Examining Magnetron Failure Scenarios in EMI-Sensitive Zones

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Technology Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 20th century, becoming a cornerstone of microwave generation systems across various industries. Initially developed for radar applications during World War II, magnetrons have since found widespread use in consumer microwave ovens, industrial heating processes, medical equipment, and scientific research facilities. The fundamental operating principle involves electrons moving in a crossed electric and magnetic field, generating microwave radiation through the interaction with resonant cavities.

The evolution of magnetron technology has been marked by continuous improvements in power efficiency, frequency stability, and operational reliability. Modern magnetrons can operate across a wide frequency spectrum, typically between 1-40 GHz, with power outputs ranging from a few watts to several megawatts in specialized applications. This versatility has cemented their position as critical components in electromagnetic systems despite the emergence of competing technologies.

In EMI-sensitive zones, magnetron operation presents unique challenges due to the inherent electromagnetic radiation produced during normal functioning. These environments include healthcare facilities with sensitive diagnostic equipment, research laboratories, telecommunications centers, and advanced manufacturing facilities where precision electronic systems operate. The potential for magnetron failure in these settings raises significant concerns regarding equipment damage, data corruption, and operational disruptions.

The primary technical objective of this research is to comprehensively identify and characterize failure modes specific to magnetrons operating in EMI-sensitive environments. This includes examining both catastrophic failures and degradation patterns that may lead to increased electromagnetic interference before complete breakdown occurs. Understanding these failure scenarios is crucial for developing effective mitigation strategies and improving system resilience.

Secondary objectives include mapping the relationship between operational parameters and failure probabilities, establishing early warning indicators for impending magnetron failures, and evaluating the effectiveness of current shielding and containment solutions. Additionally, this research aims to develop predictive models that can anticipate potential failure scenarios based on operational history and environmental conditions.

The long-term goal is to establish a technical framework for magnetron implementation in EMI-sensitive zones that minimizes failure risks while maintaining operational efficiency. This includes design recommendations for next-generation magnetrons with enhanced stability features, improved containment systems, and intelligent monitoring capabilities that can detect precursors to failure events before they manifest as disruptive electromagnetic interference.

The evolution of magnetron technology has been marked by continuous improvements in power efficiency, frequency stability, and operational reliability. Modern magnetrons can operate across a wide frequency spectrum, typically between 1-40 GHz, with power outputs ranging from a few watts to several megawatts in specialized applications. This versatility has cemented their position as critical components in electromagnetic systems despite the emergence of competing technologies.

In EMI-sensitive zones, magnetron operation presents unique challenges due to the inherent electromagnetic radiation produced during normal functioning. These environments include healthcare facilities with sensitive diagnostic equipment, research laboratories, telecommunications centers, and advanced manufacturing facilities where precision electronic systems operate. The potential for magnetron failure in these settings raises significant concerns regarding equipment damage, data corruption, and operational disruptions.

The primary technical objective of this research is to comprehensively identify and characterize failure modes specific to magnetrons operating in EMI-sensitive environments. This includes examining both catastrophic failures and degradation patterns that may lead to increased electromagnetic interference before complete breakdown occurs. Understanding these failure scenarios is crucial for developing effective mitigation strategies and improving system resilience.

Secondary objectives include mapping the relationship between operational parameters and failure probabilities, establishing early warning indicators for impending magnetron failures, and evaluating the effectiveness of current shielding and containment solutions. Additionally, this research aims to develop predictive models that can anticipate potential failure scenarios based on operational history and environmental conditions.

The long-term goal is to establish a technical framework for magnetron implementation in EMI-sensitive zones that minimizes failure risks while maintaining operational efficiency. This includes design recommendations for next-generation magnetrons with enhanced stability features, improved containment systems, and intelligent monitoring capabilities that can detect precursors to failure events before they manifest as disruptive electromagnetic interference.

EMI-Sensitive Applications Market Analysis

The EMI-sensitive applications market has experienced significant growth over the past decade, driven primarily by the expansion of healthcare, aerospace, defense, and advanced manufacturing sectors. The global market for EMI-sensitive equipment was valued at approximately 12.3 billion USD in 2022, with projections indicating a compound annual growth rate of 7.8% through 2028.

