Nitinol's Use in Adaptive Reconnaissance Drone Technology

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol in Drones: Background and Objectives

Nitinol, an alloy of nickel and titanium, has emerged as a revolutionary material in the field of adaptive reconnaissance drone technology. This shape memory alloy possesses unique properties that make it particularly suitable for enhancing the performance and capabilities of unmanned aerial vehicles (UAVs) used in reconnaissance missions.

The development of Nitinol can be traced back to the 1960s when it was first discovered by the Naval Ordnance Laboratory. Since then, its applications have expanded across various industries, including aerospace and robotics. In the context of drone technology, Nitinol's shape memory and superelastic properties have opened up new possibilities for creating adaptive and resilient structures.

The primary objective of incorporating Nitinol into reconnaissance drone technology is to enhance the adaptability and durability of these unmanned vehicles. By leveraging Nitinol's ability to change shape in response to temperature variations or mechanical stress, drones can be designed with morphing capabilities, allowing them to alter their form factor to suit different mission requirements or environmental conditions.

One of the key technological goals is to develop lightweight, shape-shifting drone components that can improve aerodynamic efficiency and maneuverability. This includes adaptive wings that can change their shape mid-flight to optimize lift and reduce drag, as well as morphing propellers that can adjust their pitch for better performance across various flight regimes.

Another significant objective is to utilize Nitinol's superelastic properties to create impact-resistant structures. This could lead to the development of drones that can withstand collisions and harsh environmental conditions, thereby increasing their operational lifespan and reliability in challenging reconnaissance missions.

The integration of Nitinol in drone technology also aims to address the need for compact storage and deployment solutions. The material's shape memory effect can be harnessed to design foldable or collapsible drone structures that can be easily transported and rapidly deployed in the field.

As the field of adaptive reconnaissance drone technology continues to evolve, researchers and engineers are exploring novel ways to exploit Nitinol's unique characteristics. This includes the development of self-healing structures, adaptive sensor mounts, and smart actuators that can respond to environmental stimuli without the need for complex control systems.

The ongoing research in this area is driven by the increasing demand for more versatile and resilient reconnaissance drones capable of operating in diverse and challenging environments. By pushing the boundaries of material science and drone engineering, the integration of Nitinol is expected to play a crucial role in shaping the future of unmanned aerial reconnaissance systems.

The development of Nitinol can be traced back to the 1960s when it was first discovered by the Naval Ordnance Laboratory. Since then, its applications have expanded across various industries, including aerospace and robotics. In the context of drone technology, Nitinol's shape memory and superelastic properties have opened up new possibilities for creating adaptive and resilient structures.

The primary objective of incorporating Nitinol into reconnaissance drone technology is to enhance the adaptability and durability of these unmanned vehicles. By leveraging Nitinol's ability to change shape in response to temperature variations or mechanical stress, drones can be designed with morphing capabilities, allowing them to alter their form factor to suit different mission requirements or environmental conditions.

One of the key technological goals is to develop lightweight, shape-shifting drone components that can improve aerodynamic efficiency and maneuverability. This includes adaptive wings that can change their shape mid-flight to optimize lift and reduce drag, as well as morphing propellers that can adjust their pitch for better performance across various flight regimes.

Another significant objective is to utilize Nitinol's superelastic properties to create impact-resistant structures. This could lead to the development of drones that can withstand collisions and harsh environmental conditions, thereby increasing their operational lifespan and reliability in challenging reconnaissance missions.

The integration of Nitinol in drone technology also aims to address the need for compact storage and deployment solutions. The material's shape memory effect can be harnessed to design foldable or collapsible drone structures that can be easily transported and rapidly deployed in the field.

As the field of adaptive reconnaissance drone technology continues to evolve, researchers and engineers are exploring novel ways to exploit Nitinol's unique characteristics. This includes the development of self-healing structures, adaptive sensor mounts, and smart actuators that can respond to environmental stimuli without the need for complex control systems.

The ongoing research in this area is driven by the increasing demand for more versatile and resilient reconnaissance drones capable of operating in diverse and challenging environments. By pushing the boundaries of material science and drone engineering, the integration of Nitinol is expected to play a crucial role in shaping the future of unmanned aerial reconnaissance systems.

