Perovskite Catalysts: Revolutionizing the Semiconductor Industry

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Catalysts Background and Objectives

Perovskite materials have emerged as a revolutionary force in materials science over the past decade, with their unique crystalline structure offering exceptional properties for various applications. Originally discovered in 1839 by Gustav Rose, perovskites are characterized by their ABX3 structure, where A and B are cations and X is an anion, typically oxygen or a halide. The historical trajectory of perovskite research has accelerated dramatically since 2009, when these materials began showing promise in photovoltaic applications, achieving remarkable efficiency improvements from 3.8% to over 25% in just a decade.

In the semiconductor industry context, perovskites represent a paradigm shift in catalytic materials. Traditional semiconductor manufacturing relies heavily on precious metal catalysts that face significant challenges including high cost, limited availability, and environmental concerns. The evolution of perovskite catalysts addresses these limitations while offering enhanced performance characteristics, positioning them as a disruptive technology in semiconductor processing.

The technical evolution of perovskites has followed several distinct phases: initial discovery and characterization, optimization of composition for stability, development of fabrication techniques, and most recently, integration into semiconductor manufacturing processes. This progression demonstrates the systematic approach to harnessing perovskite potential in increasingly sophisticated applications.

Current technical objectives for perovskite catalysts in semiconductor applications focus on several key areas. First, enhancing stability under the harsh conditions of semiconductor processing environments, including high temperatures and exposure to various chemicals. Second, improving scalability of synthesis methods to meet industrial production requirements. Third, optimizing catalytic efficiency to reduce energy consumption in semiconductor manufacturing processes. Fourth, developing perovskite compositions that minimize environmental impact while maximizing performance.

The semiconductor industry's growing demand for more efficient, sustainable manufacturing processes creates an ideal environment for perovskite catalyst adoption. As Moore's Law approaches physical limitations, novel materials like perovskites offer pathways to overcome barriers in traditional semiconductor fabrication. Their tunable band gap, exceptional charge transport properties, and potential for defect tolerance make them particularly valuable for next-generation semiconductor technologies.

Looking forward, perovskite catalysts are expected to enable more precise etching processes, more efficient deposition techniques, and potentially revolutionary approaches to semiconductor doping. The convergence of perovskite research with semiconductor manufacturing needs represents a significant opportunity for technological advancement that could reshape industry standards and capabilities over the next decade.

In the semiconductor industry context, perovskites represent a paradigm shift in catalytic materials. Traditional semiconductor manufacturing relies heavily on precious metal catalysts that face significant challenges including high cost, limited availability, and environmental concerns. The evolution of perovskite catalysts addresses these limitations while offering enhanced performance characteristics, positioning them as a disruptive technology in semiconductor processing.

The technical evolution of perovskites has followed several distinct phases: initial discovery and characterization, optimization of composition for stability, development of fabrication techniques, and most recently, integration into semiconductor manufacturing processes. This progression demonstrates the systematic approach to harnessing perovskite potential in increasingly sophisticated applications.

Current technical objectives for perovskite catalysts in semiconductor applications focus on several key areas. First, enhancing stability under the harsh conditions of semiconductor processing environments, including high temperatures and exposure to various chemicals. Second, improving scalability of synthesis methods to meet industrial production requirements. Third, optimizing catalytic efficiency to reduce energy consumption in semiconductor manufacturing processes. Fourth, developing perovskite compositions that minimize environmental impact while maximizing performance.

The semiconductor industry's growing demand for more efficient, sustainable manufacturing processes creates an ideal environment for perovskite catalyst adoption. As Moore's Law approaches physical limitations, novel materials like perovskites offer pathways to overcome barriers in traditional semiconductor fabrication. Their tunable band gap, exceptional charge transport properties, and potential for defect tolerance make them particularly valuable for next-generation semiconductor technologies.

Looking forward, perovskite catalysts are expected to enable more precise etching processes, more efficient deposition techniques, and potentially revolutionary approaches to semiconductor doping. The convergence of perovskite research with semiconductor manufacturing needs represents a significant opportunity for technological advancement that could reshape industry standards and capabilities over the next decade.

