Nitinol for Instantaneous Remote Folding Structures

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Smart Materials Background and Objectives

Nitinol, a remarkable shape memory alloy, has been at the forefront of smart materials research since its discovery in the 1960s. This unique alloy, composed of nickel and titanium, exhibits exceptional properties that have revolutionized various industries, particularly in the field of instantaneous remote folding structures. The evolution of Nitinol technology has been driven by the increasing demand for materials that can adapt to their environment and perform complex functions with minimal external input.

The primary objective of researching Nitinol for instantaneous remote folding structures is to harness its shape memory and superelastic properties to create innovative, responsive, and efficient designs. These structures have the potential to transform industries such as aerospace, medical devices, and robotics by enabling compact storage, easy deployment, and precise control of complex geometries. The goal is to develop systems that can rapidly change their shape or configuration in response to external stimuli, such as temperature changes or electrical currents, without the need for complex mechanical systems.

Throughout its development, Nitinol has undergone significant advancements in terms of material composition, processing techniques, and application methodologies. Early research focused on understanding the fundamental mechanisms behind its unique properties, such as the martensitic phase transformation that enables its shape memory effect. As the technology progressed, efforts shifted towards optimizing the alloy's performance characteristics, including its transformation temperatures, fatigue resistance, and biocompatibility.

The trajectory of Nitinol research has been marked by several key milestones. These include the refinement of manufacturing processes to produce Nitinol with consistent and predictable properties, the development of techniques to program complex shape memory behaviors, and the integration of Nitinol into smart composite materials. Recent advancements have focused on enhancing the material's responsiveness to non-thermal stimuli, such as magnetic fields or light, expanding its potential applications in remote-controlled systems.

Current research objectives in the field of Nitinol for instantaneous remote folding structures encompass several critical areas. These include improving the speed and precision of shape changes, increasing the energy efficiency of the transformation process, and developing more sophisticated control mechanisms for complex, multi-stage folding sequences. Additionally, there is a growing emphasis on creating scalable manufacturing processes to enable the production of larger Nitinol-based structures while maintaining the material's unique properties.

As we look to the future, the potential applications of Nitinol in instantaneous remote folding structures continue to expand. Researchers are exploring its use in deployable space structures, self-assembling robotics, and adaptive architectural elements. The ongoing challenge lies in bridging the gap between laboratory demonstrations and practical, real-world applications, requiring interdisciplinary collaboration between materials scientists, engineers, and industry partners.

The primary objective of researching Nitinol for instantaneous remote folding structures is to harness its shape memory and superelastic properties to create innovative, responsive, and efficient designs. These structures have the potential to transform industries such as aerospace, medical devices, and robotics by enabling compact storage, easy deployment, and precise control of complex geometries. The goal is to develop systems that can rapidly change their shape or configuration in response to external stimuli, such as temperature changes or electrical currents, without the need for complex mechanical systems.

Throughout its development, Nitinol has undergone significant advancements in terms of material composition, processing techniques, and application methodologies. Early research focused on understanding the fundamental mechanisms behind its unique properties, such as the martensitic phase transformation that enables its shape memory effect. As the technology progressed, efforts shifted towards optimizing the alloy's performance characteristics, including its transformation temperatures, fatigue resistance, and biocompatibility.

The trajectory of Nitinol research has been marked by several key milestones. These include the refinement of manufacturing processes to produce Nitinol with consistent and predictable properties, the development of techniques to program complex shape memory behaviors, and the integration of Nitinol into smart composite materials. Recent advancements have focused on enhancing the material's responsiveness to non-thermal stimuli, such as magnetic fields or light, expanding its potential applications in remote-controlled systems.

Current research objectives in the field of Nitinol for instantaneous remote folding structures encompass several critical areas. These include improving the speed and precision of shape changes, increasing the energy efficiency of the transformation process, and developing more sophisticated control mechanisms for complex, multi-stage folding sequences. Additionally, there is a growing emphasis on creating scalable manufacturing processes to enable the production of larger Nitinol-based structures while maintaining the material's unique properties.

As we look to the future, the potential applications of Nitinol in instantaneous remote folding structures continue to expand. Researchers are exploring its use in deployable space structures, self-assembling robotics, and adaptive architectural elements. The ongoing challenge lies in bridging the gap between laboratory demonstrations and practical, real-world applications, requiring interdisciplinary collaboration between materials scientists, engineers, and industry partners.

Market Demand for Remote Folding Structures

The market demand for remote folding structures has been steadily increasing across various industries, driven by the need for compact, deployable, and efficient solutions. The aerospace sector has shown significant interest in these structures for satellite deployments, solar arrays, and space habitats. The ability to launch compact payloads that can unfold into larger structures once in orbit has become crucial for cost-effective space missions.

In the military and defense sector, remote folding structures have gained traction for rapid deployment of shelters, bridges, and communication equipment. These structures offer the advantage of quick setup and teardown in challenging environments, enhancing operational efficiency and mobility.

