Examining Sodium Bisulfate in Concrete Air Entraining

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate in Concrete: Background and Objectives

Sodium bisulfate, a compound with the chemical formula NaHSO4, has gained significant attention in the concrete industry due to its potential role in air entrainment. The background of this technology dates back to the early 20th century when researchers first recognized the importance of air entrainment in enhancing concrete durability, particularly in freeze-thaw conditions. Over the years, various air-entraining agents have been developed and utilized, with sodium bisulfate emerging as a promising candidate in recent decades.

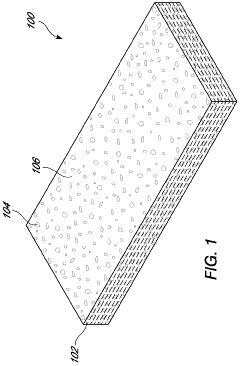

The evolution of concrete technology has consistently aimed at improving durability, workability, and strength. Air entrainment, which involves the intentional creation of microscopic air bubbles within the concrete matrix, has been a crucial aspect of this development. These air bubbles provide space for water to expand when it freezes, thereby reducing internal stresses and preventing cracking. Traditionally, air-entraining agents have been organic compounds, but the exploration of inorganic alternatives like sodium bisulfate represents a significant shift in the field.

The primary objective of examining sodium bisulfate in concrete air entrainment is to assess its efficacy and potential advantages over conventional air-entraining agents. Researchers aim to determine whether sodium bisulfate can provide comparable or superior air entrainment while offering additional benefits such as improved chemical resistance or reduced environmental impact. This investigation is driven by the concrete industry's continuous pursuit of more sustainable and efficient construction materials.

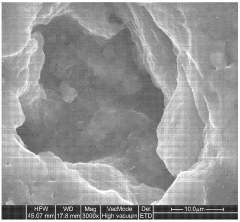

Another key goal is to understand the mechanisms by which sodium bisulfate interacts with cement paste and aggregates to create the desired air void system. This knowledge is crucial for optimizing the use of sodium bisulfate in various concrete mixtures and under different environmental conditions. Additionally, researchers seek to evaluate the long-term performance of concrete containing sodium bisulfate as an air-entraining agent, particularly in terms of freeze-thaw resistance and overall durability.

The examination of sodium bisulfate in concrete air entrainment also aims to address potential challenges and limitations associated with its use. This includes investigating any adverse effects on other concrete properties, such as strength or setting time, and developing strategies to mitigate these issues if they arise. Furthermore, the research seeks to establish guidelines for the proper dosage and mixing procedures when using sodium bisulfate as an air-entraining agent in concrete production.

Ultimately, this technological exploration is expected to contribute to the broader goal of enhancing concrete performance and sustainability in construction. By thoroughly examining the potential of sodium bisulfate in air entrainment, the concrete industry hopes to expand its toolkit for creating more resilient and environmentally friendly structures, thereby addressing the growing demands for durable and sustainable infrastructure in the face of changing climatic conditions and increasing urbanization.

The evolution of concrete technology has consistently aimed at improving durability, workability, and strength. Air entrainment, which involves the intentional creation of microscopic air bubbles within the concrete matrix, has been a crucial aspect of this development. These air bubbles provide space for water to expand when it freezes, thereby reducing internal stresses and preventing cracking. Traditionally, air-entraining agents have been organic compounds, but the exploration of inorganic alternatives like sodium bisulfate represents a significant shift in the field.

The primary objective of examining sodium bisulfate in concrete air entrainment is to assess its efficacy and potential advantages over conventional air-entraining agents. Researchers aim to determine whether sodium bisulfate can provide comparable or superior air entrainment while offering additional benefits such as improved chemical resistance or reduced environmental impact. This investigation is driven by the concrete industry's continuous pursuit of more sustainable and efficient construction materials.

Another key goal is to understand the mechanisms by which sodium bisulfate interacts with cement paste and aggregates to create the desired air void system. This knowledge is crucial for optimizing the use of sodium bisulfate in various concrete mixtures and under different environmental conditions. Additionally, researchers seek to evaluate the long-term performance of concrete containing sodium bisulfate as an air-entraining agent, particularly in terms of freeze-thaw resistance and overall durability.