Market Analysis for Adaptive Reconnaissance Drones

The market for adaptive reconnaissance drones utilizing Nitinol technology is experiencing rapid growth and transformation. This emerging sector combines the versatility of unmanned aerial vehicles (UAVs) with the unique properties of Nitinol, a shape memory alloy, to create highly adaptable and resilient drones for reconnaissance missions.

The global reconnaissance drone market is projected to expand significantly over the next decade, driven by increasing defense budgets, growing security concerns, and the need for advanced surveillance capabilities. Within this broader market, adaptive drones represent a high-value niche with substantial growth potential.

Key factors fueling demand for Nitinol-based adaptive reconnaissance drones include their ability to operate in extreme environments, enhanced maneuverability, and improved durability. These drones can adapt their shape and structure in response to changing mission requirements or environmental conditions, offering unprecedented flexibility in reconnaissance operations.

The military sector remains the primary market for adaptive reconnaissance drones, with defense agencies worldwide showing keen interest in this technology. However, there is growing potential in civilian applications, particularly in disaster response, border surveillance, and environmental monitoring.

Geographically, North America currently dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, is investing heavily in advanced drone technologies for military and homeland security purposes. China and Russia are also making significant strides in this field, driving market growth in their respective regions.

Market analysts predict a compound annual growth rate (CAGR) for adaptive reconnaissance drones that outpaces the overall drone market. This accelerated growth is attributed to the unique capabilities offered by Nitinol-enhanced drones and the increasing recognition of their strategic value in both military and civilian contexts.

Despite the promising outlook, several factors could impact market development. These include regulatory challenges surrounding drone usage, concerns about privacy and data security, and the high initial costs associated with Nitinol-based adaptive technologies. Additionally, the market faces potential supply chain disruptions due to the limited availability of high-quality Nitinol and specialized manufacturing capabilities.

As the technology matures and production scales up, prices are expected to decrease, potentially opening up new market segments and applications. This could lead to wider adoption in commercial sectors such as agriculture, infrastructure inspection, and urban planning, further expanding the market potential for adaptive reconnaissance drones.

The global reconnaissance drone market is projected to expand significantly over the next decade, driven by increasing defense budgets, growing security concerns, and the need for advanced surveillance capabilities. Within this broader market, adaptive drones represent a high-value niche with substantial growth potential.

Key factors fueling demand for Nitinol-based adaptive reconnaissance drones include their ability to operate in extreme environments, enhanced maneuverability, and improved durability. These drones can adapt their shape and structure in response to changing mission requirements or environmental conditions, offering unprecedented flexibility in reconnaissance operations.

The military sector remains the primary market for adaptive reconnaissance drones, with defense agencies worldwide showing keen interest in this technology. However, there is growing potential in civilian applications, particularly in disaster response, border surveillance, and environmental monitoring.

Geographically, North America currently dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, is investing heavily in advanced drone technologies for military and homeland security purposes. China and Russia are also making significant strides in this field, driving market growth in their respective regions.

Market analysts predict a compound annual growth rate (CAGR) for adaptive reconnaissance drones that outpaces the overall drone market. This accelerated growth is attributed to the unique capabilities offered by Nitinol-enhanced drones and the increasing recognition of their strategic value in both military and civilian contexts.

Despite the promising outlook, several factors could impact market development. These include regulatory challenges surrounding drone usage, concerns about privacy and data security, and the high initial costs associated with Nitinol-based adaptive technologies. Additionally, the market faces potential supply chain disruptions due to the limited availability of high-quality Nitinol and specialized manufacturing capabilities.

As the technology matures and production scales up, prices are expected to decrease, potentially opening up new market segments and applications. This could lead to wider adoption in commercial sectors such as agriculture, infrastructure inspection, and urban planning, further expanding the market potential for adaptive reconnaissance drones.

Nitinol Technology: Current State and Challenges

Nitinol, a shape memory alloy composed of nickel and titanium, has gained significant attention in various industries due to its unique properties. In the context of adaptive reconnaissance drone technology, Nitinol presents both promising opportunities and notable challenges.

