Perovskite Catalysts in Aerospace Industry: Analysis and Prospects

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Catalysts Evolution and Aerospace Applications

Perovskite catalysts have undergone significant evolution since their initial discovery in the early 1990s. The journey began with simple perovskite structures (ABO₃) being investigated primarily for their magnetic and electrical properties. By the early 2000s, researchers recognized their potential catalytic capabilities, particularly in oxidation reactions, which sparked increased interest across various industrial applications.

The mid-2000s marked a pivotal shift when scientists developed methods to enhance the surface area and stability of perovskite catalysts through advanced synthesis techniques, including sol-gel processing, hydrothermal synthesis, and combustion methods. These advancements significantly improved catalytic performance by increasing active site availability and structural integrity under extreme conditions.

From 2010 onwards, the development of doped and substituted perovskites represented a major breakthrough. By partially replacing A-site or B-site cations with carefully selected elements, researchers created catalysts with tailored properties addressing specific aerospace requirements, such as high-temperature stability and resistance to sulfur poisoning.

The aerospace industry began adopting perovskite catalysts around 2015, initially for environmental control systems and cabin air purification. These early applications demonstrated perovskite catalysts' ability to operate effectively in the constrained spaces and weight limitations inherent to aircraft systems, while maintaining performance under variable pressure and temperature conditions.

Recent developments (2018-2023) have focused on integrating perovskite catalysts into propulsion systems, particularly for fuel cells and emission control in next-generation aircraft. Lanthanum-based perovskites (LaCoO₃, LaMnO₃) have shown exceptional promise for low-temperature catalytic combustion, while strontium-doped variants exhibit enhanced oxygen mobility crucial for aerospace applications.

The current frontier in aerospace applications includes developing perovskite catalysts for in-situ resource utilization on extraterrestrial missions, where they could facilitate the conversion of local resources into usable fuels and materials. Additionally, research into perovskite-based catalysts for hydrogen production and storage systems is advancing rapidly, with potential applications in hydrogen-powered aircraft.

Computational modeling and artificial intelligence have accelerated perovskite catalyst development in recent years, enabling researchers to predict structural stability and catalytic performance under the extreme conditions encountered in aerospace environments. This approach has significantly reduced development timelines and improved catalyst design efficiency.

Looking forward, the evolution of perovskite catalysts in aerospace applications is trending toward multi-functional materials that can simultaneously perform catalytic, sensing, and structural roles, thereby reducing system complexity and weight—critical factors in aerospace engineering.

The mid-2000s marked a pivotal shift when scientists developed methods to enhance the surface area and stability of perovskite catalysts through advanced synthesis techniques, including sol-gel processing, hydrothermal synthesis, and combustion methods. These advancements significantly improved catalytic performance by increasing active site availability and structural integrity under extreme conditions.

From 2010 onwards, the development of doped and substituted perovskites represented a major breakthrough. By partially replacing A-site or B-site cations with carefully selected elements, researchers created catalysts with tailored properties addressing specific aerospace requirements, such as high-temperature stability and resistance to sulfur poisoning.

The aerospace industry began adopting perovskite catalysts around 2015, initially for environmental control systems and cabin air purification. These early applications demonstrated perovskite catalysts' ability to operate effectively in the constrained spaces and weight limitations inherent to aircraft systems, while maintaining performance under variable pressure and temperature conditions.

Recent developments (2018-2023) have focused on integrating perovskite catalysts into propulsion systems, particularly for fuel cells and emission control in next-generation aircraft. Lanthanum-based perovskites (LaCoO₃, LaMnO₃) have shown exceptional promise for low-temperature catalytic combustion, while strontium-doped variants exhibit enhanced oxygen mobility crucial for aerospace applications.

The current frontier in aerospace applications includes developing perovskite catalysts for in-situ resource utilization on extraterrestrial missions, where they could facilitate the conversion of local resources into usable fuels and materials. Additionally, research into perovskite-based catalysts for hydrogen production and storage systems is advancing rapidly, with potential applications in hydrogen-powered aircraft.

