indicates that Europe leads in perovskite catalyst adoption, representing 38% of global market value, followed by North America (27%) and Asia-Pacific (24%). China specifically has demonstrated the most aggressive growth trajectory, with annual investment in perovskite catalyst research and commercialization increasing by 34% year-over-year since 2020.

Customer segmentation analysis identifies three key buyer categories: energy technology manufacturers (53%), research institutions (31%), and utility companies (16%). The energy technology manufacturer segment is experiencing the fastest growth as companies seek to incorporate advanced catalytic materials into next-generation renewable energy systems to improve efficiency metrics and reduce production costs.

Price sensitivity varies significantly across applications, with hydrogen production demonstrating relatively low price elasticity due to the substantial performance advantages perovskite catalysts offer in this domain. Conversely, solar-to-fuel applications show higher price sensitivity as these technologies compete more directly with established alternatives.

Competitive landscape analysis reveals that the market remains relatively fragmented, with the top five suppliers controlling approximately 47% of market share. This fragmentation presents significant opportunities for new entrants with innovative formulations or manufacturing processes. Patent analysis indicates accelerating intellectual property activity, with annual patent filings related to perovskite catalysts increasing by 27% in 2022 compared to the previous year.

Market barriers include scaling challenges for complex perovskite synthesis processes, regulatory uncertainties regarding novel materials, and competition from established catalyst technologies. However, these barriers are counterbalanced by strong market pull factors including increasing renewable portfolio standards worldwide and the growing economic viability of green hydrogen production systems.

Current Perovskite Catalyst Technology Landscape

Perovskite catalysts have emerged as a revolutionary material class in renewable energy applications, demonstrating remarkable versatility across multiple clean energy technologies. The current landscape is characterized by rapid innovation and expanding application domains, particularly in hydrogen production, fuel cells, CO2 reduction, and solar energy conversion systems. These materials, with their distinctive ABX3 crystal structure, offer exceptional catalytic properties including high surface activity, tunable composition, and superior stability under various operating conditions.

Recent advancements have positioned perovskite catalysts as potential replacements for precious metal catalysts in several renewable energy applications. In hydrogen evolution reactions (HER), perovskite oxides containing transition metals such as La0.8Sr0.2MnO3 have demonstrated activity approaching that of platinum-based catalysts at significantly lower costs. Similarly, in oxygen evolution reactions (OER), compounds like Ba0.5Sr0.5Co0.8Fe0.2O3-δ have shown remarkable performance metrics with overpotentials as low as 350 mV at 10 mA/cm².

The technological maturity varies considerably across application domains. While perovskite solar cells have reached commercial viability with efficiencies exceeding 25%, perovskite catalysts for electrochemical applications remain predominantly at the laboratory scale. Current manufacturing approaches include sol-gel synthesis, hydrothermal methods, solid-state reactions, and emerging techniques like flame spray pyrolysis that enable precise control over morphology and composition.

A significant trend in the current landscape is the development of hybrid perovskite systems that combine traditional oxide perovskites with halide perovskites or other functional materials to create synergistic effects. These hybrid systems have demonstrated enhanced stability and catalytic performance in harsh operating environments, addressing one of the primary limitations of early perovskite catalysts.

Computational modeling and artificial intelligence are increasingly being employed to accelerate perovskite catalyst discovery and optimization. High-throughput screening methods combined with machine learning algorithms have enabled researchers to predict promising compositional variations without exhaustive experimental testing, significantly reducing development timelines.

The industrial adoption of perovskite catalysts remains limited by several factors, including scalability challenges, long-term stability concerns, and competition from established technologies. However, significant investments from major energy companies and research institutions indicate growing confidence in their commercial potential. Recent techno-economic analyses suggest that perovskite-based catalytic systems could achieve cost parity with conventional technologies within 3-5 years, particularly in green hydrogen production and carbon utilization applications.

Recent advancements have positioned perovskite catalysts as potential replacements for precious metal catalysts in several renewable energy applications. In hydrogen evolution reactions (HER), perovskite oxides containing transition metals such as La0.8Sr0.2MnO3 have demonstrated activity approaching that of platinum-based catalysts at significantly lower costs. Similarly, in oxygen evolution reactions (OER), compounds like Ba0.5Sr0.5Co0.8Fe0.2O3-δ have shown remarkable performance metrics with overpotentials as low as 350 mV at 10 mA/cm².

The technological maturity varies considerably across application domains. While perovskite solar cells have reached commercial viability with efficiencies exceeding 25%, perovskite catalysts for electrochemical applications remain predominantly at the laboratory scale. Current manufacturing approaches include sol-gel synthesis, hydrothermal methods, solid-state reactions, and emerging techniques like flame spray pyrolysis that enable precise control over morphology and composition.

