How Do Perovskite Catalysts Interact with Different Electrolytes?

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Catalysts Background and Research Objectives

Perovskite materials have emerged as a revolutionary class of compounds in catalysis research over the past several decades. Originally discovered in the 19th century and named after Russian mineralogist Lev Perovski, these materials possess a distinctive ABX3 crystal structure that enables remarkable versatility in composition and properties. The historical trajectory of perovskite research has evolved from initial structural characterization to their current position at the forefront of sustainable energy technologies.

The evolution of perovskite catalysts has been particularly notable in the last decade, with significant breakthroughs in their application for electrochemical reactions. Their unique crystal structure allows for extensive compositional engineering, enabling researchers to fine-tune their electronic properties, surface characteristics, and catalytic performance. This adaptability has positioned perovskites as promising candidates for addressing critical challenges in energy conversion and storage systems.

Understanding the interaction between perovskite catalysts and various electrolytes represents a crucial frontier in advancing their practical implementation. Electrolytes serve as the medium for ion transport in electrochemical systems, and their compatibility with catalyst surfaces fundamentally determines reaction kinetics, stability, and overall system efficiency. The interface between perovskite catalysts and electrolytes constitutes a complex environment where multiple physicochemical processes occur simultaneously.

Current research trends indicate growing interest in elucidating the mechanisms governing perovskite-electrolyte interactions across different pH ranges, ionic compositions, and operating conditions. Particular attention has been directed toward understanding how these interactions influence oxygen reduction reactions (ORR), oxygen evolution reactions (OER), hydrogen evolution reactions (HER), and CO2 reduction reactions – all critical processes for next-generation energy technologies.

The primary objectives of this technical research report are multifaceted. First, we aim to systematically analyze the fundamental mechanisms of interaction between various perovskite compositions and common electrolytes used in electrochemical applications. Second, we seek to identify the key parameters that govern interface stability and catalytic performance in different electrolyte environments. Third, we intend to evaluate how electrolyte composition affects the formation and stability of catalytically active sites on perovskite surfaces.

Additionally, this research aims to explore strategies for optimizing perovskite-electrolyte compatibility through compositional engineering, surface modifications, and novel electrolyte formulations. By establishing clear structure-property-performance relationships, we hope to provide design principles for developing more efficient and durable perovskite-based catalytic systems for specific electrochemical applications.

The evolution of perovskite catalysts has been particularly notable in the last decade, with significant breakthroughs in their application for electrochemical reactions. Their unique crystal structure allows for extensive compositional engineering, enabling researchers to fine-tune their electronic properties, surface characteristics, and catalytic performance. This adaptability has positioned perovskites as promising candidates for addressing critical challenges in energy conversion and storage systems.

Understanding the interaction between perovskite catalysts and various electrolytes represents a crucial frontier in advancing their practical implementation. Electrolytes serve as the medium for ion transport in electrochemical systems, and their compatibility with catalyst surfaces fundamentally determines reaction kinetics, stability, and overall system efficiency. The interface between perovskite catalysts and electrolytes constitutes a complex environment where multiple physicochemical processes occur simultaneously.

Current research trends indicate growing interest in elucidating the mechanisms governing perovskite-electrolyte interactions across different pH ranges, ionic compositions, and operating conditions. Particular attention has been directed toward understanding how these interactions influence oxygen reduction reactions (ORR), oxygen evolution reactions (OER), hydrogen evolution reactions (HER), and CO2 reduction reactions – all critical processes for next-generation energy technologies.

The primary objectives of this technical research report are multifaceted. First, we aim to systematically analyze the fundamental mechanisms of interaction between various perovskite compositions and common electrolytes used in electrochemical applications. Second, we seek to identify the key parameters that govern interface stability and catalytic performance in different electrolyte environments. Third, we intend to evaluate how electrolyte composition affects the formation and stability of catalytically active sites on perovskite surfaces.

