Exploring Polyurethane Efficiency in Energy Systems

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyurethane in Energy: Background and Objectives

Polyurethane, a versatile synthetic polymer, has been a subject of increasing interest in the energy sector due to its unique properties and potential applications. The evolution of polyurethane technology in energy systems can be traced back to the mid-20th century when its insulating properties were first recognized. Since then, the material has undergone significant advancements, expanding its role in various energy-related applications.

The primary objective of exploring polyurethane efficiency in energy systems is to harness its exceptional characteristics to enhance energy conservation, storage, and conversion processes. This exploration aims to address the growing global demand for sustainable and efficient energy solutions. By leveraging polyurethane's thermal insulation properties, researchers and industry professionals seek to improve energy efficiency in buildings, transportation, and industrial processes.

One of the key trends in polyurethane technology for energy applications is the development of advanced foam formulations. These formulations are designed to provide superior insulation performance while maintaining structural integrity and fire resistance. The trend towards more environmentally friendly polyurethane products has also gained momentum, with efforts focused on reducing the use of harmful blowing agents and incorporating bio-based raw materials.

In recent years, the integration of polyurethane in energy storage systems has emerged as a promising area of research. The material's flexibility and durability make it an attractive option for encapsulating and protecting battery components, potentially extending the lifespan and efficiency of energy storage devices. Additionally, polyurethane's role in renewable energy technologies, such as wind turbine blade coatings and solar panel encapsulants, has garnered attention as the world shifts towards cleaner energy sources.

The technological evolution of polyurethane in energy systems is closely tied to advancements in material science and chemical engineering. Researchers are continuously exploring novel polyurethane formulations and manufacturing processes to enhance its energy-related properties. This includes the development of nanocomposite polyurethanes, which offer improved thermal and mechanical properties, as well as the investigation of phase-change polyurethane materials for thermal energy storage applications.

As we look towards the future, the goals for polyurethane in energy systems are ambitious and multifaceted. These include further improving its insulation performance to reduce energy consumption in buildings and transportation, enhancing its durability and efficiency in energy storage applications, and expanding its use in renewable energy technologies. The ultimate aim is to position polyurethane as a key enabler in the transition towards a more sustainable and energy-efficient global economy.

The primary objective of exploring polyurethane efficiency in energy systems is to harness its exceptional characteristics to enhance energy conservation, storage, and conversion processes. This exploration aims to address the growing global demand for sustainable and efficient energy solutions. By leveraging polyurethane's thermal insulation properties, researchers and industry professionals seek to improve energy efficiency in buildings, transportation, and industrial processes.

One of the key trends in polyurethane technology for energy applications is the development of advanced foam formulations. These formulations are designed to provide superior insulation performance while maintaining structural integrity and fire resistance. The trend towards more environmentally friendly polyurethane products has also gained momentum, with efforts focused on reducing the use of harmful blowing agents and incorporating bio-based raw materials.

In recent years, the integration of polyurethane in energy storage systems has emerged as a promising area of research. The material's flexibility and durability make it an attractive option for encapsulating and protecting battery components, potentially extending the lifespan and efficiency of energy storage devices. Additionally, polyurethane's role in renewable energy technologies, such as wind turbine blade coatings and solar panel encapsulants, has garnered attention as the world shifts towards cleaner energy sources.

The technological evolution of polyurethane in energy systems is closely tied to advancements in material science and chemical engineering. Researchers are continuously exploring novel polyurethane formulations and manufacturing processes to enhance its energy-related properties. This includes the development of nanocomposite polyurethanes, which offer improved thermal and mechanical properties, as well as the investigation of phase-change polyurethane materials for thermal energy storage applications.

As we look towards the future, the goals for polyurethane in energy systems are ambitious and multifaceted. These include further improving its insulation performance to reduce energy consumption in buildings and transportation, enhancing its durability and efficiency in energy storage applications, and expanding its use in renewable energy technologies. The ultimate aim is to position polyurethane as a key enabler in the transition towards a more sustainable and energy-efficient global economy.

Market Analysis for Energy-Efficient Polyurethane Applications

The global market for energy-efficient polyurethane applications is experiencing significant growth, driven by increasing awareness of environmental issues and the need for sustainable energy solutions. Polyurethane, known for its versatility and excellent insulating properties, has found extensive use in various energy-related applications, particularly in building insulation, refrigeration, and automotive industries.