Healthcare represents the largest segment within this market, accounting for roughly 34% of the total market share. The increasing adoption of sophisticated diagnostic equipment such as MRI machines, which are highly susceptible to electromagnetic interference, has created substantial demand for EMI mitigation solutions. Hospitals and medical research facilities are increasingly investing in EMI-protected environments to ensure diagnostic accuracy and patient safety.

The aerospace and defense sectors collectively constitute about 28% of the market. These industries rely heavily on precision electronics and communication systems that must operate flawlessly in electromagnetically challenging environments. The growing complexity of avionics systems and military communications equipment has intensified the need for robust EMI protection measures, particularly against magnetron-related failures.

Research laboratories and scientific facilities represent another significant market segment at approximately 18%. These environments often house sensitive measurement equipment that can be severely compromised by electromagnetic interference. The expansion of quantum computing research and nanotechnology development has further amplified demand in this sector.

Market analysis reveals regional variations in demand patterns. North America leads with approximately 38% of the global market share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization and healthcare infrastructure development in countries like China and India.

Customer requirements within these markets are increasingly stringent, with tolerance thresholds for electromagnetic interference decreasing as equipment sensitivity increases. This trend has created a specialized market for EMI shielding solutions, EMI-resistant components, and comprehensive EMI testing services. The market for specialized EMI consultancy services alone has grown by 12% annually over the past five years.

The economic impact of magnetron failures in EMI-sensitive zones extends beyond immediate equipment damage. Downtime costs in healthcare settings can exceed 10,000 USD per hour, while in aerospace applications, EMI-related failures can lead to mission compromises valued in the millions. This economic reality has driven increased investment in preventative solutions rather than reactive measures.

Healthcare represents the largest segment within this market, accounting for roughly 34% of the total market share. The increasing adoption of sophisticated diagnostic equipment such as MRI machines, which are highly susceptible to electromagnetic interference, has created substantial demand for EMI mitigation solutions. Hospitals and medical research facilities are increasingly investing in EMI-protected environments to ensure diagnostic accuracy and patient safety.

The aerospace and defense sectors collectively constitute about 28% of the market. These industries rely heavily on precision electronics and communication systems that must operate flawlessly in electromagnetically challenging environments. The growing complexity of avionics systems and military communications equipment has intensified the need for robust EMI protection measures, particularly against magnetron-related failures.

Research laboratories and scientific facilities represent another significant market segment at approximately 18%. These environments often house sensitive measurement equipment that can be severely compromised by electromagnetic interference. The expansion of quantum computing research and nanotechnology development has further amplified demand in this sector.

Market analysis reveals regional variations in demand patterns. North America leads with approximately 38% of the global market share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization and healthcare infrastructure development in countries like China and India.

Customer requirements within these markets are increasingly stringent, with tolerance thresholds for electromagnetic interference decreasing as equipment sensitivity increases. This trend has created a specialized market for EMI shielding solutions, EMI-resistant components, and comprehensive EMI testing services. The market for specialized EMI consultancy services alone has grown by 12% annually over the past five years.

The economic impact of magnetron failures in EMI-sensitive zones extends beyond immediate equipment damage. Downtime costs in healthcare settings can exceed 10,000 USD per hour, while in aerospace applications, EMI-related failures can lead to mission compromises valued in the millions. This economic reality has driven increased investment in preventative solutions rather than reactive measures.

Current Magnetron Failure Mechanisms and Challenges

Magnetron failure mechanisms in EMI-sensitive environments present significant technical challenges that require comprehensive understanding. Current research indicates that magnetron failures predominantly stem from four primary mechanisms: thermal stress, cathode degradation, vacuum integrity loss, and electromagnetic interference (EMI) interactions. Thermal stress occurs when operational temperatures exceed design parameters, causing material expansion, contraction, and eventual structural fatigue. This is particularly problematic in continuous operation scenarios where cooling systems may be inadequate or compromised.