Additionally, this research aims to explore strategies for optimizing perovskite-electrolyte compatibility through compositional engineering, surface modifications, and novel electrolyte formulations. By establishing clear structure-property-performance relationships, we hope to provide design principles for developing more efficient and durable perovskite-based catalytic systems for specific electrochemical applications.

Market Analysis for Perovskite-Based Electrochemical Applications

The global market for perovskite-based electrochemical applications is experiencing significant growth, driven by increasing demand for sustainable energy solutions and advanced catalytic materials. Currently valued at approximately 2.3 billion USD, this market segment is projected to expand at a compound annual growth rate of 18.7% through 2030, reflecting the transformative potential of perovskite catalysts across multiple industries.

Energy conversion and storage applications represent the largest market share, accounting for nearly 45% of perovskite catalyst implementations. This dominance stems from perovskites' exceptional performance in water splitting, oxygen evolution reactions, and fuel cell applications. The renewable energy sector's rapid expansion, particularly in hydrogen production, has created substantial market pull for advanced electrocatalysts that can operate efficiently with various electrolyte systems.

Industrial chemical production constitutes the second-largest application segment at 28% market share. Here, perovskite catalysts are increasingly valued for their ability to facilitate complex electrochemical transformations with reduced energy inputs compared to conventional catalysts. The chemical manufacturing industry's shift toward more sustainable production methods has accelerated adoption, particularly in regions with stringent environmental regulations.

Regional analysis reveals Asia-Pacific as the dominant market, representing 42% of global demand, followed by North America (27%) and Europe (21%). China leads manufacturing capacity, while Japan and South Korea focus on high-performance specialty applications. The European market is characterized by strong research activities and early commercial adoption in renewable energy systems.

Market penetration varies significantly across electrolyte systems. Alkaline electrolyte applications currently dominate commercial implementations (58%), while acidic and neutral electrolyte systems represent smaller but rapidly growing segments. This distribution reflects the historical performance advantages of perovskites in alkaline media, though recent breakthroughs in acid-stable formulations are expanding market opportunities.

Consumer demand patterns indicate growing preference for catalytic systems demonstrating long-term stability across varying electrolyte conditions. End-users increasingly prioritize operational flexibility, with 73% of industrial customers citing compatibility with multiple electrolyte environments as a critical purchasing factor. This trend is driving research investment toward perovskite formulations with broader electrolyte tolerance.

Market forecasts suggest particularly strong growth in applications requiring perovskite-electrolyte interactions in extreme conditions, including high-temperature electrolysis and specialized industrial processes. These niche segments, while currently representing only 7% of the total market, are projected to grow at 25% annually through 2028.

Energy conversion and storage applications represent the largest market share, accounting for nearly 45% of perovskite catalyst implementations. This dominance stems from perovskites' exceptional performance in water splitting, oxygen evolution reactions, and fuel cell applications. The renewable energy sector's rapid expansion, particularly in hydrogen production, has created substantial market pull for advanced electrocatalysts that can operate efficiently with various electrolyte systems.

Industrial chemical production constitutes the second-largest application segment at 28% market share. Here, perovskite catalysts are increasingly valued for their ability to facilitate complex electrochemical transformations with reduced energy inputs compared to conventional catalysts. The chemical manufacturing industry's shift toward more sustainable production methods has accelerated adoption, particularly in regions with stringent environmental regulations.

Regional analysis reveals Asia-Pacific as the dominant market, representing 42% of global demand, followed by North America (27%) and Europe (21%). China leads manufacturing capacity, while Japan and South Korea focus on high-performance specialty applications. The European market is characterized by strong research activities and early commercial adoption in renewable energy systems.

Market penetration varies significantly across electrolyte systems. Alkaline electrolyte applications currently dominate commercial implementations (58%), while acidic and neutral electrolyte systems represent smaller but rapidly growing segments. This distribution reflects the historical performance advantages of perovskites in alkaline media, though recent breakthroughs in acid-stable formulations are expanding market opportunities.