Semiconductor Industry Market Demand Analysis

The semiconductor industry is experiencing unprecedented demand growth driven by several converging technological trends. The global semiconductor market reached $556 billion in 2021 and is projected to exceed $1 trillion by 2030, representing a compound annual growth rate of approximately 7%. This robust growth trajectory is primarily fueled by the accelerating digitalization across industries and the emergence of data-intensive applications.

Advanced computing applications, including artificial intelligence and machine learning systems, are creating substantial demand for high-performance semiconductors. These applications require increasingly powerful processing capabilities while maintaining energy efficiency, creating a significant market opportunity for innovative catalyst technologies like perovskites that can enhance semiconductor performance.

The Internet of Things (IoT) ecosystem continues to expand rapidly, with connected devices expected to reach 75 billion worldwide by 2025. This proliferation of smart devices is generating massive demand for specialized semiconductor components, particularly those that can operate efficiently at lower power levels – an area where perovskite-based solutions show considerable promise.

Automotive electronics represent another major growth segment, with the average semiconductor content per vehicle increasing from $312 in 2013 to over $600 in 2022. The transition toward electric vehicles and autonomous driving systems is accelerating this trend, creating demand for semiconductors that can withstand harsh operating conditions while delivering reliable performance – requirements that align well with the potential advantages of perovskite catalysts.

The 5G infrastructure rollout globally is creating substantial demand for radio frequency (RF) components and advanced semiconductor materials. Market research indicates that the 5G semiconductor market alone is expected to grow at 63.4% CAGR between 2020 and 2025, presenting a significant opportunity for novel materials like perovskites that could enhance signal processing efficiency.

Supply chain vulnerabilities exposed during recent global disruptions have intensified interest in developing more resilient and geographically diverse semiconductor manufacturing capabilities. This has created market demand for innovative production technologies that can reduce dependency on specific materials or processes, potentially positioning perovskite catalysts as valuable enablers of manufacturing flexibility.

Sustainability considerations are increasingly influencing market demand, with semiconductor manufacturers facing pressure to reduce environmental impact. Perovskite catalysts offer potential advantages in this regard, as their implementation could potentially reduce energy consumption in semiconductor manufacturing processes and enable more efficient end products, aligning with market demands for greener technologies.

Advanced computing applications, including artificial intelligence and machine learning systems, are creating substantial demand for high-performance semiconductors. These applications require increasingly powerful processing capabilities while maintaining energy efficiency, creating a significant market opportunity for innovative catalyst technologies like perovskites that can enhance semiconductor performance.

The Internet of Things (IoT) ecosystem continues to expand rapidly, with connected devices expected to reach 75 billion worldwide by 2025. This proliferation of smart devices is generating massive demand for specialized semiconductor components, particularly those that can operate efficiently at lower power levels – an area where perovskite-based solutions show considerable promise.

Automotive electronics represent another major growth segment, with the average semiconductor content per vehicle increasing from $312 in 2013 to over $600 in 2022. The transition toward electric vehicles and autonomous driving systems is accelerating this trend, creating demand for semiconductors that can withstand harsh operating conditions while delivering reliable performance – requirements that align well with the potential advantages of perovskite catalysts.

The 5G infrastructure rollout globally is creating substantial demand for radio frequency (RF) components and advanced semiconductor materials. Market research indicates that the 5G semiconductor market alone is expected to grow at 63.4% CAGR between 2020 and 2025, presenting a significant opportunity for novel materials like perovskites that could enhance signal processing efficiency.

Supply chain vulnerabilities exposed during recent global disruptions have intensified interest in developing more resilient and geographically diverse semiconductor manufacturing capabilities. This has created market demand for innovative production technologies that can reduce dependency on specific materials or processes, potentially positioning perovskite catalysts as valuable enablers of manufacturing flexibility.

Sustainability considerations are increasingly influencing market demand, with semiconductor manufacturers facing pressure to reduce environmental impact. Perovskite catalysts offer potential advantages in this regard, as their implementation could potentially reduce energy consumption in semiconductor manufacturing processes and enable more efficient end products, aligning with market demands for greener technologies.

Global Perovskite Catalyst Development Status and Challenges

Perovskite catalysts have emerged as a revolutionary technology in the semiconductor industry, with significant developments occurring globally. Currently, the United States, China, Japan, and several European countries lead research and development efforts in this field. The technological landscape is characterized by rapid innovation but faces several critical challenges that impede widespread commercial adoption.