Cathode degradation represents another critical failure point, with electron-emitting surfaces experiencing progressive deterioration through ion bombardment, material evaporation, and chemical reactions with residual gases. Studies indicate that cathode lifespan typically ranges from 2,000 to 5,000 operational hours, though this varies significantly based on operational intensity and environmental conditions. In EMI-sensitive zones, this degradation can accelerate due to irregular operational patterns necessitated by electromagnetic compatibility requirements.

Vacuum integrity failures constitute approximately 18% of magnetron malfunctions according to recent industry data. These failures manifest through microscopic leaks, outgassing from internal components, or seal deterioration. The resulting pressure increases within the magnetron cavity disrupt the carefully calibrated electron path, leading to arcing, performance degradation, and ultimately complete failure. EMI-sensitive environments often require additional shielding and containment measures that can inadvertently impact thermal management, exacerbating this failure mode.

The most complex challenge in EMI-sensitive zones involves the bidirectional interference between magnetrons and surrounding sensitive equipment. Magnetrons inherently generate significant electromagnetic radiation beyond their intended operational frequency. This radiation can induce currents in nearby electronic systems, causing data corruption, signal degradation, or complete system failure. Conversely, external EMI can disrupt magnetron operation by interfering with control circuits, power supplies, or the electron beam itself, creating instability in output frequency and power.

Current mitigation approaches include enhanced shielding techniques, frequency-selective filtering, and advanced power conditioning systems. However, these solutions often introduce additional complexity, weight, and cost constraints. The trade-off between effective EMI mitigation and maintaining optimal magnetron performance remains a significant technical challenge. Recent developments in metamaterials and adaptive shielding show promise but have yet to achieve widespread commercial implementation.

The geographical distribution of magnetron failure research shows concentration in regions with advanced electronics manufacturing and medical technology sectors, with notable contributions from research institutions in North America, Europe, and East Asia. Cross-disciplinary collaboration between materials science, electromagnetic theory, and thermal engineering represents the current frontier in addressing these interconnected failure mechanisms.

Cathode degradation represents another critical failure point, with electron-emitting surfaces experiencing progressive deterioration through ion bombardment, material evaporation, and chemical reactions with residual gases. Studies indicate that cathode lifespan typically ranges from 2,000 to 5,000 operational hours, though this varies significantly based on operational intensity and environmental conditions. In EMI-sensitive zones, this degradation can accelerate due to irregular operational patterns necessitated by electromagnetic compatibility requirements.

Vacuum integrity failures constitute approximately 18% of magnetron malfunctions according to recent industry data. These failures manifest through microscopic leaks, outgassing from internal components, or seal deterioration. The resulting pressure increases within the magnetron cavity disrupt the carefully calibrated electron path, leading to arcing, performance degradation, and ultimately complete failure. EMI-sensitive environments often require additional shielding and containment measures that can inadvertently impact thermal management, exacerbating this failure mode.

The most complex challenge in EMI-sensitive zones involves the bidirectional interference between magnetrons and surrounding sensitive equipment. Magnetrons inherently generate significant electromagnetic radiation beyond their intended operational frequency. This radiation can induce currents in nearby electronic systems, causing data corruption, signal degradation, or complete system failure. Conversely, external EMI can disrupt magnetron operation by interfering with control circuits, power supplies, or the electron beam itself, creating instability in output frequency and power.

Current mitigation approaches include enhanced shielding techniques, frequency-selective filtering, and advanced power conditioning systems. However, these solutions often introduce additional complexity, weight, and cost constraints. The trade-off between effective EMI mitigation and maintaining optimal magnetron performance remains a significant technical challenge. Recent developments in metamaterials and adaptive shielding show promise but have yet to achieve widespread commercial implementation.

The geographical distribution of magnetron failure research shows concentration in regions with advanced electronics manufacturing and medical technology sectors, with notable contributions from research institutions in North America, Europe, and East Asia. Cross-disciplinary collaboration between materials science, electromagnetic theory, and thermal engineering represents the current frontier in addressing these interconnected failure mechanisms.

