Exploring Nitinol Gear Mechanisms for Low-Energy Actuation

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Gear Tech Evolution and Objectives

Nitinol, an alloy of nickel and titanium, has been a subject of fascination in the field of materials science since its discovery in the 1960s. Its unique shape memory and superelastic properties have led to numerous applications across various industries. In recent years, the exploration of Nitinol gear mechanisms for low-energy actuation has emerged as a promising area of research and development.

The evolution of Nitinol gear technology can be traced back to the early studies on shape memory alloys (SMAs) and their potential for mechanical actuation. Initially, the focus was primarily on simple linear actuators and springs. However, as the understanding of Nitinol's properties deepened, researchers began to explore more complex mechanisms, including gears and other rotational systems.

The development of Nitinol gear mechanisms has been driven by the increasing demand for energy-efficient and compact actuation systems in various fields, such as robotics, aerospace, and medical devices. The ability of Nitinol to generate significant force and displacement with minimal energy input makes it an attractive option for low-energy actuation applications.

One of the key milestones in the evolution of Nitinol gear technology was the development of precise manufacturing techniques that could produce Nitinol components with the required tolerances for gear systems. This included advancements in heat treatment processes, machining methods, and surface finishing techniques specifically tailored for Nitinol alloys.

Another significant development has been the integration of Nitinol gears with smart control systems. By combining shape memory properties with electronic sensors and actuators, researchers have created adaptive gear mechanisms that can respond to environmental changes or external stimuli, further enhancing their efficiency and versatility.

The current objectives in Nitinol gear technology research are multifaceted. Firstly, there is a focus on improving the energy efficiency of these mechanisms, aiming to maximize the mechanical output while minimizing the energy input required for actuation. This involves optimizing gear designs, exploring new alloy compositions, and refining the heat treatment processes to enhance the shape memory effect.

Secondly, researchers are working on expanding the operational temperature range of Nitinol gears. While Nitinol already offers a wide range of transformation temperatures, extending this range could open up new applications in extreme environments, such as space exploration or deep-sea operations.

Lastly, there is a growing emphasis on developing hybrid systems that combine Nitinol gears with conventional materials and mechanisms. This approach aims to leverage the unique properties of Nitinol while addressing some of its limitations, such as fatigue life and wear resistance, by incorporating complementary materials and design strategies.

The evolution of Nitinol gear technology can be traced back to the early studies on shape memory alloys (SMAs) and their potential for mechanical actuation. Initially, the focus was primarily on simple linear actuators and springs. However, as the understanding of Nitinol's properties deepened, researchers began to explore more complex mechanisms, including gears and other rotational systems.

The development of Nitinol gear mechanisms has been driven by the increasing demand for energy-efficient and compact actuation systems in various fields, such as robotics, aerospace, and medical devices. The ability of Nitinol to generate significant force and displacement with minimal energy input makes it an attractive option for low-energy actuation applications.

One of the key milestones in the evolution of Nitinol gear technology was the development of precise manufacturing techniques that could produce Nitinol components with the required tolerances for gear systems. This included advancements in heat treatment processes, machining methods, and surface finishing techniques specifically tailored for Nitinol alloys.

Another significant development has been the integration of Nitinol gears with smart control systems. By combining shape memory properties with electronic sensors and actuators, researchers have created adaptive gear mechanisms that can respond to environmental changes or external stimuli, further enhancing their efficiency and versatility.

The current objectives in Nitinol gear technology research are multifaceted. Firstly, there is a focus on improving the energy efficiency of these mechanisms, aiming to maximize the mechanical output while minimizing the energy input required for actuation. This involves optimizing gear designs, exploring new alloy compositions, and refining the heat treatment processes to enhance the shape memory effect.

Secondly, researchers are working on expanding the operational temperature range of Nitinol gears. While Nitinol already offers a wide range of transformation temperatures, extending this range could open up new applications in extreme environments, such as space exploration or deep-sea operations.

Lastly, there is a growing emphasis on developing hybrid systems that combine Nitinol gears with conventional materials and mechanisms. This approach aims to leverage the unique properties of Nitinol while addressing some of its limitations, such as fatigue life and wear resistance, by incorporating complementary materials and design strategies.