The construction industry has also recognized the potential of remote folding structures for temporary housing, disaster relief shelters, and portable event spaces. The demand for quick-to-deploy, reusable structures has grown in response to natural disasters and humanitarian crises, where rapid shelter provision is critical.

Medical applications have emerged as another promising market for remote folding structures. Portable medical tents, collapsible operating rooms, and expandable emergency response units have shown increasing demand, especially in the wake of global health crises and the need for flexible healthcare infrastructure.

The automotive industry has begun exploring remote folding structures for convertible roofs, expandable campers, and adaptable cargo spaces. This trend aligns with the growing consumer interest in versatile and multifunctional vehicles.

Consumer electronics and mobile device manufacturers have shown interest in foldable displays and compact, expandable devices. This market segment seeks innovative solutions to combine larger screen sizes with portable form factors.

The sports and recreation sector has also contributed to the demand for remote folding structures, with applications in portable stadiums, collapsible kayaks, and easily transportable camping gear. These products cater to the increasing popularity of outdoor activities and the need for space-saving equipment.

As urbanization continues and living spaces become more compact, there is a growing market for transformable furniture and adaptable living solutions. Remote folding structures offer the potential for maximizing space utilization in small apartments and offices.

The integration of smart materials like Nitinol in remote folding structures is expected to further drive market growth. The unique properties of shape memory alloys enable more sophisticated and responsive folding mechanisms, opening up new possibilities across various applications.

In the military and defense sector, remote folding structures have gained traction for rapid deployment of shelters, bridges, and communication equipment. These structures offer the advantage of quick setup and teardown in challenging environments, enhancing operational efficiency and mobility.

The construction industry has also recognized the potential of remote folding structures for temporary housing, disaster relief shelters, and portable event spaces. The demand for quick-to-deploy, reusable structures has grown in response to natural disasters and humanitarian crises, where rapid shelter provision is critical.

Medical applications have emerged as another promising market for remote folding structures. Portable medical tents, collapsible operating rooms, and expandable emergency response units have shown increasing demand, especially in the wake of global health crises and the need for flexible healthcare infrastructure.

The automotive industry has begun exploring remote folding structures for convertible roofs, expandable campers, and adaptable cargo spaces. This trend aligns with the growing consumer interest in versatile and multifunctional vehicles.

Consumer electronics and mobile device manufacturers have shown interest in foldable displays and compact, expandable devices. This market segment seeks innovative solutions to combine larger screen sizes with portable form factors.

The sports and recreation sector has also contributed to the demand for remote folding structures, with applications in portable stadiums, collapsible kayaks, and easily transportable camping gear. These products cater to the increasing popularity of outdoor activities and the need for space-saving equipment.

As urbanization continues and living spaces become more compact, there is a growing market for transformable furniture and adaptable living solutions. Remote folding structures offer the potential for maximizing space utilization in small apartments and offices.

The integration of smart materials like Nitinol in remote folding structures is expected to further drive market growth. The unique properties of shape memory alloys enable more sophisticated and responsive folding mechanisms, opening up new possibilities across various applications.

Nitinol Technology Status and Challenges

Nitinol, a shape memory alloy composed of nickel and titanium, has gained significant attention in the field of smart materials and adaptive structures. The current status of Nitinol technology for instantaneous remote folding structures is characterized by both promising advancements and persistent challenges.

One of the primary advantages of Nitinol is its unique shape memory effect and superelasticity, which allow it to return to a predetermined shape when heated. This property makes it ideal for applications in remote folding structures, where controlled deformation is crucial. However, the widespread implementation of Nitinol in such applications faces several technical hurdles.

A major challenge lies in the precise control of the shape memory effect in complex geometries. While Nitinol can be programmed to remember specific shapes, achieving consistent and repeatable transformations across intricate structures remains difficult. This is particularly problematic for large-scale folding structures, where uniform actuation is essential for proper functionality.

Another significant obstacle is the energy efficiency of Nitinol-based systems. The activation of the shape memory effect typically requires substantial heat input, which can be energy-intensive and impractical for certain remote applications. Researchers are actively exploring methods to reduce the energy requirements and improve the response time of Nitinol actuators.

The durability and fatigue resistance of Nitinol in repeated folding cycles present another area of concern. While Nitinol exhibits excellent fatigue properties compared to conventional metals, the long-term reliability of Nitinol-based folding structures under various environmental conditions and stress levels needs further investigation.

Manufacturing challenges also persist in the Nitinol industry. The production of Nitinol with consistent properties and performance characteristics across different batches remains a complex process. This variability can lead to unpredictable behavior in folding structures, necessitating stringent quality control measures.