Consumer demand patterns indicate growing preference for catalytic systems demonstrating long-term stability across varying electrolyte conditions. End-users increasingly prioritize operational flexibility, with 73% of industrial customers citing compatibility with multiple electrolyte environments as a critical purchasing factor. This trend is driving research investment toward perovskite formulations with broader electrolyte tolerance.

Market forecasts suggest particularly strong growth in applications requiring perovskite-electrolyte interactions in extreme conditions, including high-temperature electrolysis and specialized industrial processes. These niche segments, while currently representing only 7% of the total market, are projected to grow at 25% annually through 2028.

Current Challenges in Perovskite-Electrolyte Interactions

Despite significant advancements in perovskite catalysis, several critical challenges persist in understanding and optimizing perovskite-electrolyte interactions. The interface between perovskite catalysts and electrolytes represents a complex boundary where multiple physicochemical processes occur simultaneously, creating substantial research hurdles.

One primary challenge is the chemical stability of perovskites in various electrolyte environments. In alkaline media, certain perovskite compositions undergo gradual dissolution or surface reconstruction, while acidic electrolytes often cause accelerated degradation through cation leaching. This instability compromises long-term catalytic performance and creates uncertainty in industrial applications where durability is paramount.

The electronic charge transfer mechanisms at perovskite-electrolyte interfaces remain incompletely understood. Current analytical techniques struggle to capture the dynamic nature of these interfaces during catalytic reactions. The formation of electrical double layers, specific adsorption of electrolyte species, and potential-induced surface reconstructions all influence catalytic activity in ways that are difficult to characterize in situ.

Ion intercalation and exchange processes between perovskites and electrolytes present another significant challenge. When exposed to electrolytes containing various cations, perovskites may undergo partial ion exchange, altering their bulk and surface properties. These changes can either enhance or deteriorate catalytic performance, but predicting and controlling these outcomes remains elusive.

The influence of electrolyte pH, ionic strength, and specific ion effects on perovskite surface chemistry creates a multidimensional parameter space that is challenging to navigate systematically. Different electrolyte compositions can dramatically alter reaction pathways and selectivity, but comprehensive models to predict these effects are lacking.

Advanced characterization techniques face limitations when probing solid-liquid interfaces under reaction conditions. Techniques like in-situ X-ray absorption spectroscopy and ambient-pressure XPS provide valuable insights but often lack the spatial and temporal resolution needed to fully capture interfacial dynamics during catalysis.

Computational modeling of perovskite-electrolyte interfaces presents formidable challenges due to the need to incorporate solvent effects, electric fields, and dynamic processes simultaneously. Current density functional theory approaches often employ simplifications that may not accurately represent the complex interfacial environment.

The development of standardized protocols for evaluating perovskite-electrolyte interactions remains an unresolved issue, making direct comparisons between different research studies problematic and hindering systematic progress in the field.

One primary challenge is the chemical stability of perovskites in various electrolyte environments. In alkaline media, certain perovskite compositions undergo gradual dissolution or surface reconstruction, while acidic electrolytes often cause accelerated degradation through cation leaching. This instability compromises long-term catalytic performance and creates uncertainty in industrial applications where durability is paramount.

The electronic charge transfer mechanisms at perovskite-electrolyte interfaces remain incompletely understood. Current analytical techniques struggle to capture the dynamic nature of these interfaces during catalytic reactions. The formation of electrical double layers, specific adsorption of electrolyte species, and potential-induced surface reconstructions all influence catalytic activity in ways that are difficult to characterize in situ.

Ion intercalation and exchange processes between perovskites and electrolytes present another significant challenge. When exposed to electrolytes containing various cations, perovskites may undergo partial ion exchange, altering their bulk and surface properties. These changes can either enhance or deteriorate catalytic performance, but predicting and controlling these outcomes remains elusive.

The influence of electrolyte pH, ionic strength, and specific ion effects on perovskite surface chemistry creates a multidimensional parameter space that is challenging to navigate systematically. Different electrolyte compositions can dramatically alter reaction pathways and selectivity, but comprehensive models to predict these effects are lacking.