In the building and construction sector, polyurethane foam insulation has gained substantial market share due to its superior thermal performance and ability to reduce energy consumption in both residential and commercial buildings. The growing emphasis on green building practices and stringent energy efficiency regulations in many countries has further boosted the demand for polyurethane-based insulation materials.

The refrigeration industry represents another key market for energy-efficient polyurethane applications. Polyurethane foam is widely used in refrigerators, freezers, and cold storage facilities to maintain low temperatures while minimizing energy loss. As the global cold chain logistics market expands, the demand for high-performance insulation materials like polyurethane is expected to rise significantly.

In the automotive sector, polyurethane is increasingly being utilized for lightweight components and insulation materials to improve fuel efficiency and reduce emissions. The growing electric vehicle market has also created new opportunities for polyurethane applications in battery insulation and thermal management systems.

Market analysis indicates that the Asia-Pacific region is emerging as a major growth driver for energy-efficient polyurethane applications, fueled by rapid industrialization, urbanization, and increasing energy consumption in countries like China and India. North America and Europe continue to be significant markets, with a strong focus on energy conservation and sustainable building practices.

The market is characterized by intense competition among key players, including BASF, Covestro, Huntsman Corporation, and Dow Chemical Company. These companies are investing heavily in research and development to improve the energy efficiency and sustainability of their polyurethane products, as well as exploring bio-based alternatives to address environmental concerns.

Despite the positive growth outlook, the market faces challenges such as volatile raw material prices and increasing regulatory pressure on certain chemicals used in polyurethane production. However, ongoing technological advancements and the development of more environmentally friendly formulations are expected to drive continued market expansion in the coming years.

In the building and construction sector, polyurethane foam insulation has gained substantial market share due to its superior thermal performance and ability to reduce energy consumption in both residential and commercial buildings. The growing emphasis on green building practices and stringent energy efficiency regulations in many countries has further boosted the demand for polyurethane-based insulation materials.

The refrigeration industry represents another key market for energy-efficient polyurethane applications. Polyurethane foam is widely used in refrigerators, freezers, and cold storage facilities to maintain low temperatures while minimizing energy loss. As the global cold chain logistics market expands, the demand for high-performance insulation materials like polyurethane is expected to rise significantly.

In the automotive sector, polyurethane is increasingly being utilized for lightweight components and insulation materials to improve fuel efficiency and reduce emissions. The growing electric vehicle market has also created new opportunities for polyurethane applications in battery insulation and thermal management systems.

Market analysis indicates that the Asia-Pacific region is emerging as a major growth driver for energy-efficient polyurethane applications, fueled by rapid industrialization, urbanization, and increasing energy consumption in countries like China and India. North America and Europe continue to be significant markets, with a strong focus on energy conservation and sustainable building practices.

The market is characterized by intense competition among key players, including BASF, Covestro, Huntsman Corporation, and Dow Chemical Company. These companies are investing heavily in research and development to improve the energy efficiency and sustainability of their polyurethane products, as well as exploring bio-based alternatives to address environmental concerns.

Despite the positive growth outlook, the market faces challenges such as volatile raw material prices and increasing regulatory pressure on certain chemicals used in polyurethane production. However, ongoing technological advancements and the development of more environmentally friendly formulations are expected to drive continued market expansion in the coming years.

Current Challenges in Polyurethane Energy Systems

Despite the widespread use of polyurethane in energy systems, several challenges persist in maximizing its efficiency and performance. One of the primary issues is the thermal stability of polyurethane at elevated temperatures. As energy systems often operate in high-temperature environments, the degradation of polyurethane under these conditions can lead to reduced insulation properties and compromised system integrity over time.

Another significant challenge lies in balancing the trade-off between insulation performance and mechanical strength. While increasing the porosity of polyurethane foams can enhance their insulative properties, it often comes at the cost of reduced structural integrity. This balance is crucial in applications such as refrigeration systems and building insulation, where both thermal efficiency and durability are essential.

The moisture sensitivity of polyurethane presents another hurdle in energy system applications. Exposure to humidity can lead to swelling, dimensional changes, and degradation of the material's properties. This is particularly problematic in outdoor applications or in systems with temperature fluctuations that can lead to condensation.