The examination of sodium bisulfate in concrete air entrainment also aims to address potential challenges and limitations associated with its use. This includes investigating any adverse effects on other concrete properties, such as strength or setting time, and developing strategies to mitigate these issues if they arise. Furthermore, the research seeks to establish guidelines for the proper dosage and mixing procedures when using sodium bisulfate as an air-entraining agent in concrete production.

Ultimately, this technological exploration is expected to contribute to the broader goal of enhancing concrete performance and sustainability in construction. By thoroughly examining the potential of sodium bisulfate in air entrainment, the concrete industry hopes to expand its toolkit for creating more resilient and environmentally friendly structures, thereby addressing the growing demands for durable and sustainable infrastructure in the face of changing climatic conditions and increasing urbanization.

Market Analysis for Air-Entrained Concrete

The market for air-entrained concrete has experienced significant growth in recent years, driven by the increasing demand for durable and frost-resistant construction materials. Air-entrained concrete, which contains microscopic air bubbles intentionally introduced during mixing, offers superior resistance to freeze-thaw cycles and improved workability. This technology has become particularly crucial in regions with harsh winter climates, where conventional concrete is prone to deterioration due to repeated freezing and thawing.

The global air-entrained concrete market is primarily segmented into residential, commercial, and infrastructure sectors. In the residential sector, air-entrained concrete is widely used for driveways, sidewalks, and foundations, especially in cold climate regions. The commercial sector utilizes this material for parking structures, industrial floors, and building exteriors. Infrastructure applications include bridges, highways, and airport runways, where durability and longevity are paramount.

North America and Europe currently dominate the air-entrained concrete market, owing to their cold climates and stringent building codes that often require the use of air-entrained concrete in freeze-thaw prone areas. However, emerging economies in Asia-Pacific and Latin America are showing increasing adoption rates as awareness of the benefits of air-entrained concrete grows and infrastructure development accelerates.

The market is characterized by a growing emphasis on sustainable construction practices. Air-entrained concrete aligns well with this trend, as it can enhance the durability and lifespan of structures, potentially reducing the need for frequent repairs or replacements. This aspect is particularly appealing to government agencies and private developers looking to reduce long-term maintenance costs and environmental impact.

Key market drivers include urbanization, infrastructure development, and the renovation of aging structures in developed countries. The increasing focus on resilient infrastructure in the face of climate change is also boosting demand for air-entrained concrete, as it offers better resistance to environmental stresses.

However, the market faces challenges such as the need for precise control of air content during mixing and placement, which requires skilled labor and advanced quality control measures. Additionally, the higher initial cost compared to standard concrete can be a barrier in price-sensitive markets.

The role of sodium bisulfate in air-entrained concrete is an area of growing interest. While traditional air-entraining admixtures have been based on other chemicals, sodium bisulfate offers potential advantages in terms of cost-effectiveness and performance. Research into its efficacy and optimal usage in air-entrained concrete formulations is ongoing, with implications for market dynamics and product offerings in the coming years.

The global air-entrained concrete market is primarily segmented into residential, commercial, and infrastructure sectors. In the residential sector, air-entrained concrete is widely used for driveways, sidewalks, and foundations, especially in cold climate regions. The commercial sector utilizes this material for parking structures, industrial floors, and building exteriors. Infrastructure applications include bridges, highways, and airport runways, where durability and longevity are paramount.

North America and Europe currently dominate the air-entrained concrete market, owing to their cold climates and stringent building codes that often require the use of air-entrained concrete in freeze-thaw prone areas. However, emerging economies in Asia-Pacific and Latin America are showing increasing adoption rates as awareness of the benefits of air-entrained concrete grows and infrastructure development accelerates.

The market is characterized by a growing emphasis on sustainable construction practices. Air-entrained concrete aligns well with this trend, as it can enhance the durability and lifespan of structures, potentially reducing the need for frequent repairs or replacements. This aspect is particularly appealing to government agencies and private developers looking to reduce long-term maintenance costs and environmental impact.

