Alkyl Chemistry: Exploring Renewable Chemical Synonyms

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Chemistry Evolution

Alkyl chemistry has undergone significant evolution since its inception in the early 19th century. The field began with the discovery of ethylene by Dutch chemists in 1795, which laid the foundation for understanding hydrocarbon structures. In the 1830s, Jean-Baptiste Dumas developed the theory of substitution, demonstrating that hydrogen atoms in organic compounds could be replaced by other elements, particularly halogens.

The next major milestone came in 1849 when Edward Frankland synthesized the first organometallic compound, diethylzinc. This breakthrough opened up new avenues for alkyl chemistry, leading to the development of Grignard reagents in 1900 by Victor Grignard. These organomagnesium compounds revolutionized organic synthesis, providing a powerful tool for carbon-carbon bond formation.

The early 20th century saw rapid advancements in alkyl chemistry. In 1912, Paul Sabatier developed catalytic hydrogenation, enabling the conversion of unsaturated hydrocarbons to saturated ones. This technology became crucial for industrial processes, particularly in the production of margarine and other hydrogenated fats.

The discovery of Ziegler-Natta catalysts in the 1950s marked another pivotal moment in alkyl chemistry. Karl Ziegler and Giulio Natta's work on catalytic polymerization of olefins led to the large-scale production of polyethylene and polypropylene, revolutionizing the plastics industry.

In the latter half of the 20th century, the focus shifted towards developing more environmentally friendly and sustainable alkyl chemistry processes. The concept of green chemistry, introduced in the 1990s, emphasized the need for safer, less toxic, and more energy-efficient chemical reactions.

The 21st century has seen a renewed interest in renewable resources for alkyl chemistry. Biomass-derived alkyl compounds have gained attention as potential replacements for petroleum-based chemicals. Research into bio-based feedstocks, such as plant oils and lignocellulosic biomass, has led to the development of novel alkylation processes and renewable chemical synonyms.

Recent advancements in catalysis, particularly in the field of organocatalysis and biocatalysis, have opened up new possibilities for sustainable alkyl chemistry. These approaches offer milder reaction conditions, higher selectivity, and reduced environmental impact compared to traditional metal-based catalysts.

The ongoing evolution of alkyl chemistry continues to focus on sustainability, efficiency, and the exploration of renewable resources. As the field progresses, researchers are developing innovative methods for carbon-carbon bond formation, functionalization of alkyl groups, and the synthesis of complex molecules from simple, renewable starting materials.

The next major milestone came in 1849 when Edward Frankland synthesized the first organometallic compound, diethylzinc. This breakthrough opened up new avenues for alkyl chemistry, leading to the development of Grignard reagents in 1900 by Victor Grignard. These organomagnesium compounds revolutionized organic synthesis, providing a powerful tool for carbon-carbon bond formation.

The early 20th century saw rapid advancements in alkyl chemistry. In 1912, Paul Sabatier developed catalytic hydrogenation, enabling the conversion of unsaturated hydrocarbons to saturated ones. This technology became crucial for industrial processes, particularly in the production of margarine and other hydrogenated fats.

The discovery of Ziegler-Natta catalysts in the 1950s marked another pivotal moment in alkyl chemistry. Karl Ziegler and Giulio Natta's work on catalytic polymerization of olefins led to the large-scale production of polyethylene and polypropylene, revolutionizing the plastics industry.

In the latter half of the 20th century, the focus shifted towards developing more environmentally friendly and sustainable alkyl chemistry processes. The concept of green chemistry, introduced in the 1990s, emphasized the need for safer, less toxic, and more energy-efficient chemical reactions.

The 21st century has seen a renewed interest in renewable resources for alkyl chemistry. Biomass-derived alkyl compounds have gained attention as potential replacements for petroleum-based chemicals. Research into bio-based feedstocks, such as plant oils and lignocellulosic biomass, has led to the development of novel alkylation processes and renewable chemical synonyms.