In the United States, research institutions like MIT, Stanford, and national laboratories have made substantial breakthroughs in perovskite catalyst stability and performance. These advancements have primarily focused on enhancing the longevity of perovskite materials under industrial conditions, addressing one of the technology's most persistent limitations. However, American research still struggles with scaling production methods to industrial levels.

Chinese institutions have demonstrated remarkable progress in cost-effective manufacturing techniques for perovskite catalysts. Research centers in Beijing, Shanghai, and Shenzhen have developed novel synthesis methods that significantly reduce production costs while maintaining performance metrics. The challenge remains in standardizing these processes across different manufacturing environments.

European contributions, particularly from Germany and the United Kingdom, have centered on environmental sustainability aspects of perovskite catalysts. Their research has yielded promising results in reducing toxic elements in perovskite compositions, though complete elimination of hazardous materials remains elusive while maintaining optimal performance characteristics.

The primary technical challenges currently facing perovskite catalyst development include stability under varying operational conditions, scalability of production processes, and environmental concerns related to material composition. Stability issues manifest as performance degradation when exposed to moisture, oxygen, and elevated temperatures—conditions common in semiconductor manufacturing environments. Most current solutions provide stability for months rather than the years required for commercial viability.

Scalability presents another significant hurdle, as laboratory-scale synthesis methods often fail to translate effectively to mass production. The precise control required for perovskite crystal formation becomes increasingly difficult at larger scales, resulting in inconsistent catalyst performance across batches.

Environmental considerations constitute the third major challenge, as many high-performance perovskite formulations contain lead and other toxic elements. While lead-free alternatives exist, they typically demonstrate reduced catalytic efficiency, creating a difficult trade-off between performance and environmental safety.

Geographic distribution of research expertise shows specialization patterns: North American institutions excel in fundamental material science innovations, Asian research centers lead in manufacturing process development, and European entities pioneer sustainability solutions. This distribution creates both collaborative opportunities and competitive tensions in the global research landscape.

In the United States, research institutions like MIT, Stanford, and national laboratories have made substantial breakthroughs in perovskite catalyst stability and performance. These advancements have primarily focused on enhancing the longevity of perovskite materials under industrial conditions, addressing one of the technology's most persistent limitations. However, American research still struggles with scaling production methods to industrial levels.

Chinese institutions have demonstrated remarkable progress in cost-effective manufacturing techniques for perovskite catalysts. Research centers in Beijing, Shanghai, and Shenzhen have developed novel synthesis methods that significantly reduce production costs while maintaining performance metrics. The challenge remains in standardizing these processes across different manufacturing environments.

European contributions, particularly from Germany and the United Kingdom, have centered on environmental sustainability aspects of perovskite catalysts. Their research has yielded promising results in reducing toxic elements in perovskite compositions, though complete elimination of hazardous materials remains elusive while maintaining optimal performance characteristics.

The primary technical challenges currently facing perovskite catalyst development include stability under varying operational conditions, scalability of production processes, and environmental concerns related to material composition. Stability issues manifest as performance degradation when exposed to moisture, oxygen, and elevated temperatures—conditions common in semiconductor manufacturing environments. Most current solutions provide stability for months rather than the years required for commercial viability.

Scalability presents another significant hurdle, as laboratory-scale synthesis methods often fail to translate effectively to mass production. The precise control required for perovskite crystal formation becomes increasingly difficult at larger scales, resulting in inconsistent catalyst performance across batches.

Environmental considerations constitute the third major challenge, as many high-performance perovskite formulations contain lead and other toxic elements. While lead-free alternatives exist, they typically demonstrate reduced catalytic efficiency, creating a difficult trade-off between performance and environmental safety.

Geographic distribution of research expertise shows specialization patterns: North American institutions excel in fundamental material science innovations, Asian research centers lead in manufacturing process development, and European entities pioneer sustainability solutions. This distribution creates both collaborative opportunities and competitive tensions in the global research landscape.

