Exploring Alternative Fuels Compatibility with B58 Engine Design

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine and Alt Fuels Background

The B58 engine, developed by BMW, represents a significant advancement in internal combustion engine technology. Introduced in 2015, this 3.0-liter inline-six turbocharged engine has become a cornerstone of BMW's powertrain lineup, known for its efficiency, power output, and adaptability across various vehicle platforms. The B58 engine's design incorporates several innovative features, including a closed-deck engine block, air-to-water intercooler, and advanced turbocharging technology, which contribute to its high performance and fuel efficiency.

As global concerns about environmental sustainability and energy security continue to grow, the automotive industry is increasingly exploring alternative fuels as a means to reduce carbon emissions and dependence on fossil fuels. This exploration has led to a renewed interest in adapting existing engine designs, such as the B58, to accommodate alternative fuel sources while maintaining or improving performance characteristics.

Alternative fuels encompass a wide range of options, including but not limited to ethanol, biodiesel, hydrogen, and synthetic fuels. Each of these alternatives presents unique challenges and opportunities when considering compatibility with modern engine designs. Ethanol, for instance, has a higher octane rating than gasoline, which can potentially allow for increased engine efficiency, but it also has a lower energy density and can be more corrosive to certain engine components.

The compatibility of the B58 engine with alternative fuels is a complex issue that involves considerations of material compatibility, fuel system design, combustion characteristics, and emissions control. The engine's advanced fuel injection system and robust construction provide a solid foundation for potential adaptation to alternative fuels. However, significant research and development efforts are required to ensure that any modifications maintain the engine's reliability, performance, and compliance with increasingly stringent emissions regulations.

Exploring the compatibility of alternative fuels with the B58 engine design is not only a technical challenge but also a strategic imperative for BMW and the automotive industry at large. As governments worldwide implement stricter emissions standards and push for the adoption of cleaner technologies, the ability to adapt existing high-performance engines to alternative fuels could provide a crucial bridge between current internal combustion technology and future powertrain solutions.

This exploration also aligns with broader industry trends towards sustainability and the circular economy. By investigating ways to extend the viability of existing engine designs through alternative fuel compatibility, manufacturers can potentially reduce the environmental impact of vehicle production while continuing to meet consumer demands for performance and reliability.

As global concerns about environmental sustainability and energy security continue to grow, the automotive industry is increasingly exploring alternative fuels as a means to reduce carbon emissions and dependence on fossil fuels. This exploration has led to a renewed interest in adapting existing engine designs, such as the B58, to accommodate alternative fuel sources while maintaining or improving performance characteristics.

Alternative fuels encompass a wide range of options, including but not limited to ethanol, biodiesel, hydrogen, and synthetic fuels. Each of these alternatives presents unique challenges and opportunities when considering compatibility with modern engine designs. Ethanol, for instance, has a higher octane rating than gasoline, which can potentially allow for increased engine efficiency, but it also has a lower energy density and can be more corrosive to certain engine components.

The compatibility of the B58 engine with alternative fuels is a complex issue that involves considerations of material compatibility, fuel system design, combustion characteristics, and emissions control. The engine's advanced fuel injection system and robust construction provide a solid foundation for potential adaptation to alternative fuels. However, significant research and development efforts are required to ensure that any modifications maintain the engine's reliability, performance, and compliance with increasingly stringent emissions regulations.

Exploring the compatibility of alternative fuels with the B58 engine design is not only a technical challenge but also a strategic imperative for BMW and the automotive industry at large. As governments worldwide implement stricter emissions standards and push for the adoption of cleaner technologies, the ability to adapt existing high-performance engines to alternative fuels could provide a crucial bridge between current internal combustion technology and future powertrain solutions.

This exploration also aligns with broader industry trends towards sustainability and the circular economy. By investigating ways to extend the viability of existing engine designs through alternative fuel compatibility, manufacturers can potentially reduce the environmental impact of vehicle production while continuing to meet consumer demands for performance and reliability.

Market Demand Analysis

The market demand for alternative fuels compatible with the B58 engine design has been steadily growing in recent years, driven by several key factors. Environmental concerns and stringent emissions regulations have pushed automakers to explore cleaner fuel options that can reduce carbon footprints while maintaining high performance standards. The B58 engine, known for its robust design and versatility, presents an excellent platform for alternative fuel adaptation.

Consumer interest in sustainable transportation solutions has significantly increased, with many buyers actively seeking vehicles that offer reduced environmental impact without compromising on power and drivability. This shift in consumer preferences has created a substantial market opportunity for alternative fuel-compatible engines, particularly in regions with strong environmental policies and incentives for eco-friendly vehicles.

The automotive industry has witnessed a surge in research and development activities focused on alternative fuels, including advanced biofuels, synthetic fuels, and hydrogen. These efforts aim to address the growing demand for sustainable mobility solutions while leveraging existing engine architectures like the B58. The market for alternative fuel-compatible engines is expected to expand rapidly, with projections indicating a compound annual growth rate of over 8% in the next five years.