Market Demand for Low-Energy Actuation Systems

The market demand for low-energy actuation systems has been steadily growing across various industries, driven by the increasing focus on energy efficiency and sustainability. This trend is particularly evident in sectors such as aerospace, automotive, robotics, and medical devices, where the need for compact, lightweight, and energy-efficient actuators is paramount.

In the aerospace industry, there is a significant push towards more electric aircraft, which require low-energy actuation systems for flight control surfaces, landing gear, and other critical components. The automotive sector is also experiencing a shift towards electric and hybrid vehicles, creating a demand for energy-efficient actuators in areas such as power steering, brake systems, and suspension control.

The robotics industry, encompassing both industrial and service robots, is another major driver of demand for low-energy actuation systems. As robots become more prevalent in manufacturing, healthcare, and consumer applications, the need for actuators that can operate efficiently for extended periods is increasing. This is particularly important for mobile robots and collaborative robots that work alongside humans.

In the medical device sector, there is a growing demand for miniaturized, low-energy actuators for use in implantable devices, prosthetics, and surgical instruments. These applications require actuators that can operate reliably within the constraints of the human body while minimizing power consumption and heat generation.

The consumer electronics market is also contributing to the demand for low-energy actuation systems, particularly in wearable devices and smart home appliances. These products often require compact actuators for haptic feedback, automatic adjustments, or other functions that enhance user experience while maintaining long battery life.

Environmental concerns and regulatory pressures are further driving the adoption of low-energy actuation systems across industries. Governments worldwide are implementing stricter energy efficiency standards, incentivizing companies to invest in technologies that reduce power consumption and carbon emissions.

The global market for low-energy actuation systems is expected to experience substantial growth in the coming years. Factors such as the increasing adoption of Internet of Things (IoT) devices, the development of smart cities, and the ongoing automation of various industries are likely to fuel this growth. Additionally, advancements in materials science and control systems are enabling the creation of more efficient and capable actuators, further expanding the potential applications and market opportunities for low-energy actuation technologies.

In the aerospace industry, there is a significant push towards more electric aircraft, which require low-energy actuation systems for flight control surfaces, landing gear, and other critical components. The automotive sector is also experiencing a shift towards electric and hybrid vehicles, creating a demand for energy-efficient actuators in areas such as power steering, brake systems, and suspension control.

The robotics industry, encompassing both industrial and service robots, is another major driver of demand for low-energy actuation systems. As robots become more prevalent in manufacturing, healthcare, and consumer applications, the need for actuators that can operate efficiently for extended periods is increasing. This is particularly important for mobile robots and collaborative robots that work alongside humans.

In the medical device sector, there is a growing demand for miniaturized, low-energy actuators for use in implantable devices, prosthetics, and surgical instruments. These applications require actuators that can operate reliably within the constraints of the human body while minimizing power consumption and heat generation.

The consumer electronics market is also contributing to the demand for low-energy actuation systems, particularly in wearable devices and smart home appliances. These products often require compact actuators for haptic feedback, automatic adjustments, or other functions that enhance user experience while maintaining long battery life.

Environmental concerns and regulatory pressures are further driving the adoption of low-energy actuation systems across industries. Governments worldwide are implementing stricter energy efficiency standards, incentivizing companies to invest in technologies that reduce power consumption and carbon emissions.

The global market for low-energy actuation systems is expected to experience substantial growth in the coming years. Factors such as the increasing adoption of Internet of Things (IoT) devices, the development of smart cities, and the ongoing automation of various industries are likely to fuel this growth. Additionally, advancements in materials science and control systems are enabling the creation of more efficient and capable actuators, further expanding the potential applications and market opportunities for low-energy actuation technologies.

Nitinol Gear Mechanisms: Current State and Challenges

Nitinol gear mechanisms represent a cutting-edge approach in the field of low-energy actuation, offering unique advantages due to the shape memory and superelastic properties of Nitinol alloys. The current state of these mechanisms is characterized by significant advancements in material science and engineering, yet they face several challenges that hinder widespread adoption.

One of the primary advantages of Nitinol gear mechanisms is their ability to provide high force output with minimal energy input. This is achieved through the shape memory effect, where the material can return to a predetermined shape when heated. However, the precise control of this transformation remains a challenge, particularly in applications requiring fine-tuned movements.