The current state of Nitinol technology in drone applications is characterized by ongoing research and development efforts. Researchers are exploring ways to leverage Nitinol's shape memory and superelastic properties to enhance drone performance and adaptability. One key area of focus is the development of morphing wings and adaptive structures that can change shape in response to environmental conditions or mission requirements.

However, several challenges hinder the widespread adoption of Nitinol in drone technology. One major obstacle is the complexity of controlling Nitinol's shape-changing behavior precisely. Achieving accurate and repeatable shape transformations in real-time flight conditions remains a significant technical hurdle. Additionally, the integration of Nitinol components with existing drone systems poses challenges in terms of weight, power consumption, and overall system complexity.

Another critical challenge is the limited understanding of Nitinol's long-term performance and fatigue behavior under the dynamic stress conditions experienced by drones. The material's response to repeated shape transformations and exposure to varying environmental factors needs further investigation to ensure reliability and durability in operational scenarios.

The manufacturing and processing of Nitinol for drone applications also present challenges. Achieving consistent material properties and performance across different batches of Nitinol can be difficult, potentially affecting the reliability of drone components. Moreover, the high cost of Nitinol compared to conventional materials used in drone construction may limit its widespread adoption, particularly in cost-sensitive applications.

Despite these challenges, ongoing research efforts are making progress in addressing these issues. Advanced manufacturing techniques, such as 3D printing of Nitinol structures, are being explored to improve material consistency and enable more complex geometries. Researchers are also developing sophisticated control algorithms and sensing systems to enhance the precision of Nitinol-based adaptive structures in drones.

The integration of Nitinol with other smart materials and advanced composites is another area of active research, aiming to create hybrid systems that combine the benefits of multiple materials. This approach could potentially overcome some of the limitations of using Nitinol alone, such as improving the speed of shape transformations or enhancing overall system efficiency.

As the technology continues to evolve, addressing these challenges will be crucial for realizing the full potential of Nitinol in adaptive reconnaissance drone technology. Overcoming these hurdles could lead to significant advancements in drone capabilities, enabling more versatile and efficient unmanned aerial systems for various applications.

The current state of Nitinol technology in drone applications is characterized by ongoing research and development efforts. Researchers are exploring ways to leverage Nitinol's shape memory and superelastic properties to enhance drone performance and adaptability. One key area of focus is the development of morphing wings and adaptive structures that can change shape in response to environmental conditions or mission requirements.

However, several challenges hinder the widespread adoption of Nitinol in drone technology. One major obstacle is the complexity of controlling Nitinol's shape-changing behavior precisely. Achieving accurate and repeatable shape transformations in real-time flight conditions remains a significant technical hurdle. Additionally, the integration of Nitinol components with existing drone systems poses challenges in terms of weight, power consumption, and overall system complexity.

Another critical challenge is the limited understanding of Nitinol's long-term performance and fatigue behavior under the dynamic stress conditions experienced by drones. The material's response to repeated shape transformations and exposure to varying environmental factors needs further investigation to ensure reliability and durability in operational scenarios.

The manufacturing and processing of Nitinol for drone applications also present challenges. Achieving consistent material properties and performance across different batches of Nitinol can be difficult, potentially affecting the reliability of drone components. Moreover, the high cost of Nitinol compared to conventional materials used in drone construction may limit its widespread adoption, particularly in cost-sensitive applications.

Despite these challenges, ongoing research efforts are making progress in addressing these issues. Advanced manufacturing techniques, such as 3D printing of Nitinol structures, are being explored to improve material consistency and enable more complex geometries. Researchers are also developing sophisticated control algorithms and sensing systems to enhance the precision of Nitinol-based adaptive structures in drones.

The integration of Nitinol with other smart materials and advanced composites is another area of active research, aiming to create hybrid systems that combine the benefits of multiple materials. This approach could potentially overcome some of the limitations of using Nitinol alone, such as improving the speed of shape transformations or enhancing overall system efficiency.

As the technology continues to evolve, addressing these challenges will be crucial for realizing the full potential of Nitinol in adaptive reconnaissance drone technology. Overcoming these hurdles could lead to significant advancements in drone capabilities, enabling more versatile and efficient unmanned aerial systems for various applications.