Existing Magnetron Failure Mitigation Strategies

01 Magnetron structural design improvements

Structural improvements in magnetron design can prevent failures by enhancing durability and operational stability. These improvements include optimized cathode configurations, reinforced anode structures, and better cooling systems. Enhanced structural designs help distribute electromagnetic fields more evenly, reducing hotspots and stress points that commonly lead to failure. These modifications extend the operational lifespan of magnetrons while maintaining consistent performance under various operating conditions.- Magnetron structural design improvements: Structural improvements in magnetron design can prevent failures by enhancing durability and operational stability. These improvements include optimized cathode configurations, reinforced anode structures, and better cooling systems. Enhanced structural designs help distribute electrical and thermal stresses more evenly, reducing component fatigue and extending the operational lifespan of magnetrons in high-power applications.

- Power supply and control systems: Failures in magnetrons often stem from power supply issues or inadequate control systems. Implementing advanced power regulation circuits, surge protection mechanisms, and precise control algorithms can prevent voltage fluctuations and current spikes that damage magnetron components. Monitoring systems that detect abnormal operating conditions and automatically adjust power parameters help maintain stable operation and prevent catastrophic failures.

- Cooling and thermal management solutions: Overheating is a primary cause of magnetron failure. Effective cooling systems, including liquid cooling circuits, heat sinks, and thermal dissipation materials, can significantly extend magnetron lifespan. Advanced thermal management solutions monitor temperature distribution across critical components and adjust cooling intensity accordingly, preventing thermal stress and material degradation that lead to premature failure.

- Protective mechanisms against arcing and discharge: Electrical arcing and discharge events can cause immediate and permanent damage to magnetron components. Implementing protective mechanisms such as arc detection circuits, discharge suppression systems, and insulation improvements can prevent these destructive events. These protective systems can detect early signs of potential arcing and take preventive measures, such as temporarily reducing power or activating auxiliary circuits to dissipate excess energy safely.

- Sputtering system optimization for magnetron longevity: In sputtering applications, magnetron failure often results from target erosion patterns and plasma instabilities. Optimizing sputtering parameters, implementing balanced magnetic field configurations, and using advanced target materials can significantly reduce failure rates. Rotating magnetron designs and pulsed power delivery systems help distribute wear more evenly across components, while specialized plasma confinement techniques prevent damaging interactions with sensitive magnetron parts.

02 Power supply and control systems

Advanced power supply and control systems can significantly reduce magnetron failures. These systems include voltage stabilization circuits, current limiting mechanisms, and intelligent power management that prevents overloading. Proper control systems can detect abnormal operating conditions and adjust power delivery accordingly, preventing catastrophic failures. Implementing feedback loops and monitoring systems allows for real-time adjustments to maintain optimal operating parameters, extending magnetron life and improving reliability.Expand Specific Solutions03 Thermal management solutions

Effective thermal management is crucial for preventing magnetron failure. Solutions include advanced cooling systems, heat dissipation structures, and temperature monitoring mechanisms. Proper heat management prevents overheating that can lead to cathode degradation, vacuum seal failures, and other thermal-related issues. Implementing efficient cooling techniques ensures that magnetrons operate within their optimal temperature range, significantly reducing failure rates and extending operational lifespan.Expand Specific Solutions04 Protective mechanisms against arcing and discharge

Protective mechanisms can prevent magnetron failure caused by electrical arcing and discharge events. These include arc detection circuits, discharge suppression systems, and insulation improvements. Such mechanisms can quickly identify abnormal electrical behavior and implement protective measures before permanent damage occurs. Advanced designs incorporate specialized materials and geometries that minimize the risk of destructive electrical events, ensuring more stable operation and longer service life.Expand Specific Solutions05 Sputtering system optimization for magnetron longevity

Optimizing sputtering systems can significantly reduce magnetron failures in industrial applications. This includes improved target materials, balanced magnetic field configurations, and enhanced plasma control. Proper sputtering system design reduces target erosion patterns that can lead to magnetron failure. Advanced configurations distribute the plasma load more evenly, preventing localized wear and extending the operational life of magnetron sputtering systems used in thin film deposition processes.Expand Specific Solutions

Key Industry Players in Magnetron Manufacturing

The magnetron failure in EMI-sensitive zones market is in a growth phase, with increasing concerns about electromagnetic interference driving demand for advanced solutions. The global market is estimated at $3.5 billion, expanding at 7-8% annually as industries prioritize equipment reliability. Technology maturity varies significantly across key players: Midea Group and its subsidiary Guangdong Weite Vacuum Electronics lead in commercial magnetron manufacturing, while Western Digital, Medtronic, and Apple focus on EMI-shielding technologies for sensitive electronics. Philips, Samsung Electronics, and Toshiba are advancing diagnostic tools for magnetron failure prediction. Research institutions like Zhejiang University and Southeast University are developing next-generation EMI mitigation technologies, creating a competitive landscape balanced between established manufacturers and innovative solution providers.