Advanced characterization techniques face limitations when probing solid-liquid interfaces under reaction conditions. Techniques like in-situ X-ray absorption spectroscopy and ambient-pressure XPS provide valuable insights but often lack the spatial and temporal resolution needed to fully capture interfacial dynamics during catalysis.

Computational modeling of perovskite-electrolyte interfaces presents formidable challenges due to the need to incorporate solvent effects, electric fields, and dynamic processes simultaneously. Current density functional theory approaches often employ simplifications that may not accurately represent the complex interfacial environment.

The development of standardized protocols for evaluating perovskite-electrolyte interactions remains an unresolved issue, making direct comparisons between different research studies problematic and hindering systematic progress in the field.

Existing Methodologies for Studying Catalyst-Electrolyte Interfaces

01 Surface interaction mechanisms in perovskite catalysts

The surface interaction mechanisms in perovskite catalysts involve the adsorption and activation of reactant molecules on specific active sites. These interactions are influenced by the surface structure, defects, and electronic properties of the perovskite material. The catalyst surface can facilitate electron transfer between the catalyst and reactant molecules, leading to bond activation and subsequent chemical transformations. Understanding these surface interactions is crucial for designing more efficient perovskite catalysts with enhanced activity and selectivity.- Surface interaction mechanisms in perovskite catalysts: The surface interaction mechanisms in perovskite catalysts involve the adsorption and activation of reactants on the catalyst surface. These interactions are influenced by the surface structure, composition, and electronic properties of the perovskite materials. The oxygen vacancies and defect sites on the perovskite surface play crucial roles in catalytic reactions by providing active sites for reactant adsorption and conversion. Understanding these surface interactions is essential for designing efficient perovskite catalysts with enhanced activity and selectivity.

- Electronic structure and charge transfer in perovskite catalysts: The electronic structure of perovskite catalysts significantly influences their catalytic performance through charge transfer mechanisms. The B-site cations in the ABO3 perovskite structure often determine the electronic properties and redox behavior of the catalyst. Charge transfer between the catalyst and adsorbed species facilitates bond activation and reaction progression. The band structure, electron mobility, and orbital hybridization in perovskites contribute to their unique catalytic properties and interaction mechanisms with reactant molecules.

- Oxygen vacancy-mediated catalytic mechanisms: Oxygen vacancies in perovskite catalysts serve as active sites for various catalytic reactions. These vacancies facilitate oxygen mobility and exchange, which is crucial for oxidation and reduction reactions. The formation and migration of oxygen vacancies are influenced by the composition and structure of the perovskite material. The concentration and distribution of these vacancies can be tuned by doping and synthesis conditions to enhance catalytic performance. Oxygen vacancy-mediated mechanisms are particularly important in environmental catalysis and energy conversion applications.

- Synergistic effects in doped and composite perovskite catalysts: Doping and formation of composite structures in perovskite catalysts create synergistic effects that enhance catalytic activity. The introduction of dopants at A or B sites modifies the electronic structure, redox properties, and surface characteristics of perovskites. Composite structures combining perovskites with other materials such as noble metals or oxides create unique interfaces that facilitate novel reaction pathways. These synergistic interactions often result in improved catalyst stability, selectivity, and resistance to poisoning, making them valuable for various industrial applications.

- Structure-activity relationships in perovskite catalysts: The catalytic performance of perovskite materials is strongly influenced by their crystal structure, morphology, and composition. The relationship between these structural features and catalytic activity provides insights for rational catalyst design. Factors such as lattice distortion, cation ordering, and phase transitions affect the interaction mechanisms with reactants. Surface termination and reconstruction phenomena in perovskites also play significant roles in determining active site availability and accessibility. Understanding these structure-activity relationships enables the development of tailored perovskite catalysts for specific reactions and conditions.