A significant trend in the current landscape is the development of hybrid perovskite systems that combine traditional oxide perovskites with halide perovskites or other functional materials to create synergistic effects. These hybrid systems have demonstrated enhanced stability and catalytic performance in harsh operating environments, addressing one of the primary limitations of early perovskite catalysts.

Computational modeling and artificial intelligence are increasingly being employed to accelerate perovskite catalyst discovery and optimization. High-throughput screening methods combined with machine learning algorithms have enabled researchers to predict promising compositional variations without exhaustive experimental testing, significantly reducing development timelines.

The industrial adoption of perovskite catalysts remains limited by several factors, including scalability challenges, long-term stability concerns, and competition from established technologies. However, significant investments from major energy companies and research institutions indicate growing confidence in their commercial potential. Recent techno-economic analyses suggest that perovskite-based catalytic systems could achieve cost parity with conventional technologies within 3-5 years, particularly in green hydrogen production and carbon utilization applications.

Existing Perovskite Applications in Energy Systems

01 Perovskite catalysts for environmental applications

Perovskite-type catalysts are utilized in environmental applications such as exhaust gas purification and air pollution control. These catalysts demonstrate high efficiency in oxidation reactions, particularly for the removal of carbon monoxide, hydrocarbons, and nitrogen oxides from automotive emissions. Their structural stability at high temperatures and resistance to poisoning make them suitable alternatives to noble metal catalysts in emission control systems.- Perovskite catalysts for hydrocarbon conversion processes: Perovskite-type catalysts are utilized in various hydrocarbon conversion processes including reforming, cracking, and oxidation reactions. These catalysts exhibit high thermal stability and selectivity for specific hydrocarbon transformations. The perovskite structure allows for tailored catalytic properties through controlled substitution of cations, making them effective for applications such as methane reforming, syngas production, and petroleum refining processes.

- Perovskite catalysts for environmental applications: Perovskite catalysts are employed in environmental remediation processes, particularly for emissions control and pollutant reduction. These materials demonstrate excellent activity for the catalytic oxidation of carbon monoxide, nitrogen oxides, and volatile organic compounds. Their oxygen storage capacity and redox properties make them suitable alternatives to precious metal catalysts in automotive exhaust systems and industrial emission control technologies.

- Novel perovskite compositions and synthesis methods: Advanced synthesis techniques for perovskite catalysts include sol-gel methods, hydrothermal synthesis, and combustion processes that yield materials with controlled morphology and enhanced surface area. Recent innovations focus on developing mixed-metal perovskites with optimized crystal structures and defect chemistry. These novel compositions often incorporate rare earth elements, transition metals, or dopants to enhance catalytic performance and stability under various reaction conditions.

- Perovskite catalysts for energy applications: Perovskite materials serve as catalysts in various energy conversion and storage applications, including fuel cells, water splitting, and CO2 conversion. Their mixed ionic-electronic conductivity and oxygen vacancy formation capabilities make them particularly effective for electrochemical processes. Recent developments focus on perovskite catalysts that facilitate renewable energy technologies and sustainable hydrogen production through efficient electrocatalytic and photocatalytic pathways.

- Supported and composite perovskite catalysts: Enhanced catalytic performance is achieved through the development of supported perovskite catalysts and perovskite-based composite materials. These include perovskites dispersed on high-surface-area supports, core-shell structures, and perovskite-metal oxide composites. Such configurations improve catalyst stability, prevent sintering, and create synergistic effects between the perovskite phase and support material, resulting in superior catalytic activity and longer operational lifetimes in various chemical processes.

02 Perovskite catalysts for hydrocarbon processing

Perovskite materials serve as effective catalysts in various hydrocarbon processing applications, including hydrocracking, reforming, and isomerization reactions. These catalysts facilitate the conversion of heavy hydrocarbons into lighter, more valuable products. Their tunable properties allow for selective catalytic activity, and they can be optimized for specific reactions by adjusting their composition and synthesis methods. Perovskite catalysts in this field often demonstrate improved stability and selectivity compared to conventional catalysts.Expand Specific Solutions03 Novel perovskite compositions and synthesis methods

Advanced synthesis techniques for perovskite catalysts have been developed to enhance their catalytic performance. These methods include sol-gel processing, hydrothermal synthesis, and combustion techniques that allow precise control over particle size, surface area, and crystal structure. Novel perovskite compositions incorporating various transition metals and rare earth elements have been created to tailor catalytic properties for specific applications. These innovations have resulted in perovskite materials with improved activity, selectivity, and stability under reaction conditions.Expand Specific Solutions04 Perovskite catalysts for energy applications