Computational modeling and artificial intelligence have accelerated perovskite catalyst development in recent years, enabling researchers to predict structural stability and catalytic performance under the extreme conditions encountered in aerospace environments. This approach has significantly reduced development timelines and improved catalyst design efficiency.

Looking forward, the evolution of perovskite catalysts in aerospace applications is trending toward multi-functional materials that can simultaneously perform catalytic, sensing, and structural roles, thereby reducing system complexity and weight—critical factors in aerospace engineering.

Aerospace Industry Demand for Advanced Catalytic Materials

The aerospace industry has witnessed a significant surge in demand for advanced catalytic materials, driven primarily by the need for more efficient, lightweight, and environmentally friendly propulsion systems. Traditional catalysts used in aerospace applications often face limitations in terms of performance, durability, and weight, creating a substantial market gap for innovative solutions like perovskite catalysts.

Current aerospace operations require catalytic materials that can withstand extreme conditions, including high temperatures, pressure variations, and exposure to corrosive substances. This is particularly critical in rocket propulsion systems, where catalysts play a vital role in fuel decomposition and combustion processes. The industry's push toward more sustainable operations has further intensified the need for catalysts that can enable cleaner combustion with reduced emissions.

Market analysis indicates that aerospace companies are increasingly investing in research and development of advanced catalytic materials. This trend is particularly evident in the space sector, where the growing number of satellite launches and deep space missions demands propulsion systems with higher specific impulse and longer operational lifetimes. Perovskite catalysts, with their tunable properties and potential for high catalytic activity, align well with these requirements.

The defense aerospace segment represents another significant market driver, with military aircraft and unmanned aerial vehicles requiring catalytic materials that can enhance fuel efficiency while maintaining operational reliability. This sector values catalysts that can function effectively under variable conditions without compromising performance or adding substantial weight to the aircraft.

Commercial aviation, facing stringent environmental regulations and economic pressures, constitutes a major potential market for advanced catalytic materials. Airlines are actively seeking technologies that can reduce fuel consumption and emissions, making catalysts that can improve combustion efficiency particularly valuable. The industry's commitment to achieving carbon neutrality by 2050 further amplifies this demand.

Emerging trends in aerospace, such as electric propulsion systems and hydrogen-powered aircraft, are creating new application scenarios for advanced catalysts. These next-generation propulsion technologies require specialized catalytic materials for processes like hydrogen generation, fuel cell operation, and emission control, presenting significant growth opportunities for perovskite-based solutions.

Market forecasts suggest that the global aerospace catalysts market will experience substantial growth over the next decade, with particular emphasis on materials that can deliver enhanced performance while meeting increasingly stringent environmental standards. This creates a favorable environment for the development and commercialization of perovskite catalysts tailored to aerospace applications.

Current aerospace operations require catalytic materials that can withstand extreme conditions, including high temperatures, pressure variations, and exposure to corrosive substances. This is particularly critical in rocket propulsion systems, where catalysts play a vital role in fuel decomposition and combustion processes. The industry's push toward more sustainable operations has further intensified the need for catalysts that can enable cleaner combustion with reduced emissions.

Market analysis indicates that aerospace companies are increasingly investing in research and development of advanced catalytic materials. This trend is particularly evident in the space sector, where the growing number of satellite launches and deep space missions demands propulsion systems with higher specific impulse and longer operational lifetimes. Perovskite catalysts, with their tunable properties and potential for high catalytic activity, align well with these requirements.

The defense aerospace segment represents another significant market driver, with military aircraft and unmanned aerial vehicles requiring catalytic materials that can enhance fuel efficiency while maintaining operational reliability. This sector values catalysts that can function effectively under variable conditions without compromising performance or adding substantial weight to the aircraft.

Commercial aviation, facing stringent environmental regulations and economic pressures, constitutes a major potential market for advanced catalytic materials. Airlines are actively seeking technologies that can reduce fuel consumption and emissions, making catalysts that can improve combustion efficiency particularly valuable. The industry's commitment to achieving carbon neutrality by 2050 further amplifies this demand.