Fleet operators and commercial vehicle manufacturers have shown particular interest in alternative fuel options for the B58 engine, driven by the potential for reduced operating costs and compliance with increasingly stringent emissions standards. This sector represents a significant portion of the market demand, as large-scale adoption of alternative fuels in commercial fleets can lead to substantial environmental benefits and cost savings.

Government initiatives and policies promoting the use of alternative fuels have further stimulated market demand. Many countries have implemented tax incentives, grants, and infrastructure development programs to encourage the adoption of cleaner fuel technologies. These supportive measures have created a favorable environment for the development and commercialization of alternative fuel-compatible engines like the B58.

The potential for enhanced energy security through reduced dependence on conventional fossil fuels has also contributed to the growing market demand. Countries and regions seeking to diversify their energy sources view alternative fuels as a strategic option, driving investment and research in this area. This geopolitical factor adds another layer of complexity to the market dynamics, influencing both public and private sector decisions regarding alternative fuel adoption.

As the automotive industry continues to evolve, the market demand for alternative fuel-compatible B58 engines is expected to remain strong. The convergence of environmental consciousness, technological advancements, and regulatory pressures creates a fertile ground for innovation and market growth in this sector. Manufacturers and suppliers who can successfully adapt the B58 engine design to accommodate alternative fuels are likely to gain a competitive edge in this rapidly expanding market.

Consumer interest in sustainable transportation solutions has significantly increased, with many buyers actively seeking vehicles that offer reduced environmental impact without compromising on power and drivability. This shift in consumer preferences has created a substantial market opportunity for alternative fuel-compatible engines, particularly in regions with strong environmental policies and incentives for eco-friendly vehicles.

The automotive industry has witnessed a surge in research and development activities focused on alternative fuels, including advanced biofuels, synthetic fuels, and hydrogen. These efforts aim to address the growing demand for sustainable mobility solutions while leveraging existing engine architectures like the B58. The market for alternative fuel-compatible engines is expected to expand rapidly, with projections indicating a compound annual growth rate of over 8% in the next five years.

Fleet operators and commercial vehicle manufacturers have shown particular interest in alternative fuel options for the B58 engine, driven by the potential for reduced operating costs and compliance with increasingly stringent emissions standards. This sector represents a significant portion of the market demand, as large-scale adoption of alternative fuels in commercial fleets can lead to substantial environmental benefits and cost savings.

Government initiatives and policies promoting the use of alternative fuels have further stimulated market demand. Many countries have implemented tax incentives, grants, and infrastructure development programs to encourage the adoption of cleaner fuel technologies. These supportive measures have created a favorable environment for the development and commercialization of alternative fuel-compatible engines like the B58.

The potential for enhanced energy security through reduced dependence on conventional fossil fuels has also contributed to the growing market demand. Countries and regions seeking to diversify their energy sources view alternative fuels as a strategic option, driving investment and research in this area. This geopolitical factor adds another layer of complexity to the market dynamics, influencing both public and private sector decisions regarding alternative fuel adoption.

As the automotive industry continues to evolve, the market demand for alternative fuel-compatible B58 engines is expected to remain strong. The convergence of environmental consciousness, technological advancements, and regulatory pressures creates a fertile ground for innovation and market growth in this sector. Manufacturers and suppliers who can successfully adapt the B58 engine design to accommodate alternative fuels are likely to gain a competitive edge in this rapidly expanding market.

Current Challenges

The B58 engine, renowned for its performance and efficiency, faces several challenges when considering compatibility with alternative fuels. One of the primary obstacles is the engine's high-pressure direct injection system, which is optimized for gasoline. Alternative fuels often have different chemical compositions and combustion characteristics, potentially leading to issues with fuel atomization and distribution within the combustion chamber.

Fuel system compatibility is another significant challenge. The B58's fuel lines, pumps, and injectors are designed specifically for gasoline, and alternative fuels may cause corrosion, degradation, or clogging of these components. This is particularly problematic with ethanol-based fuels, which can be more corrosive than traditional gasoline.

The engine management system presents a further hurdle. The B58's ECU is calibrated for gasoline combustion, and alternative fuels may require substantial reprogramming to optimize fuel injection timing, ignition timing, and air-fuel ratios. This recalibration process can be complex and time-consuming, potentially affecting the engine's performance and efficiency.

Emissions control is another critical challenge. The B58's catalytic converter and exhaust system are designed to handle specific types and levels of emissions produced by gasoline combustion. Alternative fuels may produce different emission profiles, potentially overwhelming or damaging the existing emissions control systems.

Material compatibility is a concern, particularly with seals, gaskets, and other non-metallic components. Some alternative fuels can cause swelling, shrinking, or degradation of these materials, leading to potential leaks or component failures over time.