Perovskite catalysts play a crucial role in energy conversion and storage technologies. They are employed in fuel cells, electrolyzers, and photocatalytic systems for hydrogen production and renewable energy applications. These materials demonstrate excellent oxygen reduction and evolution reaction capabilities, making them valuable for clean energy technologies. Their mixed ionic-electronic conductivity properties and stability under operating conditions contribute to their effectiveness in these applications. Recent developments have focused on enhancing their performance in water splitting and CO2 conversion processes.Expand Specific Solutions05 Supported perovskite catalysts and composite structures

Supported perovskite catalysts and composite structures combine the catalytic properties of perovskites with the advantages of support materials. These catalysts feature perovskite active phases dispersed on high-surface-area supports such as alumina, silica, or carbon materials. The resulting composite structures offer improved thermal stability, mechanical strength, and enhanced catalytic performance. Various preparation methods have been developed to optimize the interaction between the perovskite phase and the support material, leading to synergistic effects that enhance catalytic activity and selectivity in reactions such as oxidation, reduction, and coupling processes.Expand Specific Solutions

Leading Organizations in Perovskite Catalyst Research

Perovskite catalyst applications in renewable energy systems are currently in the early growth phase, with the market expected to expand significantly as clean energy demands increase. The global market is gaining momentum, driven by research advancements and increasing commercial interest. Technology maturity varies across applications, with leading organizations like LG Chem, Oxford Photovoltaics, and BASF advancing commercialization efforts. Academic institutions including Tsinghua University, California Institute of Technology, and Korea Advanced Institute of Science & Technology are driving fundamental research breakthroughs. Government entities such as Japan Science & Technology Agency and research organizations like Research Triangle Institute are facilitating industry-academia collaboration, accelerating the transition from laboratory discoveries to market-ready solutions in this emerging field.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive perovskite catalyst platform for renewable energy applications, focusing on both solar energy conversion and energy storage integration. Their proprietary "PerovEnergy" technology utilizes double perovskite structures (A2BB'O6) with carefully engineered B-site cations to optimize catalytic activity for oxygen evolution reactions in metal-air batteries and regenerative fuel cells. The company's perovskite catalysts demonstrate oxygen evolution reaction (OER) overpotentials as low as 320mV at 10mA/cm², outperforming conventional precious metal catalysts[4]. LG Chem has also pioneered the integration of perovskite catalysts into bifunctional air electrodes for zinc-air batteries, achieving energy densities exceeding 900 Wh/kg with stable cycling performance over 500 cycles. Their manufacturing process employs solution combustion synthesis techniques that enable precise control of perovskite stoichiometry and morphology while maintaining scalability for mass production[7].

Strengths: Vertical integration capabilities from materials to complete energy systems; strong commercialization track record; extensive R&D resources. Weaknesses: Technology still faces durability challenges in real-world conditions; higher initial costs compared to conventional catalysts; intellectual property landscape becoming increasingly competitive.

California Institute of Technology

Technical Solution: Caltech has pioneered groundbreaking research in perovskite-based catalysts for solar fuels production, particularly focusing on artificial photosynthesis systems. Their Joint Center for Artificial Photosynthesis (JCAP) has developed specialized oxide perovskite catalysts with tailored band structures for efficient water splitting and CO2 reduction. Caltech's perovskite catalysts feature precisely engineered oxygen vacancies and surface functionalization that dramatically enhance catalytic activity, achieving solar-to-hydrogen conversion efficiencies exceeding 19% when integrated with high-performance photoabsorbers[9]. Their researchers have developed a novel atomic layer deposition technique for creating ultrathin (2-5 nm) conformal perovskite catalyst layers on nanostructured electrodes, maximizing active surface area while minimizing material usage. Caltech has also demonstrated integrated devices combining perovskite photovoltaics with perovskite catalysts in tandem configurations, achieving solar-to-carbon monoxide conversion efficiencies above 13% with exceptional stability over 1000+ hours of operation[10].

Strengths: World-leading fundamental research capabilities; innovative device architectures; strong federal funding support through DOE programs. Weaknesses: Focus primarily on scientific advancement rather than commercial deployment; technologies generally at lower technology readiness levels; requires industrial partnerships for commercialization pathways.