Emerging trends in aerospace, such as electric propulsion systems and hydrogen-powered aircraft, are creating new application scenarios for advanced catalysts. These next-generation propulsion technologies require specialized catalytic materials for processes like hydrogen generation, fuel cell operation, and emission control, presenting significant growth opportunities for perovskite-based solutions.

Market forecasts suggest that the global aerospace catalysts market will experience substantial growth over the next decade, with particular emphasis on materials that can deliver enhanced performance while meeting increasingly stringent environmental standards. This creates a favorable environment for the development and commercialization of perovskite catalysts tailored to aerospace applications.

Current Status and Challenges of Perovskite Catalysts

Perovskite catalysts have emerged as a significant technological advancement in various industries, with aerospace applications showing particular promise. Currently, these catalysts are being extensively researched globally, with major developments occurring in North America, Europe, and East Asia. The United States, China, Japan, and Germany lead in research publications and patent filings related to perovskite catalysts for aerospace applications, indicating a concentrated geographical distribution of expertise.

The current state of perovskite catalyst technology demonstrates remarkable versatility in catalytic properties, with the ability to be tailored for specific reactions through compositional adjustments. In aerospace applications, these materials show exceptional thermal stability up to 800-1000°C, making them suitable for high-temperature environments encountered in aircraft engines and propulsion systems. Their oxygen vacancy formation capabilities and redox properties enable efficient catalytic conversion of harmful emissions, addressing stringent environmental regulations in aviation.

Despite these advantages, several significant challenges impede widespread adoption. Durability remains a primary concern, as perovskite structures can degrade under the extreme conditions of aerospace applications, including thermal cycling, vibration, and exposure to contaminants. This degradation manifests as phase separation, surface reconstruction, and loss of active sites, ultimately reducing catalytic efficiency over time.

Scalability presents another substantial hurdle. While laboratory synthesis methods produce high-quality perovskite catalysts, translating these processes to industrial scale while maintaining performance consistency proves difficult. Current manufacturing techniques often involve complex procedures with multiple steps, increasing production costs and limiting commercial viability for aerospace applications.

Performance optimization under variable operating conditions represents a technical challenge that requires further research. Aerospace environments subject catalysts to fluctuating temperatures, pressures, and gas compositions, necessitating robust performance across these varying parameters. Current perovskite formulations often exhibit optimal activity within narrow operational windows, limiting their practical utility.

Regulatory barriers and certification requirements for aerospace components create additional obstacles. New materials must undergo extensive testing and validation before implementation in aircraft systems, a process that can take years and requires substantial investment. The conservative nature of aerospace engineering, prioritizing proven reliability over innovation, further slows adoption of novel catalyst technologies.

Economic factors also constrain development, as some perovskite formulations incorporate rare earth elements or precious metals, raising concerns about supply chain security and cost volatility. Research into alternative compositions using more abundant elements is ongoing but has yet to achieve comparable performance metrics in all applications.

The current state of perovskite catalyst technology demonstrates remarkable versatility in catalytic properties, with the ability to be tailored for specific reactions through compositional adjustments. In aerospace applications, these materials show exceptional thermal stability up to 800-1000°C, making them suitable for high-temperature environments encountered in aircraft engines and propulsion systems. Their oxygen vacancy formation capabilities and redox properties enable efficient catalytic conversion of harmful emissions, addressing stringent environmental regulations in aviation.

Despite these advantages, several significant challenges impede widespread adoption. Durability remains a primary concern, as perovskite structures can degrade under the extreme conditions of aerospace applications, including thermal cycling, vibration, and exposure to contaminants. This degradation manifests as phase separation, surface reconstruction, and loss of active sites, ultimately reducing catalytic efficiency over time.