Current Perovskite Catalyst Implementation Solutions

01 Perovskite catalysts for hydrocarbon processing

Perovskite-type catalysts are utilized in various hydrocarbon processing applications including cracking, reforming, and conversion processes. These catalysts demonstrate high activity and selectivity for transforming hydrocarbons into valuable products. Their unique crystal structure allows for excellent thermal stability and resistance to coking, making them suitable for high-temperature reactions in petroleum refining and petrochemical industries.- Perovskite catalysts for environmental applications: Perovskite-type catalysts are utilized in environmental applications such as exhaust gas purification, NOx reduction, and air pollution control. These catalysts demonstrate high efficiency in converting harmful emissions into less harmful substances through oxidation and reduction reactions. Their structural stability at high temperatures makes them particularly suitable for automotive catalytic converters and industrial emission control systems.

- Perovskite catalysts for hydrocarbon processing: Perovskite materials serve as effective catalysts in various hydrocarbon processing applications, including hydrocracking, reforming, and conversion processes. These catalysts facilitate the transformation of heavy hydrocarbons into lighter, more valuable products. Their unique crystal structure allows for selective catalytic activity, while their thermal stability enables operation under the harsh conditions typical of petroleum refining processes.

- Novel perovskite compositions and synthesis methods: Innovative approaches to synthesizing perovskite catalysts with enhanced properties have been developed. These methods include sol-gel processing, hydrothermal synthesis, and combustion techniques that allow precise control over composition, crystal structure, and surface properties. The resulting materials exhibit improved catalytic activity, selectivity, and stability. Doping strategies with various elements are employed to tailor the electronic and structural properties for specific catalytic applications.

- Perovskite catalysts for energy conversion and storage: Perovskite materials play a crucial role in energy conversion and storage technologies, including fuel cells, electrolyzers, and photocatalytic systems. These catalysts facilitate efficient energy conversion processes by promoting electrochemical reactions at lower overpotentials. Their oxygen vacancy formation and transport properties make them particularly valuable for oxygen reduction and evolution reactions. Modified perovskites with optimized compositions demonstrate enhanced stability and activity in renewable energy applications.

- Supported perovskite catalysts and composite structures: Perovskite catalysts supported on various substrates or incorporated into composite structures exhibit enhanced performance characteristics. These supported catalysts benefit from increased surface area, improved dispersion, and better mechanical stability. The interaction between the perovskite active phase and the support material can create synergistic effects that enhance catalytic activity. Various preparation techniques have been developed to optimize the interface between the perovskite and support materials for specific applications.

02 Perovskite catalysts for environmental applications

Perovskite catalysts are employed in environmental remediation processes, particularly for emissions control and pollutant removal. These materials show remarkable activity for oxidation of carbon monoxide, nitrogen oxides, and volatile organic compounds. Their versatile composition allows for tailoring to specific environmental applications, including automotive exhaust treatment and industrial emission control systems.Expand Specific Solutions03 Novel perovskite compositions and synthesis methods

Advanced synthesis techniques for developing novel perovskite catalyst compositions with enhanced properties are described. These methods include sol-gel processing, hydrothermal synthesis, and combustion techniques that allow precise control over crystal structure, particle size, and surface area. The resulting materials exhibit improved catalytic performance through careful manipulation of A-site and B-site cations in the ABO₃ perovskite structure.Expand Specific Solutions04 Perovskite catalysts for energy applications

Perovskite materials serve as catalysts in various energy conversion and storage applications. These include fuel cells, water splitting for hydrogen production, and thermochemical energy storage systems. Their oxygen vacancy formation capabilities and mixed ionic-electronic conductivity make them particularly valuable for renewable energy technologies and clean energy production processes.Expand Specific Solutions05 Doped and modified perovskite catalysts

Doping and modification strategies are employed to enhance the catalytic properties of perovskite materials. Partial substitution of A-site or B-site cations with various elements can significantly improve catalytic activity, selectivity, and stability. Surface modifications and composite formations with other materials create synergistic effects that expand the application range of perovskite catalysts in various chemical processes.Expand Specific Solutions

Leading Companies and Research Institutions in Perovskite Catalysis

Perovskite catalysts are emerging as transformative materials in the semiconductor industry, currently in the early growth phase with rapidly expanding market potential. The technology is transitioning from research to commercialization, with global market projections showing significant upward trajectory. Leading academic institutions like Oxford University, Tsinghua University, and KAIST are driving fundamental research, while companies including LG Chem, Toshiba, and Micron Technology are advancing industrial applications. Research collaborations between universities and corporations, particularly in Asia and Europe, are accelerating development. The technology shows promise for addressing efficiency challenges in semiconductor manufacturing, though commercial-scale implementation remains in early stages as companies work to overcome stability and scalability issues.