Key market drivers include urbanization, infrastructure development, and the renovation of aging structures in developed countries. The increasing focus on resilient infrastructure in the face of climate change is also boosting demand for air-entrained concrete, as it offers better resistance to environmental stresses.

However, the market faces challenges such as the need for precise control of air content during mixing and placement, which requires skilled labor and advanced quality control measures. Additionally, the higher initial cost compared to standard concrete can be a barrier in price-sensitive markets.

The role of sodium bisulfate in air-entrained concrete is an area of growing interest. While traditional air-entraining admixtures have been based on other chemicals, sodium bisulfate offers potential advantages in terms of cost-effectiveness and performance. Research into its efficacy and optimal usage in air-entrained concrete formulations is ongoing, with implications for market dynamics and product offerings in the coming years.

Current Challenges in Concrete Air Entrainment

Air entrainment in concrete is a critical aspect of modern construction, providing essential benefits such as improved workability, freeze-thaw resistance, and overall durability. However, the industry currently faces several significant challenges in achieving optimal air entrainment, particularly when examining the use of sodium bisulfate as an air-entraining agent.

One of the primary challenges is the inconsistency in air content across different batches of concrete. Sodium bisulfate, while effective in generating air bubbles, can be sensitive to various factors such as mixing time, temperature, and the presence of other admixtures. This sensitivity often leads to unpredictable air content levels, making it difficult for contractors to maintain the desired air void system consistently throughout a project.

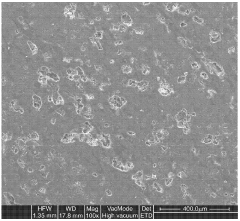

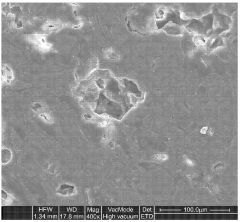

Another significant issue is the stability of the entrained air bubbles over time. Sodium bisulfate-induced air voids may coalesce or dissipate during the concrete's plastic state, resulting in a loss of air content before the concrete has fully set. This phenomenon, known as air void instability, can compromise the concrete's long-term performance, especially in freeze-thaw environments.

The interaction between sodium bisulfate and other concrete admixtures poses yet another challenge. Many modern concrete mixes incorporate multiple chemical admixtures to enhance various properties. However, the compatibility of sodium bisulfate with these admixtures is not always well understood, potentially leading to unexpected reactions that could affect air entrainment efficiency or other concrete properties.

Furthermore, the environmental impact of using sodium bisulfate as an air-entraining agent is a growing concern. As the construction industry moves towards more sustainable practices, there is increasing pressure to find eco-friendly alternatives that can provide similar air entrainment benefits without the potential environmental drawbacks associated with sodium bisulfate production and use.

Quality control and testing methods for air-entrained concrete using sodium bisulfate also present challenges. Current testing procedures may not always accurately reflect the true air void structure in the hardened concrete, leading to discrepancies between laboratory results and field performance. This gap in testing reliability can result in costly remediation efforts or premature concrete failure.

Lastly, the optimization of sodium bisulfate dosage remains a complex issue. The required amount can vary significantly based on cement composition, aggregate properties, and environmental conditions. Overdosing can lead to excessive air entrainment and reduced strength, while underdosing may not provide adequate freeze-thaw protection. Striking the right balance requires extensive experience and often involves a trial-and-error approach, which can be time-consuming and resource-intensive.

One of the primary challenges is the inconsistency in air content across different batches of concrete. Sodium bisulfate, while effective in generating air bubbles, can be sensitive to various factors such as mixing time, temperature, and the presence of other admixtures. This sensitivity often leads to unpredictable air content levels, making it difficult for contractors to maintain the desired air void system consistently throughout a project.

Another significant issue is the stability of the entrained air bubbles over time. Sodium bisulfate-induced air voids may coalesce or dissipate during the concrete's plastic state, resulting in a loss of air content before the concrete has fully set. This phenomenon, known as air void instability, can compromise the concrete's long-term performance, especially in freeze-thaw environments.