Despite these challenges, recent advancements in Nitinol technology have shown promise. Researchers have made progress in developing new alloy compositions and heat treatment processes to enhance the material's properties. Additionally, innovative design approaches, such as the integration of Nitinol with other smart materials or the use of hybrid actuation systems, are being explored to overcome some of the existing limitations.

The geographical distribution of Nitinol technology development is primarily concentrated in North America, Europe, and Asia, with the United States, Germany, and Japan leading in research and patent filings. This global effort is driving the technology forward, but also highlights the need for international collaboration to address the complex challenges associated with Nitinol-based instantaneous remote folding structures.

One of the primary advantages of Nitinol is its unique shape memory effect and superelasticity, which allow it to return to a predetermined shape when heated. This property makes it ideal for applications in remote folding structures, where controlled deformation is crucial. However, the widespread implementation of Nitinol in such applications faces several technical hurdles.

A major challenge lies in the precise control of the shape memory effect in complex geometries. While Nitinol can be programmed to remember specific shapes, achieving consistent and repeatable transformations across intricate structures remains difficult. This is particularly problematic for large-scale folding structures, where uniform actuation is essential for proper functionality.

Another significant obstacle is the energy efficiency of Nitinol-based systems. The activation of the shape memory effect typically requires substantial heat input, which can be energy-intensive and impractical for certain remote applications. Researchers are actively exploring methods to reduce the energy requirements and improve the response time of Nitinol actuators.

The durability and fatigue resistance of Nitinol in repeated folding cycles present another area of concern. While Nitinol exhibits excellent fatigue properties compared to conventional metals, the long-term reliability of Nitinol-based folding structures under various environmental conditions and stress levels needs further investigation.

Manufacturing challenges also persist in the Nitinol industry. The production of Nitinol with consistent properties and performance characteristics across different batches remains a complex process. This variability can lead to unpredictable behavior in folding structures, necessitating stringent quality control measures.

Despite these challenges, recent advancements in Nitinol technology have shown promise. Researchers have made progress in developing new alloy compositions and heat treatment processes to enhance the material's properties. Additionally, innovative design approaches, such as the integration of Nitinol with other smart materials or the use of hybrid actuation systems, are being explored to overcome some of the existing limitations.

The geographical distribution of Nitinol technology development is primarily concentrated in North America, Europe, and Asia, with the United States, Germany, and Japan leading in research and patent filings. This global effort is driving the technology forward, but also highlights the need for international collaboration to address the complex challenges associated with Nitinol-based instantaneous remote folding structures.

Current Nitinol-based Folding Solutions

01 Shape memory properties of Nitinol for folding applications

Nitinol, a nickel-titanium alloy, exhibits shape memory and superelastic properties, making it ideal for folding applications. When heated, Nitinol can return to a predetermined shape, allowing for compact storage and easy deployment in various devices and structures.- Shape memory properties of Nitinol for folding applications: Nitinol, a nickel-titanium alloy, exhibits shape memory and superelastic properties, making it ideal for folding applications. These unique characteristics allow Nitinol structures to be folded and unfolded repeatedly without permanent deformation, enabling the creation of compact, deployable devices in various fields such as aerospace, medical, and consumer products.