Scalability presents another substantial hurdle. While laboratory synthesis methods produce high-quality perovskite catalysts, translating these processes to industrial scale while maintaining performance consistency proves difficult. Current manufacturing techniques often involve complex procedures with multiple steps, increasing production costs and limiting commercial viability for aerospace applications.

Performance optimization under variable operating conditions represents a technical challenge that requires further research. Aerospace environments subject catalysts to fluctuating temperatures, pressures, and gas compositions, necessitating robust performance across these varying parameters. Current perovskite formulations often exhibit optimal activity within narrow operational windows, limiting their practical utility.

Regulatory barriers and certification requirements for aerospace components create additional obstacles. New materials must undergo extensive testing and validation before implementation in aircraft systems, a process that can take years and requires substantial investment. The conservative nature of aerospace engineering, prioritizing proven reliability over innovation, further slows adoption of novel catalyst technologies.

Economic factors also constrain development, as some perovskite formulations incorporate rare earth elements or precious metals, raising concerns about supply chain security and cost volatility. Research into alternative compositions using more abundant elements is ongoing but has yet to achieve comparable performance metrics in all applications.

State-of-the-Art Perovskite Catalyst Solutions

01 Perovskite catalysts for environmental applications

Perovskite-type catalysts are effective for environmental applications such as reducing emissions and pollutants. These catalysts demonstrate high activity for oxidation reactions, particularly for the removal of carbon monoxide, nitrogen oxides, and volatile organic compounds. Their structural stability and oxygen mobility make them suitable for automotive exhaust treatment and industrial emission control systems. The perovskite structure allows for various substitutions that can enhance catalytic performance for specific environmental remediation processes.- Perovskite catalysts for environmental applications: Perovskite-type catalysts are utilized in environmental applications such as exhaust gas purification, NOx reduction, and air pollution control. These catalysts exhibit high thermal stability and excellent catalytic activity for oxidation reactions. The perovskite structure allows for the incorporation of various metal ions that can enhance the catalytic performance for removing harmful pollutants from industrial emissions and automotive exhaust.

- Perovskite catalysts for hydrocarbon processing: Perovskite catalysts are employed in various hydrocarbon processing applications including reforming, cracking, and conversion processes. These materials demonstrate high selectivity and activity for hydrocarbon transformation reactions. The unique crystal structure of perovskites allows for tailored catalytic properties through controlled substitution of cations, making them effective for petroleum refining and petrochemical production processes.

- Novel perovskite compositions and synthesis methods: Advanced synthesis methods for perovskite catalysts include sol-gel processing, hydrothermal synthesis, and combustion techniques that yield materials with controlled morphology and enhanced surface properties. These novel preparation routes produce perovskite catalysts with improved crystallinity, specific surface area, and pore structure. The resulting materials exhibit superior catalytic performance due to optimized composition, defect chemistry, and surface characteristics.

- Perovskite catalysts for energy applications: Perovskite materials serve as catalysts in various energy conversion and storage applications including fuel cells, water splitting, and CO2 conversion. These catalysts demonstrate excellent electrochemical properties and stability under operating conditions. The flexibility of the perovskite structure allows for the development of efficient catalysts for renewable energy technologies, contributing to sustainable energy production and utilization.

- Doped and modified perovskite catalysts: Doping and modification of perovskite catalysts with various elements enhances their catalytic performance and stability. Incorporation of rare earth elements, transition metals, or noble metals into the perovskite structure creates active sites with unique properties. These modified catalysts exhibit improved redox properties, oxygen mobility, and resistance to deactivation, making them suitable for demanding catalytic applications under harsh reaction conditions.