Recent advancements in catalysis, particularly in the field of organocatalysis and biocatalysis, have opened up new possibilities for sustainable alkyl chemistry. These approaches offer milder reaction conditions, higher selectivity, and reduced environmental impact compared to traditional metal-based catalysts.

The ongoing evolution of alkyl chemistry continues to focus on sustainability, efficiency, and the exploration of renewable resources. As the field progresses, researchers are developing innovative methods for carbon-carbon bond formation, functionalization of alkyl groups, and the synthesis of complex molecules from simple, renewable starting materials.

Renewable Chemical Demand

The demand for renewable chemicals in the alkyl chemistry sector has been steadily increasing over the past decade, driven by growing environmental concerns and the push for sustainable alternatives to petroleum-based products. This trend is particularly evident in the production of alkyl-based compounds, which are widely used in various industries, including personal care, lubricants, and plastics.

Market analysis indicates that the global renewable chemicals market is experiencing robust growth, with a significant portion attributed to alkyl-based products. The shift towards bio-based alkyl compounds is fueled by consumer preferences for eco-friendly products and stringent regulations aimed at reducing carbon footprints. Industries are actively seeking renewable sources for alkyl groups, such as plant-based oils and agricultural residues, to replace traditional fossil fuel-derived feedstocks.

The personal care and cosmetics industry has emerged as a key driver in the demand for renewable alkyl chemicals. Manufacturers are increasingly incorporating bio-based alkyl surfactants, emollients, and conditioning agents into their formulations to meet the rising consumer demand for natural and sustainable products. This sector's commitment to green chemistry has led to the development of novel alkyl derivatives from renewable sources, expanding the market potential for these sustainable alternatives.

In the lubricants industry, there is a growing interest in renewable alkyl-based additives and base oils. These bio-derived alternatives offer improved biodegradability and reduced environmental impact compared to their petroleum-based counterparts. The automotive and industrial sectors are particularly keen on adopting these sustainable options to enhance their environmental credentials and comply with evolving regulations.

The plastics industry is another significant consumer of alkyl chemicals, and the demand for renewable alternatives is on the rise. Bioplastics incorporating renewable alkyl components are gaining traction in packaging, automotive, and consumer goods applications. This shift is driven by the need to reduce plastic waste and dependence on fossil fuels, aligning with circular economy principles.

Agricultural and forestry by-products are becoming increasingly important sources for renewable alkyl chemicals. The valorization of these waste streams not only provides a sustainable feedstock for alkyl chemistry but also contributes to the development of a more circular bioeconomy. This approach is attracting investments and research efforts to optimize the extraction and conversion processes of bio-based alkyl precursors.

As the renewable chemicals market continues to evolve, collaborations between chemical companies, biotechnology firms, and academic institutions are intensifying. These partnerships aim to develop innovative processes for the production of renewable alkyl chemicals, focusing on improving yield, reducing costs, and expanding the range of available bio-based alkyl derivatives.

Market analysis indicates that the global renewable chemicals market is experiencing robust growth, with a significant portion attributed to alkyl-based products. The shift towards bio-based alkyl compounds is fueled by consumer preferences for eco-friendly products and stringent regulations aimed at reducing carbon footprints. Industries are actively seeking renewable sources for alkyl groups, such as plant-based oils and agricultural residues, to replace traditional fossil fuel-derived feedstocks.

The personal care and cosmetics industry has emerged as a key driver in the demand for renewable alkyl chemicals. Manufacturers are increasingly incorporating bio-based alkyl surfactants, emollients, and conditioning agents into their formulations to meet the rising consumer demand for natural and sustainable products. This sector's commitment to green chemistry has led to the development of novel alkyl derivatives from renewable sources, expanding the market potential for these sustainable alternatives.

In the lubricants industry, there is a growing interest in renewable alkyl-based additives and base oils. These bio-derived alternatives offer improved biodegradability and reduced environmental impact compared to their petroleum-based counterparts. The automotive and industrial sectors are particularly keen on adopting these sustainable options to enhance their environmental credentials and comply with evolving regulations.