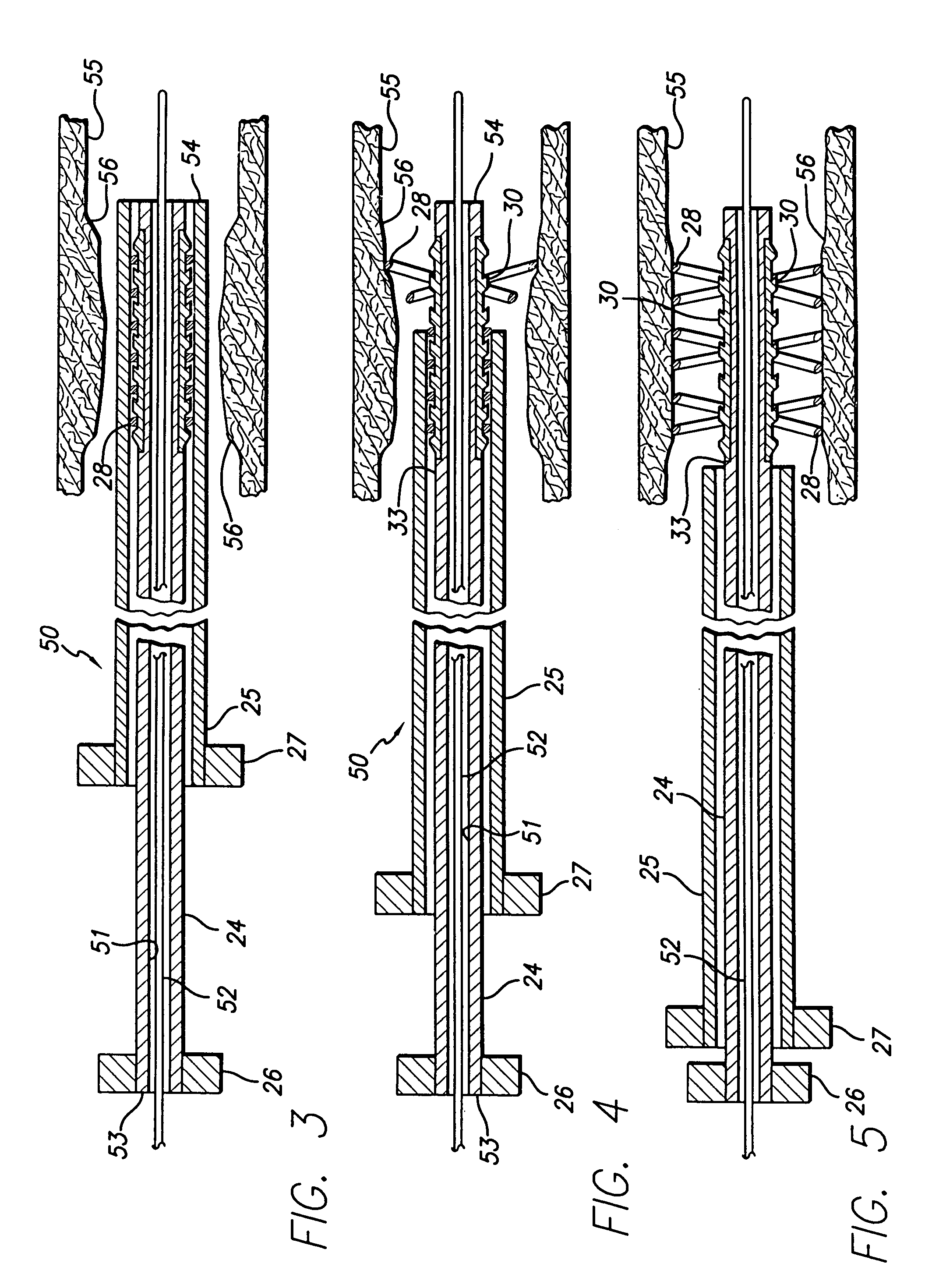

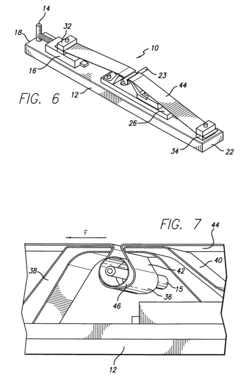

- Nitinol-based folding mechanisms in medical devices: Nitinol is widely used in medical devices for its folding capabilities, particularly in minimally invasive surgical instruments and implants. These devices can be folded into a compact form for insertion through small incisions or catheters, then expanded to their functional shape once in place. This property is especially valuable in cardiovascular and orthopedic applications.

- Nitinol folding techniques in aerospace and satellite technology: The aerospace industry utilizes Nitinol's folding properties for deployable structures in satellites and spacecraft. These structures, such as antennas, solar panels, and booms, can be compactly folded during launch and transportation, then unfolded once in orbit. This allows for larger structures to be deployed in space while minimizing launch volume and weight.

- Manufacturing and processing methods for Nitinol folding components: Specialized manufacturing and processing techniques are employed to create Nitinol components with precise folding characteristics. These methods include heat treatment, shape setting, and surface finishing processes that optimize the material's performance in folding applications. Advanced manufacturing techniques, such as 3D printing and laser cutting, are also being explored to create complex Nitinol folding structures.

- Nitinol folding applications in consumer products and industrial equipment: Nitinol's folding properties are being leveraged in various consumer products and industrial equipment. Examples include foldable eyewear frames, collapsible antennas for portable devices, and compact tools. In industrial settings, Nitinol folding mechanisms are used in robotics, actuators, and self-deploying structures, offering space-saving solutions and improved functionality.

02 Nitinol-based folding mechanisms in medical devices

Nitinol is widely used in medical devices for its folding capabilities, particularly in minimally invasive surgical instruments and implants. These devices can be folded into a compact form for insertion and then expanded to their functional shape once in place, reducing trauma and improving patient outcomes.Expand Specific Solutions03 Nitinol folding in aerospace and automotive applications

The unique folding properties of Nitinol are utilized in aerospace and automotive industries for deployable structures, actuators, and energy-absorbing components. These applications take advantage of Nitinol's ability to fold and unfold repeatedly without fatigue, enhancing performance and efficiency.Expand Specific Solutions04 Manufacturing and processing techniques for Nitinol folding structures

Specialized manufacturing and processing techniques are employed to create Nitinol folding structures. These methods include heat treatment, laser cutting, and surface modification to optimize the material's folding performance and durability in various applications.Expand Specific Solutions05 Control and actuation of Nitinol folding mechanisms