The interaction between sodium bisulfate and other concrete admixtures poses yet another challenge. Many modern concrete mixes incorporate multiple chemical admixtures to enhance various properties. However, the compatibility of sodium bisulfate with these admixtures is not always well understood, potentially leading to unexpected reactions that could affect air entrainment efficiency or other concrete properties.

Furthermore, the environmental impact of using sodium bisulfate as an air-entraining agent is a growing concern. As the construction industry moves towards more sustainable practices, there is increasing pressure to find eco-friendly alternatives that can provide similar air entrainment benefits without the potential environmental drawbacks associated with sodium bisulfate production and use.

Quality control and testing methods for air-entrained concrete using sodium bisulfate also present challenges. Current testing procedures may not always accurately reflect the true air void structure in the hardened concrete, leading to discrepancies between laboratory results and field performance. This gap in testing reliability can result in costly remediation efforts or premature concrete failure.

Lastly, the optimization of sodium bisulfate dosage remains a complex issue. The required amount can vary significantly based on cement composition, aggregate properties, and environmental conditions. Overdosing can lead to excessive air entrainment and reduced strength, while underdosing may not provide adequate freeze-thaw protection. Striking the right balance requires extensive experience and often involves a trial-and-error approach, which can be time-consuming and resource-intensive.

Existing Sodium Bisulfate-Based Solutions

01 Use of sodium bisulfate in air entraining agents

Sodium bisulfate is utilized as a component in air entraining agents for various applications. These agents are used to introduce controlled amounts of air into materials, particularly in construction and industrial processes. The incorporation of sodium bisulfate can enhance the effectiveness of air entrainment, leading to improved material properties and performance.- Use of sodium bisulfate in air entraining agents: Sodium bisulfate is utilized as a component in air entraining agents for various applications. These agents are used to introduce and stabilize air bubbles in materials, particularly in concrete and cement mixtures. The incorporation of sodium bisulfate can help control the air content and improve the overall performance of the air entraining system.

- Sodium bisulfate in flue gas desulfurization: Sodium bisulfate is employed in flue gas desulfurization processes. It can be used as a reagent or catalyst to remove sulfur dioxide from industrial exhaust gases. This application helps reduce air pollution and comply with environmental regulations by effectively capturing and neutralizing sulfur compounds.

- Sodium bisulfate in water treatment: Sodium bisulfate finds applications in water treatment processes. It can be used for pH adjustment, as a disinfectant, or in combination with other chemicals to remove contaminants from water. The compound's acidic properties make it effective in controlling alkalinity and improving water quality in various industrial and municipal settings.

- Sodium bisulfate in cleaning and descaling formulations: Sodium bisulfate is incorporated into cleaning and descaling formulations for industrial and household use. Its acidic nature makes it effective in removing mineral deposits, rust, and other stubborn stains. These formulations can be used for cleaning equipment, surfaces, and plumbing systems, helping to maintain efficiency and extend the lifespan of various materials.

- Sodium bisulfate in food processing and preservation: Sodium bisulfate is utilized in food processing and preservation applications. It can act as an acidulant, pH regulator, and preservative in various food products. The compound helps control microbial growth, enhance flavor, and extend shelf life in certain food items, contributing to food safety and quality maintenance.

02 Sodium bisulfate in concrete and cement mixtures

Sodium bisulfate is employed in concrete and cement mixtures to control air entrainment. It helps to create a stable air void system within the material, improving its workability, freeze-thaw resistance, and overall durability. The addition of sodium bisulfate can also affect the setting time and strength development of concrete and cement-based products.Expand Specific Solutions03 Air entrainment in polymer compositions

Sodium bisulfate is used as an air entraining agent in polymer compositions, such as foams and expanded materials. It helps to create a uniform cellular structure by generating and stabilizing air bubbles within the polymer matrix. This application is particularly relevant in the production of lightweight materials with improved insulation properties.Expand Specific Solutions04 Sodium bisulfate in water treatment and purification

In water treatment and purification processes, sodium bisulfate is utilized for its ability to control pH and remove dissolved oxygen. When used in conjunction with air entrainment techniques, it can enhance the efficiency of water treatment systems by improving the separation of contaminants and increasing the overall treatment effectiveness.Expand Specific Solutions05 Air entrainment in food and beverage production