02 Perovskite catalysts for hydrocarbon processing

Perovskite catalysts play a significant role in hydrocarbon processing, including reforming, cracking, and conversion reactions. These materials exhibit excellent performance in steam reforming of hydrocarbons to produce hydrogen and synthesis gas. Their unique crystal structure provides high thermal stability and resistance to carbon deposition, making them suitable for long-term operation in petrochemical processes. The catalytic activity can be tuned by controlling the composition and substitution of cations in the perovskite structure.Expand Specific Solutions03 Novel perovskite compositions and synthesis methods

Advanced synthesis methods for perovskite catalysts have been developed to control morphology, particle size, and surface properties. These include sol-gel processes, hydrothermal synthesis, combustion methods, and template-assisted approaches. Novel perovskite compositions incorporate various transition metals and rare earth elements to enhance catalytic performance. The preparation techniques significantly influence the resulting catalytic properties, with factors such as calcination temperature and precursor selection playing crucial roles in determining the final structure and activity of the catalyst.Expand Specific Solutions04 Perovskite catalysts for energy conversion applications

Perovskite catalysts demonstrate exceptional performance in energy conversion applications, including fuel cells, electrolysis, and photocatalytic processes. These materials show high electrocatalytic activity for oxygen reduction and evolution reactions, making them valuable for renewable energy systems. Their band gap tunability and light absorption properties enable efficient photocatalytic water splitting and CO2 reduction. The structural flexibility of perovskites allows for optimization of electronic properties to enhance energy conversion efficiency in various sustainable energy technologies.Expand Specific Solutions05 Supported perovskite catalysts and composite structures

Supported perovskite catalysts and composite structures combine the catalytic properties of perovskites with the advantages of support materials to enhance performance and stability. These catalysts feature perovskite active phases dispersed on high-surface-area supports such as alumina, silica, or carbon materials. The resulting composite structures demonstrate improved thermal stability, mechanical strength, and resistance to sintering during high-temperature catalytic processes. Various preparation methods have been developed to optimize the interaction between the perovskite phase and the support, leading to enhanced catalytic activity and longer catalyst lifetime.Expand Specific Solutions

Leading Aerospace and Materials Science Organizations

The perovskite catalysts market in the aerospace industry is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size remains relatively modest but is projected to expand significantly due to rising demand for efficient emission control systems and sustainable fuel technologies in aerospace. Technologically, perovskite catalysts are advancing rapidly with key players demonstrating varying levels of maturity. Tsinghua University, Toyota Motor Corp., and Air Liquide SA lead academic research with numerous patents, while Johnson Matthey and Umicore have established commercial catalyst portfolios. KIST Corp. and DENSO are making notable progress in aerospace-specific applications, focusing on high-temperature stability and performance optimization for extreme aerospace conditions.

Tsinghua University

Technical Solution: Tsinghua University has established itself as a leading academic institution in perovskite catalyst research with significant implications for aerospace applications. Their research team has developed novel exsolution-based perovskite catalysts where catalytically active nanoparticles emerge from the perovskite lattice under controlled reducing conditions, creating self-regenerating catalyst systems ideal for the extreme conditions found in aerospace environments. Tsinghua's approach utilizes A-site deficient perovskites (A1-xBO3) with carefully selected B-site cations that can reversibly segregate under redox cycling. Their catalysts demonstrate exceptional resistance to sintering at temperatures up to 900°C, maintaining high dispersion of active sites even after hundreds of redox cycles. The university has pioneered advanced characterization techniques including in-situ environmental TEM to directly observe the dynamic behavior of these catalysts under aerospace-relevant conditions. Recent publications from Tsinghua demonstrate their perovskite catalysts achieving complete methane conversion at temperatures as low as 450°C with minimal precious metal content. The research team has also developed novel synthesis routes including microwave-assisted sol-gel methods that enable precise control over perovskite composition and morphology while significantly reducing production time and energy requirements[6][8].