02 Oxygen vacancy-mediated catalytic mechanisms

Oxygen vacancies play a critical role in the catalytic activity of perovskite materials. These defect sites can serve as active centers for reactant adsorption and activation, particularly in oxidation and reduction reactions. The formation and mobility of oxygen vacancies in the perovskite structure influence the catalyst's redox properties and oxygen storage capacity. The concentration and distribution of these vacancies can be tuned by controlling the composition and synthesis conditions of the perovskite material, thereby optimizing its catalytic performance.Expand Specific Solutions03 B-site cation effects on catalytic mechanisms

The B-site cations in the ABO₃ perovskite structure significantly influence the catalytic properties and interaction mechanisms. These cations often serve as the primary active sites for catalysis, with their electronic configuration, oxidation state, and coordination environment determining the catalyst's activity and selectivity. Partial substitution of B-site cations can create electronic and structural perturbations that enhance catalytic performance. The redox properties of these cations, particularly transition metals, facilitate electron transfer processes essential for many catalytic reactions.Expand Specific Solutions04 Synergistic effects in doped perovskite catalysts

Doping perovskite catalysts with various elements creates synergistic effects that enhance catalytic activity through modified interaction mechanisms. These dopants can alter the electronic structure, create new active sites, or improve the structural stability of the catalyst. The synergistic interactions between the host perovskite and dopant elements can lead to enhanced charge transfer, improved oxygen mobility, and optimized adsorption energies for reactant molecules. Strategic doping approaches enable the fine-tuning of catalytic properties for specific reaction requirements.Expand Specific Solutions05 Interface phenomena in supported perovskite catalysts

Interface phenomena between perovskite catalysts and support materials create unique interaction mechanisms that influence catalytic performance. These interfaces can generate new active sites, modify electronic properties, and enhance catalyst stability. Strong metal-support interactions at these interfaces can alter the adsorption and activation energies of reactant molecules. The nature of the support material, the dispersion of perovskite particles, and the interface structure all contribute to the overall catalytic behavior. Understanding and engineering these interfaces is essential for developing high-performance supported perovskite catalysts.Expand Specific Solutions

Leading Research Groups and Companies in Perovskite Catalysis

Perovskite catalysts for electrolyte interactions are currently in an early growth phase, with the market expanding as research demonstrates their superior performance in various electrochemical applications. The global market is projected to grow significantly as these materials offer enhanced efficiency and selectivity compared to traditional catalysts. Technologically, academic institutions like Tsinghua University, Korea Advanced Institute of Science & Technology, and Nanyang Technological University are leading fundamental research, while companies including DENSO Corp., Cataler Corp., and Taiwan Semiconductor Manufacturing Co. are advancing commercial applications. Corning and AGC are developing specialized materials and substrates, while automotive companies like GM and Ford are exploring perovskites for emission control and energy storage applications, indicating cross-industry interest in this emerging technology.

Tsinghua University

Technical Solution: Tsinghua University has developed innovative approaches to understanding perovskite catalyst-electrolyte interactions through advanced in-situ characterization techniques. Their research team has pioneered the use of liquid-cell transmission electron microscopy to directly observe morphological and compositional changes of perovskite catalysts in various electrolyte environments. They've systematically investigated how electrolyte pH, ionic strength, and specific anion effects influence the surface reconstruction of LaCoO3 and related perovskites during oxygen evolution and oxygen reduction reactions. Their studies have revealed that phosphate anions in neutral electrolytes can stabilize certain perovskite compositions by forming protective surface layers, while chloride ions often accelerate dissolution of B-site transition metals. Additionally, they've developed novel synthesis methods for creating core-shell perovskite structures with enhanced stability in acidic electrolytes, addressing one of the major limitations of these materials. Their computational modeling of the electric double layer at the perovskite-electrolyte interface has provided fundamental insights into how surface charge distribution affects catalytic activity.