The B58's high compression ratio, while beneficial for efficiency with gasoline, may pose challenges with alternative fuels. Some alternative fuels have different octane ratings or combustion characteristics, which could lead to knocking or pre-ignition issues if not properly addressed.

Cold-start performance is another area of concern, especially with biofuels. These fuels often have different vaporization characteristics, which can make cold starts more difficult, particularly in colder climates.

Lastly, the long-term durability and reliability of the B58 engine when using alternative fuels remain uncertain. Extended use of non-standard fuels may lead to accelerated wear on engine components, potentially shortening the engine's lifespan or increasing maintenance requirements.

Addressing these challenges will require extensive research, testing, and potentially significant modifications to the B58 engine design. The goal is to maintain the engine's performance and reliability while adapting it to work efficiently and safely with a broader range of fuel types.

Fuel system compatibility is another significant challenge. The B58's fuel lines, pumps, and injectors are designed specifically for gasoline, and alternative fuels may cause corrosion, degradation, or clogging of these components. This is particularly problematic with ethanol-based fuels, which can be more corrosive than traditional gasoline.

The engine management system presents a further hurdle. The B58's ECU is calibrated for gasoline combustion, and alternative fuels may require substantial reprogramming to optimize fuel injection timing, ignition timing, and air-fuel ratios. This recalibration process can be complex and time-consuming, potentially affecting the engine's performance and efficiency.

Emissions control is another critical challenge. The B58's catalytic converter and exhaust system are designed to handle specific types and levels of emissions produced by gasoline combustion. Alternative fuels may produce different emission profiles, potentially overwhelming or damaging the existing emissions control systems.

Material compatibility is a concern, particularly with seals, gaskets, and other non-metallic components. Some alternative fuels can cause swelling, shrinking, or degradation of these materials, leading to potential leaks or component failures over time.

The B58's high compression ratio, while beneficial for efficiency with gasoline, may pose challenges with alternative fuels. Some alternative fuels have different octane ratings or combustion characteristics, which could lead to knocking or pre-ignition issues if not properly addressed.

Cold-start performance is another area of concern, especially with biofuels. These fuels often have different vaporization characteristics, which can make cold starts more difficult, particularly in colder climates.

Lastly, the long-term durability and reliability of the B58 engine when using alternative fuels remain uncertain. Extended use of non-standard fuels may lead to accelerated wear on engine components, potentially shortening the engine's lifespan or increasing maintenance requirements.

Addressing these challenges will require extensive research, testing, and potentially significant modifications to the B58 engine design. The goal is to maintain the engine's performance and reliability while adapting it to work efficiently and safely with a broader range of fuel types.

Existing Compatibility Solutions

01 Software compatibility for B58 engine systems

Compatibility issues in B58 engine systems often involve software integration. This includes developing compatible software interfaces, ensuring proper communication between different engine components, and creating adaptable firmware for various vehicle models using the B58 engine.- Software compatibility for B58 engine systems: Compatibility issues in B58 engine systems often involve software integration. This includes developing compatible software interfaces, ensuring proper communication between engine control units and other vehicle systems, and implementing software updates to maintain compatibility with newer vehicle models or features.

- Hardware compatibility for B58 engine components: Ensuring hardware compatibility is crucial for B58 engines. This involves designing and manufacturing components that can seamlessly integrate with existing engine systems, as well as developing adapters or interfaces to allow compatibility between different generations or variants of B58 engines and vehicle models.

- Fuel system compatibility for B58 engines: Compatibility of fuel systems is essential for optimal B58 engine performance. This includes developing fuel injectors, pumps, and management systems that are compatible with various fuel types and engine configurations, as well as ensuring proper integration with the engine's electronic control systems.

- Emissions control compatibility for B58 engines: Ensuring compatibility with emissions control systems is critical for B58 engines to meet regulatory standards. This involves developing compatible catalytic converters, exhaust gas recirculation systems, and other emissions reduction technologies that can be integrated with the B58 engine architecture.

- Diagnostic and maintenance compatibility for B58 engines: Compatibility in diagnostic and maintenance systems is important for efficient servicing of B58 engines. This includes developing compatible diagnostic tools, software interfaces for maintenance procedures, and ensuring compatibility with existing vehicle service equipment and protocols.