Advanced control and actuation systems are developed to precisely manage the folding and unfolding of Nitinol structures. These systems may involve thermal, electrical, or mechanical stimuli to trigger the shape memory effect and control the folding process in real-time applications.Expand Specific Solutions

Key Players in Nitinol Industry

The research on Nitinol for instantaneous remote folding structures is in an emerging phase, with significant potential for growth. The market for this technology is expanding, driven by applications in aerospace, medical devices, and smart materials. While the market size is still developing, it is expected to grow rapidly as the technology matures. The technical maturity varies among key players, with companies like W. L. Gore & Associates and Abbott Laboratories leading in advanced applications. Universities such as Tsinghua University and Huazhong University of Science & Technology are contributing to fundamental research, while specialized firms like Shape Change Technologies LLC are focusing on specific Nitinol applications. The competitive landscape is diverse, with a mix of established corporations, research institutions, and innovative startups driving progress in this field.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates, Inc. has been actively researching Nitinol applications for instantaneous remote folding structures, particularly in the medical device and aerospace industries. Their research focuses on integrating Nitinol with advanced materials to create innovative, shape-changing structures. Gore has developed proprietary techniques for bonding Nitinol to polymers and fabrics, enabling the creation of flexible, durable structures that can be remotely activated[10]. Their work includes the development of self-expanding medical implants and deployable space structures. Gore's research also encompasses the creation of smart textiles that incorporate Nitinol wires for adaptive clothing and protective gear[12]. The company has made significant advancements in the miniaturization of Nitinol-based actuators, allowing for the development of micro-scale devices with remote folding capabilities[14].

Strengths: Extensive experience in materials science and engineering; strong focus on practical applications across multiple industries. Weaknesses: Broad product portfolio may dilute focus on Nitinol-specific research; potential intellectual property constraints.

Abbott Laboratories

Technical Solution: Abbott Laboratories has been conducting extensive research on Nitinol for instantaneous remote folding structures, primarily focused on medical applications. Their work centers on developing minimally invasive medical devices that can be remotely deployed within the human body. Abbott has made significant advancements in the design of Nitinol-based stents and heart valve repair devices that can be compacted for delivery and then expanded to their functional shape once in place[13]. The company's research includes the development of novel Nitinol alloy compositions with improved biocompatibility and fatigue resistance[15]. Abbott has also been working on smart Nitinol-based implants that can change shape in response to external magnetic fields, allowing for non-invasive adjustments post-implantation[17]. Their research extends to the integration of Nitinol with other smart materials to create multi-functional medical devices with enhanced diagnostic and therapeutic capabilities[19].

Strengths: Extensive resources for medical research and clinical trials; strong focus on practical applications in healthcare. Weaknesses: Research primarily limited to medical applications; potential regulatory challenges in bringing new Nitinol-based devices to market.

Core Innovations in Nitinol Actuation

Avoiding stress-induced martensitic transformation in nickel titanium alloys used in medical devices

PatentInactiveUS7175655B1

Innovation

- A process involving heating a shape memory alloy to a temperature above its martensite deformation temperature (Md) to deform it into a restrained shape in an austenitic state, allowing it to be cooled and stored within a delivery system, such as a catheter, without inducing stress-induced martensite, ensuring the alloy remains in an austenitic state during deployment in the body.

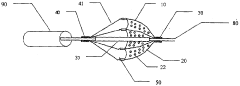

Integral embolic protection device and method of manufacture

PatentInactiveCA2539838A1

Innovation

- An integral embolic protection device fabricated from a single nitinol tube with a filtering membrane and skeleton frame, utilizing laser cutting techniques for improved expansion and conformance, incorporating dual geometry and slits for enhanced filtering capacity and reduced length, and the option to apply biological or pharmaceutical agents for additional benefits.

Environmental Impact of Nitinol Production

The production of Nitinol, a shape memory alloy composed of nickel and titanium, has significant environmental implications that warrant careful consideration. The manufacturing process of Nitinol involves energy-intensive procedures and the use of potentially hazardous materials, which can lead to various environmental impacts.

One of the primary concerns is the high energy consumption associated with Nitinol production. The melting and alloying of nickel and titanium require extremely high temperatures, typically achieved through vacuum arc remelting or vacuum induction melting. These processes consume substantial amounts of electricity, contributing to greenhouse gas emissions and increasing the carbon footprint of Nitinol manufacturing.

The extraction and processing of raw materials, particularly nickel and titanium, also pose environmental challenges. Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution. The refining processes for both metals involve chemical treatments and high-temperature reactions, which may release harmful emissions and generate hazardous waste.

Water usage is another critical environmental factor in Nitinol production. The manufacturing process requires substantial amounts of water for cooling and cleaning purposes. Improper management of wastewater can lead to contamination of local water sources with heavy metals and other pollutants.