Environmental concerns also pose challenges to the use of polyurethane in energy systems. Traditional polyurethane formulations often rely on blowing agents with high global warming potential. The industry is under pressure to develop more environmentally friendly alternatives without compromising on performance or cost-effectiveness.

The recyclability and end-of-life management of polyurethane components in energy systems remain significant challenges. Unlike some other materials used in energy applications, polyurethane is not easily recyclable, leading to disposal issues and environmental concerns at the end of the product lifecycle.

Achieving consistent quality and performance across large-scale production is another ongoing challenge. Variations in raw materials, processing conditions, and environmental factors during manufacturing can lead to inconsistencies in the final product's properties, affecting the overall efficiency of energy systems.

Lastly, the cost-effectiveness of high-performance polyurethane formulations for energy systems remains a challenge. While advanced formulations can offer superior properties, their higher costs can limit widespread adoption, particularly in price-sensitive markets or applications.

Addressing these challenges requires ongoing research and development efforts, focusing on innovative formulations, processing techniques, and application methodologies to enhance the efficiency and sustainability of polyurethane in energy systems.

Another significant challenge lies in balancing the trade-off between insulation performance and mechanical strength. While increasing the porosity of polyurethane foams can enhance their insulative properties, it often comes at the cost of reduced structural integrity. This balance is crucial in applications such as refrigeration systems and building insulation, where both thermal efficiency and durability are essential.

The moisture sensitivity of polyurethane presents another hurdle in energy system applications. Exposure to humidity can lead to swelling, dimensional changes, and degradation of the material's properties. This is particularly problematic in outdoor applications or in systems with temperature fluctuations that can lead to condensation.

Environmental concerns also pose challenges to the use of polyurethane in energy systems. Traditional polyurethane formulations often rely on blowing agents with high global warming potential. The industry is under pressure to develop more environmentally friendly alternatives without compromising on performance or cost-effectiveness.

The recyclability and end-of-life management of polyurethane components in energy systems remain significant challenges. Unlike some other materials used in energy applications, polyurethane is not easily recyclable, leading to disposal issues and environmental concerns at the end of the product lifecycle.

Achieving consistent quality and performance across large-scale production is another ongoing challenge. Variations in raw materials, processing conditions, and environmental factors during manufacturing can lead to inconsistencies in the final product's properties, affecting the overall efficiency of energy systems.

Lastly, the cost-effectiveness of high-performance polyurethane formulations for energy systems remains a challenge. While advanced formulations can offer superior properties, their higher costs can limit widespread adoption, particularly in price-sensitive markets or applications.

Addressing these challenges requires ongoing research and development efforts, focusing on innovative formulations, processing techniques, and application methodologies to enhance the efficiency and sustainability of polyurethane in energy systems.

Existing Polyurethane Energy Efficiency Techniques

01 Improved polyurethane formulations

Advanced polyurethane formulations are developed to enhance efficiency in various applications. These formulations may include modified isocyanates, polyols, or additives that improve physical properties, processing characteristics, or overall performance of the polyurethane products.- Improved polyurethane formulations: Advanced polyurethane formulations are developed to enhance efficiency in various applications. These formulations may include modified isocyanates, polyols, or additives that improve physical properties, processing characteristics, or overall performance of the polyurethane products.

- Energy-efficient polyurethane production processes: Novel production processes are designed to increase the energy efficiency of polyurethane manufacturing. These may involve optimized reaction conditions, innovative mixing technologies, or improved curing methods that reduce energy consumption while maintaining or enhancing product quality.

- Recycling and sustainability in polyurethane production: Techniques for recycling polyurethane waste and incorporating recycled materials into new products are developed to improve overall efficiency and sustainability. This includes methods for breaking down polyurethane into its component parts for reuse or developing new applications for recycled polyurethane materials.

- High-performance polyurethane coatings: Efficient polyurethane coating formulations are created to provide enhanced protection, durability, and performance in various applications. These coatings may offer improved chemical resistance, weatherability, or faster curing times, leading to increased efficiency in application and use.

- Polyurethane foam optimization: Advancements in polyurethane foam technology focus on improving insulation properties, reducing density while maintaining strength, and enhancing fire resistance. These optimizations lead to more efficient use of materials and improved performance in applications such as construction and automotive industries.