The plastics industry is another significant consumer of alkyl chemicals, and the demand for renewable alternatives is on the rise. Bioplastics incorporating renewable alkyl components are gaining traction in packaging, automotive, and consumer goods applications. This shift is driven by the need to reduce plastic waste and dependence on fossil fuels, aligning with circular economy principles.

Agricultural and forestry by-products are becoming increasingly important sources for renewable alkyl chemicals. The valorization of these waste streams not only provides a sustainable feedstock for alkyl chemistry but also contributes to the development of a more circular bioeconomy. This approach is attracting investments and research efforts to optimize the extraction and conversion processes of bio-based alkyl precursors.

As the renewable chemicals market continues to evolve, collaborations between chemical companies, biotechnology firms, and academic institutions are intensifying. These partnerships aim to develop innovative processes for the production of renewable alkyl chemicals, focusing on improving yield, reducing costs, and expanding the range of available bio-based alkyl derivatives.

Challenges in Synthesis

The synthesis of renewable chemical synonyms in alkyl chemistry faces several significant challenges. One of the primary obstacles is the limited availability of suitable renewable feedstocks. While biomass offers a promising source of renewable carbon, its complex and heterogeneous nature often requires extensive pretreatment and purification steps before it can be effectively utilized in alkyl chemistry processes.

Another major challenge lies in the development of efficient and selective catalytic systems. Traditional catalysts used in petroleum-based alkyl chemistry may not be optimal for renewable feedstocks, necessitating the design of new catalytic materials tailored to the unique characteristics of bio-based precursors. This includes addressing issues such as catalyst deactivation due to impurities present in renewable feedstocks and improving selectivity to minimize unwanted side reactions.

The economic viability of renewable alkyl chemistry processes also presents a significant hurdle. Many current synthetic routes for renewable chemical synonyms are not cost-competitive with their petroleum-based counterparts, primarily due to higher production costs and lower yields. Overcoming this challenge requires innovative process designs and the development of more efficient conversion technologies to improve overall economics.

Scaling up laboratory-scale processes to industrial production levels poses another set of challenges. Issues such as heat and mass transfer limitations, reactor design, and process control become more pronounced at larger scales, necessitating careful engineering and optimization to maintain product quality and process efficiency.

Furthermore, the synthesis of renewable chemical synonyms often involves complex reaction pathways with multiple intermediates. Controlling reaction selectivity and minimizing the formation of undesired byproducts is crucial for achieving high yields and product purity. This requires a deep understanding of reaction mechanisms and the development of advanced separation and purification techniques.

Lastly, ensuring consistent product quality and meeting industry specifications can be challenging when working with renewable feedstocks. The inherent variability in biomass composition and the presence of trace impurities can impact final product properties, necessitating robust quality control measures and potentially additional purification steps.

Another major challenge lies in the development of efficient and selective catalytic systems. Traditional catalysts used in petroleum-based alkyl chemistry may not be optimal for renewable feedstocks, necessitating the design of new catalytic materials tailored to the unique characteristics of bio-based precursors. This includes addressing issues such as catalyst deactivation due to impurities present in renewable feedstocks and improving selectivity to minimize unwanted side reactions.

The economic viability of renewable alkyl chemistry processes also presents a significant hurdle. Many current synthetic routes for renewable chemical synonyms are not cost-competitive with their petroleum-based counterparts, primarily due to higher production costs and lower yields. Overcoming this challenge requires innovative process designs and the development of more efficient conversion technologies to improve overall economics.

Scaling up laboratory-scale processes to industrial production levels poses another set of challenges. Issues such as heat and mass transfer limitations, reactor design, and process control become more pronounced at larger scales, necessitating careful engineering and optimization to maintain product quality and process efficiency.