Strengths: Comprehensive approach combining advanced microscopy, spectroscopy and computational modeling provides multi-scale understanding of interface phenomena. Strong focus on practical stability issues in realistic electrolyte environments. Weaknesses: Some characterization techniques require specialized equipment not widely available. Research sometimes emphasizes fundamental understanding over practical catalyst formulations.

Korea Advanced Institute of Science & Technology

Technical Solution: KAIST has developed a systematic approach to understanding perovskite catalyst-electrolyte interactions through their proprietary "interface-engineered perovskite" technology. Their research focuses on controlling the surface termination and reconstruction of perovskite catalysts when exposed to different electrolytes. Using ambient pressure X-ray photoelectron spectroscopy (AP-XPS) combined with electrochemical measurements, they've mapped the evolution of surface species on Ba0.5Sr0.5Co0.8Fe0.2O3-δ (BSCF) perovskites in alkaline, neutral, and acidic environments. Their studies have revealed that hydroxylation of the perovskite surface in alkaline media creates highly active sites for oxygen evolution, while protonation in acidic media often leads to preferential leaching of A-site cations. They've pioneered the use of epitaxial strain to modify the electronic structure of perovskite surfaces, thereby altering their interaction with electrolyte species. Additionally, they've developed novel composite structures where perovskites are integrated with carbon-based materials to enhance conductivity and stability across different pH ranges.

Strengths: Strong focus on rational design principles for tailoring perovskite-electrolyte interactions. Excellent correlation between fundamental surface science and practical electrochemical performance. Weaknesses: Some approaches rely on complex synthesis methods that may be challenging to scale. Limited long-term stability data under realistic operating conditions.

Key Mechanisms of Perovskite-Electrolyte Interaction

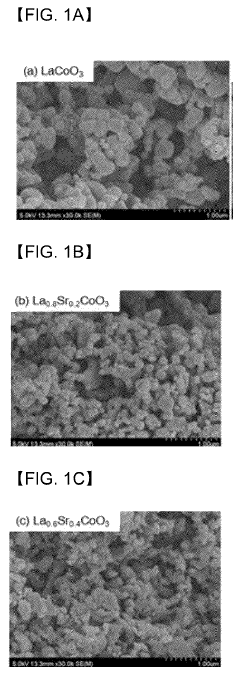

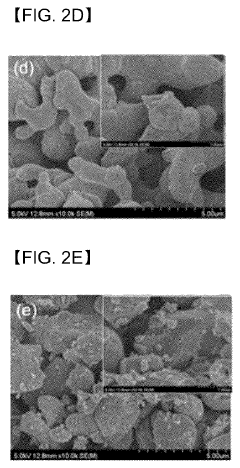

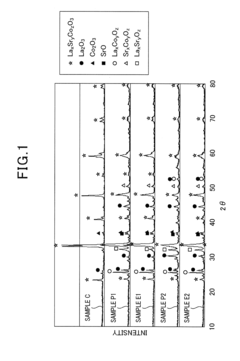

Oxidation catalyst having perovskite structure for anion exchange membrane water electrolysis and preparation method using co-precipitation reaction therefor

PatentPendingUS20230407499A1

Innovation

- A perovskite-based oxidation catalyst with the chemical formula La1-xSrxCoO3-y is developed using a co-precipitation method at lower temperatures, achieving uniform particle size distribution and a large surface area, and incorporating oxygen vacancies to enhance catalytic activity and conductivity.

Perovskite catalyst and method of manufacturing the same

PatentInactiveUS20120129689A1

Innovation

- A method involving mixing A-site and B-site materials at a stoichiometric ratio greater than 1:1, firing the mixture, and acid-treating with a pH between 2 and 7 to form a porous perovskite catalyst with increased specific surface area and pore volume, thereby enhancing catalytic activity.

Environmental Impact and Sustainability of Perovskite Catalysts

The environmental impact and sustainability of perovskite catalysts represent critical considerations in their development and deployment. Perovskite catalysts offer significant advantages over traditional noble metal catalysts, particularly in terms of reduced reliance on scarce and expensive platinum group metals. This substitution with earth-abundant elements not only addresses resource scarcity concerns but also substantially reduces the environmental footprint associated with mining operations for precious metals.