The superelasticity of Nitinol allows for the design of gear mechanisms that can withstand large deformations without permanent damage. This property is particularly valuable in applications subject to high stress or requiring flexibility. Nevertheless, the fatigue life of Nitinol components in repetitive actuation scenarios is still a concern and an area of ongoing research.

Temperature sensitivity is both a strength and a challenge for Nitinol gear mechanisms. While it enables thermal actuation, it also makes the system susceptible to environmental temperature fluctuations, potentially leading to unintended actuation or performance variations. Developing robust control systems to mitigate these effects is a key area of focus.

Manufacturing Nitinol components with the precision required for gear mechanisms presents another significant challenge. The material's unique properties make traditional machining techniques less effective, necessitating specialized processes such as electrical discharge machining (EDM) or laser cutting. These methods can be costly and time-consuming, limiting the scalability of Nitinol gear production.

The integration of Nitinol gears with other materials and components in complex systems poses additional challenges. Issues such as differential thermal expansion, wear resistance, and long-term stability of interfaces between Nitinol and other materials need to be addressed to ensure reliable performance in diverse applications.

Despite these challenges, the potential of Nitinol gear mechanisms for low-energy actuation continues to drive research and development efforts. Innovations in material processing, design optimization, and control strategies are gradually overcoming existing limitations. As these advancements progress, Nitinol gear mechanisms are poised to play an increasingly important role in fields such as robotics, aerospace, and medical devices, where efficient, compact, and reliable actuation systems are crucial.

One of the primary advantages of Nitinol gear mechanisms is their ability to provide high force output with minimal energy input. This is achieved through the shape memory effect, where the material can return to a predetermined shape when heated. However, the precise control of this transformation remains a challenge, particularly in applications requiring fine-tuned movements.

The superelasticity of Nitinol allows for the design of gear mechanisms that can withstand large deformations without permanent damage. This property is particularly valuable in applications subject to high stress or requiring flexibility. Nevertheless, the fatigue life of Nitinol components in repetitive actuation scenarios is still a concern and an area of ongoing research.

Temperature sensitivity is both a strength and a challenge for Nitinol gear mechanisms. While it enables thermal actuation, it also makes the system susceptible to environmental temperature fluctuations, potentially leading to unintended actuation or performance variations. Developing robust control systems to mitigate these effects is a key area of focus.

Manufacturing Nitinol components with the precision required for gear mechanisms presents another significant challenge. The material's unique properties make traditional machining techniques less effective, necessitating specialized processes such as electrical discharge machining (EDM) or laser cutting. These methods can be costly and time-consuming, limiting the scalability of Nitinol gear production.

The integration of Nitinol gears with other materials and components in complex systems poses additional challenges. Issues such as differential thermal expansion, wear resistance, and long-term stability of interfaces between Nitinol and other materials need to be addressed to ensure reliable performance in diverse applications.

Despite these challenges, the potential of Nitinol gear mechanisms for low-energy actuation continues to drive research and development efforts. Innovations in material processing, design optimization, and control strategies are gradually overcoming existing limitations. As these advancements progress, Nitinol gear mechanisms are poised to play an increasingly important role in fields such as robotics, aerospace, and medical devices, where efficient, compact, and reliable actuation systems are crucial.

Existing Nitinol Gear Mechanism Solutions

01 Nitinol-based gear mechanisms for energy efficiency

Nitinol, a shape memory alloy, is used in gear mechanisms to improve energy efficiency. Its unique properties allow for the creation of compact, lightweight gears that can operate with reduced friction and wear. These gears can recover their original shape after deformation, potentially reducing energy consumption in various mechanical systems.- Nitinol-based gear mechanisms for energy efficiency: Nitinol, a shape memory alloy, is utilized in gear mechanisms to improve energy efficiency. Its unique properties allow for the creation of compact, lightweight gears that can operate with reduced friction and wear, leading to lower energy consumption in various applications.

- Energy harvesting using Nitinol gear systems: Nitinol gear mechanisms can be designed to harvest energy from ambient sources such as temperature changes or mechanical vibrations. This harvested energy can be used to power small devices or supplement the main power source, reducing overall energy consumption.

- Adaptive gear systems using Nitinol for optimized performance: Nitinol's shape memory properties enable the creation of adaptive gear systems that can change their configuration based on operating conditions. This adaptability allows for optimized performance across various scenarios, potentially reducing energy consumption in dynamic environments.