Furthermore, the synthesis of renewable chemical synonyms often involves complex reaction pathways with multiple intermediates. Controlling reaction selectivity and minimizing the formation of undesired byproducts is crucial for achieving high yields and product purity. This requires a deep understanding of reaction mechanisms and the development of advanced separation and purification techniques.

Lastly, ensuring consistent product quality and meeting industry specifications can be challenging when working with renewable feedstocks. The inherent variability in biomass composition and the presence of trace impurities can impact final product properties, necessitating robust quality control measures and potentially additional purification steps.

Current Renewable Methods

01 Alkyl-based chemical reactions and synthesis

This category focuses on various chemical reactions and synthesis methods involving alkyl groups. It includes processes for creating alkyl compounds, modifying existing molecules with alkyl groups, and studying the reactivity of alkyl-containing substances. These reactions are fundamental in organic chemistry and have applications in pharmaceuticals, materials science, and industrial processes.- Alkyl-based chemical reactions and synthesis: This category focuses on various chemical reactions and synthesis methods involving alkyl groups. It includes processes for creating alkyl compounds, modifying existing molecules with alkyl groups, and studying the reactivity of alkyl-containing substances. These reactions are fundamental in organic chemistry and have applications in pharmaceuticals, materials science, and industrial processes.

- Alkyl-modified materials and coatings: This area explores the use of alkyl groups to modify materials and create specialized coatings. Alkyl modifications can enhance properties such as hydrophobicity, durability, and chemical resistance. Applications include surface treatments, protective coatings, and the development of advanced materials with tailored characteristics for various industries.

- Alkyl-based polymers and plastics: This category covers the development and application of polymers and plastics that incorporate alkyl groups in their structure. These materials can exhibit unique properties such as flexibility, thermal stability, and chemical resistance. Research in this area includes new polymerization techniques, structure-property relationships, and the creation of novel alkyl-based plastic materials for diverse applications.

- Alkyl-based surfactants and emulsifiers: This point focuses on the development and application of alkyl-based surfactants and emulsifiers. These compounds play crucial roles in various industries, including personal care, cleaning products, and food processing. Research in this area includes designing new alkyl-based surfactants with improved performance, studying their interfacial properties, and optimizing formulations for specific applications.

- Analytical methods for alkyl compounds: This category encompasses analytical techniques and methods specifically developed or adapted for the detection, quantification, and characterization of alkyl compounds. It includes spectroscopic methods, chromatography techniques, and other analytical approaches tailored to study alkyl groups in various matrices. These methods are essential for quality control, environmental monitoring, and research in alkyl chemistry.

02 Alkyl-modified materials and coatings

This area explores the use of alkyl groups to modify materials and create specialized coatings. By incorporating alkyl chains into polymers, surfaces, or nanoparticles, researchers can alter properties such as hydrophobicity, durability, and chemical resistance. These modifications have applications in areas like protective coatings, self-cleaning surfaces, and advanced materials for various industries.Expand Specific Solutions03 Alkyl-based surfactants and emulsifiers

This category covers the development and application of alkyl-based surfactants and emulsifiers. These compounds, which contain both hydrophilic and hydrophobic parts, are crucial in creating stable emulsions, foams, and dispersions. They find use in personal care products, cleaning agents, food processing, and industrial applications where controlling surface tension and interfacial properties is important.Expand Specific Solutions04 Alkyl-functionalized nanomaterials

This area focuses on the functionalization of nanomaterials with alkyl groups. By attaching alkyl chains to nanoparticles, nanotubes, or other nanostructures, researchers can modify their properties, improve their dispersibility in various media, and enhance their compatibility with other materials. These functionalized nanomaterials have potential applications in electronics, energy storage, catalysis, and biomedical fields.Expand Specific Solutions05 Analytical methods for alkyl compounds

This category encompasses analytical techniques and methods specifically developed or adapted for the detection, quantification, and characterization of alkyl compounds. It includes spectroscopic methods, chromatography techniques, and advanced imaging approaches that enable researchers to study the structure, purity, and behavior of alkyl-containing molecules in various contexts, from environmental samples to complex chemical mixtures.Expand Specific Solutions