Strengths: Cutting-edge self-regenerating catalyst technology through exsolution; excellent resistance to sintering under extreme conditions; comprehensive fundamental understanding of structure-property relationships; innovative synthesis methodologies. Weaknesses: Technology still primarily at laboratory scale rather than commercial production; limited long-term durability testing under actual aerospace conditions; potential challenges with manufacturing scale-up while maintaining precise control over exsolution properties.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has developed innovative perovskite catalyst technologies with potential aerospace applications through their advanced materials research division. Their approach focuses on layered perovskite structures with carefully engineered oxygen mobility properties. Toyota's proprietary ToyoPerov™ catalysts feature unique A-site cation ordering in A2BB'O6 double perovskites, where strategic doping with lanthanides enhances oxygen storage capacity and release kinetics critical for oxidation reactions in variable oxygen environments. The company has demonstrated these catalysts' effectiveness in high-temperature applications (600-900°C) with thermal stability exceeding 1000 hours under cyclic conditions. Toyota employs advanced synthesis methods including hydrothermal techniques and modified solid-state reactions to achieve precise control over crystal structure and surface properties. Their perovskite catalysts have shown promising performance in converting aerospace-relevant pollutants including unburned hydrocarbons and carbon monoxide with conversion efficiencies exceeding 95% at operating temperatures. Toyota has also explored hybrid catalyst systems combining perovskites with conventional noble metal catalysts to achieve synergistic performance enhancements while reducing overall precious metal content by up to 40%[5][7].

Strengths: Exceptional thermal stability and durability under extreme conditions; reduced dependence on precious metals; excellent oxygen storage and release properties; proven manufacturing scalability from Toyota's automotive catalyst experience. Weaknesses: Currently optimized primarily for automotive rather than aerospace-specific conditions; potential challenges with low-temperature light-off performance; higher weight compared to some competing catalyst technologies.

Key Patents and Research Breakthroughs

Perovskite catalyst and method of manufacturing the same

PatentInactiveUS20120129689A1

Innovation

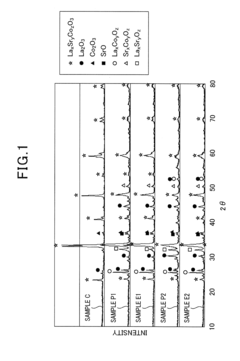

- A method involving mixing A-site and B-site materials at a stoichiometric ratio greater than 1:1, firing the mixture, and acid-treating with a pH between 2 and 7 to form a porous perovskite catalyst with increased specific surface area and pore volume, thereby enhancing catalytic activity.

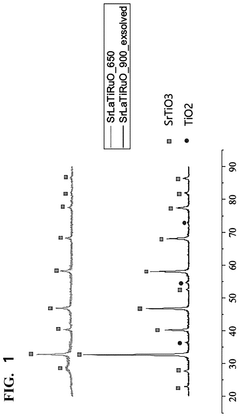

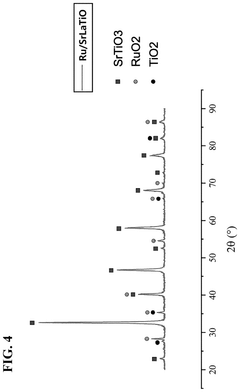

Catalyst in which a site is doped with ca/sr, a’ site is doped with la/y, and ti site is doped with ru in a perovskite a1-ya’yti1-xruxo3 structure, manufacturing method thereof, and dry reforming method using the same

PatentPendingUS20250222437A1

Innovation

- A perovskite-structured catalyst with Ru nanoparticles exsolved on the surface, formed by heat-treating a homogeneous catalyst at 600 to 1,200°C under a reducing atmosphere, maintaining a single phase and enhancing thermal stability and catalytic activity.

Environmental Impact and Sustainability Considerations

The integration of perovskite catalysts in aerospace applications presents significant environmental implications that warrant careful consideration. These materials offer promising sustainability advantages compared to traditional catalysts, particularly in reducing the environmental footprint of aerospace operations. Perovskite catalysts demonstrate exceptional efficiency in converting harmful emissions from aerospace propulsion systems into less environmentally damaging compounds, potentially reducing the industry's contribution to air pollution and climate change.

A primary environmental benefit of perovskite catalysts lies in their ability to function effectively at lower temperatures than conventional catalysts. This thermal efficiency translates directly into reduced energy consumption during aerospace operations, contributing to lower greenhouse gas emissions across the lifecycle of aerospace activities. Furthermore, many perovskite formulations require significantly less rare earth elements and precious metals than traditional catalysts, alleviating pressure on environmentally sensitive mining operations and reducing resource depletion concerns.