02 Energy-efficient polyurethane production processes

Novel production processes are designed to increase the energy efficiency of polyurethane manufacturing. These may involve optimized reaction conditions, innovative mixing technologies, or improved curing methods that reduce energy consumption while maintaining or enhancing product quality.Expand Specific Solutions03 Polyurethane recycling and sustainability

Techniques for recycling polyurethane materials and improving their sustainability are developed. These may include chemical or mechanical recycling methods, the use of bio-based raw materials, or the development of biodegradable polyurethanes to enhance overall efficiency and reduce environmental impact.Expand Specific Solutions04 Enhanced polyurethane foam efficiency

Innovations in polyurethane foam technology focus on improving insulation properties, reducing density while maintaining strength, or enhancing flame retardancy. These advancements lead to more efficient use of materials and improved performance in applications such as construction and automotive industries.Expand Specific Solutions05 Polyurethane catalysts and additives for improved efficiency

Development of novel catalysts and additives that enhance the efficiency of polyurethane reactions or impart specific properties to the final product. These may include catalysts that accelerate curing, reduce side reactions, or additives that improve dispersion, compatibility, or long-term stability of polyurethane systems.Expand Specific Solutions

Key Players in Polyurethane Energy Solutions

The exploration of polyurethane efficiency in energy systems is currently in a growth phase, with increasing market size and technological advancements. The global market for polyurethane in energy applications is expanding, driven by the demand for sustainable and energy-efficient solutions. Technologically, the field is progressing rapidly, with companies like Covestro Deutschland AG, BASF Corp., and Dow Global Technologies LLC leading innovation. These firms, along with others such as DuPont de Nemours, Inc. and Bayer Intellectual Property GmbH, are developing advanced polyurethane formulations and applications specifically tailored for energy systems. The technology's maturity varies across different energy sectors, with some areas showing high readiness levels while others remain in early development stages.

BASF Corp.

Technical Solution: BASF has developed a novel polyurethane-based energy storage system called "Cellasto". This technology utilizes the unique properties of polyurethane to create a flexible, durable, and efficient energy storage solution. The Cellasto system incorporates specially formulated polyurethane foams that can store and release energy through mechanical deformation. This allows for the capture of kinetic energy from various sources, such as vehicle suspension systems or industrial machinery, and its conversion into usable electrical energy.

Strengths: High energy density, flexibility, and durability. Weaknesses: Limited to specific applications, may have lower efficiency compared to traditional battery technologies.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered a polyurethane-based thermal energy storage system called "VORASTAR". This innovative technology utilizes phase change materials (PCMs) encapsulated within a polyurethane matrix. The PCMs absorb and release thermal energy as they change phase, allowing for efficient storage and release of heat or cold. The polyurethane matrix provides structural integrity and enhances the overall thermal performance of the system. VORASTAR can be applied in building insulation, HVAC systems, and industrial processes to improve energy efficiency and reduce peak energy demands.

Strengths: High thermal storage capacity, customizable for different temperature ranges. Weaknesses: May require specialized manufacturing processes, potential long-term stability issues.

Innovative Polyurethane Energy Technologies

Use of thermoplastic polyurethanes for converting mechanical energy to electrical energy

PatentInactiveEP2695209A1

Innovation

- The use of thermoplastic polyurethanes, composed of linear bifunctional hydroxyl-terminated polyols, diol chain extenders, and organic diisocyanates, with a specific molar ratio of NCO groups to OH groups, enhances the modulus of elasticity, electrical resistance, and breakdown field strength, improving the efficiency of energy production by stretching and relaxing the polymer between electrodes.

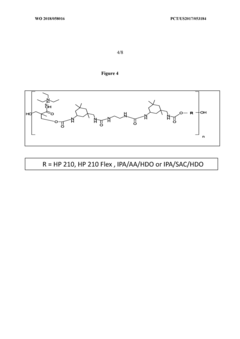

Biorenewable high performance polyester polyols

PatentWO2018058016A1

Innovation

- A process for manufacturing polyester polyols with high biorenewable content using polyfunctional carboxylic acids and polyhydric alcohols derived from biological sources, such as succinic acid and 1,3-propanediol, to produce high-performance polyurethane systems with superior mechanical properties.