Key Industry Players

The renewable chemical synonyms in Alkyl Chemistry field is in its early development stage, with a growing market driven by increasing environmental concerns and sustainability initiatives. The market size is expanding, though still relatively small compared to traditional petrochemical-based products. Technological maturity varies, with some processes nearing commercialization while others remain in research phases. Key players like China Petroleum & Chemical Corp., Vertex Pharmaceuticals, and Novartis AG are investing in R&D to advance bio-based alkyl chemistry. Academic institutions such as The Scripps Research Institute and The Rockefeller University are contributing fundamental research, while companies like Biogen and Zoetis are exploring applications in pharmaceuticals and animal health.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been actively exploring renewable chemical synonyms in alkyl chemistry. Their approach focuses on developing bio-based alkyl compounds as alternatives to petroleum-derived chemicals. Sinopec has invested in advanced catalytic processes to convert biomass-derived feedstocks into renewable alkyl chemicals[1]. They have successfully developed a proprietary technology for producing bio-based alkyl benzene, which can be used as a renewable substitute for traditional petrochemical-based alkyl benzene in detergents and other applications[2]. Additionally, Sinopec has made significant progress in the production of renewable alkyl esters through transesterification of vegetable oils, achieving high yields and purity levels comparable to conventional petroleum-based processes[3].

Strengths: Extensive petrochemical expertise, large-scale production capabilities, and established market presence. Weaknesses: Potential challenges in scaling up bio-based processes and competing with traditional petroleum-based products on cost.

The Scripps Research Institute

Technical Solution: The Scripps Research Institute has been at the forefront of exploring renewable chemical synonyms in alkyl chemistry through innovative synthetic methodologies. Their approach focuses on developing novel catalytic systems for the sustainable synthesis of alkyl compounds from renewable resources. Scripps researchers have pioneered the use of biocatalysis for the selective functionalization of alkyl groups, enabling the production of complex molecules from simple, renewable starting materials[4]. They have also developed metal-free organocatalytic methods for the synthesis of chiral alkyl compounds, which offer a more environmentally friendly alternative to traditional metal-catalyzed processes[5]. Furthermore, Scripps has made significant advancements in flow chemistry techniques for the continuous production of renewable alkyl derivatives, improving efficiency and reducing waste in chemical synthesis[6].

Strengths: Cutting-edge research capabilities, interdisciplinary approach, and strong track record in catalysis and synthetic methodology. Weaknesses: Potential challenges in translating academic research into industrial-scale processes.

Innovative Alkyl Pathways

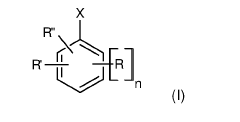

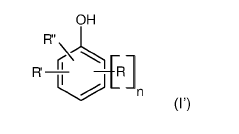

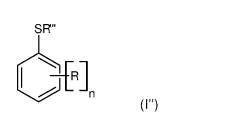

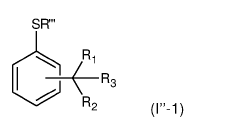

Substituted alkyl(THIO)phenols, processes for producing same, and uses thereof

PatentWO2022171887A1

Innovation

- Development of new substituted alkylphenol and alkylthiophenol compounds obtained through alkylation reactions involving olefins from co-dimerization or metathesis between different olefins, including biosourced isobutene oligomers, to create compounds with specific branched alkane chains suitable for various applications.

Use of redox mediators as additives in electrolytes of lithium sulfur batteries

PatentWO2015044829A1

Innovation

- Incorporating a redox mediator with a potential difference between 2.29 and 4 V in the electrolyte composition, specifically between 2.6 and 3.5 V, to facilitate low overpotential charging of lithium-sulfur cells with a cathode containing electroactive sulfur materials like Li2S, and an anode, using an aprotic organic solvent and alkali metal salt.