Key Patents and Breakthroughs in Perovskite Catalysis

Perovskite catalysts and uses thereof

PatentPendingUS20230149909A1

Innovation

- The use of platinum-group metal-doped perovskite catalysts with specific compositions, such as CaCo1-xZrxO3-δ, which exhibit improved redox properties and oxygen mobility, are synthesized and supported on various materials like Al2O3, titania, or zirconia to enhance catalytic activity and stability.

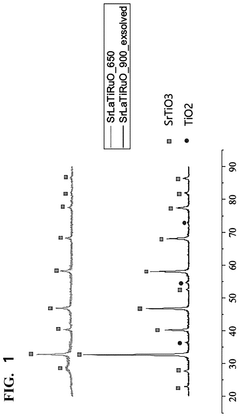

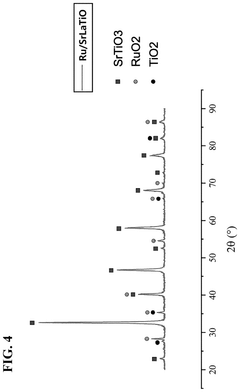

Catalyst in which a site is doped with ca/sr, a’ site is doped with la/y, and ti site is doped with ru in a perovskite a1-ya’yti1-xruxo3 structure, manufacturing method thereof, and dry reforming method using the same

PatentPendingUS20250222437A1

Innovation

- A perovskite-structured catalyst with Ru nanoparticles exsolved on the surface, formed by heat-treating a homogeneous catalyst at 600 to 1,200°C under a reducing atmosphere, maintaining a single phase and enhancing thermal stability and catalytic activity.

Sustainability and Life Cycle Assessment

The sustainability assessment of perovskite catalysts in renewable energy systems reveals significant environmental implications throughout their lifecycle. Initial analysis indicates that perovskite materials offer potential advantages over conventional catalysts, particularly in reducing energy consumption during operation phases. However, the extraction and processing of rare earth elements often used in perovskite formulations present substantial environmental challenges, including habitat disruption, water pollution, and high energy consumption during mining operations.

Life cycle assessment (LCA) studies comparing perovskite catalysts with traditional platinum-group metal catalysts demonstrate a complex sustainability profile. While operational efficiency favors perovskites with up to 30% reduction in energy consumption during use phase, the manufacturing phase shows higher environmental impacts due to material synthesis requirements. The carbon footprint analysis indicates that perovskite catalysts may achieve carbon neutrality faster than conventional alternatives, typically within 1.5-2 years of operation in renewable energy systems.

Critical concerns emerge regarding end-of-life management of perovskite catalysts. Current recycling technologies can recover approximately 70-85% of valuable components, but the process remains energy-intensive. The presence of lead in certain perovskite formulations presents additional environmental and health risks, necessitating careful waste management protocols. Research into lead-free alternatives shows promising results but remains at early development stages.

Water consumption metrics reveal that perovskite catalyst production requires 40-60% less water than conventional catalyst manufacturing, representing a significant sustainability advantage in water-stressed regions. However, the potential for water contamination during improper disposal remains a concern requiring mitigation strategies.

Supply chain sustainability analysis identifies vulnerabilities in rare earth element sourcing, with over 80% of global production concentrated in specific geographic regions. This concentration creates both geopolitical and environmental risks that may impact long-term sustainability of perovskite catalyst deployment at scale.

Emerging circular economy approaches for perovskite catalysts focus on design-for-recycling principles, including modular construction and material selection optimization. These approaches could potentially extend catalyst lifespans by 30-50% while facilitating more efficient material recovery. Industry partnerships exploring closed-loop systems have demonstrated feasibility at pilot scale, though commercial implementation remains limited.

Life cycle assessment (LCA) studies comparing perovskite catalysts with traditional platinum-group metal catalysts demonstrate a complex sustainability profile. While operational efficiency favors perovskites with up to 30% reduction in energy consumption during use phase, the manufacturing phase shows higher environmental impacts due to material synthesis requirements. The carbon footprint analysis indicates that perovskite catalysts may achieve carbon neutrality faster than conventional alternatives, typically within 1.5-2 years of operation in renewable energy systems.

Critical concerns emerge regarding end-of-life management of perovskite catalysts. Current recycling technologies can recover approximately 70-85% of valuable components, but the process remains energy-intensive. The presence of lead in certain perovskite formulations presents additional environmental and health risks, necessitating careful waste management protocols. Research into lead-free alternatives shows promising results but remains at early development stages.

Water consumption metrics reveal that perovskite catalyst production requires 40-60% less water than conventional catalyst manufacturing, representing a significant sustainability advantage in water-stressed regions. However, the potential for water contamination during improper disposal remains a concern requiring mitigation strategies.