02 Hardware compatibility and integration

Ensuring hardware compatibility is crucial for B58 engine systems. This involves designing compatible connectors, adapters, and interfaces to integrate the engine with various vehicle systems. It also includes developing standardized mounting solutions and ensuring proper fitment across different vehicle models.Expand Specific Solutions03 Fuel system compatibility

Adapting fuel systems for compatibility with the B58 engine is essential. This includes developing compatible fuel injectors, fuel pumps, and fuel lines that can handle the engine's specific requirements. It also involves optimizing fuel delivery systems for different fuel types and ensuring proper fuel pressure regulation.Expand Specific Solutions04 Emissions control and compatibility

Ensuring compatibility with emissions control systems is crucial for B58 engines. This involves developing compatible catalytic converters, exhaust gas recirculation systems, and other emissions-related components. It also includes optimizing engine management systems to meet various regional emissions standards.Expand Specific Solutions05 Diagnostic and maintenance compatibility

Developing compatible diagnostic and maintenance systems for B58 engines is important. This includes creating standardized diagnostic protocols, designing compatible scan tools, and ensuring that maintenance procedures and schedules are adaptable across different vehicle models using the B58 engine.Expand Specific Solutions

Key Industry Players

The exploration of alternative fuels compatibility with B58 engine design is in a nascent stage, with the market still developing. Major players like Ford Global Technologies, Caterpillar, and Shell Internationale Research are investing in research and development, indicating growing interest. The technology's maturity varies across companies, with established automotive manufacturers like Ford and Chery Automobile Co. potentially having an edge due to their existing engine expertise. Emerging players such as Virent and Amyris are focusing on sustainable fuel technologies, which could be crucial for future compatibility. The market size is expected to expand as environmental regulations tighten and demand for alternative fuel solutions increases.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive approach to alternative fuel compatibility with the B58 engine design. Their strategy involves modifying the fuel injection system to accommodate various alternative fuels, including ethanol blends and biodiesel. Ford has implemented a flexible fuel sensor system that can detect the fuel composition and adjust engine parameters accordingly[1]. They have also redesigned the fuel lines and seals to resist corrosion from biofuels. Ford's approach includes advanced engine control algorithms that optimize combustion timing and fuel mixture for different alternative fuels, ensuring optimal performance and emissions control[2]. Additionally, they have developed a thermal management system that addresses the varying cooling requirements of different alternative fuels, maintaining engine efficiency across a range of fuel types[3].

Strengths: Versatile fuel compatibility, advanced sensor technology, and optimized engine control. Weaknesses: Potential increased complexity and cost of engine components, possible trade-offs in performance optimization for specific fuels.

Caterpillar, Inc.

Technical Solution: Caterpillar has focused on adapting the B58 engine design for alternative fuels in heavy-duty applications. Their approach centers on a dual-fuel system that allows the engine to run on a combination of diesel and natural gas or other alternative fuels[4]. Caterpillar has developed specialized fuel injectors capable of handling both high-pressure diesel and lower-pressure gas fuels. They have also implemented advanced combustion control strategies that optimize the fuel mixture ratio based on load demands and emissions requirements[5]. Caterpillar's system includes a dynamic gas blending technology that continuously adjusts the ratio of diesel to alternative fuel, maximizing efficiency and reducing emissions. Furthermore, they have enhanced the engine's durability with materials resistant to the potentially corrosive effects of some alternative fuels[6].

Strengths: Flexibility in fuel usage, potential for significant emissions reduction, and adaptability to various operating conditions. Weaknesses: Increased system complexity, potential higher initial costs, and dependency on availability of multiple fuel types.