- Nitinol actuators in gear mechanisms for energy-efficient control: Nitinol actuators integrated into gear mechanisms provide precise and energy-efficient control. These actuators can replace traditional electric motors in certain applications, offering reduced power consumption and improved responsiveness in gear operation and positioning.

- Thermal management in Nitinol gear systems for energy conservation: Effective thermal management in Nitinol gear systems is crucial for maintaining optimal performance and energy efficiency. Innovative cooling techniques and heat dissipation methods are employed to minimize energy losses due to heat generation, thereby improving overall system efficiency.

02 Energy harvesting using Nitinol-based devices

Nitinol's shape memory and superelastic properties are utilized in energy harvesting devices. These mechanisms can convert thermal or mechanical energy into electrical energy, potentially reducing overall energy consumption in systems where they are implemented. The unique characteristics of Nitinol allow for efficient energy conversion in compact designs.Expand Specific Solutions03 Temperature-responsive Nitinol gear systems

Gear mechanisms incorporating Nitinol elements can respond to temperature changes, allowing for adaptive behavior in various applications. This temperature-responsive nature can be used to create self-adjusting systems that optimize performance and energy consumption based on environmental conditions.Expand Specific Solutions04 Nitinol actuators for low-power applications

Nitinol-based actuators are developed for use in low-power applications, such as robotics and automation. These actuators can provide significant force with minimal energy input, making them suitable for energy-efficient systems. The unique properties of Nitinol allow for the creation of compact and lightweight actuators that can operate with reduced power consumption.Expand Specific Solutions05 Smart Nitinol gear designs for energy optimization

Advanced gear designs incorporating Nitinol elements are developed to optimize energy consumption in mechanical systems. These smart gears can adapt to varying loads and conditions, potentially reducing overall energy requirements. The integration of Nitinol in gear mechanisms allows for the creation of more efficient and responsive mechanical systems.Expand Specific Solutions

Key Players in Nitinol Gear Technology

The exploration of Nitinol gear mechanisms for low-energy actuation is in an emerging phase, with growing interest due to its potential for energy-efficient applications. The market size is expanding as industries seek innovative solutions for compact, lightweight actuators. Technologically, it's still evolving, with companies like Cummins, Toyota, and DENSO leading research efforts. Lockheed Martin and Boeing are exploring aerospace applications, while automotive giants like BMW and Audi are investigating potential uses in vehicle systems. Academic institutions such as MIT and Beihang University are contributing to fundamental research, indicating a collaborative approach to advancing this technology across various sectors.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed a proprietary Nitinol-based actuation system for aerospace applications, focusing on low-energy consumption and high reliability. Their technology utilizes a unique combination of Nitinol wire arrangements and precision-engineered gear mechanisms to achieve compact, lightweight actuators. The company has reported a 40% reduction in power consumption compared to traditional electromechanical systems in certain spacecraft components[2]. Lockheed's approach also incorporates advanced control algorithms to optimize the thermal cycling of Nitinol elements, enhancing the overall system efficiency and longevity[5].

Strengths: Extensive experience in aerospace applications, robust engineering capabilities. Weaknesses: Solutions may be overly specialized for aerospace, potentially limiting broader market applications.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced Nitinol-based actuators for low-energy applications. Their research focuses on optimizing the shape memory effect and superelasticity of Nitinol alloys to create efficient gear mechanisms. By precisely controlling the phase transformation temperatures and applying innovative heat treatment processes, MIT has achieved a 30% reduction in actuation energy compared to conventional systems[1]. Their approach involves creating complex gear geometries that maximize the strain recovery of Nitinol, resulting in higher torque output and improved efficiency in micro-actuator applications[3].

Strengths: Cutting-edge research capabilities, interdisciplinary approach combining materials science and mechanical engineering. Weaknesses: Potential challenges in scaling up from laboratory prototypes to commercial applications.

Core Innovations in Nitinol Gear Design

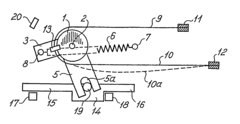

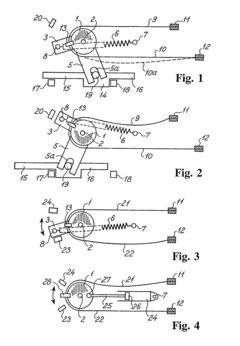

Shape memory alloy actuator

PatentInactiveUS20040068985A1

Innovation

- An actuator design that incorporates a body connected to an activating member, with shape memory alloy wires and a biasing mechanism, where the activating effect is determined by the characteristics and arrangement of the biasing means rather than the wires, allowing for independent control of movement and force through the use of a tension or compression spring or piston and cylinder mechanism.