The production of Nitinol also generates various waste products, including metal scraps, slag, and chemical byproducts. Proper disposal and recycling of these materials are essential to minimize environmental impact. However, the unique properties of Nitinol can make recycling challenging, potentially leading to increased landfill waste.

Despite these environmental concerns, it is important to note that Nitinol's unique properties, such as its shape memory and superelasticity, enable the development of more efficient and durable products in various industries. This can potentially lead to reduced material consumption and longer product lifespans, which may offset some of the environmental impacts associated with its production.

To mitigate the environmental impact of Nitinol production, several strategies can be implemented. These include improving energy efficiency in manufacturing processes, developing cleaner extraction methods for raw materials, implementing closed-loop water systems, and investing in advanced recycling technologies. Additionally, research into alternative production methods, such as powder metallurgy or additive manufacturing, may offer more environmentally friendly approaches to Nitinol fabrication.

One of the primary concerns is the high energy consumption associated with Nitinol production. The melting and alloying of nickel and titanium require extremely high temperatures, typically achieved through vacuum arc remelting or vacuum induction melting. These processes consume substantial amounts of electricity, contributing to greenhouse gas emissions and increasing the carbon footprint of Nitinol manufacturing.

The extraction and processing of raw materials, particularly nickel and titanium, also pose environmental challenges. Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution. The refining processes for both metals involve chemical treatments and high-temperature reactions, which may release harmful emissions and generate hazardous waste.

Water usage is another critical environmental factor in Nitinol production. The manufacturing process requires substantial amounts of water for cooling and cleaning purposes. Improper management of wastewater can lead to contamination of local water sources with heavy metals and other pollutants.

The production of Nitinol also generates various waste products, including metal scraps, slag, and chemical byproducts. Proper disposal and recycling of these materials are essential to minimize environmental impact. However, the unique properties of Nitinol can make recycling challenging, potentially leading to increased landfill waste.

Despite these environmental concerns, it is important to note that Nitinol's unique properties, such as its shape memory and superelasticity, enable the development of more efficient and durable products in various industries. This can potentially lead to reduced material consumption and longer product lifespans, which may offset some of the environmental impacts associated with its production.

To mitigate the environmental impact of Nitinol production, several strategies can be implemented. These include improving energy efficiency in manufacturing processes, developing cleaner extraction methods for raw materials, implementing closed-loop water systems, and investing in advanced recycling technologies. Additionally, research into alternative production methods, such as powder metallurgy or additive manufacturing, may offer more environmentally friendly approaches to Nitinol fabrication.

Standardization of Nitinol in Engineering

The standardization of Nitinol in engineering is a critical step towards ensuring consistent performance and reliability in applications utilizing this unique shape memory alloy. As the use of Nitinol expands across various industries, including aerospace, medical devices, and consumer electronics, the need for standardized specifications and testing methods becomes increasingly apparent.

One of the primary challenges in standardizing Nitinol is its complex phase transformation behavior, which is highly sensitive to composition, processing, and thermal history. To address this, industry leaders and research institutions have been collaborating to develop comprehensive standards that cover material composition, thermomechanical properties, and testing protocols.

The American Society for Testing and Materials (ASTM) has been at the forefront of these efforts, publishing several standards specific to Nitinol. These include ASTM F2063, which outlines the standard specification for wrought Nickel-Titanium shape memory alloys for medical devices and surgical implants, and ASTM F2516, which provides a standard test method for tension testing of Nickel-Titanium superelastic materials.