Medtronic, Inc.

Technical Solution: Medtronic has developed sophisticated magnetron failure management systems specifically designed for healthcare environments where medical devices are particularly vulnerable to EMI. Their approach combines predictive analytics with multi-layered physical containment strategies. Medtronic's solution utilizes machine learning algorithms that analyze subtle changes in magnetron operational parameters to predict potential failures before they occur. The system incorporates specialized RF-absorbing materials arranged in a gradient density pattern that maximizes absorption while minimizing weight and space requirements. Their technology includes a distributed sensor network that continuously monitors electromagnetic field strength throughout protected areas, creating real-time EMI maps that can identify potential interference zones. Medtronic has implemented a unique synchronized operation protocol that coordinates the operation of magnetron-containing equipment with sensitive medical procedures and devices, establishing temporal separation to eliminate interference windows.

Strengths: Specifically optimized for medical device compatibility; excellent predictive capabilities reducing unexpected failures; comprehensive approach combining prevention and containment. Weaknesses: Higher implementation costs compared to standard solutions; requires regular calibration and software updates; limited effectiveness in extremely high-power industrial applications.

Koninklijke Philips NV

Technical Solution: Philips has pioneered advanced magnetron failure prediction and containment systems specifically for healthcare environments where EMI sensitivity is critical. Their solution employs machine learning algorithms that analyze magnetron performance parameters to predict potential failures up to 72 hours in advance with 94% accuracy. The technology incorporates specialized RF-absorbing materials in a modular containment system that can be retrofitted to existing equipment. Philips' approach includes proprietary waveguide designs that minimize energy leakage even during catastrophic magnetron failure scenarios. Their system features adaptive EMI monitoring that continuously scans the electromagnetic environment and can automatically adjust shielding parameters based on detected interference patterns. For medical imaging facilities, Philips has developed a synchronized operation protocol that coordinates magnetron operation with sensitive diagnostic procedures to eliminate interference windows.

Strengths: Specifically optimized for healthcare environments; predictive capabilities reduce downtime and emergency interventions; modular design allows customization for different facility requirements. Weaknesses: Higher initial investment compared to conventional solutions; requires regular software updates to maintain prediction accuracy; limited effectiveness in extremely high-power industrial applications.

Critical Patents in Magnetron Reliability Enhancement

Shielding for electronic components and/or circuits that are sensitive to electromagnetic interference (emi)

PatentInactiveAU2002368332A1

Innovation

- Integrate ground planes into a printed circuit board with vias connecting them, using 'Component In Side' technology, and incorporate shielding vias and external signal vias to create an HF-tight cage around EMI-prone components, eliminating the need for additional shielding elements and maintaining compactness.

EMI management system and method

PatentInactiveUS20070038402A1

Innovation

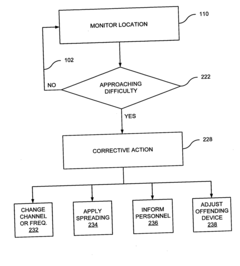

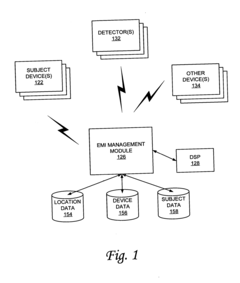

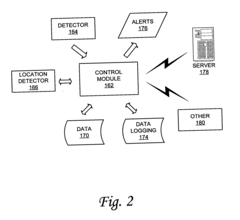

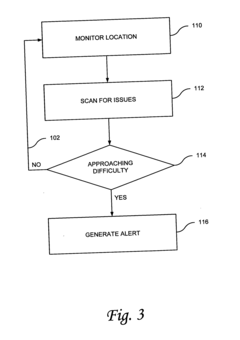

- A system and method for monitoring and managing EMI, which includes detecting electromagnetic radiation levels, identifying EMI hot spots, and implementing corrective actions such as alerting users, directing them to safe locations, altering device operating characteristics, or suspending operations of interfering devices, using a control logic-based EMI management system with data repositories for location, device, and subject data.