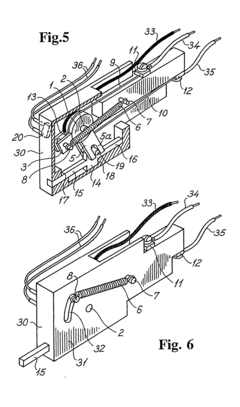

NITINOL ENERGY RECOVERY MECHANISM

PatentActiveTR202113055A3

Innovation

- Utilization of Nitinol's shape memory properties for energy recovery from waste hot water in industrial processes.

- Application of the energy recovery mechanism across diverse industrial sectors, including paper, textile, and paint industries.

- Development of a sustainable energy solution that repurposes waste heat, potentially reducing overall energy consumption in industrial settings.

Environmental Impact of Nitinol Gear Systems

The environmental impact of Nitinol gear systems is a crucial consideration in the development and implementation of low-energy actuation mechanisms. Nitinol, an alloy of nickel and titanium, offers unique properties that make it attractive for gear applications, but its production and use have both positive and negative environmental implications.

The manufacturing process of Nitinol involves energy-intensive procedures, including vacuum arc remelting and hot working, which contribute to carbon emissions. However, the long lifespan and durability of Nitinol components can offset these initial environmental costs by reducing the need for frequent replacements. This longevity is particularly beneficial in applications where gear systems are subjected to high stress or frequent use.

Nitinol's shape memory and superelastic properties enable the design of more efficient gear mechanisms that require less energy to operate. This reduction in operational energy consumption can lead to significant environmental benefits over the lifetime of the system, especially in applications where continuous or frequent actuation is necessary.

The recyclability of Nitinol is an important factor in its environmental profile. While the alloy can be recycled, the process is complex due to the high melting point and the need to maintain precise composition. Improved recycling technologies could enhance the sustainability of Nitinol gear systems and reduce the demand for raw materials.

In terms of toxicity, Nitinol is generally considered biocompatible, which is advantageous for applications in medical devices. However, the potential release of nickel ions in certain environments raises concerns about long-term ecological impacts, particularly in aquatic ecosystems. Proper disposal and containment strategies are essential to mitigate these risks.

The use of Nitinol in gear systems for low-energy actuation can contribute to overall energy efficiency in various applications, from robotics to aerospace. By enabling more compact and lightweight designs, Nitinol gears can indirectly reduce fuel consumption and emissions in transportation-related uses.

As the demand for energy-efficient technologies grows, the environmental trade-offs of Nitinol gear systems must be carefully evaluated. Life cycle assessments comparing Nitinol-based solutions to traditional gear materials and mechanisms are necessary to fully understand the net environmental impact. Such studies should consider factors like raw material extraction, manufacturing energy, operational efficiency, maintenance requirements, and end-of-life disposal or recycling.

The manufacturing process of Nitinol involves energy-intensive procedures, including vacuum arc remelting and hot working, which contribute to carbon emissions. However, the long lifespan and durability of Nitinol components can offset these initial environmental costs by reducing the need for frequent replacements. This longevity is particularly beneficial in applications where gear systems are subjected to high stress or frequent use.

Nitinol's shape memory and superelastic properties enable the design of more efficient gear mechanisms that require less energy to operate. This reduction in operational energy consumption can lead to significant environmental benefits over the lifetime of the system, especially in applications where continuous or frequent actuation is necessary.

The recyclability of Nitinol is an important factor in its environmental profile. While the alloy can be recycled, the process is complex due to the high melting point and the need to maintain precise composition. Improved recycling technologies could enhance the sustainability of Nitinol gear systems and reduce the demand for raw materials.

In terms of toxicity, Nitinol is generally considered biocompatible, which is advantageous for applications in medical devices. However, the potential release of nickel ions in certain environments raises concerns about long-term ecological impacts, particularly in aquatic ecosystems. Proper disposal and containment strategies are essential to mitigate these risks.