Regulatory Framework

The regulatory framework surrounding renewable chemical synonyms in alkyl chemistry is a complex and evolving landscape. As the global push for sustainability intensifies, governments and international bodies are increasingly focusing on the development and implementation of regulations that promote the use of renewable resources in chemical production.

At the forefront of this regulatory shift is the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. REACH has been instrumental in driving the adoption of renewable alternatives in alkyl chemistry by requiring manufacturers to assess and manage the risks associated with chemicals they produce or import. This has led to increased research and development in renewable chemical synonyms, as companies seek to comply with stricter environmental standards.

In the United States, the Toxic Substances Control Act (TSCA) has been amended to include provisions that encourage the development of sustainable chemistry. The Environmental Protection Agency (EPA) has established programs such as the Green Chemistry Challenge Awards to recognize and promote innovative approaches to reducing the environmental impact of chemical processes, including those in alkyl chemistry.

The United Nations' Sustainable Development Goals (SDGs) have also played a significant role in shaping the regulatory landscape. Goal 12, which focuses on responsible consumption and production, has prompted many countries to implement policies that favor the use of renewable resources in chemical manufacturing. This has led to the creation of incentives and subsidies for companies that invest in renewable chemical technologies.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for the sustainable production of chemicals. ISO 14001, which sets out the criteria for an environmental management system, has become a benchmark for companies seeking to demonstrate their commitment to sustainability in chemical production.

Many countries have introduced specific regulations targeting the use of renewable resources in chemical manufacturing. For instance, Brazil's National Biofuels Policy (RenovaBio) has indirectly influenced the alkyl chemistry sector by promoting the production of biofuels, which often involve renewable chemical processes.

The regulatory framework also extends to labeling and certification schemes. Eco-labels and green certifications are becoming increasingly important in the chemical industry, with many countries implementing mandatory labeling requirements for products containing renewable chemicals. This transparency helps consumers make informed choices and drives market demand for sustainable alternatives in alkyl chemistry.

As the field of renewable chemical synonyms in alkyl chemistry continues to advance, regulators face the challenge of keeping pace with technological developments. Many jurisdictions are adopting adaptive regulatory approaches that allow for flexibility in addressing new innovations while maintaining rigorous safety and environmental standards.

At the forefront of this regulatory shift is the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. REACH has been instrumental in driving the adoption of renewable alternatives in alkyl chemistry by requiring manufacturers to assess and manage the risks associated with chemicals they produce or import. This has led to increased research and development in renewable chemical synonyms, as companies seek to comply with stricter environmental standards.

In the United States, the Toxic Substances Control Act (TSCA) has been amended to include provisions that encourage the development of sustainable chemistry. The Environmental Protection Agency (EPA) has established programs such as the Green Chemistry Challenge Awards to recognize and promote innovative approaches to reducing the environmental impact of chemical processes, including those in alkyl chemistry.

The United Nations' Sustainable Development Goals (SDGs) have also played a significant role in shaping the regulatory landscape. Goal 12, which focuses on responsible consumption and production, has prompted many countries to implement policies that favor the use of renewable resources in chemical manufacturing. This has led to the creation of incentives and subsidies for companies that invest in renewable chemical technologies.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for the sustainable production of chemicals. ISO 14001, which sets out the criteria for an environmental management system, has become a benchmark for companies seeking to demonstrate their commitment to sustainability in chemical production.

Many countries have introduced specific regulations targeting the use of renewable resources in chemical manufacturing. For instance, Brazil's National Biofuels Policy (RenovaBio) has indirectly influenced the alkyl chemistry sector by promoting the production of biofuels, which often involve renewable chemical processes.

The regulatory framework also extends to labeling and certification schemes. Eco-labels and green certifications are becoming increasingly important in the chemical industry, with many countries implementing mandatory labeling requirements for products containing renewable chemicals. This transparency helps consumers make informed choices and drives market demand for sustainable alternatives in alkyl chemistry.