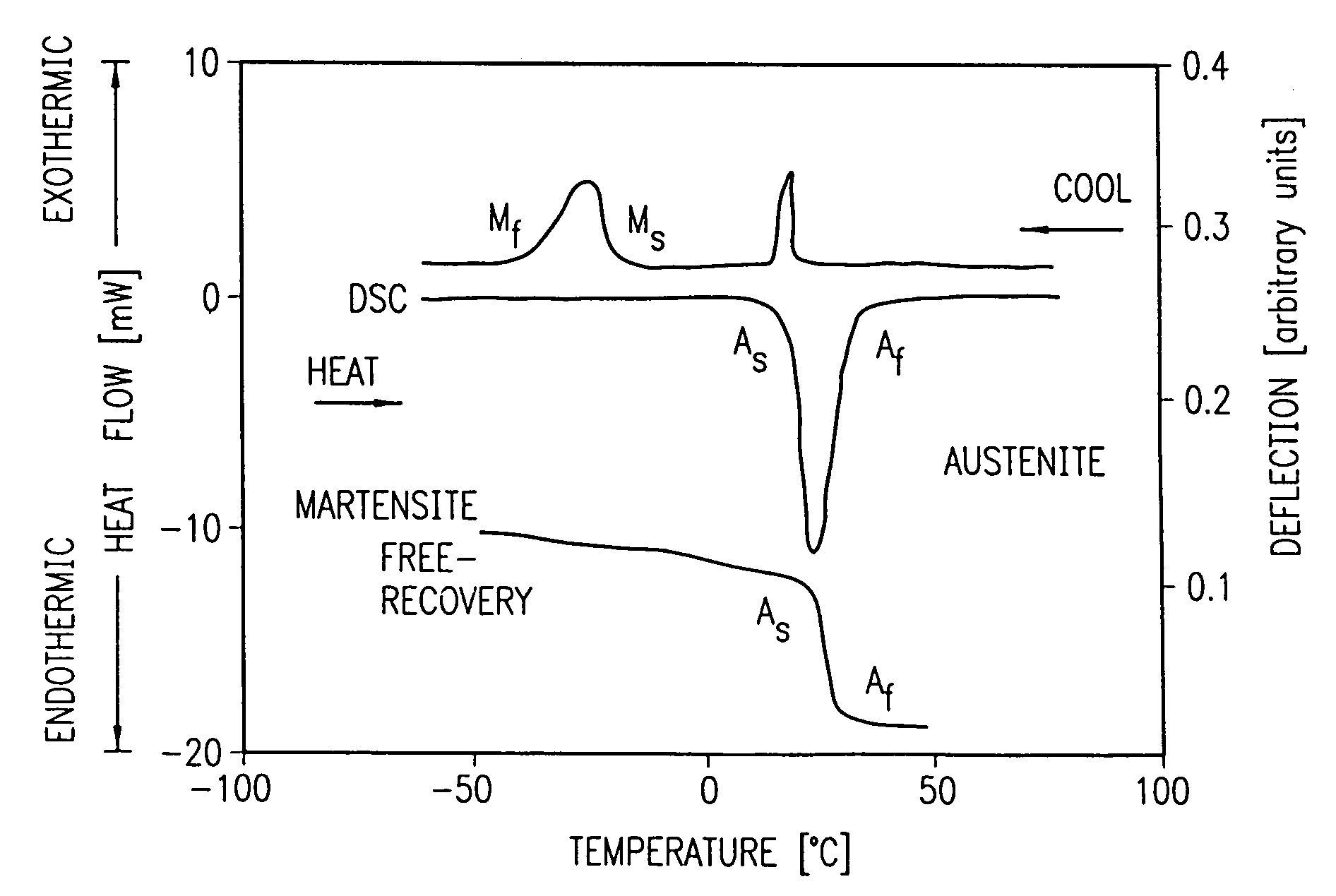

In addition to material specifications, standardization efforts have focused on characterization techniques. Differential Scanning Calorimetry (DSC) has been widely adopted as a standard method for determining transformation temperatures in Nitinol. ASTM F2004 provides guidelines for this test method, ensuring consistency across different laboratories and manufacturers.