The use of Nitinol in gear systems for low-energy actuation can contribute to overall energy efficiency in various applications, from robotics to aerospace. By enabling more compact and lightweight designs, Nitinol gears can indirectly reduce fuel consumption and emissions in transportation-related uses.

As the demand for energy-efficient technologies grows, the environmental trade-offs of Nitinol gear systems must be carefully evaluated. Life cycle assessments comparing Nitinol-based solutions to traditional gear materials and mechanisms are necessary to fully understand the net environmental impact. Such studies should consider factors like raw material extraction, manufacturing energy, operational efficiency, maintenance requirements, and end-of-life disposal or recycling.

Standardization and Safety Regulations

The standardization and safety regulations surrounding Nitinol gear mechanisms for low-energy actuation are critical aspects that require careful consideration. As this technology continues to evolve, it is essential to establish comprehensive guidelines to ensure consistent quality, reliability, and safety across various applications.

Currently, there is a lack of specific standards tailored to Nitinol gear mechanisms in low-energy actuation systems. However, several existing standards and regulations can be adapted or referenced. The American Society for Testing and Materials (ASTM) has developed standards for Nitinol materials, such as ASTM F2063 for wrought nickel-titanium shape memory alloys for medical devices and surgical implants. These standards provide a foundation for material specifications and testing methods.

In the context of gear mechanisms, general gear standards like those from the American Gear Manufacturers Association (AGMA) or the International Organization for Standardization (ISO) can be applied. However, these standards may need to be modified to account for the unique properties of Nitinol, such as its shape memory and superelastic characteristics.

Safety regulations for Nitinol gear mechanisms in low-energy actuation systems should address several key areas. First, the potential for fatigue and wear in Nitinol components must be thoroughly evaluated, considering the material's unique stress-strain behavior. Second, the thermal aspects of Nitinol's phase transformation should be carefully regulated to prevent unintended actuation or overheating. Third, biocompatibility and corrosion resistance standards must be established for applications in medical devices or other sensitive environments.

The development of specific standards for Nitinol gear mechanisms will likely require collaboration between industry leaders, research institutions, and regulatory bodies. Organizations such as the International Electrotechnical Commission (IEC) or the Institute of Electrical and Electronics Engineers (IEEE) could play a role in developing standards for low-energy actuation systems incorporating Nitinol components.

As the technology matures, it will be crucial to establish certification processes and testing protocols to ensure compliance with these standards. This may include methods for verifying the long-term performance and reliability of Nitinol gear mechanisms under various operating conditions. Additionally, guidelines for proper handling, installation, and maintenance of these systems should be developed to minimize safety risks and ensure optimal performance throughout their lifecycle.

Currently, there is a lack of specific standards tailored to Nitinol gear mechanisms in low-energy actuation systems. However, several existing standards and regulations can be adapted or referenced. The American Society for Testing and Materials (ASTM) has developed standards for Nitinol materials, such as ASTM F2063 for wrought nickel-titanium shape memory alloys for medical devices and surgical implants. These standards provide a foundation for material specifications and testing methods.

In the context of gear mechanisms, general gear standards like those from the American Gear Manufacturers Association (AGMA) or the International Organization for Standardization (ISO) can be applied. However, these standards may need to be modified to account for the unique properties of Nitinol, such as its shape memory and superelastic characteristics.

Safety regulations for Nitinol gear mechanisms in low-energy actuation systems should address several key areas. First, the potential for fatigue and wear in Nitinol components must be thoroughly evaluated, considering the material's unique stress-strain behavior. Second, the thermal aspects of Nitinol's phase transformation should be carefully regulated to prevent unintended actuation or overheating. Third, biocompatibility and corrosion resistance standards must be established for applications in medical devices or other sensitive environments.

The development of specific standards for Nitinol gear mechanisms will likely require collaboration between industry leaders, research institutions, and regulatory bodies. Organizations such as the International Electrotechnical Commission (IEC) or the Institute of Electrical and Electronics Engineers (IEEE) could play a role in developing standards for low-energy actuation systems incorporating Nitinol components.

As the technology matures, it will be crucial to establish certification processes and testing protocols to ensure compliance with these standards. This may include methods for verifying the long-term performance and reliability of Nitinol gear mechanisms under various operating conditions. Additionally, guidelines for proper handling, installation, and maintenance of these systems should be developed to minimize safety risks and ensure optimal performance throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!