Existing Nitinol Applications in Drone Technology

01 Shape memory properties of Nitinol

Nitinol exhibits unique shape memory properties, allowing it to return to a predetermined shape when heated. This adaptability makes it suitable for various applications in medical devices, aerospace, and automotive industries. The material can be deformed and then recover its original shape upon heating, enabling the creation of compact, deployable structures.- Shape memory properties of Nitinol: Nitinol exhibits unique shape memory properties, allowing it to return to a predetermined shape when heated. This adaptability makes it suitable for various applications in medical devices, aerospace, and automotive industries. The material can be deformed and then recover its original shape upon heating, enabling the creation of compact, deployable structures.

- Superelasticity of Nitinol: Nitinol's superelastic behavior allows it to undergo large deformations and return to its original shape without permanent damage. This property is particularly useful in applications requiring flexibility and durability, such as orthodontic wires, eyeglass frames, and medical stents. The material can withstand repeated stress cycles without fatigue, making it ideal for long-term use in dynamic environments.

- Nitinol in medical applications: The biocompatibility and adaptability of Nitinol make it an excellent material for various medical applications. It is commonly used in minimally invasive surgical instruments, implantable devices, and dental appliances. The material's ability to change shape in response to temperature or stress allows for the creation of self-expanding stents, bone anchors, and other innovative medical devices that can adapt to the human body's environment.

- Nitinol in actuators and sensors: The unique properties of Nitinol make it suitable for use in actuators and sensors. Its shape memory effect can be utilized to create compact, efficient actuators that respond to temperature changes or electrical stimulation. In sensor applications, Nitinol's sensitivity to temperature and stress can be exploited to detect and measure environmental changes, making it valuable in various industries, including automotive and aerospace.

- Processing and manufacturing of Nitinol: The adaptability of Nitinol is closely tied to its processing and manufacturing techniques. Precise control of composition, heat treatment, and forming processes is crucial to achieve desired properties. Advanced manufacturing methods, such as additive manufacturing and laser processing, are being explored to create complex Nitinol structures with tailored properties. These techniques allow for the production of customized Nitinol components with specific transformation temperatures and mechanical characteristics.

02 Superelasticity of Nitinol

Nitinol's superelastic behavior allows it to undergo large deformations and return to its original shape without permanent damage. This property is particularly useful in applications requiring flexibility and durability, such as orthodontic wires, eyeglass frames, and medical stents. The material can withstand repeated stress cycles without fatigue, making it ideal for dynamic environments.Expand Specific Solutions03 Nitinol in medical applications

The biocompatibility and adaptability of Nitinol make it an excellent choice for various medical applications. It is commonly used in minimally invasive surgical instruments, implantable devices, and dental appliances. The material's ability to change shape at body temperature allows for the creation of self-expanding stents and other innovative medical devices that can be easily inserted and deployed within the body.Expand Specific Solutions04 Nitinol in actuators and sensors

The unique properties of Nitinol make it suitable for use in actuators and sensors. Its shape memory effect can be utilized to create compact, efficient actuators that respond to temperature changes. Additionally, the material's sensitivity to stress and temperature variations allows for the development of advanced sensors for various industrial and scientific applications.Expand Specific Solutions05 Manufacturing and processing of Nitinol

The adaptability of Nitinol extends to its manufacturing and processing techniques. Various methods, such as laser cutting, shape setting, and heat treatment, can be employed to tailor the material's properties for specific applications. Advanced manufacturing processes allow for the creation of complex Nitinol structures with precise control over their shape memory and superelastic behaviors.Expand Specific Solutions

Core Innovations in Nitinol for Adaptive Drones

Mixture of powders for preparing a sintered nickel-titanium-rare earth metal (ni-ti-re) alloy

PatentWO2013109846A1

Innovation

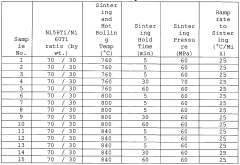

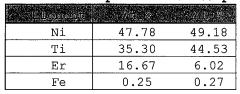

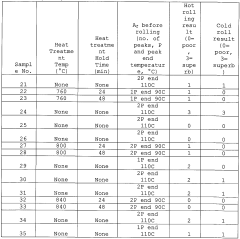

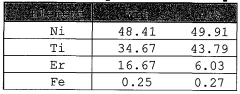

- A mixture of nickel-titanium-rare earth (Ni-Ti-RE) alloy powders with specific compositions and sintering conditions to produce a sintered alloy that maintains workability and superelasticity while enhancing radiopacity, using spark plasma sintering and thermomechanical processing.