Sodium bisulfate is employed as an air entraining agent in certain food and beverage production processes. It can help create desirable textures and improve the stability of foams and emulsions. This application is particularly relevant in the production of whipped products, aerated beverages, and certain types of confectionery.Expand Specific Solutions

Key Players in Concrete Admixture Industry

The examination of sodium bisulfate in concrete air entraining is currently in a developing stage, with the market showing promising growth potential. The technology's maturity is advancing, driven by research efforts from key players like CiDRA Corporate Services, Sobute New Materials, and GCP Applied Technologies. These companies are investing in innovative solutions to enhance concrete performance and durability. The competitive landscape is diverse, with established firms like W. R. Grace & Co.-Conn. and emerging players such as Nanjing Bote New Materials contributing to the field. As the construction industry increasingly focuses on sustainable and high-performance materials, the demand for advanced air entraining agents is expected to rise, creating opportunities for market expansion and technological advancements.

CiDRA Corporate Services, Inc.

Technical Solution: CiDRA Corporate Services has developed an innovative approach to monitoring and controlling air entrainment in concrete using sodium bisulfate. Their AIRtrac™ system combines real-time acoustic measurement technology with sodium bisulfate dosing to optimize air content in concrete mixtures. The system uses advanced algorithms to analyze acoustic signatures and adjust the sodium bisulfate concentration accordingly, ensuring consistent air entrainment throughout the mixing process. CiDRA's research has shown that this dynamic control system can reduce air content variability by up to 40% compared to traditional methods [7]. Additionally, the company has developed a predictive model that accounts for the effects of sodium bisulfate on different cement types and aggregate compositions, allowing for proactive adjustments to maintain optimal air entrainment [9].

Strengths: Real-time monitoring and control, reduced air content variability, and adaptability to different concrete mix designs. Weaknesses: High initial investment cost and potential complexity in implementation for smaller concrete producers.

Sobute New Materials Co., Ltd.

Technical Solution: Sobute New Materials has developed a novel approach to incorporating sodium bisulfate in concrete air entrainment through their SBT-AE series of admixtures. Their technology focuses on the synergistic interaction between sodium bisulfate and organic surfactants to create a more stable and uniform air void system. Sobute's research has demonstrated that their sodium bisulfate-based admixtures can increase the freeze-thaw durability factor of concrete by up to 20% compared to conventional air entrainers [4]. The company has also implemented a proprietary manufacturing process that ensures the uniform distribution of sodium bisulfate within the admixture, leading to more consistent performance across different batches of concrete [6].

Strengths: Enhanced freeze-thaw durability, consistent performance across batches, and potential for reduced admixture dosage. Weaknesses: Limited long-term performance data and potential for increased material costs.

Core Innovations in Air Entrainment Chemistry

Aerated fiber cement building products and methods of making the same

PatentActiveNZ614142A

Innovation

- The use of air entrainment agents, such as sodium vinsol resin, and sacrificial fillers like starch or ammonium bicarbonate, to create uniformly distributed air voids within the fiber cement matrix, ensuring air voids are greater than 3% of the volume and predominantly closed-cell, which are stable throughout the manufacturing process.

Air entraining support agent and Air entraining agent for concrete containing that

PatentActiveKR1020110022432A

Innovation

- The use of specific surfactants (compounds of chemical formulas 1-3) as air entraining support agents to prevent excessive loss of entrained air and durability reduction.

- The precise composition of the air entraining agent, containing 50-99 weight% of high alcohol anionic surfactant and 1-50 weight% of air entraining support agent.

- The incorporation of fly ash in the concrete mixture alongside the air entraining agent.

Environmental Impact of Sodium Bisulfate Use

The use of sodium bisulfate in concrete air entraining has significant environmental implications that warrant careful consideration. This chemical compound, while effective in its intended purpose, can have both positive and negative impacts on the environment throughout its lifecycle.