Core Innovations

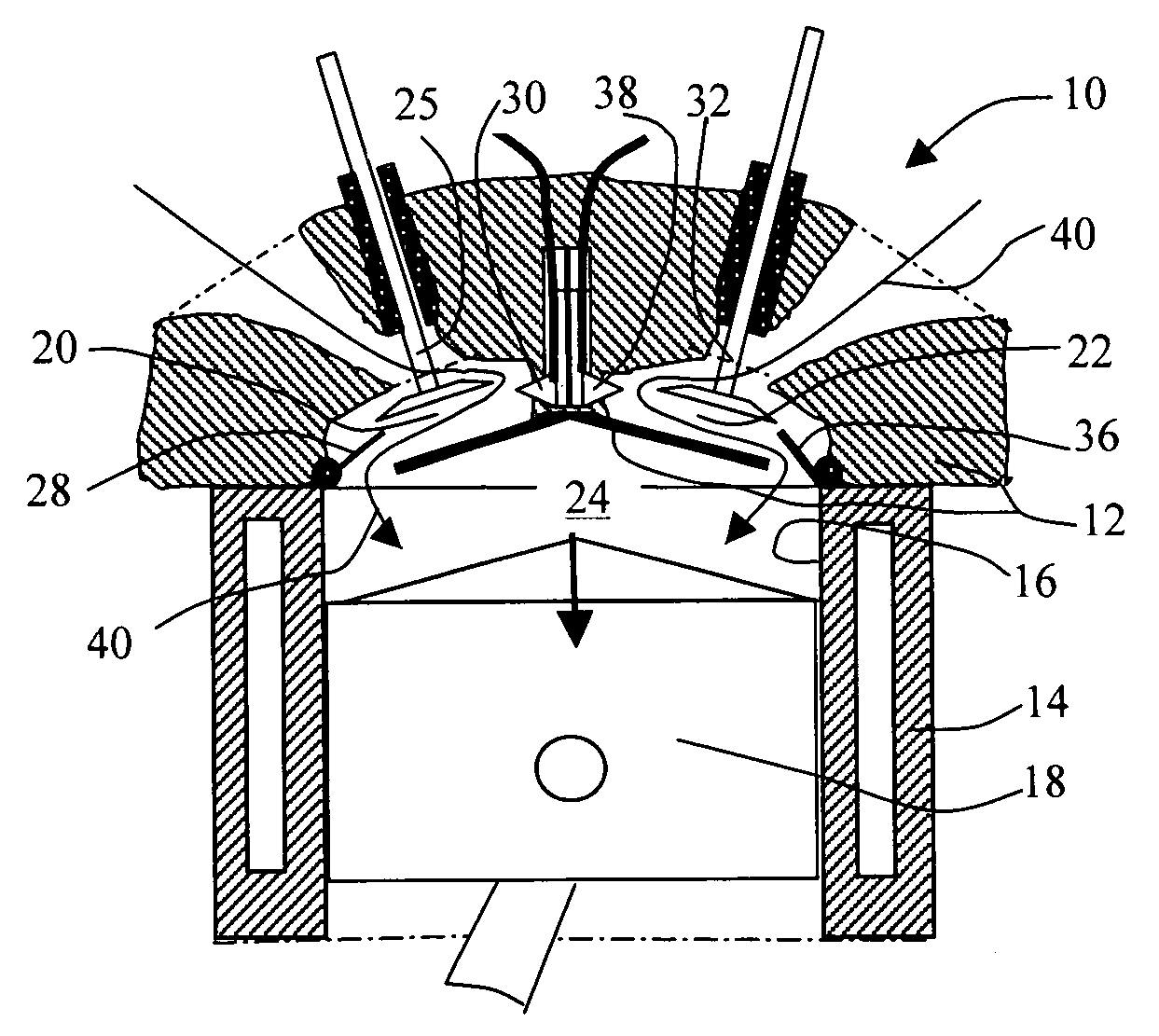

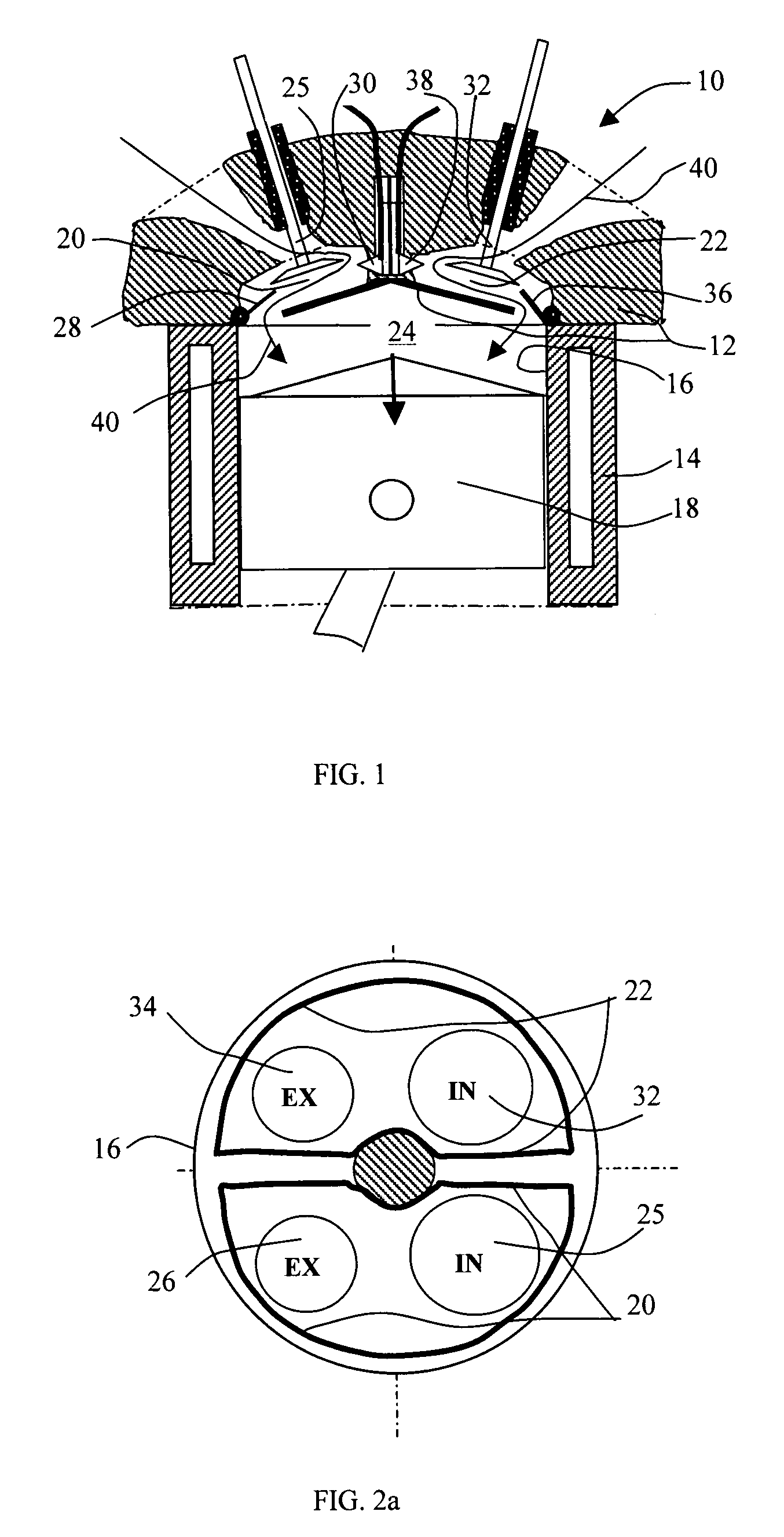

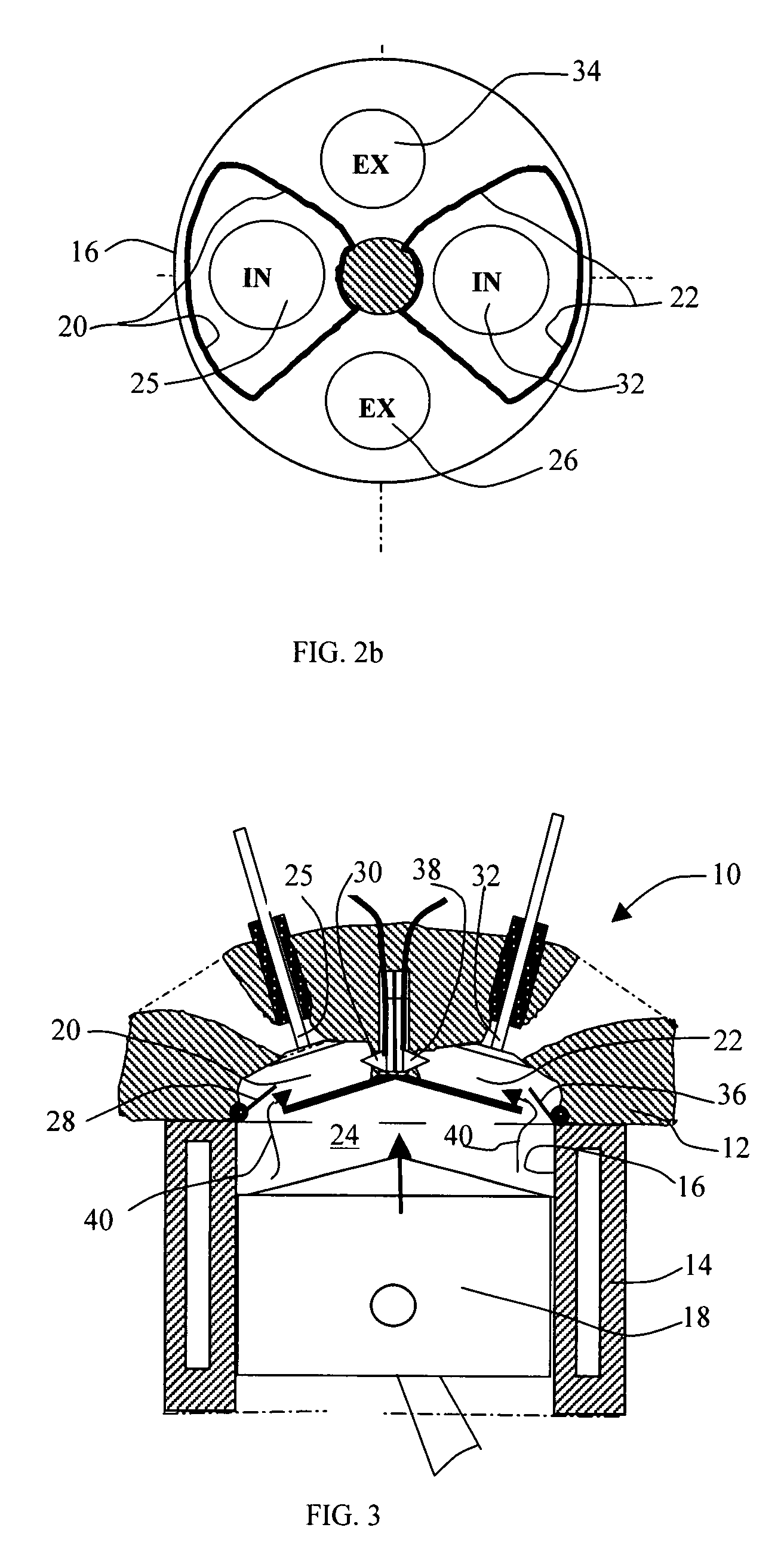

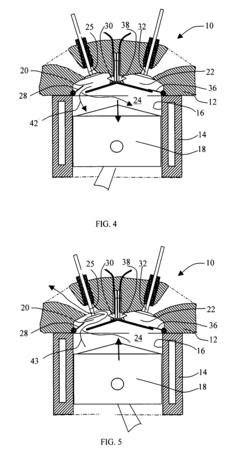

Cao cycles of internal combustion engine with increased expansion ratio, constant-volume combustion, variable compression ratio, and cold start mechanism

PatentInactiveUS7624709B2

Innovation

- The engine design incorporates a piston and cylinder assembly with multiple combustion chambers and a unique valve system that allows for a 2n+2 stroke cycle, enabling a nearly doubled expansion ratio without increasing engine size, and a variable compression ratio mechanism by deactivating combustion chambers or early closing them during compression. Additionally, a holding chamber aids in cold start through low-pressure expansion and re-compression.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and adoption of alternative fuels for engines like the B58. These regulations are continuously evolving to address environmental concerns and reduce the carbon footprint of vehicles. In recent years, there has been a global push towards stricter emissions standards, particularly focusing on reducing greenhouse gas emissions and improving air quality.

The European Union has been at the forefront of implementing stringent emissions regulations through its Euro standards. The current Euro 6 standard, introduced in 2014, sets limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. The upcoming Euro 7 standard, expected to be implemented in the near future, will further tighten these limits and introduce new testing procedures to ensure real-world compliance.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) set emissions standards for vehicles. The EPA's Tier 3 standards, phased in from 2017 to 2025, aim to reduce tailpipe and evaporative emissions from passenger cars, light-duty trucks, and some heavy-duty vehicles. CARB's Low Emission Vehicle (LEV) III standards are even more stringent, pushing automakers to develop cleaner technologies.