Oxford University Innovation Ltd.

Technical Solution: Oxford University Innovation has developed advanced perovskite catalysts with unique compositional engineering techniques that enhance semiconductor manufacturing processes. Their technology focuses on lead-free perovskite formulations that maintain high catalytic activity while addressing environmental concerns. The research team has pioneered methods to control the crystal structure and surface properties of perovskite materials, resulting in catalysts that can operate at lower temperatures than conventional alternatives, reducing energy consumption in semiconductor fabrication. Their patented synthesis approach creates highly stable perovskite structures with controlled defect concentrations, which significantly improves the lifetime and performance of catalysts used in critical semiconductor manufacturing steps such as atomic layer deposition and chemical vapor deposition processes.

Strengths: Superior catalytic activity at lower temperatures, environmentally friendly lead-free formulations, and excellent stability under semiconductor processing conditions. Weaknesses: Higher production costs compared to conventional catalysts and limited large-scale manufacturing experience.

International Business Machines Corp.

Technical Solution: IBM has developed advanced perovskite catalyst technologies specifically designed to address critical challenges in semiconductor manufacturing. Their approach focuses on utilizing complex perovskite structures with precisely controlled defect chemistry to catalyze key reactions in semiconductor processing. IBM's research has demonstrated that their engineered perovskite catalysts can significantly enhance the selectivity and efficiency of atomic layer deposition processes used in advanced logic node fabrication. The company has pioneered methods to incorporate these catalysts into self-aligned multi-patterning techniques, enabling feature sizes below 5nm with improved yield and reduced variability. IBM's perovskite catalysts feature unique compositional gradients that optimize surface reactivity while maintaining bulk stability, allowing for extended catalyst lifetime in production environments. Additionally, they have developed integration schemes that enable these catalysts to be incorporated into existing semiconductor manufacturing lines with minimal process modifications.

Strengths: Exceptional catalytic selectivity, proven integration with advanced logic manufacturing processes, and extensive intellectual property portfolio. Weaknesses: Complex synthesis requirements increase production costs and specialized nature limits broader applications outside cutting-edge semiconductor manufacturing.

Key Patents and Technical Innovations in Perovskite Catalysis

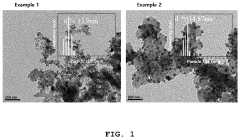

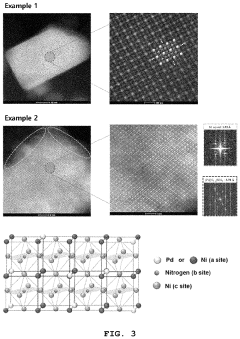

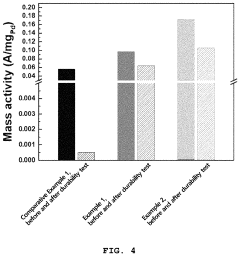

Perovskite compound, method for producing the perovskite compound, catalyst for fuel cell including the perovskite compound and method for producing the catalyst

PatentActiveUS11214497B2

Innovation

- A perovskite compound with a palladium-first metal alloy core and a palladium shell is synthesized by mixing carbon support and palladium precursor solutions, annealing in an ammonia atmosphere, and galvanically displacing the first metal on the surface with palladium, forming a palladium shell to stabilize the catalyst.

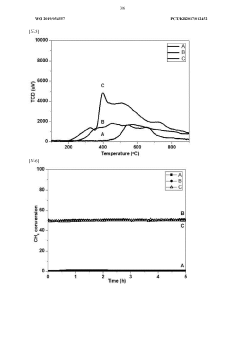

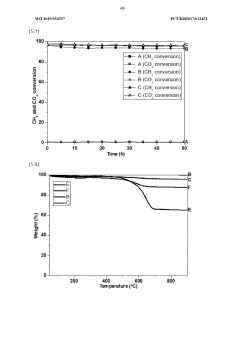

Perovskite metal oxide catalyst, in which metal ion is substituted, for reducing carbon deposition, preparation method therefor, and methane reforming reaction method using same

PatentWO2019054557A1

Innovation

- A perovskite metal oxide catalyst with nickel, cobalt, or iron ions substituted in the lattice structure is developed, specifically SrTiO3, which reduces carbon deposition and maintains catalytic activity, allowing for stable operation in SMR, DRM, and CPOM reactions with reduced energy consumption and extended catalyst life.