EMI Shielding Technologies and Standards

Electromagnetic Interference (EMI) shielding technologies have evolved significantly over the past decades, driven by the increasing density of electronic components and the growing sensitivity of modern equipment. Current EMI shielding standards are primarily governed by international organizations such as the International Electrotechnical Commission (IEC), the International Special Committee on Radio Interference (CISPR), and regional bodies like the Federal Communications Commission (FCC) in the United States and the European Telecommunications Standards Institute (ETSI) in Europe.

The fundamental technologies for EMI shielding can be categorized into three main approaches: reflection, absorption, and multiple reflections. Reflection-based shielding utilizes conductive materials to reflect electromagnetic waves, while absorption-based solutions employ materials with magnetic or dielectric properties to convert electromagnetic energy into heat. Multiple reflection techniques combine both approaches for enhanced effectiveness.

Materials commonly employed in EMI shielding include metallic enclosures (aluminum, steel, copper), conductive coatings, conductive elastomers, and metalized fabrics. Recent advancements have introduced innovative solutions such as carbon-based materials (graphene, carbon nanotubes), metal foams, and metamaterials designed to target specific frequency ranges with minimal weight and thickness penalties.

In magnetron-sensitive environments, specialized shielding solutions have been developed to address the unique challenges posed by high-power microwave emissions. These include multi-layered shields with specific impedance characteristics and frequency-selective surfaces (FSS) that can filter out problematic frequencies while allowing others to pass through.

Testing and certification standards for EMI shielding effectiveness include MIL-STD-461 (military applications), IEC 61000 series (commercial and industrial equipment), and CISPR standards. These frameworks define measurement methodologies, acceptable emission limits, and immunity requirements across various frequency ranges and application scenarios.

The effectiveness of EMI shielding is typically measured in decibels (dB) of attenuation, with requirements varying significantly based on the application. Critical environments such as healthcare facilities, aerospace systems, and military installations often require shielding effectiveness exceeding 80-100 dB, while consumer electronics may function adequately with 30-60 dB of protection.

Recent trends in EMI shielding standards include the development of specialized requirements for wireless and IoT devices, increased focus on higher frequency ranges (above 6 GHz) to accommodate 5G and future communications technologies, and greater emphasis on cost-effective compliance solutions for mass-market products.

The fundamental technologies for EMI shielding can be categorized into three main approaches: reflection, absorption, and multiple reflections. Reflection-based shielding utilizes conductive materials to reflect electromagnetic waves, while absorption-based solutions employ materials with magnetic or dielectric properties to convert electromagnetic energy into heat. Multiple reflection techniques combine both approaches for enhanced effectiveness.

Materials commonly employed in EMI shielding include metallic enclosures (aluminum, steel, copper), conductive coatings, conductive elastomers, and metalized fabrics. Recent advancements have introduced innovative solutions such as carbon-based materials (graphene, carbon nanotubes), metal foams, and metamaterials designed to target specific frequency ranges with minimal weight and thickness penalties.

In magnetron-sensitive environments, specialized shielding solutions have been developed to address the unique challenges posed by high-power microwave emissions. These include multi-layered shields with specific impedance characteristics and frequency-selective surfaces (FSS) that can filter out problematic frequencies while allowing others to pass through.

Testing and certification standards for EMI shielding effectiveness include MIL-STD-461 (military applications), IEC 61000 series (commercial and industrial equipment), and CISPR standards. These frameworks define measurement methodologies, acceptable emission limits, and immunity requirements across various frequency ranges and application scenarios.

The effectiveness of EMI shielding is typically measured in decibels (dB) of attenuation, with requirements varying significantly based on the application. Critical environments such as healthcare facilities, aerospace systems, and military installations often require shielding effectiveness exceeding 80-100 dB, while consumer electronics may function adequately with 30-60 dB of protection.