Regulatory Framework for Advanced Drone Materials

The regulatory framework for advanced drone materials, particularly in the context of Nitinol's use in adaptive reconnaissance drone technology, is a complex and evolving landscape. As the development of cutting-edge materials for unmanned aerial vehicles (UAVs) continues to advance, governments and regulatory bodies worldwide are working to establish comprehensive guidelines to ensure safety, security, and ethical use of these technologies.

In the United States, the Federal Aviation Administration (FAA) plays a crucial role in overseeing the use of drones and their components. The FAA's Part 107 regulations, which govern the commercial use of small unmanned aircraft systems, have been updated to address the integration of advanced materials like Nitinol. These regulations now include specific provisions for the testing and certification of shape memory alloys used in drone construction, with a focus on their unique properties and potential impacts on flight characteristics.

The European Union Aviation Safety Agency (EASA) has also implemented new regulations concerning the use of advanced materials in drone technology. The EASA's framework includes stringent requirements for material testing, performance validation, and risk assessment, particularly for alloys like Nitinol that exhibit dynamic properties. These regulations aim to ensure that adaptive materials used in reconnaissance drones meet high standards of reliability and safety across various operating conditions.

In Asia, countries like Japan and South Korea have taken proactive steps to regulate the use of advanced materials in drone technology. The Japanese Civil Aviation Bureau (JCAB) has introduced guidelines specifically addressing the use of shape memory alloys in UAVs, focusing on their potential to enhance drone adaptability and performance in challenging environments. Similarly, South Korea's Ministry of Land, Infrastructure and Transport has established a dedicated task force to develop regulations for next-generation drone materials, including Nitinol and other smart alloys.

International organizations such as the International Civil Aviation Organization (ICAO) are working to harmonize global standards for advanced drone materials. The ICAO's Unmanned Aircraft Systems Advisory Group has initiated discussions on creating a unified framework for the certification and use of adaptive materials in reconnaissance drones, aiming to facilitate cross-border operations and technology sharing.

As the regulatory landscape continues to evolve, manufacturers and researchers working with Nitinol in drone technology must navigate a complex web of national and international regulations. Compliance with these frameworks is essential not only for legal operation but also for ensuring public trust and acceptance of advanced drone technologies. The ongoing dialogue between industry stakeholders, regulatory bodies, and policymakers will be crucial in shaping future regulations that balance innovation with safety and security concerns.

In the United States, the Federal Aviation Administration (FAA) plays a crucial role in overseeing the use of drones and their components. The FAA's Part 107 regulations, which govern the commercial use of small unmanned aircraft systems, have been updated to address the integration of advanced materials like Nitinol. These regulations now include specific provisions for the testing and certification of shape memory alloys used in drone construction, with a focus on their unique properties and potential impacts on flight characteristics.

The European Union Aviation Safety Agency (EASA) has also implemented new regulations concerning the use of advanced materials in drone technology. The EASA's framework includes stringent requirements for material testing, performance validation, and risk assessment, particularly for alloys like Nitinol that exhibit dynamic properties. These regulations aim to ensure that adaptive materials used in reconnaissance drones meet high standards of reliability and safety across various operating conditions.

In Asia, countries like Japan and South Korea have taken proactive steps to regulate the use of advanced materials in drone technology. The Japanese Civil Aviation Bureau (JCAB) has introduced guidelines specifically addressing the use of shape memory alloys in UAVs, focusing on their potential to enhance drone adaptability and performance in challenging environments. Similarly, South Korea's Ministry of Land, Infrastructure and Transport has established a dedicated task force to develop regulations for next-generation drone materials, including Nitinol and other smart alloys.

International organizations such as the International Civil Aviation Organization (ICAO) are working to harmonize global standards for advanced drone materials. The ICAO's Unmanned Aircraft Systems Advisory Group has initiated discussions on creating a unified framework for the certification and use of adaptive materials in reconnaissance drones, aiming to facilitate cross-border operations and technology sharing.