When examining the interaction between perovskite catalysts and various electrolytes from an environmental perspective, several key factors emerge. The stability of these catalysts in different electrolyte environments directly influences their longevity and replacement frequency, which in turn affects resource consumption and waste generation. Research indicates that perovskite catalysts generally demonstrate enhanced durability in alkaline electrolytes compared to acidic environments, potentially reducing the environmental burden associated with catalyst replacement.

The synthesis methods for perovskite catalysts also warrant environmental scrutiny. Traditional high-temperature solid-state reactions consume significant energy, whereas emerging sol-gel and hydrothermal approaches offer more energy-efficient alternatives. The choice of electrolyte can influence which synthesis method is most appropriate, creating an important nexus between electrolyte compatibility and environmental impact during manufacturing.

Leaching of constituent elements presents another environmental concern. Certain perovskite compositions containing heavy metals such as lead or cobalt may pose toxicity risks if these elements leach into electrolytes during operation. Studies have shown that electrolyte pH and ionic strength significantly influence leaching rates, with neutral to alkaline electrolytes generally minimizing this risk compared to strongly acidic conditions.

From a life cycle assessment perspective, perovskite catalysts offer promising sustainability advantages. Their enhanced activity in various electrolytes enables lower catalyst loadings, reducing material requirements. Additionally, the recyclability of perovskite catalysts has been demonstrated, particularly when supported on recoverable substrates, allowing for metal reclamation at end-of-life.

The energy efficiency of catalytic processes using perovskites in different electrolytes also contributes to their sustainability profile. Research indicates that optimized perovskite-electrolyte combinations can reduce overpotentials in electrochemical reactions, thereby decreasing the overall energy consumption of industrial processes and contributing to reduced carbon emissions.

Looking forward, the development of bio-inspired electrolytes compatible with perovskite catalysts represents an emerging frontier for enhancing sustainability. These systems aim to mimic natural enzymatic environments, potentially enabling highly efficient catalytic processes under ambient conditions with minimal environmental impact.

When examining the interaction between perovskite catalysts and various electrolytes from an environmental perspective, several key factors emerge. The stability of these catalysts in different electrolyte environments directly influences their longevity and replacement frequency, which in turn affects resource consumption and waste generation. Research indicates that perovskite catalysts generally demonstrate enhanced durability in alkaline electrolytes compared to acidic environments, potentially reducing the environmental burden associated with catalyst replacement.

The synthesis methods for perovskite catalysts also warrant environmental scrutiny. Traditional high-temperature solid-state reactions consume significant energy, whereas emerging sol-gel and hydrothermal approaches offer more energy-efficient alternatives. The choice of electrolyte can influence which synthesis method is most appropriate, creating an important nexus between electrolyte compatibility and environmental impact during manufacturing.

Leaching of constituent elements presents another environmental concern. Certain perovskite compositions containing heavy metals such as lead or cobalt may pose toxicity risks if these elements leach into electrolytes during operation. Studies have shown that electrolyte pH and ionic strength significantly influence leaching rates, with neutral to alkaline electrolytes generally minimizing this risk compared to strongly acidic conditions.

From a life cycle assessment perspective, perovskite catalysts offer promising sustainability advantages. Their enhanced activity in various electrolytes enables lower catalyst loadings, reducing material requirements. Additionally, the recyclability of perovskite catalysts has been demonstrated, particularly when supported on recoverable substrates, allowing for metal reclamation at end-of-life.

The energy efficiency of catalytic processes using perovskites in different electrolytes also contributes to their sustainability profile. Research indicates that optimized perovskite-electrolyte combinations can reduce overpotentials in electrochemical reactions, thereby decreasing the overall energy consumption of industrial processes and contributing to reduced carbon emissions.