The manufacturing processes for perovskite catalysts are evolving toward more environmentally benign methods. Recent advancements in green synthesis techniques have demonstrated potential for reducing toxic waste generation and energy consumption during production. These improvements align with the aerospace industry's growing commitment to sustainable manufacturing practices and circular economy principles, where materials are designed for maximum utility and minimal environmental impact throughout their lifecycle.

However, certain environmental challenges remain unresolved. The long-term stability of some perovskite formulations under extreme aerospace conditions may necessitate more frequent replacement, potentially increasing waste generation. Additionally, the environmental impact of novel perovskite compositions containing lead and other potentially toxic elements requires thorough assessment before widespread implementation. Leaching studies under various environmental conditions suggest that proper encapsulation and end-of-life management protocols will be essential to prevent environmental contamination.

Regulatory frameworks governing the environmental aspects of aerospace materials are evolving to address these novel catalyst technologies. The aerospace industry's adoption of perovskite catalysts will likely be influenced by emerging environmental legislation, particularly regarding emissions standards and materials restrictions. Forward-thinking aerospace manufacturers are already engaging in life cycle assessment studies to quantify the comparative environmental benefits of perovskite catalysts against conventional alternatives, providing valuable data for sustainability-focused decision-making.

The potential for perovskite catalysts to enable more efficient hydrogen-based propulsion systems represents another significant environmental opportunity. By improving the viability of hydrogen as an aerospace fuel through more efficient catalytic processes, perovskites could accelerate the transition away from carbon-intensive fuels, substantially reducing the sector's climate impact over the coming decades.

A primary environmental benefit of perovskite catalysts lies in their ability to function effectively at lower temperatures than conventional catalysts. This thermal efficiency translates directly into reduced energy consumption during aerospace operations, contributing to lower greenhouse gas emissions across the lifecycle of aerospace activities. Furthermore, many perovskite formulations require significantly less rare earth elements and precious metals than traditional catalysts, alleviating pressure on environmentally sensitive mining operations and reducing resource depletion concerns.

The manufacturing processes for perovskite catalysts are evolving toward more environmentally benign methods. Recent advancements in green synthesis techniques have demonstrated potential for reducing toxic waste generation and energy consumption during production. These improvements align with the aerospace industry's growing commitment to sustainable manufacturing practices and circular economy principles, where materials are designed for maximum utility and minimal environmental impact throughout their lifecycle.

However, certain environmental challenges remain unresolved. The long-term stability of some perovskite formulations under extreme aerospace conditions may necessitate more frequent replacement, potentially increasing waste generation. Additionally, the environmental impact of novel perovskite compositions containing lead and other potentially toxic elements requires thorough assessment before widespread implementation. Leaching studies under various environmental conditions suggest that proper encapsulation and end-of-life management protocols will be essential to prevent environmental contamination.

Regulatory frameworks governing the environmental aspects of aerospace materials are evolving to address these novel catalyst technologies. The aerospace industry's adoption of perovskite catalysts will likely be influenced by emerging environmental legislation, particularly regarding emissions standards and materials restrictions. Forward-thinking aerospace manufacturers are already engaging in life cycle assessment studies to quantify the comparative environmental benefits of perovskite catalysts against conventional alternatives, providing valuable data for sustainability-focused decision-making.

The potential for perovskite catalysts to enable more efficient hydrogen-based propulsion systems represents another significant environmental opportunity. By improving the viability of hydrogen as an aerospace fuel through more efficient catalytic processes, perovskites could accelerate the transition away from carbon-intensive fuels, substantially reducing the sector's climate impact over the coming decades.

Space Qualification and Testing Protocols

Space qualification and testing protocols for perovskite catalysts represent a critical challenge for their implementation in aerospace applications. These materials must undergo rigorous evaluation to ensure they can withstand the extreme conditions encountered during space missions, including vacuum environments, radiation exposure, thermal cycling, and mechanical stress during launch.