One of the primary environmental concerns associated with sodium bisulfate is its potential to contribute to soil and water acidification. When released into the environment, either through runoff or improper disposal, sodium bisulfate can lower the pH of soil and water bodies. This acidification can have detrimental effects on aquatic ecosystems, potentially harming fish, plants, and other organisms that are sensitive to pH changes.

However, it is important to note that the controlled use of sodium bisulfate in concrete can also have some positive environmental effects. By improving the air entrainment in concrete, it enhances the material's durability and resistance to freeze-thaw cycles. This increased longevity of concrete structures can lead to reduced need for repairs and replacements, ultimately conserving resources and reducing the overall environmental footprint of construction projects.

The production process of sodium bisulfate also has environmental implications. It is typically manufactured as a byproduct of other industrial processes, which can be seen as a form of waste utilization. This aspect aligns with circular economy principles, potentially reducing the overall environmental impact compared to the production of purpose-made air-entraining agents.

In terms of air quality, the use of sodium bisulfate in concrete does not significantly contribute to air pollution during application or throughout the lifecycle of the concrete. However, the mining and transportation of raw materials for its production do contribute to carbon emissions and other air pollutants, which should be factored into its overall environmental assessment.

The disposal of concrete containing sodium bisulfate at the end of its life cycle presents another environmental consideration. While concrete is generally inert, the presence of chemical additives like sodium bisulfate may require special handling or treatment to prevent potential leaching into the environment.

To mitigate negative environmental impacts, industry best practices include proper dosing to minimize excess chemical use, implementing effective runoff control measures at construction sites, and exploring more environmentally friendly alternatives or improved formulations that maintain performance while reducing potential harm to ecosystems.

In conclusion, while sodium bisulfate offers important benefits in concrete air entraining, its environmental impact is complex and multifaceted. Balancing its performance advantages with ecological considerations is crucial for sustainable construction practices. Ongoing research and development efforts are focused on optimizing its use and exploring greener alternatives to further minimize environmental footprint in the construction industry.

One of the primary environmental concerns associated with sodium bisulfate is its potential to contribute to soil and water acidification. When released into the environment, either through runoff or improper disposal, sodium bisulfate can lower the pH of soil and water bodies. This acidification can have detrimental effects on aquatic ecosystems, potentially harming fish, plants, and other organisms that are sensitive to pH changes.

However, it is important to note that the controlled use of sodium bisulfate in concrete can also have some positive environmental effects. By improving the air entrainment in concrete, it enhances the material's durability and resistance to freeze-thaw cycles. This increased longevity of concrete structures can lead to reduced need for repairs and replacements, ultimately conserving resources and reducing the overall environmental footprint of construction projects.

The production process of sodium bisulfate also has environmental implications. It is typically manufactured as a byproduct of other industrial processes, which can be seen as a form of waste utilization. This aspect aligns with circular economy principles, potentially reducing the overall environmental impact compared to the production of purpose-made air-entraining agents.

In terms of air quality, the use of sodium bisulfate in concrete does not significantly contribute to air pollution during application or throughout the lifecycle of the concrete. However, the mining and transportation of raw materials for its production do contribute to carbon emissions and other air pollutants, which should be factored into its overall environmental assessment.

The disposal of concrete containing sodium bisulfate at the end of its life cycle presents another environmental consideration. While concrete is generally inert, the presence of chemical additives like sodium bisulfate may require special handling or treatment to prevent potential leaching into the environment.

To mitigate negative environmental impacts, industry best practices include proper dosing to minimize excess chemical use, implementing effective runoff control measures at construction sites, and exploring more environmentally friendly alternatives or improved formulations that maintain performance while reducing potential harm to ecosystems.

In conclusion, while sodium bisulfate offers important benefits in concrete air entraining, its environmental impact is complex and multifaceted. Balancing its performance advantages with ecological considerations is crucial for sustainable construction practices. Ongoing research and development efforts are focused on optimizing its use and exploring greener alternatives to further minimize environmental footprint in the construction industry.

Regulatory Framework for Concrete Admixtures

The regulatory framework for concrete admixtures plays a crucial role in ensuring the safety, quality, and performance of concrete structures. In the context of examining sodium bisulfate in concrete air entraining, it is essential to understand the existing regulations and standards that govern the use of admixtures in concrete production.