As the field of renewable chemical synonyms in alkyl chemistry continues to advance, regulators face the challenge of keeping pace with technological developments. Many jurisdictions are adopting adaptive regulatory approaches that allow for flexibility in addressing new innovations while maintaining rigorous safety and environmental standards.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impacts of renewable chemical synonyms in Alkyl Chemistry. This comprehensive approach examines the entire lifecycle of these chemicals, from raw material extraction to disposal, providing valuable insights into their sustainability and potential environmental consequences.

In the context of renewable chemical synonyms, LCA begins with the assessment of feedstock production. This involves analyzing the environmental impacts of cultivating and harvesting biomass sources, such as agricultural crops or forestry residues. Factors such as land use change, water consumption, and greenhouse gas emissions associated with farming practices are carefully evaluated.

The next stage focuses on the conversion processes used to transform biomass into renewable alkyl chemicals. This includes examining the energy requirements, chemical inputs, and waste generation during various conversion technologies, such as fermentation, catalytic processes, or thermochemical treatments. The environmental footprint of these processes is compared to traditional petrochemical routes to assess potential benefits.

Production and manufacturing stages are then scrutinized, considering factors like energy efficiency, resource consumption, and emissions. This phase also evaluates the potential for process integration and optimization to minimize environmental impacts. The use of renewable energy sources in manufacturing processes is often a key consideration in improving the overall sustainability profile.

The use phase of renewable alkyl chemicals is assessed to determine their performance and environmental impacts during application. This may include evaluating their biodegradability, toxicity, and potential for bioaccumulation compared to their fossil-based counterparts. The analysis also considers the potential for these chemicals to reduce environmental impacts in their end-use applications.

End-of-life scenarios are crucial in LCA, examining the fate of renewable alkyl chemicals after their useful life. This includes assessing options for recycling, biodegradation, or disposal, and their associated environmental impacts. The potential for these chemicals to contribute to a circular economy is often a key consideration in this phase.

Throughout the LCA process, various environmental impact categories are evaluated, including global warming potential, eutrophication, acidification, and resource depletion. These assessments provide a holistic view of the environmental performance of renewable chemical synonyms in Alkyl Chemistry, enabling informed decision-making and identifying areas for improvement in the pursuit of more sustainable chemical alternatives.

In the context of renewable chemical synonyms, LCA begins with the assessment of feedstock production. This involves analyzing the environmental impacts of cultivating and harvesting biomass sources, such as agricultural crops or forestry residues. Factors such as land use change, water consumption, and greenhouse gas emissions associated with farming practices are carefully evaluated.

The next stage focuses on the conversion processes used to transform biomass into renewable alkyl chemicals. This includes examining the energy requirements, chemical inputs, and waste generation during various conversion technologies, such as fermentation, catalytic processes, or thermochemical treatments. The environmental footprint of these processes is compared to traditional petrochemical routes to assess potential benefits.

Production and manufacturing stages are then scrutinized, considering factors like energy efficiency, resource consumption, and emissions. This phase also evaluates the potential for process integration and optimization to minimize environmental impacts. The use of renewable energy sources in manufacturing processes is often a key consideration in improving the overall sustainability profile.

The use phase of renewable alkyl chemicals is assessed to determine their performance and environmental impacts during application. This may include evaluating their biodegradability, toxicity, and potential for bioaccumulation compared to their fossil-based counterparts. The analysis also considers the potential for these chemicals to reduce environmental impacts in their end-use applications.

End-of-life scenarios are crucial in LCA, examining the fate of renewable alkyl chemicals after their useful life. This includes assessing options for recycling, biodegradation, or disposal, and their associated environmental impacts. The potential for these chemicals to contribute to a circular economy is often a key consideration in this phase.

Throughout the LCA process, various environmental impact categories are evaluated, including global warming potential, eutrophication, acidification, and resource depletion. These assessments provide a holistic view of the environmental performance of renewable chemical synonyms in Alkyl Chemistry, enabling informed decision-making and identifying areas for improvement in the pursuit of more sustainable chemical alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!