Environmental Impact and Sustainability Considerations

The integration of perovskite catalysts into semiconductor manufacturing processes presents significant environmental implications that must be carefully considered alongside their technological benefits. Traditional semiconductor fabrication relies heavily on rare earth elements and precious metals that involve environmentally damaging extraction processes, substantial energy consumption, and toxic waste generation. Perovskite catalysts offer a promising alternative pathway with potentially reduced environmental footprints.

Perovskite materials demonstrate remarkable versatility in their composition, allowing for the substitution of scarce or environmentally problematic elements with more abundant and less harmful alternatives. This compositional flexibility enables the design of catalysts that minimize reliance on critical raw materials while maintaining or even enhancing performance characteristics. The ability to fine-tune perovskite structures at the atomic level facilitates more efficient catalytic processes, potentially reducing energy requirements in semiconductor manufacturing.

Life cycle assessments of perovskite-based semiconductor technologies reveal notable sustainability advantages. The synthesis of perovskite catalysts typically requires lower processing temperatures compared to conventional catalysts, translating to reduced energy consumption during manufacturing. Additionally, certain perovskite formulations enable more efficient use of precursor materials, minimizing waste generation throughout the production chain.

However, sustainability challenges remain. Some perovskite compositions contain lead or other potentially toxic elements that pose environmental and health risks if improperly managed. The semiconductor industry must develop robust recycling and end-of-life management protocols specifically designed for perovskite-containing components to mitigate these concerns. Current research focuses on lead-free perovskite alternatives that maintain the exceptional catalytic properties while eliminating toxicity issues.

Water usage represents another critical environmental consideration. Perovskite catalyst implementation may offer opportunities to reduce water consumption in semiconductor manufacturing—an industry notorious for its intensive water requirements. Innovative perovskite-based processes that minimize aqueous processing steps could significantly improve the water footprint of semiconductor production facilities, particularly in water-stressed regions.

Carbon footprint reduction potential exists through the enhanced efficiency of perovskite-catalyzed reactions. By enabling more selective chemical transformations and reducing process steps, these advanced catalysts can decrease the overall energy intensity of semiconductor manufacturing. This efficiency gain translates directly to reduced greenhouse gas emissions when viewed from a comprehensive production perspective.

As the semiconductor industry continues its pursuit of sustainability alongside technological advancement, perovskite catalysts represent a promising direction that aligns environmental responsibility with innovation. Their successful implementation will require holistic approaches that address the entire technology lifecycle, from raw material sourcing to end-of-life management.

Perovskite materials demonstrate remarkable versatility in their composition, allowing for the substitution of scarce or environmentally problematic elements with more abundant and less harmful alternatives. This compositional flexibility enables the design of catalysts that minimize reliance on critical raw materials while maintaining or even enhancing performance characteristics. The ability to fine-tune perovskite structures at the atomic level facilitates more efficient catalytic processes, potentially reducing energy requirements in semiconductor manufacturing.

Life cycle assessments of perovskite-based semiconductor technologies reveal notable sustainability advantages. The synthesis of perovskite catalysts typically requires lower processing temperatures compared to conventional catalysts, translating to reduced energy consumption during manufacturing. Additionally, certain perovskite formulations enable more efficient use of precursor materials, minimizing waste generation throughout the production chain.

However, sustainability challenges remain. Some perovskite compositions contain lead or other potentially toxic elements that pose environmental and health risks if improperly managed. The semiconductor industry must develop robust recycling and end-of-life management protocols specifically designed for perovskite-containing components to mitigate these concerns. Current research focuses on lead-free perovskite alternatives that maintain the exceptional catalytic properties while eliminating toxicity issues.

Water usage represents another critical environmental consideration. Perovskite catalyst implementation may offer opportunities to reduce water consumption in semiconductor manufacturing—an industry notorious for its intensive water requirements. Innovative perovskite-based processes that minimize aqueous processing steps could significantly improve the water footprint of semiconductor production facilities, particularly in water-stressed regions.