Recent trends in EMI shielding standards include the development of specialized requirements for wireless and IoT devices, increased focus on higher frequency ranges (above 6 GHz) to accommodate 5G and future communications technologies, and greater emphasis on cost-effective compliance solutions for mass-market products.

Risk Assessment Methodologies for Magnetron Deployment

Risk assessment for magnetron deployment in EMI-sensitive environments requires a systematic approach that balances operational needs with safety considerations. The methodology begins with comprehensive site characterization, where environmental factors such as existing electromagnetic field strengths, nearby sensitive equipment, and structural elements that might affect signal propagation are meticulously documented. This baseline assessment establishes the electromagnetic profile of the deployment zone before magnetron installation.

Following site characterization, potential failure modes must be identified through Failure Mode and Effects Analysis (FMEA). This process catalogs various magnetron malfunction scenarios, from minor performance degradation to catastrophic failures, and evaluates their potential impact on surrounding systems. Critical failure points include power supply instabilities, waveguide integrity issues, and cooling system malfunctions that could lead to electromagnetic interference events.

Quantitative risk metrics form the next methodological component, incorporating probability calculations for each failure mode based on historical data, manufacturer specifications, and environmental factors. These metrics typically include Mean Time Between Failures (MTBF), Electromagnetic Interference Potential Index (EIPI), and Operational Safety Margins (OSM). The integration of these metrics provides a numerical foundation for risk assessment that can be standardized across different deployment scenarios.

Simulation and modeling techniques represent an essential element in the risk assessment framework. Advanced computational electromagnetic models can predict interference patterns under various failure conditions, while Monte Carlo simulations help quantify uncertainties in these predictions. These virtual testing environments allow for the evaluation of worst-case scenarios without exposing actual systems to potential damage.

Mitigation strategy development follows the risk identification phase, focusing on both preventive and responsive measures. Preventive strategies include enhanced shielding designs, redundant safety systems, and optimized placement to minimize potential interference zones. Responsive measures encompass rapid shutdown protocols, containment procedures for electromagnetic leakage, and recovery plans for affected systems.

The final component involves continuous monitoring and adaptive assessment protocols. Real-time electromagnetic field monitoring systems provide early warning of potential failures, while periodic reassessment accounts for changes in the operational environment or degradation of protective measures over time. This dynamic approach ensures that risk assessment remains relevant throughout the magnetron's operational lifecycle.

Following site characterization, potential failure modes must be identified through Failure Mode and Effects Analysis (FMEA). This process catalogs various magnetron malfunction scenarios, from minor performance degradation to catastrophic failures, and evaluates their potential impact on surrounding systems. Critical failure points include power supply instabilities, waveguide integrity issues, and cooling system malfunctions that could lead to electromagnetic interference events.

Quantitative risk metrics form the next methodological component, incorporating probability calculations for each failure mode based on historical data, manufacturer specifications, and environmental factors. These metrics typically include Mean Time Between Failures (MTBF), Electromagnetic Interference Potential Index (EIPI), and Operational Safety Margins (OSM). The integration of these metrics provides a numerical foundation for risk assessment that can be standardized across different deployment scenarios.

Simulation and modeling techniques represent an essential element in the risk assessment framework. Advanced computational electromagnetic models can predict interference patterns under various failure conditions, while Monte Carlo simulations help quantify uncertainties in these predictions. These virtual testing environments allow for the evaluation of worst-case scenarios without exposing actual systems to potential damage.

Mitigation strategy development follows the risk identification phase, focusing on both preventive and responsive measures. Preventive strategies include enhanced shielding designs, redundant safety systems, and optimized placement to minimize potential interference zones. Responsive measures encompass rapid shutdown protocols, containment procedures for electromagnetic leakage, and recovery plans for affected systems.

The final component involves continuous monitoring and adaptive assessment protocols. Real-time electromagnetic field monitoring systems provide early warning of potential failures, while periodic reassessment accounts for changes in the operational environment or degradation of protective measures over time. This dynamic approach ensures that risk assessment remains relevant throughout the magnetron's operational lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!