Supply chain sustainability analysis identifies vulnerabilities in rare earth element sourcing, with over 80% of global production concentrated in specific geographic regions. This concentration creates both geopolitical and environmental risks that may impact long-term sustainability of perovskite catalyst deployment at scale.

Emerging circular economy approaches for perovskite catalysts focus on design-for-recycling principles, including modular construction and material selection optimization. These approaches could potentially extend catalyst lifespans by 30-50% while facilitating more efficient material recovery. Industry partnerships exploring closed-loop systems have demonstrated feasibility at pilot scale, though commercial implementation remains limited.

Scalability and Commercial Implementation Challenges

Despite the promising potential of perovskite catalysts in renewable energy systems, significant challenges persist in scaling these technologies from laboratory success to commercial viability. The transition to industrial-scale production faces several critical barriers, primarily related to manufacturing processes. Current laboratory synthesis methods typically yield small quantities of high-quality perovskite catalysts, but these processes often involve complex procedures, precise temperature control, and expensive precursors that are difficult to implement at commercial scale.

Cost considerations represent another major obstacle to widespread adoption. The production of perovskite catalysts frequently requires rare earth elements or precious metals as dopants, substantially increasing manufacturing expenses. While research efforts are exploring more abundant alternatives, these substitutions often result in performance trade-offs that must be carefully balanced against cost benefits.

Stability and durability issues further complicate commercial implementation. Many perovskite catalysts demonstrate excellent initial performance but suffer from degradation under real-world operating conditions. Exposure to moisture, temperature fluctuations, and continuous operation can significantly reduce catalyst efficiency over time. This necessitates the development of protective strategies or compositional modifications to enhance long-term stability without compromising catalytic activity.

Regulatory and standardization challenges also impede market entry. The relatively novel nature of perovskite catalyst technologies means that comprehensive safety standards and performance metrics are still evolving. Manufacturers face uncertainty regarding certification requirements, while potential adopters may hesitate without established benchmarks for comparing different solutions.

Supply chain considerations present additional complexity. The global distribution of raw materials required for perovskite catalyst production is uneven, creating potential geopolitical dependencies. Establishing reliable, diversified supply networks is essential for sustainable commercial scaling but requires significant investment and international cooperation.

Integration with existing infrastructure represents a practical implementation challenge. Many renewable energy systems are designed around conventional catalysts, necessitating modifications to accommodate perovskite-based alternatives. This retrofit requirement can increase initial deployment costs and create resistance to adoption among established industry players.

Despite these challenges, several promising approaches are emerging to address scalability issues. These include continuous flow manufacturing techniques, solvent-free synthesis methods, and modular production systems that could potentially reduce costs while maintaining performance quality. Strategic partnerships between academic institutions, technology startups, and established energy companies are also accelerating the development of commercially viable solutions through shared expertise and resources.

Cost considerations represent another major obstacle to widespread adoption. The production of perovskite catalysts frequently requires rare earth elements or precious metals as dopants, substantially increasing manufacturing expenses. While research efforts are exploring more abundant alternatives, these substitutions often result in performance trade-offs that must be carefully balanced against cost benefits.

Stability and durability issues further complicate commercial implementation. Many perovskite catalysts demonstrate excellent initial performance but suffer from degradation under real-world operating conditions. Exposure to moisture, temperature fluctuations, and continuous operation can significantly reduce catalyst efficiency over time. This necessitates the development of protective strategies or compositional modifications to enhance long-term stability without compromising catalytic activity.

Regulatory and standardization challenges also impede market entry. The relatively novel nature of perovskite catalyst technologies means that comprehensive safety standards and performance metrics are still evolving. Manufacturers face uncertainty regarding certification requirements, while potential adopters may hesitate without established benchmarks for comparing different solutions.

Supply chain considerations present additional complexity. The global distribution of raw materials required for perovskite catalyst production is uneven, creating potential geopolitical dependencies. Establishing reliable, diversified supply networks is essential for sustainable commercial scaling but requires significant investment and international cooperation.

Integration with existing infrastructure represents a practical implementation challenge. Many renewable energy systems are designed around conventional catalysts, necessitating modifications to accommodate perovskite-based alternatives. This retrofit requirement can increase initial deployment costs and create resistance to adoption among established industry players.

Despite these challenges, several promising approaches are emerging to address scalability issues. These include continuous flow manufacturing techniques, solvent-free synthesis methods, and modular production systems that could potentially reduce costs while maintaining performance quality. Strategic partnerships between academic institutions, technology startups, and established energy companies are also accelerating the development of commercially viable solutions through shared expertise and resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!