These regulations have a significant impact on the development of alternative fuels and their compatibility with engines like the B58. Manufacturers must ensure that any alternative fuel used in these engines meets or exceeds the emissions standards set by regulatory bodies. This has led to increased research and development in areas such as biofuels, synthetic fuels, and hydrogen fuel cells.

One of the key challenges in developing alternative fuels for the B58 engine is ensuring that they can meet these stringent emissions requirements while maintaining or improving engine performance. This often involves a delicate balance between fuel composition, engine tuning, and exhaust aftertreatment systems. For example, some biofuels may produce lower carbon dioxide emissions but could potentially increase other pollutants if not properly optimized.

The regulatory landscape also influences the economic viability of alternative fuels. As emissions standards become more stringent, the cost of developing compliant conventional engines increases, potentially making alternative fuel solutions more attractive. However, this must be balanced against the costs of developing and implementing new fuel technologies and infrastructure.

Looking ahead, emissions regulations are expected to continue evolving, with a growing focus on lifecycle emissions and carbon neutrality. This shift may favor certain alternative fuels that offer significant reductions in overall carbon footprint, even if their tailpipe emissions are similar to conventional fuels. As a result, the compatibility of the B58 engine with various alternative fuels will need to be evaluated not just on immediate emissions performance, but also on their potential to meet future regulatory requirements and sustainability goals.

The European Union has been at the forefront of implementing stringent emissions regulations through its Euro standards. The current Euro 6 standard, introduced in 2014, sets limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. The upcoming Euro 7 standard, expected to be implemented in the near future, will further tighten these limits and introduce new testing procedures to ensure real-world compliance.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) set emissions standards for vehicles. The EPA's Tier 3 standards, phased in from 2017 to 2025, aim to reduce tailpipe and evaporative emissions from passenger cars, light-duty trucks, and some heavy-duty vehicles. CARB's Low Emission Vehicle (LEV) III standards are even more stringent, pushing automakers to develop cleaner technologies.

These regulations have a significant impact on the development of alternative fuels and their compatibility with engines like the B58. Manufacturers must ensure that any alternative fuel used in these engines meets or exceeds the emissions standards set by regulatory bodies. This has led to increased research and development in areas such as biofuels, synthetic fuels, and hydrogen fuel cells.

One of the key challenges in developing alternative fuels for the B58 engine is ensuring that they can meet these stringent emissions requirements while maintaining or improving engine performance. This often involves a delicate balance between fuel composition, engine tuning, and exhaust aftertreatment systems. For example, some biofuels may produce lower carbon dioxide emissions but could potentially increase other pollutants if not properly optimized.