Carbon footprint reduction potential exists through the enhanced efficiency of perovskite-catalyzed reactions. By enabling more selective chemical transformations and reducing process steps, these advanced catalysts can decrease the overall energy intensity of semiconductor manufacturing. This efficiency gain translates directly to reduced greenhouse gas emissions when viewed from a comprehensive production perspective.

As the semiconductor industry continues its pursuit of sustainability alongside technological advancement, perovskite catalysts represent a promising direction that aligns environmental responsibility with innovation. Their successful implementation will require holistic approaches that address the entire technology lifecycle, from raw material sourcing to end-of-life management.

Supply Chain Security and Material Sourcing Strategies

The global supply chain for perovskite materials presents both significant opportunities and challenges for semiconductor industry adoption. Raw materials for perovskite catalysts—including lead, tin, halides, and organic components—are sourced from diverse geographical regions, creating potential vulnerabilities in supply continuity. Lead, a primary component in many high-performance perovskite formulations, faces increasing regulatory scrutiny worldwide, necessitating strategic sourcing approaches and alternative material development.

Current supply chains for perovskite materials lack the maturity and resilience of traditional semiconductor materials like silicon. This immaturity manifests in price volatility, quality inconsistencies, and delivery uncertainties that could impede large-scale industrial implementation. The concentration of certain critical raw materials in politically sensitive regions further compounds these challenges, with over 70% of some rare earth elements controlled by a single nation.

Material purity requirements for semiconductor-grade perovskite catalysts exceed 99.9999%, demanding sophisticated purification processes and rigorous quality control protocols. Leading semiconductor manufacturers are addressing these challenges through vertical integration strategies, establishing dedicated perovskite material production facilities to ensure consistent supply and quality standards.

Diversification of supplier networks represents another crucial strategy, with companies developing relationships with multiple suppliers across different geographical regions. This approach not only mitigates geopolitical risks but also creates competitive pricing dynamics. Industry consortia are emerging to establish common material standards and certification processes, enhancing supply chain transparency and material consistency.

Recycling and circular economy initiatives are gaining traction as sustainability concerns grow. Advanced recovery techniques can reclaim up to 90% of valuable materials from perovskite waste streams, reducing dependency on virgin material sources. These processes are particularly important for lead-containing formulations, where environmental considerations intersect with supply security objectives.

Long-term material sourcing strategies must balance immediate availability with sustainability goals. Research into earth-abundant alternatives to scarce elements continues, with promising developments in lead-free perovskite formulations that maintain comparable catalytic performance. Strategic stockpiling of critical materials is becoming standard practice among major manufacturers, providing buffer capacity against short-term supply disruptions while longer-term sourcing solutions mature.

Current supply chains for perovskite materials lack the maturity and resilience of traditional semiconductor materials like silicon. This immaturity manifests in price volatility, quality inconsistencies, and delivery uncertainties that could impede large-scale industrial implementation. The concentration of certain critical raw materials in politically sensitive regions further compounds these challenges, with over 70% of some rare earth elements controlled by a single nation.

Material purity requirements for semiconductor-grade perovskite catalysts exceed 99.9999%, demanding sophisticated purification processes and rigorous quality control protocols. Leading semiconductor manufacturers are addressing these challenges through vertical integration strategies, establishing dedicated perovskite material production facilities to ensure consistent supply and quality standards.

Diversification of supplier networks represents another crucial strategy, with companies developing relationships with multiple suppliers across different geographical regions. This approach not only mitigates geopolitical risks but also creates competitive pricing dynamics. Industry consortia are emerging to establish common material standards and certification processes, enhancing supply chain transparency and material consistency.

Recycling and circular economy initiatives are gaining traction as sustainability concerns grow. Advanced recovery techniques can reclaim up to 90% of valuable materials from perovskite waste streams, reducing dependency on virgin material sources. These processes are particularly important for lead-containing formulations, where environmental considerations intersect with supply security objectives.

Long-term material sourcing strategies must balance immediate availability with sustainability goals. Research into earth-abundant alternatives to scarce elements continues, with promising developments in lead-free perovskite formulations that maintain comparable catalytic performance. Strategic stockpiling of critical materials is becoming standard practice among major manufacturers, providing buffer capacity against short-term supply disruptions while longer-term sourcing solutions mature.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!