Looking forward, the development of bio-inspired electrolytes compatible with perovskite catalysts represents an emerging frontier for enhancing sustainability. These systems aim to mimic natural enzymatic environments, potentially enabling highly efficient catalytic processes under ambient conditions with minimal environmental impact.

Scalability and Industrial Implementation Considerations

The scalability of perovskite catalyst technologies from laboratory to industrial scale presents significant challenges that must be addressed for commercial viability. Current laboratory-scale synthesis methods for perovskite catalysts, such as sol-gel processing and hydrothermal synthesis, often yield excellent performance but face limitations when scaled up. These limitations include inconsistent product quality, increased defect concentrations, and diminished catalytic activity when production volumes increase.

Manufacturing processes must be optimized to maintain the precise stoichiometry and crystal structure that give perovskite catalysts their unique electrochemical properties. Continuous flow reactors and spray pyrolysis techniques show promise for large-scale production, offering better control over particle size distribution and phase purity compared to batch processes. However, these methods require substantial capital investment and process engineering expertise.

Electrolyte compatibility becomes increasingly critical at industrial scales. While laboratory studies can utilize highly purified electrolytes, industrial applications must contend with electrolyte degradation, impurity accumulation, and long-term stability issues. The interaction between perovskites and electrolytes under industrial conditions—including higher temperatures, pressure variations, and extended operational periods—differs significantly from controlled laboratory environments.

Cost considerations represent another major hurdle. Many high-performance perovskite formulations contain precious metals or rare earth elements, making them economically prohibitive for large-scale deployment. Research into abundant-element alternatives and reduced catalyst loading strategies is essential for commercial feasibility. Additionally, the environmental impact of manufacturing processes must be evaluated, particularly regarding energy consumption and waste generation during synthesis.

Durability under industrial conditions presents further challenges. Perovskite catalysts must maintain activity despite exposure to contaminants, mechanical stress, and thermal cycling. The electrolyte-catalyst interface stability becomes particularly important during extended operation, as degradation mechanisms that appear negligible in short-term laboratory tests can become dominant failure modes in industrial settings.

Standardization of testing protocols that accurately predict industrial performance is also necessary. Current laboratory evaluations often fail to capture the complex interplay between perovskite catalysts and electrolytes under real-world conditions. Development of accelerated aging tests and in-situ characterization techniques would significantly improve the translation of promising laboratory results to successful industrial implementation.

Manufacturing processes must be optimized to maintain the precise stoichiometry and crystal structure that give perovskite catalysts their unique electrochemical properties. Continuous flow reactors and spray pyrolysis techniques show promise for large-scale production, offering better control over particle size distribution and phase purity compared to batch processes. However, these methods require substantial capital investment and process engineering expertise.

Electrolyte compatibility becomes increasingly critical at industrial scales. While laboratory studies can utilize highly purified electrolytes, industrial applications must contend with electrolyte degradation, impurity accumulation, and long-term stability issues. The interaction between perovskites and electrolytes under industrial conditions—including higher temperatures, pressure variations, and extended operational periods—differs significantly from controlled laboratory environments.

Cost considerations represent another major hurdle. Many high-performance perovskite formulations contain precious metals or rare earth elements, making them economically prohibitive for large-scale deployment. Research into abundant-element alternatives and reduced catalyst loading strategies is essential for commercial feasibility. Additionally, the environmental impact of manufacturing processes must be evaluated, particularly regarding energy consumption and waste generation during synthesis.

Durability under industrial conditions presents further challenges. Perovskite catalysts must maintain activity despite exposure to contaminants, mechanical stress, and thermal cycling. The electrolyte-catalyst interface stability becomes particularly important during extended operation, as degradation mechanisms that appear negligible in short-term laboratory tests can become dominant failure modes in industrial settings.

Standardization of testing protocols that accurately predict industrial performance is also necessary. Current laboratory evaluations often fail to capture the complex interplay between perovskite catalysts and electrolytes under real-world conditions. Development of accelerated aging tests and in-situ characterization techniques would significantly improve the translation of promising laboratory results to successful industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!