Environmental Impact of Polyurethane in Energy Systems

The environmental impact of polyurethane in energy systems is a critical consideration as the world moves towards more sustainable practices. Polyurethane, widely used in various energy applications, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of polyurethane in energy systems is its insulation properties. When used in buildings, polyurethane foam significantly reduces energy consumption for heating and cooling. This leads to lower greenhouse gas emissions associated with energy production. Additionally, polyurethane's lightweight nature contributes to fuel efficiency in transportation, further reducing carbon footprints.

However, the production of polyurethane raises environmental concerns. The manufacturing process often involves the use of fossil fuels and releases volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to air pollution and can have negative impacts on human health and ecosystems. Furthermore, the use of isocyanates in polyurethane production poses potential risks to workers and the environment if not properly managed.

The end-of-life disposal of polyurethane products is another environmental challenge. Many polyurethane materials are not biodegradable and can persist in landfills for extended periods. Incineration of polyurethane waste can release toxic substances, including hydrogen cyanide and carbon monoxide, necessitating advanced emission control systems.

Recent advancements in polyurethane technology have focused on improving its environmental profile. Bio-based polyurethanes, derived from renewable resources such as vegetable oils, are gaining traction. These alternatives reduce dependence on fossil fuels and often have a lower carbon footprint. Additionally, research into recyclable and biodegradable polyurethanes is progressing, aiming to address end-of-life issues.

The energy efficiency gains from polyurethane use must be balanced against its environmental impacts throughout its lifecycle. Life Cycle Assessment (LCA) studies have shown that the energy savings from polyurethane insulation often outweigh the environmental costs of production and disposal. However, these assessments vary depending on specific applications and local energy mixes.

As environmental regulations become more stringent, the polyurethane industry is adapting. Manufacturers are investing in cleaner production technologies, such as water-based systems that reduce VOC emissions. There is also a growing focus on developing polyurethane recycling technologies to create a more circular economy for these materials.

In conclusion, while polyurethane offers significant benefits in energy efficiency, its environmental impact remains a complex issue. Continued research and innovation in production methods, renewable sourcing, and end-of-life management are crucial for improving the sustainability of polyurethane in energy systems.

One of the primary environmental benefits of polyurethane in energy systems is its insulation properties. When used in buildings, polyurethane foam significantly reduces energy consumption for heating and cooling. This leads to lower greenhouse gas emissions associated with energy production. Additionally, polyurethane's lightweight nature contributes to fuel efficiency in transportation, further reducing carbon footprints.

However, the production of polyurethane raises environmental concerns. The manufacturing process often involves the use of fossil fuels and releases volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to air pollution and can have negative impacts on human health and ecosystems. Furthermore, the use of isocyanates in polyurethane production poses potential risks to workers and the environment if not properly managed.

The end-of-life disposal of polyurethane products is another environmental challenge. Many polyurethane materials are not biodegradable and can persist in landfills for extended periods. Incineration of polyurethane waste can release toxic substances, including hydrogen cyanide and carbon monoxide, necessitating advanced emission control systems.

Recent advancements in polyurethane technology have focused on improving its environmental profile. Bio-based polyurethanes, derived from renewable resources such as vegetable oils, are gaining traction. These alternatives reduce dependence on fossil fuels and often have a lower carbon footprint. Additionally, research into recyclable and biodegradable polyurethanes is progressing, aiming to address end-of-life issues.

The energy efficiency gains from polyurethane use must be balanced against its environmental impacts throughout its lifecycle. Life Cycle Assessment (LCA) studies have shown that the energy savings from polyurethane insulation often outweigh the environmental costs of production and disposal. However, these assessments vary depending on specific applications and local energy mixes.

As environmental regulations become more stringent, the polyurethane industry is adapting. Manufacturers are investing in cleaner production technologies, such as water-based systems that reduce VOC emissions. There is also a growing focus on developing polyurethane recycling technologies to create a more circular economy for these materials.

In conclusion, while polyurethane offers significant benefits in energy efficiency, its environmental impact remains a complex issue. Continued research and innovation in production methods, renewable sourcing, and end-of-life management are crucial for improving the sustainability of polyurethane in energy systems.