As the regulatory landscape continues to evolve, manufacturers and researchers working with Nitinol in drone technology must navigate a complex web of national and international regulations. Compliance with these frameworks is essential not only for legal operation but also for ensuring public trust and acceptance of advanced drone technologies. The ongoing dialogue between industry stakeholders, regulatory bodies, and policymakers will be crucial in shaping future regulations that balance innovation with safety and security concerns.

Environmental Impact of Nitinol in Drone Manufacturing

The environmental impact of Nitinol in drone manufacturing is a crucial consideration as the use of this shape memory alloy becomes more prevalent in adaptive reconnaissance drone technology. Nitinol, an alloy of nickel and titanium, offers unique properties that make it ideal for creating lightweight, flexible, and durable drone components. However, its production and use come with several environmental implications that must be carefully evaluated.

The manufacturing process of Nitinol involves energy-intensive procedures, including vacuum arc remelting and hot working, which contribute to significant carbon emissions. The extraction and processing of nickel and titanium, the primary constituents of Nitinol, also have substantial environmental footprints. Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly.

Despite these concerns, the use of Nitinol in drone manufacturing can potentially offset some environmental impacts through improved drone performance and longevity. The material's shape memory and superelastic properties allow for the creation of more efficient and adaptable drone designs, potentially reducing the need for frequent replacements and minimizing waste generation in the long term.

Recycling Nitinol presents both challenges and opportunities. While the alloy is theoretically recyclable, the process is complex due to the difficulty in separating nickel and titanium. Developing efficient recycling methods for Nitinol could significantly reduce the environmental burden associated with its production and disposal.

The use of Nitinol in drones may also have indirect environmental benefits. Adaptive reconnaissance drones equipped with Nitinol components can potentially operate more efficiently in diverse environments, enabling more accurate environmental monitoring and data collection. This improved capability could contribute to better environmental management and conservation efforts.

However, the increased durability and performance of Nitinol-equipped drones may lead to more widespread use of these devices, potentially raising concerns about noise pollution and wildlife disturbance in sensitive ecosystems. Balancing the benefits of advanced drone technology with its potential ecological impacts will be crucial for sustainable implementation.

As the drone industry continues to evolve, manufacturers and researchers must focus on developing more environmentally friendly production methods for Nitinol and exploring alternative materials with similar properties but lower environmental impacts. Additionally, implementing life cycle assessments for Nitinol-based drone components will be essential in fully understanding and mitigating their environmental effects throughout their production, use, and disposal phases.

The manufacturing process of Nitinol involves energy-intensive procedures, including vacuum arc remelting and hot working, which contribute to significant carbon emissions. The extraction and processing of nickel and titanium, the primary constituents of Nitinol, also have substantial environmental footprints. Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly.

Despite these concerns, the use of Nitinol in drone manufacturing can potentially offset some environmental impacts through improved drone performance and longevity. The material's shape memory and superelastic properties allow for the creation of more efficient and adaptable drone designs, potentially reducing the need for frequent replacements and minimizing waste generation in the long term.

Recycling Nitinol presents both challenges and opportunities. While the alloy is theoretically recyclable, the process is complex due to the difficulty in separating nickel and titanium. Developing efficient recycling methods for Nitinol could significantly reduce the environmental burden associated with its production and disposal.

The use of Nitinol in drones may also have indirect environmental benefits. Adaptive reconnaissance drones equipped with Nitinol components can potentially operate more efficiently in diverse environments, enabling more accurate environmental monitoring and data collection. This improved capability could contribute to better environmental management and conservation efforts.

However, the increased durability and performance of Nitinol-equipped drones may lead to more widespread use of these devices, potentially raising concerns about noise pollution and wildlife disturbance in sensitive ecosystems. Balancing the benefits of advanced drone technology with its potential ecological impacts will be crucial for sustainable implementation.

As the drone industry continues to evolve, manufacturers and researchers must focus on developing more environmentally friendly production methods for Nitinol and exploring alternative materials with similar properties but lower environmental impacts. Additionally, implementing life cycle assessments for Nitinol-based drone components will be essential in fully understanding and mitigating their environmental effects throughout their production, use, and disposal phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!