Standard aerospace qualification procedures must be adapted specifically for perovskite catalysts, considering their unique structural and chemical properties. The testing regime typically begins with ground-based simulation of space environments in specialized chambers that can replicate vacuum conditions of 10^-6 torr or lower, while simultaneously exposing materials to radiation doses equivalent to those experienced in various orbital configurations.

Thermal cycling tests are particularly important for perovskite catalysts due to their known sensitivity to temperature fluctuations. Current protocols require materials to withstand rapid temperature variations between -150°C and +150°C for low Earth orbit applications, with more extreme ranges for deep space missions. Accelerated life testing methodologies have been developed to compress years of thermal cycling into manageable test periods, though correlation factors between accelerated and actual degradation remain under investigation.

Vibration and shock testing protocols follow MIL-STD-1540 guidelines, subjecting catalyst samples to forces exceeding 20G to simulate launch conditions. For perovskite catalysts specifically, additional attention must be paid to potential phase transitions or structural degradation under these mechanical stresses, as these could compromise catalytic performance.

Long-term stability verification presents unique challenges, as ground-based testing cannot fully replicate the combined effects of space conditions over extended periods. The aerospace industry has addressed this through the development of Technology Readiness Level (TRL) assessment frameworks specifically adapted for catalytic materials, requiring demonstration in increasingly representative environments before flight qualification.

Recent advances include the establishment of standardized test protocols for evaluating catalytic efficiency retention after exposure to atomic oxygen and solar UV radiation—two factors known to degrade surface properties of many materials in low Earth orbit. Several aerospace agencies have collaborated to develop reference test cases and performance benchmarks specifically for perovskite-based systems.

Qualification testing culminates in demonstration missions, where perovskite catalysts are deployed in non-critical subsystems to gather performance data in actual space environments before being approved for mission-critical applications. This graduated approach has successfully qualified several perovskite formulations for specific aerospace applications, though comprehensive standardization across the industry remains a work in progress.

Standard aerospace qualification procedures must be adapted specifically for perovskite catalysts, considering their unique structural and chemical properties. The testing regime typically begins with ground-based simulation of space environments in specialized chambers that can replicate vacuum conditions of 10^-6 torr or lower, while simultaneously exposing materials to radiation doses equivalent to those experienced in various orbital configurations.

Thermal cycling tests are particularly important for perovskite catalysts due to their known sensitivity to temperature fluctuations. Current protocols require materials to withstand rapid temperature variations between -150°C and +150°C for low Earth orbit applications, with more extreme ranges for deep space missions. Accelerated life testing methodologies have been developed to compress years of thermal cycling into manageable test periods, though correlation factors between accelerated and actual degradation remain under investigation.

Vibration and shock testing protocols follow MIL-STD-1540 guidelines, subjecting catalyst samples to forces exceeding 20G to simulate launch conditions. For perovskite catalysts specifically, additional attention must be paid to potential phase transitions or structural degradation under these mechanical stresses, as these could compromise catalytic performance.

Long-term stability verification presents unique challenges, as ground-based testing cannot fully replicate the combined effects of space conditions over extended periods. The aerospace industry has addressed this through the development of Technology Readiness Level (TRL) assessment frameworks specifically adapted for catalytic materials, requiring demonstration in increasingly representative environments before flight qualification.

Recent advances include the establishment of standardized test protocols for evaluating catalytic efficiency retention after exposure to atomic oxygen and solar UV radiation—two factors known to degrade surface properties of many materials in low Earth orbit. Several aerospace agencies have collaborated to develop reference test cases and performance benchmarks specifically for perovskite-based systems.

Qualification testing culminates in demonstration missions, where perovskite catalysts are deployed in non-critical subsystems to gather performance data in actual space environments before being approved for mission-critical applications. This graduated approach has successfully qualified several perovskite formulations for specific aerospace applications, though comprehensive standardization across the industry remains a work in progress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!