Cost-Benefit Analysis of Polyurethane Energy Solutions

The cost-benefit analysis of polyurethane energy solutions reveals a complex interplay of economic factors and performance advantages. Initial investment in polyurethane-based systems often exceeds that of traditional materials, primarily due to higher raw material costs and specialized manufacturing processes. However, the long-term benefits frequently outweigh these upfront expenses.

Energy efficiency stands as a primary advantage of polyurethane solutions. In building insulation applications, polyurethane foam demonstrates superior thermal resistance properties, leading to significant reductions in heating and cooling costs over time. Studies indicate that buildings utilizing polyurethane insulation can achieve energy savings of up to 30% compared to conventional insulation materials.

In the automotive sector, polyurethane components contribute to weight reduction, enhancing fuel efficiency. The lightweight nature of polyurethane parts can result in fuel savings of 3-5% over the vehicle's lifetime, translating to substantial cost benefits for consumers and reduced environmental impact.

Durability and longevity of polyurethane products further enhance their cost-effectiveness. Polyurethane-based materials often exhibit extended lifespans compared to alternatives, reducing replacement and maintenance costs. In industrial applications, such as pipeline insulation, polyurethane coatings provide superior protection against corrosion and thermal loss, minimizing downtime and repair expenses.

However, the cost-benefit equation varies across different energy-related applications. In some cases, such as solar panel manufacturing, the benefits of polyurethane may be less pronounced, and alternative materials might offer more favorable cost-performance ratios.

Environmental considerations also factor into the cost-benefit analysis. While polyurethane production involves energy-intensive processes and petrochemical-based raw materials, the energy savings achieved during product use often offset these initial environmental costs. Additionally, advancements in bio-based polyurethanes are improving the overall environmental profile of these solutions.

Market dynamics play a crucial role in determining the economic viability of polyurethane energy solutions. As production scales increase and technologies mature, economies of scale are likely to drive down costs, further improving the cost-benefit ratio. Government regulations and incentives promoting energy efficiency can also significantly influence the adoption and economic attractiveness of polyurethane-based systems.

In conclusion, while the initial costs of polyurethane energy solutions may be higher, the long-term benefits in energy savings, durability, and performance often justify the investment. As technology advances and market conditions evolve, the cost-benefit balance is expected to shift further in favor of polyurethane-based energy solutions across various applications.

Energy efficiency stands as a primary advantage of polyurethane solutions. In building insulation applications, polyurethane foam demonstrates superior thermal resistance properties, leading to significant reductions in heating and cooling costs over time. Studies indicate that buildings utilizing polyurethane insulation can achieve energy savings of up to 30% compared to conventional insulation materials.

In the automotive sector, polyurethane components contribute to weight reduction, enhancing fuel efficiency. The lightweight nature of polyurethane parts can result in fuel savings of 3-5% over the vehicle's lifetime, translating to substantial cost benefits for consumers and reduced environmental impact.

Durability and longevity of polyurethane products further enhance their cost-effectiveness. Polyurethane-based materials often exhibit extended lifespans compared to alternatives, reducing replacement and maintenance costs. In industrial applications, such as pipeline insulation, polyurethane coatings provide superior protection against corrosion and thermal loss, minimizing downtime and repair expenses.

However, the cost-benefit equation varies across different energy-related applications. In some cases, such as solar panel manufacturing, the benefits of polyurethane may be less pronounced, and alternative materials might offer more favorable cost-performance ratios.

Environmental considerations also factor into the cost-benefit analysis. While polyurethane production involves energy-intensive processes and petrochemical-based raw materials, the energy savings achieved during product use often offset these initial environmental costs. Additionally, advancements in bio-based polyurethanes are improving the overall environmental profile of these solutions.

Market dynamics play a crucial role in determining the economic viability of polyurethane energy solutions. As production scales increase and technologies mature, economies of scale are likely to drive down costs, further improving the cost-benefit ratio. Government regulations and incentives promoting energy efficiency can also significantly influence the adoption and economic attractiveness of polyurethane-based systems.

In conclusion, while the initial costs of polyurethane energy solutions may be higher, the long-term benefits in energy savings, durability, and performance often justify the investment. As technology advances and market conditions evolve, the cost-benefit balance is expected to shift further in favor of polyurethane-based energy solutions across various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!