The regulatory landscape also influences the economic viability of alternative fuels. As emissions standards become more stringent, the cost of developing compliant conventional engines increases, potentially making alternative fuel solutions more attractive. However, this must be balanced against the costs of developing and implementing new fuel technologies and infrastructure.

Looking ahead, emissions regulations are expected to continue evolving, with a growing focus on lifecycle emissions and carbon neutrality. This shift may favor certain alternative fuels that offer significant reductions in overall carbon footprint, even if their tailpipe emissions are similar to conventional fuels. As a result, the compatibility of the B58 engine with various alternative fuels will need to be evaluated not just on immediate emissions performance, but also on their potential to meet future regulatory requirements and sustainability goals.

Economic Feasibility

The economic feasibility of adapting the B58 engine design for alternative fuels is a critical consideration in the automotive industry's transition towards more sustainable propulsion systems. This analysis examines the financial implications of modifying the B58 engine to accommodate alternative fuels, taking into account various economic factors.

Initial investment costs for engine modification are substantial, encompassing research and development, retooling of production lines, and potential redesign of auxiliary systems. However, these upfront expenses must be weighed against long-term benefits and market demands. The scalability of production plays a crucial role in determining the economic viability, as higher production volumes can lead to economies of scale, reducing per-unit costs.

Operational costs associated with alternative fuel compatibility may vary depending on the specific fuel type. Some alternative fuels may require more frequent maintenance or specialized components, potentially increasing lifecycle costs. Conversely, certain alternative fuels could offer improved efficiency or lower fuel costs, offsetting initial investments over time.

Market demand for alternative fuel vehicles is a key driver of economic feasibility. Consumer preferences, government regulations, and environmental concerns all influence the potential market size. As global efforts to reduce carbon emissions intensify, the demand for alternative fuel vehicles is expected to grow, potentially improving the economic outlook for B58 engine modifications.

Regulatory incentives and penalties also significantly impact economic feasibility. Government subsidies, tax breaks, or carbon credits for alternative fuel vehicles can enhance the financial attractiveness of engine modifications. Conversely, stringent emissions regulations may necessitate these adaptations, regardless of immediate economic returns, to ensure long-term market viability.

The availability and cost of alternative fuels themselves are crucial factors. The economic feasibility of engine modifications is closely tied to the stability and affordability of the target fuel supply. Infrastructure development for alternative fuel distribution and refueling must also be considered in the overall economic assessment.

Competitive positioning is another important aspect. Being an early adopter of alternative fuel compatibility could provide a significant market advantage, potentially justifying higher initial investments. However, this must be balanced against the risk of investing in a technology that may not become the industry standard.

In conclusion, the economic feasibility of adapting the B58 engine for alternative fuels is a complex interplay of factors. While initial costs may be substantial, long-term market trends, regulatory environments, and potential competitive advantages suggest that such modifications could be economically viable, especially as the automotive industry continues its shift towards more sustainable technologies.

Initial investment costs for engine modification are substantial, encompassing research and development, retooling of production lines, and potential redesign of auxiliary systems. However, these upfront expenses must be weighed against long-term benefits and market demands. The scalability of production plays a crucial role in determining the economic viability, as higher production volumes can lead to economies of scale, reducing per-unit costs.

Operational costs associated with alternative fuel compatibility may vary depending on the specific fuel type. Some alternative fuels may require more frequent maintenance or specialized components, potentially increasing lifecycle costs. Conversely, certain alternative fuels could offer improved efficiency or lower fuel costs, offsetting initial investments over time.

Market demand for alternative fuel vehicles is a key driver of economic feasibility. Consumer preferences, government regulations, and environmental concerns all influence the potential market size. As global efforts to reduce carbon emissions intensify, the demand for alternative fuel vehicles is expected to grow, potentially improving the economic outlook for B58 engine modifications.

Regulatory incentives and penalties also significantly impact economic feasibility. Government subsidies, tax breaks, or carbon credits for alternative fuel vehicles can enhance the financial attractiveness of engine modifications. Conversely, stringent emissions regulations may necessitate these adaptations, regardless of immediate economic returns, to ensure long-term market viability.

The availability and cost of alternative fuels themselves are crucial factors. The economic feasibility of engine modifications is closely tied to the stability and affordability of the target fuel supply. Infrastructure development for alternative fuel distribution and refueling must also be considered in the overall economic assessment.

Competitive positioning is another important aspect. Being an early adopter of alternative fuel compatibility could provide a significant market advantage, potentially justifying higher initial investments. However, this must be balanced against the risk of investing in a technology that may not become the industry standard.

In conclusion, the economic feasibility of adapting the B58 engine for alternative fuels is a complex interplay of factors. While initial costs may be substantial, long-term market trends, regulatory environments, and potential competitive advantages suggest that such modifications could be economically viable, especially as the automotive industry continues its shift towards more sustainable technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!