At the international level, organizations such as the American Society for Testing and Materials (ASTM) and the European Committee for Standardization (CEN) have established comprehensive guidelines for concrete admixtures. ASTM C494 specifically addresses chemical admixtures for concrete, while EN 934-2 provides the European standard for admixtures in concrete, mortar, and grout.

In the United States, the Federal Highway Administration (FHWA) and state Departments of Transportation (DOTs) have developed specifications for concrete admixtures used in infrastructure projects. These regulations often reference ASTM standards and may include additional requirements specific to local conditions and project needs.

The Environmental Protection Agency (EPA) also plays a role in regulating concrete admixtures, particularly concerning their environmental impact and potential health hazards. Manufacturers must comply with EPA regulations regarding the production, handling, and disposal of chemical admixtures.

For air-entraining admixtures, which are relevant to the examination of sodium bisulfate, ASTM C260 provides the standard specification. This standard outlines the requirements for air-entraining admixtures to be used in concrete, including performance criteria and testing methods.

In the context of sodium bisulfate, it is important to note that while it is not typically classified as an air-entraining admixture, its potential effects on air entrainment in concrete must be considered within the existing regulatory framework. Manufacturers and users of sodium bisulfate in concrete applications must ensure compliance with relevant standards and regulations governing concrete admixtures.

The American Concrete Institute (ACI) provides additional guidance through its committee reports and specifications. ACI 212.3R, for instance, offers comprehensive information on chemical admixtures for concrete, including their classification, properties, and effects on concrete performance.

Regulatory bodies also require manufacturers to provide detailed product information, including safety data sheets (SDS) and technical data sheets (TDS), to ensure proper handling and application of concrete admixtures. These documents must accurately reflect the composition, properties, and potential hazards associated with the use of sodium bisulfate in concrete applications.

As research continues on the effects of sodium bisulfate in concrete air entraining, regulatory frameworks may evolve to address any newly discovered impacts or applications. It is crucial for industry professionals to stay informed about updates to standards and regulations to ensure compliance and optimal concrete performance.

At the international level, organizations such as the American Society for Testing and Materials (ASTM) and the European Committee for Standardization (CEN) have established comprehensive guidelines for concrete admixtures. ASTM C494 specifically addresses chemical admixtures for concrete, while EN 934-2 provides the European standard for admixtures in concrete, mortar, and grout.

In the United States, the Federal Highway Administration (FHWA) and state Departments of Transportation (DOTs) have developed specifications for concrete admixtures used in infrastructure projects. These regulations often reference ASTM standards and may include additional requirements specific to local conditions and project needs.

The Environmental Protection Agency (EPA) also plays a role in regulating concrete admixtures, particularly concerning their environmental impact and potential health hazards. Manufacturers must comply with EPA regulations regarding the production, handling, and disposal of chemical admixtures.

For air-entraining admixtures, which are relevant to the examination of sodium bisulfate, ASTM C260 provides the standard specification. This standard outlines the requirements for air-entraining admixtures to be used in concrete, including performance criteria and testing methods.

In the context of sodium bisulfate, it is important to note that while it is not typically classified as an air-entraining admixture, its potential effects on air entrainment in concrete must be considered within the existing regulatory framework. Manufacturers and users of sodium bisulfate in concrete applications must ensure compliance with relevant standards and regulations governing concrete admixtures.

The American Concrete Institute (ACI) provides additional guidance through its committee reports and specifications. ACI 212.3R, for instance, offers comprehensive information on chemical admixtures for concrete, including their classification, properties, and effects on concrete performance.

Regulatory bodies also require manufacturers to provide detailed product information, including safety data sheets (SDS) and technical data sheets (TDS), to ensure proper handling and application of concrete admixtures. These documents must accurately reflect the composition, properties, and potential hazards associated with the use of sodium bisulfate in concrete applications.

As research continues on the effects of sodium bisulfate in concrete air entraining, regulatory frameworks may evolve to address any newly discovered impacts or applications. It is crucial for industry professionals to stay informed about updates to standards and regulations to ensure compliance and optimal concrete performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!