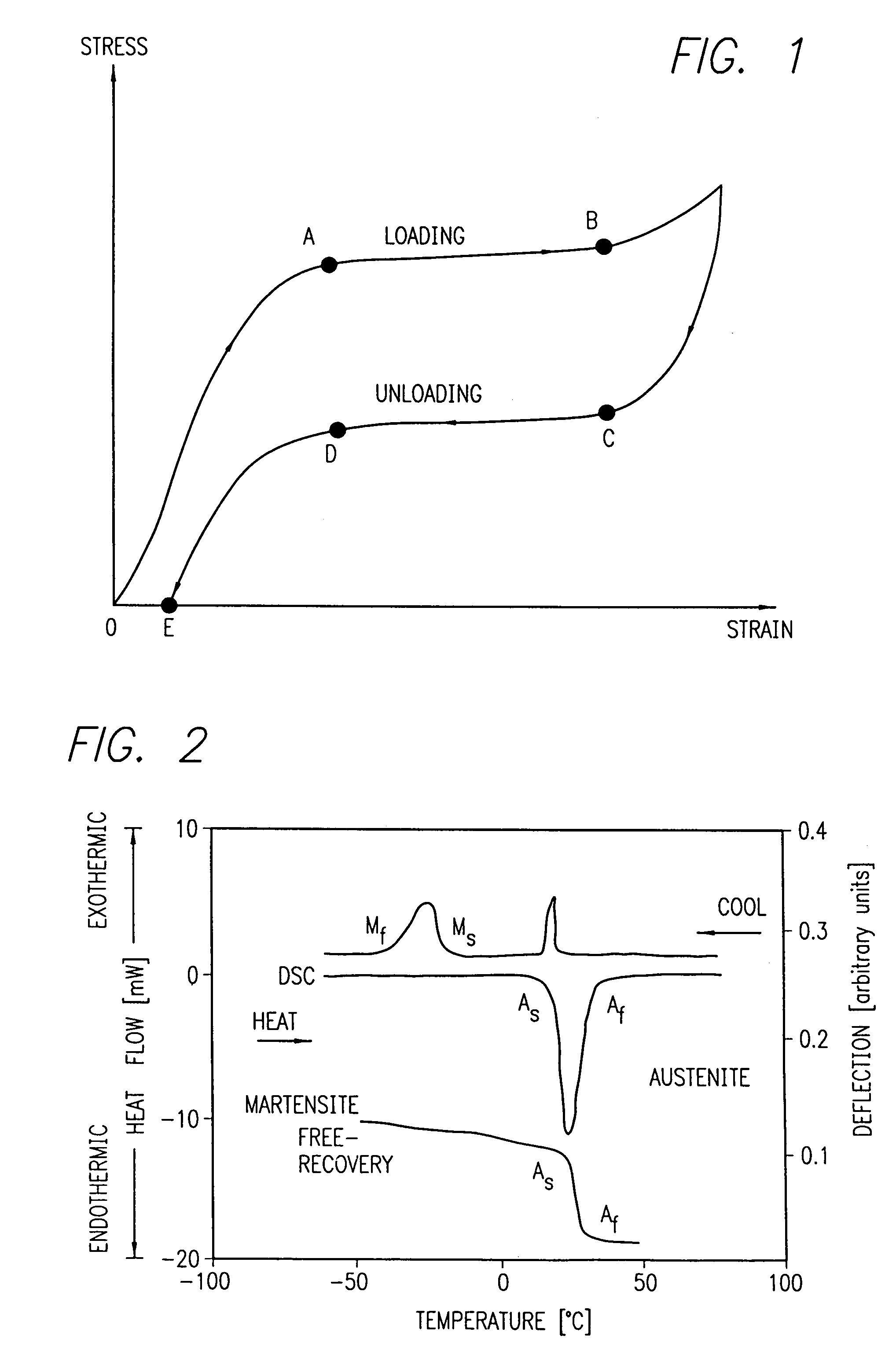

The standardization process also addresses the unique challenges posed by Nitinol's superelastic behavior. Traditional stress-strain curves are often inadequate for fully characterizing Nitinol's mechanical properties. As a result, new testing protocols have been developed to capture the material's loading and unloading behavior, including the upper and lower plateaus characteristic of superelastic deformation.

Fatigue testing is another area where standardization is crucial, particularly for applications involving cyclic loading. ASTM E2948 provides guidance on strain-controlled fatigue testing for Nitinol, which is essential for predicting the long-term performance of devices such as stents and actuators.

As the field of remote folding structures advances, standardization efforts are expanding to include specific guidelines for Nitinol-based deployable systems. These standards aim to address the unique requirements of shape-setting processes, actuation mechanisms, and the repeatability of folding and unfolding operations.

The ongoing standardization of Nitinol in engineering is expected to facilitate innovation, improve quality control, and enhance the reliability of Nitinol-based products. As research continues to uncover new properties and applications of this remarkable alloy, standardization efforts will evolve to keep pace with technological advancements, ensuring that Nitinol remains at the forefront of materials science and engineering.

One of the primary challenges in standardizing Nitinol is its complex phase transformation behavior, which is highly sensitive to composition, processing, and thermal history. To address this, industry leaders and research institutions have been collaborating to develop comprehensive standards that cover material composition, thermomechanical properties, and testing protocols.

The American Society for Testing and Materials (ASTM) has been at the forefront of these efforts, publishing several standards specific to Nitinol. These include ASTM F2063, which outlines the standard specification for wrought Nickel-Titanium shape memory alloys for medical devices and surgical implants, and ASTM F2516, which provides a standard test method for tension testing of Nickel-Titanium superelastic materials.

In addition to material specifications, standardization efforts have focused on characterization techniques. Differential Scanning Calorimetry (DSC) has been widely adopted as a standard method for determining transformation temperatures in Nitinol. ASTM F2004 provides guidelines for this test method, ensuring consistency across different laboratories and manufacturers.

The standardization process also addresses the unique challenges posed by Nitinol's superelastic behavior. Traditional stress-strain curves are often inadequate for fully characterizing Nitinol's mechanical properties. As a result, new testing protocols have been developed to capture the material's loading and unloading behavior, including the upper and lower plateaus characteristic of superelastic deformation.

Fatigue testing is another area where standardization is crucial, particularly for applications involving cyclic loading. ASTM E2948 provides guidance on strain-controlled fatigue testing for Nitinol, which is essential for predicting the long-term performance of devices such as stents and actuators.

As the field of remote folding structures advances, standardization efforts are expanding to include specific guidelines for Nitinol-based deployable systems. These standards aim to address the unique requirements of shape-setting processes, actuation mechanisms, and the repeatability of folding and unfolding operations.

The ongoing standardization of Nitinol in engineering is expected to facilitate innovation, improve quality control, and enhance the reliability of Nitinol-based products. As research continues to uncover new properties and applications of this remarkable alloy, standardization efforts will evolve to keep pace with technological advancements, ensuring that Nitinol remains at the forefront of materials science and engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!